Talk me out of (or into) a Delta

Posted by MightyMouth

|

Re: Talk me out of (or into) a Delta November 05, 2015 08:11PM |

Registered: 13 years ago Posts: 301 |

Quote

hercek

If you want to print quickly then you also need high acceleration especially if your models will have a lot of holes. And if you need high accelerations then you need a delta. And my suspicion is that it needs to be delta with ball angle joints and not magnetic joints. I do not know whether magnetic joints can handle high accelerations. People did not respond to my questions about this.

This one has ebay 12x5x4mm countersunk magnets with M4x6 set screws (pole piece) on the carriages/effector. Rods use ebay 10mm steel threaded balls with M4x20 steel set screws into carbon rods.

[www.youtube.com]

|

Re: Talk me out of (or into) a Delta November 06, 2015 04:40PM |

Registered: 10 years ago Posts: 732 |

I think I hear some magnetic joint rattle in the video.

Anyway, the video is not much useful since I do not know what acceleration the printer is using.

It is not important so much now since n8bot reported that his magnetic joints can handle accelerations of 9000 mm/s². So it looks like you can print quickly with magnetic joints if you select them carefully and they represent only a slight mass disadvantage.

Anyway, the video is not much useful since I do not know what acceleration the printer is using.

It is not important so much now since n8bot reported that his magnetic joints can handle accelerations of 9000 mm/s². So it looks like you can print quickly with magnetic joints if you select them carefully and they represent only a slight mass disadvantage.

|

Re: Talk me out of (or into) a Delta May 01, 2018 05:52AM |

Registered: 5 years ago Posts: 9 |

I'll add something 100% on topic. Time lapse videos look bad on cartasian, and very cool on delta

After reading so many days I can finally feel I'm close to call myself a beginner.

Now that I found parts cheap and so close to me, extruded aluminum and quality rails (in both V style and MGN), I'm really torn between building a delta or a CR10 style frame.

If I choose the CR10 I will not buy it ready made, but build it myself because I don't like that I'll pay for things I'll never use, like the MB, power supply, acrylic parts, heat bed (if you can call it that), motors and extrudes.

Most of the things discussed here are no longer that accurate, so considering 2018, can you please help me chose an all metal frame that will have these attributes:

1. minimum 400mm xyz. Both can do that, but I'm more concern about trepidation at this size. I wonder if 3030 will be a better choice, and not just for delta. Delta seem to need a diagonal support for CW and ACW rotation. I was planning to add 2 panels to the delta for temperature stabilization, and maybe a good design will keep the delta frame rock solid too.

2. I'm trying to use a Prometheus system, and a V2 hot end. How easy is it to implement and maintain that on each frame?

3. Accurate and fast printing. I think delta has an advantage here, but I'm not entirely sure. I've seen videos with delta rattling and making unpleasant noises that can only lead to inaccuracy in time!?

I understand CR10 can be somewhat accurate if you keep the speed low.

I wonder how accurate and fast a printer can be if you use only good parts, money is no object.

4. Mechanical parts needed for assembling the entire frame. It seems CR10 style has an advantage. Fewer and no fancy parts here (like the Vertex). Just looking at this video I can pretty easily make a BOM of the parts I need:

[youtu.be]

Most people change the acrylic with 3D printed parts from what I've seen. Maybe I can make the ones that benefit out of aluminum.

Mr. Carter has a very good delta BOM here. I wonder if now he would change something to the original design:

[docs.google.com]

5. I'm sure there are solutions to this problem also, but I'm also concern about the electronics enclosure and the precise holes for mounting them smart and secure. That goes for mechanical parts also. For example, on the original delta design, the carriage was not aligned with the belt, and that caused oscillations that lead to the ball rod to unscrew itself. Now there's another design on thingiverse that corrects that. On the CR10 the belt touches the frame sometimes. There's a fix for that also, can't remember what it was. My head is about to pop.

This is not electronics, more of a cnc and a good CAD problem, but it was just an example on how important the holes are. This is just info I picked up along the way, because I didn't have time to do a good research. After 100 hours of investigating I'm still picking the frame... I will open a topic once I actually start building it, which I hope to be very soon because I'm sick of searching and learning, something that I never thought I'll ever say.

I need to start buying stuff or I'll go even crazier.

This is me when I try to make short comments...

Edited 1 time(s). Last edit at 05/01/2018 05:55AM by Gheorghe.

After reading so many days I can finally feel I'm close to call myself a beginner.

Now that I found parts cheap and so close to me, extruded aluminum and quality rails (in both V style and MGN), I'm really torn between building a delta or a CR10 style frame.

If I choose the CR10 I will not buy it ready made, but build it myself because I don't like that I'll pay for things I'll never use, like the MB, power supply, acrylic parts, heat bed (if you can call it that), motors and extrudes.

Most of the things discussed here are no longer that accurate, so considering 2018, can you please help me chose an all metal frame that will have these attributes:

1. minimum 400mm xyz. Both can do that, but I'm more concern about trepidation at this size. I wonder if 3030 will be a better choice, and not just for delta. Delta seem to need a diagonal support for CW and ACW rotation. I was planning to add 2 panels to the delta for temperature stabilization, and maybe a good design will keep the delta frame rock solid too.

