Scaling Issue with XY.

Posted by MrMeeeseeeks

|

Scaling Issue with XY. November 25, 2015 10:57PM |

Registered: 8 years ago Posts: 35 |

|

Re: Scaling Issue with XY. November 26, 2015 05:08AM |

Registered: 10 years ago Posts: 14,672 |

Try reducing your configured diagonal rod length a little. You will then need to recalibrate the delta radius and homed height.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Scaling Issue with XY. November 26, 2015 05:19AM |

Registered: 10 years ago Posts: 732 |

I would say that such kind of an error is impossible. X, Y, and Z errors are all tied together in delta. If your bed is leveled and your Z height is correct then also X and Y dimensions will be correct.

Is your bed leveled? Is really the decrease in size uniform in all directions of XY plane (regardless of the part size)?

Is your bed leveled? Is really the decrease in size uniform in all directions of XY plane (regardless of the part size)?

|

Re: Scaling Issue with XY. November 26, 2015 05:55AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Scaling Issue with XY. November 26, 2015 06:27AM |

Registered: 10 years ago Posts: 732 |

If you have correct Z-height then you must have correct steps per mm.

If you have steps/mm correct and you have perfectly leveled bed then you must have correct also XY dimensions.

The only caveat is that if you have correct steps/mm, and have wrong both diagonal rod length and delta radius, and the bed size is small compared to diagonal rod length(*) then you can get something very near to leveled bed. It will not be perfectly leveled but will be near enough for many people to call it leveled. The point is that errors from diagonal rod length and delta radius can partially compensate each other. This is the reason why people recommend to optimize either diagonal rod length or delta radius. I say have a big bed or measure diagonal rod length (this can be done precisely with calipers) and optimize only the delta radius.

(*) Small bed size compared to diagonal rod means you cannot probe points far enough opposite of a tower. Those are the places where diagonal rod is almost horizontal and its length error cannot compensate for delta radius error well enough to escape user attention.

So you are not wrong if only approximate leveling is considered ok. Although you should probably rather say: XY depends on delta rod length as well as on delta diagonal. Also the XY errors from this will not be perfectly uniform ... which again escapes most people attention as well as the fact that bed is not perfectly leveled.

If you have steps/mm correct and you have perfectly leveled bed then you must have correct also XY dimensions.

The only caveat is that if you have correct steps/mm, and have wrong both diagonal rod length and delta radius, and the bed size is small compared to diagonal rod length(*) then you can get something very near to leveled bed. It will not be perfectly leveled but will be near enough for many people to call it leveled. The point is that errors from diagonal rod length and delta radius can partially compensate each other. This is the reason why people recommend to optimize either diagonal rod length or delta radius. I say have a big bed or measure diagonal rod length (this can be done precisely with calipers) and optimize only the delta radius.

(*) Small bed size compared to diagonal rod means you cannot probe points far enough opposite of a tower. Those are the places where diagonal rod is almost horizontal and its length error cannot compensate for delta radius error well enough to escape user attention.

So you are not wrong if only approximate leveling is considered ok. Although you should probably rather say: XY depends on delta rod length as well as on delta diagonal. Also the XY errors from this will not be perfectly uniform ... which again escapes most people attention as well as the fact that bed is not perfectly leveled.

|

Re: Scaling Issue with XY. November 26, 2015 12:12PM |

Registered: 8 years ago Posts: 89 |

you could try this: [www.thingiverse.com]

|

Re: Scaling Issue with XY. November 26, 2015 12:16PM |

Registered: 8 years ago Posts: 197 |

All i know is my prints came out to small.

I lower the the rod size.

230 which there are. To 225 and everything prints on point.

So lower your rod length of printing to small.

Up it if printing to large.

I didnt touch the print radius, but mines always seems to stay the same give or take 1.

Been able to get good prints since i switch rods

I lower the the rod size.

230 which there are. To 225 and everything prints on point.

So lower your rod length of printing to small.

Up it if printing to large.

I didnt touch the print radius, but mines always seems to stay the same give or take 1.

Been able to get good prints since i switch rods

|

Re: Scaling Issue with XY. November 26, 2015 09:34PM |

Registered: 9 years ago Posts: 83 |

Quote

hercek

I would say that such kind of an error is impossible. X, Y, and Z errors are all tied together in delta. If your bed is leveled and your Z height is correct then also X and Y dimensions will be correct.

Quite possible. X and Y are derived values, based on polar <-> rectangular conversions. To change X or Y, your printer moves all three motors differently, based on diagonal rod length and delta radius.

With your delta radius correct for your diagonal rod length, you will achieve "flat" tracking in the XY plane, but you may have the wrong scale. Fix the diagonal rod length to fix the scale, but now you have to adjust the delta radius to compensate.

To change Z, you move all three motors the same amount, in the same direction, and it's based strictly on steps/mm of the 3 motors. If your motor+pulley+belt combination yields 200 steps/mm, then -20 steps on X/Y/Z motor (or A/B/C if you prefer) then your print head will lift up 10mm without changing position in X/Y, regardless of the settings for diagonal rod / delta radius.

|

Re: Scaling Issue with XY. May 15, 2018 01:25PM |

Registered: 10 years ago Posts: 732 |

OK; so this crap happened to me after the last change to the printer. The Z dimension is precise but XY dimension is smaller by about 0.7%. Therefore I did some simulations how much diagonal rod length influences the YX dimension.