2. I'm trying to use a Prometheus system, and a V2 hot end. How easy is it to implement and maintain that on each frame?

3. Accurate and fast printing. I think delta has an advantage here, but I'm not entirely sure. I've seen videos with delta rattling and making unpleasant noises that can only lead to inaccuracy in time!?

I understand CR10 can be somewhat accurate if you keep the speed low.

I wonder how accurate and fast a printer can be if you use only good parts, money is no object.

4. Mechanical parts needed for assembling the entire frame. It seems CR10 style has an advantage. Fewer and no fancy parts here (like the Vertex). Just looking at this video I can pretty easily make a BOM of the parts I need:

[youtu.be]

Most people change the acrylic with 3D printed parts from what I've seen. Maybe I can make the ones that benefit out of aluminum.

Mr. Carter has a very good delta BOM here. I wonder if now he would change something to the original design:

[docs.google.com]

5. I'm sure there are solutions to this problem also, but I'm also concern about the electronics enclosure and the precise holes for mounting them smart and secure. That goes for mechanical parts also. For example, on the original delta design, the carriage was not aligned with the belt, and that caused oscillations that lead to the ball rod to unscrew itself. Now there's another design on thingiverse that corrects that. On the CR10 the belt touches the frame sometimes. There's a fix for that also, can't remember what it was. My head is about to pop.

This is not electronics, more of a cnc and a good CAD problem, but it was just an example on how important the holes are. This is just info I picked up along the way, because I didn't have time to do a good research. After 100 hours of investigating I'm still picking the frame... I will open a topic once I actually start building it, which I hope to be very soon because I'm sick of searching and learning, something that I never thought I'll ever say.

I need to start buying stuff or I'll go even crazier.

This is me when I try to make short comments...

Edited 1 time(s). Last edit at 05/01/2018 05:55AM by Gheorghe.

|

Re: Talk me out of (or into) a Delta May 01, 2018 06:03AM |

Registered: 6 years ago Posts: 60 |

|

Re: Talk me out of (or into) a Delta May 01, 2018 06:23AM |

Registered: 5 years ago Posts: 9 |

So the only downside of CR10 is speed? I'll trade speed for accuracy any time, even tho everybody wants to have them both, including me.

Speed is relative anyway. When I mean I want it fast, I mean I don't want to be the last to finish the race, not to actually win the race. I know you can't have the cake and eat it too.

So how hassle free are Deltas these days? The Prometheus system allows the use of 2 filaments with one hot end, but I can change the tool head on Delta too, with a good effector .

Not as fast, but not too complicated. I think...

If I choose Delta it will have the Duet MB, good MGN rails/carriages, and maybe jump to the 9mm belts, and 8/5mm carbon rods.

All in attempt to make it as stable as possible.

Edited 2 time(s). Last edit at 05/01/2018 06:58AM by Gheorghe.

Speed is relative anyway. When I mean I want it fast, I mean I don't want to be the last to finish the race, not to actually win the race. I know you can't have the cake and eat it too.

So how hassle free are Deltas these days? The Prometheus system allows the use of 2 filaments with one hot end, but I can change the tool head on Delta too, with a good effector .

Not as fast, but not too complicated. I think...

If I choose Delta it will have the Duet MB, good MGN rails/carriages, and maybe jump to the 9mm belts, and 8/5mm carbon rods.

All in attempt to make it as stable as possible.

Edited 2 time(s). Last edit at 05/01/2018 06:58AM by Gheorghe.

|

Re: Talk me out of (or into) a Delta May 01, 2018 12:04PM |

Registered: 10 years ago Posts: 14,672 |

Deltas can be hassle-free if they are built carefully with quality parts. This doesn't come cheap. My own delta (see [miscsolutions.wordpress.com]) is hassle-free and very reliable, but it cost over £1000 in parts. Cartesian printers such as the CR10 are less fussy about precise construction, so you can get away with much less precision; but they can't do the same speeds.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Talk me out of (or into) a Delta May 02, 2018 05:22PM |

Registered: 8 years ago Posts: 49 |

I can confirm that, by putting around 800 € in a custom KOSSEL XL, it is pretty darn good (better than the ultimaker 2 I have at work)... I used the Smart effector from DUET ( really good stuff !) and haydn magnetic rods, and a smoothie (I'm french... like the smoothie, but in 2018 Duet is way better).

I have a flying extruder (Bondtech BMG ) on my delta which prevent me from doing something like the Prometheus system... but the result with one material are absolutely stunning ! Some high end delta (like the Atom 3.0) have a multi-material system, but personally i don't like bowden...

) on my delta which prevent me from doing something like the Prometheus system... but the result with one material are absolutely stunning ! Some high end delta (like the Atom 3.0) have a multi-material system, but personally i don't like bowden...

The big downfall for delta IMO is indeed that going for multi material is not the best with delta...I think that if you want to go serious on Multi-material you have to go for an independent extruder (IDEX) system like in the BNC sigma...

( Edit : With the smart effector You never fail a print because you can probe the bed distance before every print... It make the machine very reliable)

Edited 1 time(s). Last edit at 05/02/2018 05:24PM by Archiclem.

I have a flying extruder (Bondtech BMG

) on my delta which prevent me from doing something like the Prometheus system... but the result with one material are absolutely stunning ! Some high end delta (like the Atom 3.0) have a multi-material system, but personally i don't like bowden...

) on my delta which prevent me from doing something like the Prometheus system... but the result with one material are absolutely stunning ! Some high end delta (like the Atom 3.0) have a multi-material system, but personally i don't like bowden...The big downfall for delta IMO is indeed that going for multi material is not the best with delta...I think that if you want to go serious on Multi-material you have to go for an independent extruder (IDEX) system like in the BNC sigma...

( Edit : With the smart effector You never fail a print because you can probe the bed distance before every print... It make the machine very reliable)

Edited 1 time(s). Last edit at 05/02/2018 05:24PM by Archiclem.

|

Re: Talk me out of (or into) a Delta May 03, 2018 03:31AM |

Registered: 10 years ago Posts: 732 |

Is Kossel XL such a bad design that you need to check calibration before every print? What is the reason for constant (re)calibration? Is the frame wobbly? Maybe the outside temperature changes a lot between different printer runs? ...Quote

Archiclem

Edit : With the smart effector You never fail a print because you can probe the bed distance before every print... It make the machine very reliable

I have a poor Rostock (well quite a modified one so it is not that much of a Rostock any more) and I have never needed to (re)calibrate the printer if I did not change something on it.

|

Re: Talk me out of (or into) a Delta May 03, 2018 03:42AM |

Registered: 8 years ago Posts: 49 |

The prusa I3 does that, and given the reviews, you might wanna reconsider your view on auto-probing.

I just do the bed distance (1 center point), not the whole grid leveling probing.

Futhermore those mechanical endstops are not that precise to begin with. So with this technique, it compensate for it. because it starts the print as soon as it find the bed, without re-homing.

In my opinion, just the different bed temperature is enough to change the first layer height... But I agree with you, it is not mandatory. It makes just a way more reliable machine...

I just do the bed distance (1 center point), not the whole grid leveling probing.

Futhermore those mechanical endstops are not that precise to begin with. So with this technique, it compensate for it. because it starts the print as soon as it find the bed, without re-homing.

In my opinion, just the different bed temperature is enough to change the first layer height... But I agree with you, it is not mandatory. It makes just a way more reliable machine...

|

Re: Talk me out of (or into) a Delta May 03, 2018 04:27AM |

Registered: 10 years ago Posts: 732 |

Oh, I'm a fan of auto-probing. I guess I was the first one who introduced it properly for delta machines. What I'm surprised about is an opinion of auto-probing need before every print. Either it is overrated or the average printers suck.

I heard a lot of complains about mechanical endstops too. I had become worried about it and modified my firmware to touch them 5 times when homing and measure the errors. I rarely make changes without measuring first to see whether the changes are needed at all. So I wanted to know whether I need to replace my mechanical endstops with optical or hall sensors.

Results of my mechanical endstop measurements: It is only about 1 in 1000 cases when the difference is 2 microsteps (between the nearest and the furthest touches). I never had a difference of 3 micrometers. One of the 5 end stop touches is off by 1 microstep quite often though. Microstep length is 12.5 µm. My measurements indicate that the microswitch can be precise plenty enough. I would say that the only requirement is that if the microswitch has a lever then one needs to press it at the location between the lever hinge and the microswitch button so that the lever does not increase the error but keeps it the same or decreases it.

Just to give some feedback on "crappy" microswitch talk I hear way too often too.

I agree. A different bed temperature or different hotend temperature has a significant effect. This cannot be ignored.

I heard a lot of complains about mechanical endstops too. I had become worried about it and modified my firmware to touch them 5 times when homing and measure the errors. I rarely make changes without measuring first to see whether the changes are needed at all. So I wanted to know whether I need to replace my mechanical endstops with optical or hall sensors.

Results of my mechanical endstop measurements: It is only about 1 in 1000 cases when the difference is 2 microsteps (between the nearest and the furthest touches). I never had a difference of 3 micrometers. One of the 5 end stop touches is off by 1 microstep quite often though. Microstep length is 12.5 µm. My measurements indicate that the microswitch can be precise plenty enough. I would say that the only requirement is that if the microswitch has a lever then one needs to press it at the location between the lever hinge and the microswitch button so that the lever does not increase the error but keeps it the same or decreases it.

Just to give some feedback on "crappy" microswitch talk I hear way too often too.

I agree. A different bed temperature or different hotend temperature has a significant effect. This cannot be ignored.

|

Re: Talk me out of (or into) a Delta May 04, 2018 03:29AM |

Registered: 7 years ago Posts: 51 |

Quote

hercek

Oh, I'm a fan of auto-probing. I guess I was the first one who introduced it properly for delta machines. What I'm surprised about is an opinion of auto-probing need before every print. Either it is overrated or the average printers suck.

I heard a lot of complains about mechanical endstops too. I had become worried about it and modified my firmware to touch them 5 times when homing and measure the errors. I rarely make changes without measuring first to see whether the changes are needed at all. So I wanted to know whether I need to replace my mechanical endstops with optical or hall sensors.

Results of my mechanical endstop measurements: It is only about 1 in 1000 cases when the difference is 2 microsteps (between the nearest and the furthest touches). I never had a difference of 3 micrometers. One of the 5 end stop touches is off by 1 microstep quite often though. Microstep length is 12.5 µm. My measurements indicate that the microswitch can be precise plenty enough. I would say that the only requirement is that if the microswitch has a lever then one needs to press it at the location between the lever hinge and the microswitch button so that the lever does not increase the error but keeps it the same or decreases it.