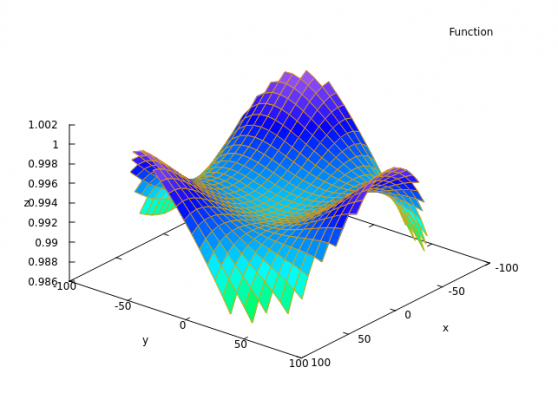

Here are some charts so that you can see how it looks like. Bed diameter is 200 mm, delta radius is 270 mm, diagonal rod is 297 mm, It is specified in firmware as 298 mm; i.e. there is 1 mm error in the diagonal rod length. The printer is numerically calibrated. This calibration does not optimize diagonal rod length. It only mitigates its influence on Z-leveling by making delta radius smaller by about 0.2%. Of course, this compensation is not perfect but it is pretty good. See that there is below 0.02 mm Z-leveling error after the compensation:

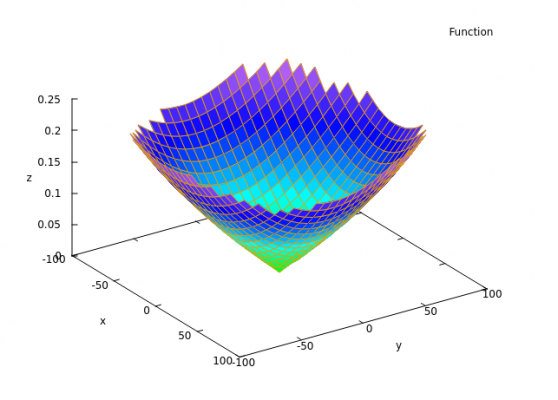

Most people will ignore this in the calibration data and nobody notices this in the printed parts. They will stick pretty well and have uniform bottom. But there is a significant XY error. Here is the chart of its absolute value:

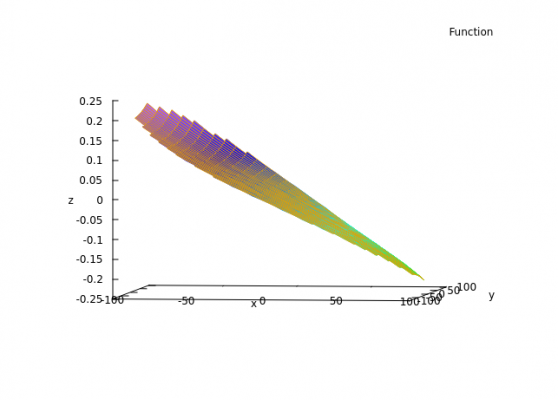

You can see that there is 0.25 mm error at the edge of the build area, i.e. the whole part would be about 0.5 mm smaller in this case (if printed over the whole print area). Also notice that the error is almost linear. But not perfectly. It is not a perfect cone. If you cheat on diagonal rod length and compensate with with calibration then your parts will be slightly distorted. You can see it nicely when we look only at the X component of the XY error:

It is clearly visible that the error is not a plane. But it is quite near to it. That is the compromise between using long diagonal rods for small carriage speeds and short diagonal rods for good numerical calibration. Long rods mean no problems with support for high carriage speed. Also long rods make it easier to sloppily calibrate the printer (the printer tolerates calibration errors more). Short rods mean more stable numerical calibration. Choose your poison.

Here are some charts so that you can see how it looks like. Bed diameter is 200 mm, delta radius is 270 mm, diagonal rod is 297 mm, It is specified in firmware as 298 mm; i.e. there is 1 mm error in the diagonal rod length. The printer is numerically calibrated. This calibration does not optimize diagonal rod length. It only mitigates its influence on Z-leveling by making delta radius smaller by about 0.2%. Of course, this compensation is not perfect but it is pretty good. See that there is below 0.02 mm Z-leveling error after the compensation:

Most people will ignore this in the calibration data and nobody notices this in the printed parts. They will stick pretty well and have uniform bottom. But there is a significant XY error. Here is the chart of its absolute value:

You can see that there is 0.25 mm error at the edge of the build area, i.e. the whole part would be about 0.5 mm smaller in this case (if printed over the whole print area). Also notice that the error is almost linear. But not perfectly. It is not a perfect cone. If you cheat on diagonal rod length and compensate with with calibration then your parts will be slightly distorted. You can see it nicely when we look only at the X component of the XY error:

It is clearly visible that the error is not a plane. But it is quite near to it. That is the compromise between using long diagonal rods for small carriage speeds and short diagonal rods for good numerical calibration. Long rods mean no problems with support for high carriage speed. Also long rods make it easier to sloppily calibrate the printer (the printer tolerates calibration errors more). Short rods mean more stable numerical calibration. Choose your poison.

Sorry, only registered users may post in this forum.

)

)