Just to give some feedback on "crappy" microswitch talk I hear way too often too.

I agree. A different bed temperature or different hotend temperature has a significant effect. This cannot be ignored.

I do autoprobing before every print because it is fast enough and I often change bed, glass with hairspray for PETG and PEI for ABS/PLA.

I'm too lazy to change my starting gcode. So for me it's not a "need" but just laziness.

Edited 1 time(s). Last edit at 05/04/2018 03:31AM by Vigilant.

|

Re: Talk me out of (or into) a Delta May 04, 2018 06:02AM |

Registered: 10 years ago Posts: 14,672 |

Same here, I do auto calibration before each print because it's quick and easy. Because of thermal expansion of the frame, I'd want to do a single probe to establish an accurate Z=0 height anyway before starting to print, and it's almost as quick (15 to 25 seconds) to auto calibrate. The endstop microswitches are probably repeatable enough, but I trust the strain gauge Z probe more.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Talk me out of (or into) a Delta May 04, 2018 11:30AM |

Registered: 6 years ago Posts: 1,007 |

Quote

hercek

Oh, I'm a fan of auto-probing. I guess I was the first one who introduced it properly for delta machines. What I'm surprised about is an opinion of auto-probing need before every print. Either it is overrated or the average printers suck.

I heard a lot of complains about mechanical endstops too. I had become worried about it and modified my firmware to touch them 5 times when homing and measure the errors. I rarely make changes without measuring first to see whether the changes are needed at all. So I wanted to know whether I need to replace my mechanical endstops with optical or hall sensors.

Results of my mechanical endstop measurements: It is only about 1 in 1000 cases when the difference is 2 microsteps (between the nearest and the furthest touches). I never had a difference of 3 micrometers. One of the 5 end stop touches is off by 1 microstep quite often though. Microstep length is 12.5 µm. My measurements indicate that the microswitch can be precise plenty enough. I would say that the only requirement is that if the microswitch has a lever then one needs to press it at the location between the lever hinge and the microswitch button so that the lever does not increase the error but keeps it the same or decreases it.

Just to give some feedback on "crappy" microswitch talk I hear way too often too.

I agree. A different bed temperature or different hotend temperature has a significant effect. This cannot be ignored.

I totally agree on the mechanical switch. In fact is is amazing when you look inside, how they are made, that one can get such repeatability. The mechanism is not necessary for our purpose and I modified one to get rid of this mechanism and the results exceed what can be achieved by these chinese proximity sensors for cheap, simple, light, small etc...

Some Renishaw are purely mechanical.

Yet, when it comes to use the nozzle touching the bed to set Z, a purely mechanical system works (I did it for my Prusa) but DC42 strain gauges integrated in the effector is quite neat, in fact neater. These beat all switches, probes ... in a Delta.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Talk me out of (or into) a Delta May 04, 2018 01:12PM |

Registered: 10 years ago Posts: 732 |

Ok, there is some reason to do one point (or 3 point) probe before each print. Thanks all for pointing that out.

If people change bed temperature often or change the bed itself often then it makes sense.

Some probes will not help when changing hotend temperature since they do not probe with the hotend tip.

Frame may have significant influence too if heat chamber is sometimes used (and sometimes not) or the room temperatures changes significantly.

I print only ABS, always at the same temperatures, no heat chamber, so I did not have any need for this. The biggest variable would be frame temperature which can lead to about 3 microstep difference in my case. Not surprising I never minded that.

Edit and revert of the edit.

Edited 2 time(s). Last edit at 05/05/2018 10:31AM by hercek.

If people change bed temperature often or change the bed itself often then it makes sense.

Some probes will not help when changing hotend temperature since they do not probe with the hotend tip.

Frame may have significant influence too if heat chamber is sometimes used (and sometimes not) or the room temperatures changes significantly.

I print only ABS, always at the same temperatures, no heat chamber, so I did not have any need for this. The biggest variable would be frame temperature which can lead to about 3 microstep difference in my case. Not surprising I never minded that.

Edit and revert of the edit.

Edited 2 time(s). Last edit at 05/05/2018 10:31AM by hercek.

|

Re: Talk me out of (or into) a Delta June 12, 2018 04:17AM |

Registered: 8 years ago Posts: 3,525 |

Hercek - the debate about probe or not to probe before every print is the age-old argument running through 3D printing, that of solid-machine versus software compensation of the less-solid-machine, and to be fair both approaches have their pros/cons.

On the question of delta or cartesian. I've spent a lot of time working with deltas, and have enjoyed it immensely, but recently my Kossel XL has had some troubles and has been out of action and I have been using my CR10 instead, and getting great results. It was then that I realised I didn't ask my Kossel XL to print fast very often, which after all is its unique selling point. One which I am not as able to utilise with all the mods and add-ons which add mass to the effector, and force me to use lower jerk/accel values.

There was nothing I could buy ready-made for the same money that would match it when I built it two years ago but now if I wanted to speed up my printing buying another CR10 would be much cheaper, easier and possibly a more reliable way to do it. But 2 years ago there were not capable machines for $300-$400 being sold where as now there are.

This discussion does paradoxically make me want to make a new medium sized delta - but make it a race horse and truly optimise it for high-speed printing, but alas finding the time is hard.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

On the question of delta or cartesian. I've spent a lot of time working with deltas, and have enjoyed it immensely, but recently my Kossel XL has had some troubles and has been out of action and I have been using my CR10 instead, and getting great results. It was then that I realised I didn't ask my Kossel XL to print fast very often, which after all is its unique selling point. One which I am not as able to utilise with all the mods and add-ons which add mass to the effector, and force me to use lower jerk/accel values.

There was nothing I could buy ready-made for the same money that would match it when I built it two years ago but now if I wanted to speed up my printing buying another CR10 would be much cheaper, easier and possibly a more reliable way to do it. But 2 years ago there were not capable machines for $300-$400 being sold where as now there are.

This discussion does paradoxically make me want to make a new medium sized delta - but make it a race horse and truly optimise it for high-speed printing, but alas finding the time is hard.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Talk me out of (or into) a Delta June 12, 2018 05:07AM |

Registered: 10 years ago Posts: 732 |

CR10 looks really nice. Well, I always recommend cartesian to a delta if quick speed is not the goal. Ease of cartesian calibration is a huge advantage.

What print speed do you achieve with CR10 without a big ringing around corners?

The point is that it looks like many people run their delta at around 50 mm/s but I assume cartesians should be pretty good at that speed too. And if so then there is hardly any reason to get bothered with complicated and non-intuitive delta calibration.

What print speed do you achieve with CR10 without a big ringing around corners?

The point is that it looks like many people run their delta at around 50 mm/s but I assume cartesians should be pretty good at that speed too. And if so then there is hardly any reason to get bothered with complicated and non-intuitive delta calibration.

|

Re: Talk me out of (or into) a Delta June 12, 2018 05:16AM |

Registered: 8 years ago Posts: 3,525 |

I haven't pushed the cr-10 too much in speed terms, but perhaps I will have a go at printing some speed versus quality test objects to see what it can do. It is a big bed moving in y (I have the 300x300mm version) but this doesn't seem to throw up any major problems at 50mm/s which I have it set to.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Talk me out of (or into) a Delta June 12, 2018 12:21PM |

Registered: 8 years ago Posts: 3,525 |

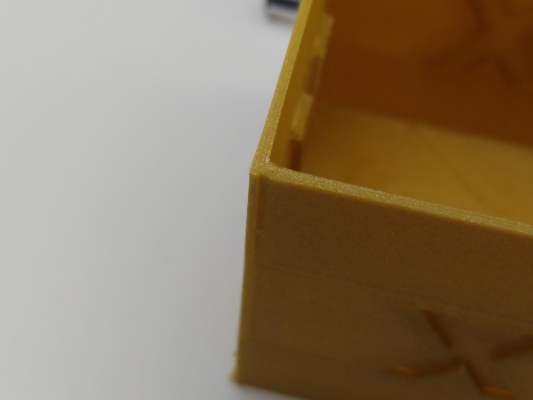

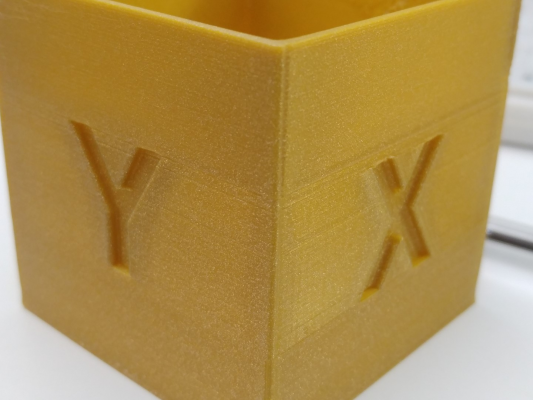

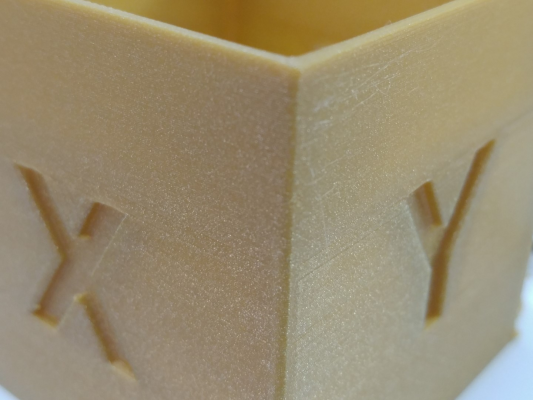

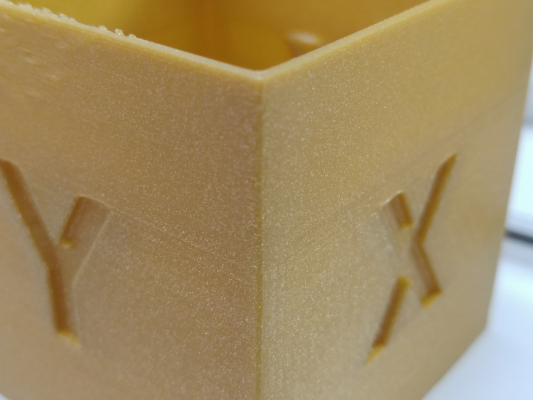

So a few tests on the cr10 - I am assuming the OP of this thread won't mind the hijack.

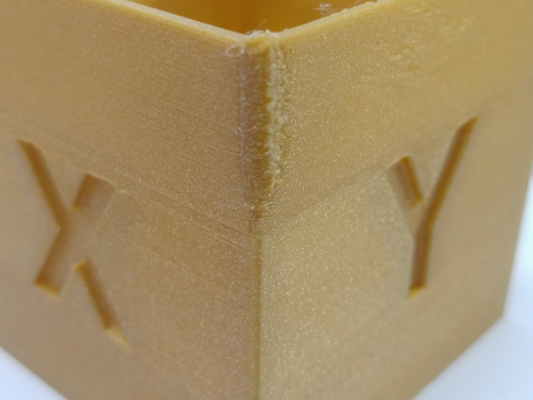

This was a 60x60x60 cube xyz-cube.stl (scaled up 300%) in PLA printed with 0.2mm layers, 3 perimeters, 1 bottom layer, no top layers.

Up until the top of the lettering, it was running at 150% 75mm/s perimeters and 37.5mm/s external perimeters.

After the lettering, I ramped the speed up in 50% increments/5 layers or so from 150% to 300%. (150mm/s perimeters and 75mm/s external perimeters).I would have allowed more layers per speed change but I didn't have time to attend to it much.

Its overextruding at the seam but then there is no linear/pressure advance running on this setup.

The penultimate corner before the seam shows the classic overshoot before being pulled back into position.

However up until I cranked it up it was producing smooth walls, nice layer registration, no more or less ghosting than my kossel XL would manage.

Edited 1 time(s). Last edit at 06/12/2018 12:22PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

This was a 60x60x60 cube xyz-cube.stl (scaled up 300%) in PLA printed with 0.2mm layers, 3 perimeters, 1 bottom layer, no top layers.

Up until the top of the lettering, it was running at 150% 75mm/s perimeters and 37.5mm/s external perimeters.

After the lettering, I ramped the speed up in 50% increments/5 layers or so from 150% to 300%. (150mm/s perimeters and 75mm/s external perimeters).I would have allowed more layers per speed change but I didn't have time to attend to it much.

Its overextruding at the seam but then there is no linear/pressure advance running on this setup.

The penultimate corner before the seam shows the classic overshoot before being pulled back into position.

However up until I cranked it up it was producing smooth walls, nice layer registration, no more or less ghosting than my kossel XL would manage.

Edited 1 time(s). Last edit at 06/12/2018 12:22PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Talk me out of (or into) a Delta June 12, 2018 02:22PM |

Registered: 10 years ago Posts: 150 |

Okay, well, since my delta robot Zatsit has been officially introduced on this site:

[reprap.org]

let me discreetly promote it (A Kickstarter campaign is planned soon). I feel authorized to do so, because Zatsit's very original approach modifies the terms of the debate on this post.

Zatsit is a delta, with all the advantages of a delta, but it avoids some disadvantages: as it does not use mechanical components to assemble, and as all dimensions are from a CNC cut, the geometrical characteristics of the machine do not depend on any adjustment, nor on the skill or meticulousness of the assembler. All Zatsit react in the same way to the calibration procedures proposed by the firmwares, to compensate for the specific geometric defects of the deltas: zero correction, more or less. Consequently, the dimensions of the printed objects are exact, if the extrusion is well calibrated.

Another feature is that it is a mechanical base kit only. You can choose the electronics you like, and everything else. You will not have to upgrade a complete kit, but one that will underperform by one component or another, which will have to be replaced. Zatsit only offers mechanics, but at least on the mechanical side, it will be optimal anyway.

Zatsit has many other advantages. The best is to make your opinion, by following the link above, or by directly watching the assembly instruction videos, very explicit, here :

[hackaday.io]

Enjoy!

Edited 1 time(s). Last edit at 06/12/2018 02:25PM by M_Xeno.

[reprap.org]

let me discreetly promote it (A Kickstarter campaign is planned soon). I feel authorized to do so, because Zatsit's very original approach modifies the terms of the debate on this post.

Zatsit is a delta, with all the advantages of a delta, but it avoids some disadvantages: as it does not use mechanical components to assemble, and as all dimensions are from a CNC cut, the geometrical characteristics of the machine do not depend on any adjustment, nor on the skill or meticulousness of the assembler. All Zatsit react in the same way to the calibration procedures proposed by the firmwares, to compensate for the specific geometric defects of the deltas: zero correction, more or less. Consequently, the dimensions of the printed objects are exact, if the extrusion is well calibrated.

Another feature is that it is a mechanical base kit only. You can choose the electronics you like, and everything else. You will not have to upgrade a complete kit, but one that will underperform by one component or another, which will have to be replaced. Zatsit only offers mechanics, but at least on the mechanical side, it will be optimal anyway.

Zatsit has many other advantages. The best is to make your opinion, by following the link above, or by directly watching the assembly instruction videos, very explicit, here :

[hackaday.io]

Enjoy!

Edited 1 time(s). Last edit at 06/12/2018 02:25PM by M_Xeno.

|

Re: Talk me out of (or into) a Delta June 12, 2018 02:56PM |

Registered: 10 years ago Posts: 732 |

|

Re: Talk me out of (or into) a Delta June 12, 2018 03:15PM |

Registered: 8 years ago Posts: 3,525 |

I'll let you know on Thursday, the machine is at my work and I can't remember what its set to, middle of the road would be my best guess.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Talk me out of (or into) a Delta June 14, 2018 03:19PM |

Registered: 8 years ago Posts: 3,525 |

It was set to 3000.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Talk me out of (or into) a Delta June 14, 2018 06:32PM |

Registered: 10 years ago Posts: 732 |

OK, that is not bad. I use 9000 on my rostock but I think some people reported using 4000 on their delta. That is only slightly more than your CR10.

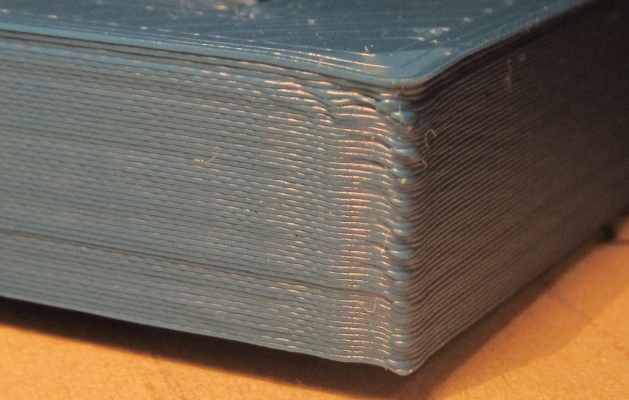

Here is an example of a corner on a rostock 9000 mm/s², 120 mm/s, 0.2 mm layer height. Steel belt. The unwanted ring wave peak-to-peak distance is about 0.2 mm, the same as layer height.

Edited 2 time(s). Last edit at 06/14/2018 06:35PM by hercek.

Here is an example of a corner on a rostock 9000 mm/s², 120 mm/s, 0.2 mm layer height. Steel belt. The unwanted ring wave peak-to-peak distance is about 0.2 mm, the same as layer height.

Edited 2 time(s). Last edit at 06/14/2018 06:35PM by hercek.

|

Re: Talk me out of (or into) a Delta June 15, 2018 09:47AM |

Registered: 10 years ago Posts: 150 |

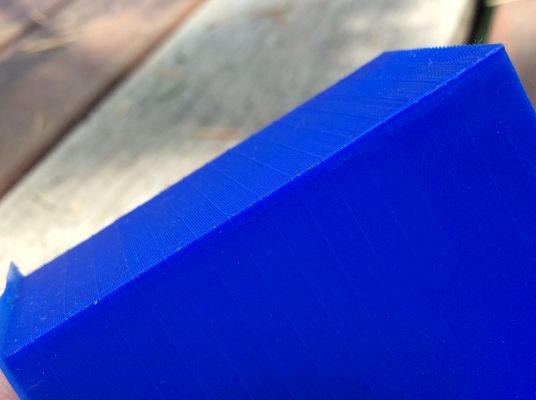

Here is a speed test I had my Zatsit delta printer do some time ago.

Equipment of the machine:

Motors 0.9° at 24V

Duet Wifi Electronics

Extruder: E3D Titan in Flystruder position, gimballed

Parameters:

PLA

1G acceleration

Layer height 0.2mm, then 0.1mm, and finally 0.08mm (due to limited maximum extrusion rate)

Each slice increases the speed of the previous slice by 1.2x. We start from the bottom at 30mm/s, so:

30 mm/s, height 0.2mm

36

43

52

62

74

90

107

129

155

186 mm/s (height 0.15mm)

223 mm/s (height 0.1mm)

267 mm/s (height 0.08mm)

320

385

462 mm/s

As you can see, there is practically no ringing at any speed. There are signs of under-extrusion from 320mm/s, but the mechanics remain faultless.

I am now concentrating my efforts on improving extrusion, while keeping an ultra-light head:

[reprap.org]

Edited 1 time(s). Last edit at 06/16/2018 04:02AM by M_Xeno.

Equipment of the machine:

Motors 0.9° at 24V

Duet Wifi Electronics

Extruder: E3D Titan in Flystruder position, gimballed

Parameters:

PLA

1G acceleration

Layer height 0.2mm, then 0.1mm, and finally 0.08mm (due to limited maximum extrusion rate)

Each slice increases the speed of the previous slice by 1.2x. We start from the bottom at 30mm/s, so:

30 mm/s, height 0.2mm

36

43

52

62

74

90

107

129

155

186 mm/s (height 0.15mm)

223 mm/s (height 0.1mm)

267 mm/s (height 0.08mm)

320

385

462 mm/s

As you can see, there is practically no ringing at any speed. There are signs of under-extrusion from 320mm/s, but the mechanics remain faultless.

I am now concentrating my efforts on improving extrusion, while keeping an ultra-light head:

[reprap.org]

Edited 1 time(s). Last edit at 06/16/2018 04:02AM by M_Xeno.

|

Re: Talk me out of (or into) a Delta June 15, 2018 05:42PM |

Registered: 8 years ago Posts: 3,525 |

It's nice and you are getting great layer registration at those speeds. What do you think is causing the repeating pattern every 15 layers or so?

When you say acceleration is 1G that's 9800mm/s/s?

Edited 1 time(s). Last edit at 06/15/2018 05:45PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

When you say acceleration is 1G that's 9800mm/s/s?

Edited 1 time(s). Last edit at 06/15/2018 05:45PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Talk me out of (or into) a Delta June 16, 2018 03:09AM |

Registered: 10 years ago Posts: 150 |

The pattern is voluntary, and it is from the STL model, to mark the limit between each speed range.

Yes, acceleration was 10000mm/s² that time, so about 1G (1). Usually, I am using 6000mm/s² or so.

I tried 3G, no step loss, while extruding with a Flystruder, but extrusion is problematic at this rate.

Without any extrusion, and nothing on the effector, the printer supports any acceleration without loss of steps, thanks to the little compliance of the hinged linkage. Very snappy to look at, but not very useful...

(1) P.S. : Since I had activated pressure advance, I had to set the e-jerk so that the extruder would not stall, and this may have indirectly limited the acceleration of the X-Y motion by a small amount.

Edited 3 time(s). Last edit at 06/16/2018 03:57AM by M_Xeno.

Yes, acceleration was 10000mm/s² that time, so about 1G (1). Usually, I am using 6000mm/s² or so.

I tried 3G, no step loss, while extruding with a Flystruder, but extrusion is problematic at this rate.

Without any extrusion, and nothing on the effector, the printer supports any acceleration without loss of steps, thanks to the little compliance of the hinged linkage. Very snappy to look at, but not very useful...

(1) P.S. : Since I had activated pressure advance, I had to set the e-jerk so that the extruder would not stall, and this may have indirectly limited the acceleration of the X-Y motion by a small amount.

Edited 3 time(s). Last edit at 06/16/2018 03:57AM by M_Xeno.

|

Re: Talk me out of (or into) a Delta June 16, 2018 04:36AM |

Registered: 10 years ago Posts: 732 |

|

Re: Talk me out of (or into) a Delta June 16, 2018 05:07AM |

Registered: 10 years ago Posts: 150 |

I just weighed, on a previous prototype, not very different from the current one, everything that moves (everything, including carriages, slides, and even belts!), with the Hot-End water-cooled, but without the flystruder setup, the Bowden tube nor the water supply hoses, which are actually carried by the Flystruder support. That's 212 grams, including the printing effector with Hot-End, which weighs 25g, including electric wires (but without water hoses).

I use 6mm GT2 belts, original Gates, 600mm long (for a carriage stroke of 500mm or so), with a 0.8mm Kevlar string to complet the belt circuit. The belts are tensioned to death, and the design of the motor supports, in Hylite, incorporates a ball bearing to prevent the axis of the motor from overhanging, and can therefore support the tension.

Edited 2 time(s). Last edit at 06/16/2018 05:22AM by M_Xeno.

I use 6mm GT2 belts, original Gates, 600mm long (for a carriage stroke of 500mm or so), with a 0.8mm Kevlar string to complet the belt circuit. The belts are tensioned to death, and the design of the motor supports, in Hylite, incorporates a ball bearing to prevent the axis of the motor from overhanging, and can therefore support the tension.

Edited 2 time(s). Last edit at 06/16/2018 05:22AM by M_Xeno.

|

Re: Talk me out of (or into) a Delta June 19, 2018 01:41PM |

Registered: 7 years ago Posts: 15 |

OP, I can enthusiastically recommend a medium / large Kossel style printer, provided you do your homework, and don't mind making a few tweaks here and there by deviating a bit from the official build manual.

I've had a very positive experience with the Chinese-made BIQU Kossel Plus which has a bed diameter of 24 cm and print height of 36 cm, so it's slightly taller than the Kossel XL you linked. This machine works just fine at 100 mm/s with the stock RAMPS board, and since it's already significantly faster as well as more accurate than my cartesian machine, I haven't bothered printing at higher speeds; I'm happy with the performance. The kit cost me 350 USD nearly 2 years ago, so you could probably get it for even less than that now.

What's more, mine uses linear rails and not wheels, but I don't know if the rails are really significantly better. The kit includes everything to get you up and running once it is built and configured, so you don't need to purchase any extras unless you're keen on making some improvements.

Edited 2 time(s). Last edit at 06/19/2018 01:48PM by scndctr.

I've had a very positive experience with the Chinese-made BIQU Kossel Plus which has a bed diameter of 24 cm and print height of 36 cm, so it's slightly taller than the Kossel XL you linked. This machine works just fine at 100 mm/s with the stock RAMPS board, and since it's already significantly faster as well as more accurate than my cartesian machine, I haven't bothered printing at higher speeds; I'm happy with the performance. The kit cost me 350 USD nearly 2 years ago, so you could probably get it for even less than that now.

What's more, mine uses linear rails and not wheels, but I don't know if the rails are really significantly better. The kit includes everything to get you up and running once it is built and configured, so you don't need to purchase any extras unless you're keen on making some improvements.

Edited 2 time(s). Last edit at 06/19/2018 01:48PM by scndctr.

|

Re: Talk me out of (or into) a Delta September 06, 2018 02:40AM |

Registered: 6 years ago Posts: 50 |

Quote

scndctr

What's more, mine uses linear rails and not wheels, but I don't know if the rails are really significantly better.

Generally using linear rails on a delta it does not, assuming you are using polycarb wheels, improve the print quality. This is due to being unable to adjust pre-load on the linear bearings, something that is a critical element to be able to adjust in order to get perfect prints on a delta (fyi if your carriages and/or effector can move down the Z axis under their own weight you don't have appropriate levels of bearing pre-load).

Sorry, only registered users may post in this forum.