Aligning linear guides

Posted by the_digital_dentist

|

Aligning linear guides November 28, 2015 09:02AM |

Registered: 11 years ago Posts: 5,780 |

How do you align the linear guides or v slot frame members to be parallel in a Delta?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aligning linear guides November 28, 2015 09:06AM |

Registered: 8 years ago Posts: 916 |

|

Re: Aligning linear guides November 28, 2015 12:46PM |

Registered: 9 years ago Posts: 483 |

I made full length aluminum tnuts (500mm) that were a tight fit in the slot. If your tnuts aren't a tight fit, then make an alignment jig.

I used Misumi 30 degree extrusions to hold the horizontal pieces. I used the Misumi tnuts on these and had to use a jig. If I do another with the 30 degree extrusions, I'd make full length tnuts that extended into both slots. The 30 degree extrusions don't have any blind connection methods from Misumi, so I had to drill through holes for the bolts.

The horizontal frame members were made on my CNC router, so were all identical. When assembled the frame was square within my measuring capabilities, so I didn't need to do any further truing of the uprights.

I used Misumi 30 degree extrusions to hold the horizontal pieces. I used the Misumi tnuts on these and had to use a jig. If I do another with the 30 degree extrusions, I'd make full length tnuts that extended into both slots. The 30 degree extrusions don't have any blind connection methods from Misumi, so I had to drill through holes for the bolts.

The horizontal frame members were made on my CNC router, so were all identical. When assembled the frame was square within my measuring capabilities, so I didn't need to do any further truing of the uprights.

|

Re: Aligning linear guides November 28, 2015 05:41PM |

Registered: 11 years ago Posts: 5,780 |

As far as I can tell, there are two critical alignments- the linear guides need to be parallel and spaced at 120 degree intervals. I'm trying to think of how you measure and make the mounts adjustable so that the guides can be accurately positioned within those specific parameters. You could cut a flat template on a milling machine that would ensure proper spacing and parallelism of the guides/frame members at each end of the frame, but you still have to ensure they are all orthogonal to both ends of the frame as well. Orthogonality can be checked by measuring diagonals from one guide/frame member to adjacent guide/frame members.

Has anyone done a tall print of a rectangular solid and checked the sides for flatness and the angles for orthogonality?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Has anyone done a tall print of a rectangular solid and checked the sides for flatness and the angles for orthogonality?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aligning linear guides November 29, 2015 12:17AM |

Registered: 9 years ago Posts: 483 |

If one tower is perpendicular to the bed in X and Y directions (or on each side of the rectangular upright) and the distance between each tower is the same at the top and bottom, then the frame is true. With a true frame, then the linear guide can be trued with a jig or a long, accurately made tnut. The hard part is accurately measuring corner to corner on the uprights. A tooling ball could help with this.

I can see where poorly printed brackets would make trueing the frame a difficult proposition.

p.s. The actual distance between the towers isn't important (as far as truing the frame goes). A story board can be used to verify the distances are equal.

I can see where poorly printed brackets would make trueing the frame a difficult proposition.

p.s. The actual distance between the towers isn't important (as far as truing the frame goes). A story board can be used to verify the distances are equal.

|

Re: Aligning linear guides December 02, 2015 04:03AM |

Registered: 8 years ago Posts: 9 |

|

Re: Aligning linear guides December 02, 2015 04:18AM |

Registered: 10 years ago Posts: 14,672 |

For me the answer was to use metal corners instead of plastic, use single 2060 extrusions instead of a pair of 2020 for two of the bottom horizontals, and make sure all the horizontals are the same length. Then the towers will be parallel if the corners are true and the extrusions are straight. Fortunately, aluminium extrusions are generally a lot straighter than the quoted tolerance allows.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Aligning linear guides December 02, 2015 07:47AM |

Registered: 11 years ago Posts: 5,780 |

I see a lot of metal or plastic corner gussets on a lot of machines made from T slot aluminum. I haven't seen one of those machines that takes advantage of the T slot design to screw the corners together. I'm trying to figure out what those gussets are actually doing in those builds. Are they being used to square the frame? Are the typical 20mm square T-slot beams so flexible they need the extra extra support to control flex? If so, why are the gussets so small? If so, why not use larger cross section T-slot extrusions?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aligning linear guides December 02, 2015 08:21AM |

Registered: 10 years ago Posts: 104 |

Quote

the_digital_dentist

I see a lot of metal or plastic corner gussets on a lot of machines made from T slot aluminum. I haven't seen one of those machines that takes advantage of the T slot design to screw the corners together. I'm trying to figure out what those gussets are actually doing in those builds. Are they being used to square the frame? Are the typical 20mm square T-slot beams so flexible they need the extra extra support to control flex? If so, why are the gussets so small? If so, why not use larger cross section T-slot extrusions?

Well on Delta Machines it is obviously because they are 60° corners as far as others I don't know.

|

Re: Aligning linear guides December 02, 2015 11:03AM |

Registered: 10 years ago Posts: 14,672 |

It's possible to make a "square delta" and this has been done at least twice. The problem is that pairs of arms are connected to 3 of the 4 towers, and when the effector is near the 4th tower the arms have to stretch a long way from the diagonally opposite tower. So you need long arms to that tower (or to all the towers), which reduces the maximum print height.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Aligning linear guides December 02, 2015 11:57AM |

Registered: 9 years ago Posts: 346 |

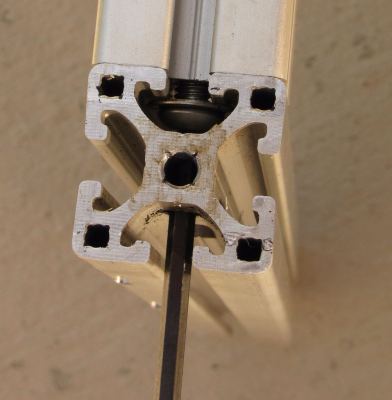

Instead of 2040 you could use two 2020 at an angle of 60 deg. and with some kind of support brackets to install the linear rails.

As shown here

Not sure it is actually attractive if you are not printing the part. Very difficult part to machine.

As shown here

Not sure it is actually attractive if you are not printing the part. Very difficult part to machine.

|

Re: Aligning linear guides December 02, 2015 02:00PM |

Registered: 9 years ago Posts: 483 |

Quote

the_digital_dentist

I see a lot of metal or plastic corner gussets on a lot of machines made from T slot aluminum. I haven't seen one of those machines that takes advantage of the T slot design to screw the corners together. I'm trying to figure out what those gussets are actually doing in those builds. Are they being used to square the frame? Are the typical 20mm square T-slot beams so flexible they need the extra extra support to control flex? If so, why are the gussets so small? If so, why not use larger cross section T-slot extrusions?

First, 20mm extrusions are IMHO too small or marginal at best. I used 2550 Misumi extrusions.

Second, one through bolt is much weaker than using gussets with 4 or more bolts.

Third, the through bolt depends on the ends of the extrusion having perfect 90 degree cuts. This is not as easy to achieve as it seems.

|

Re: Aligning linear guides December 02, 2015 08:39PM |

Registered: 11 years ago Posts: 5,780 |

I was under the impression that if you order extrusions from Misumi, for example, that they routinely mill the ends square. In my case I cut and milled the ends of the extrusions myself.

How is one bolt through the part weaker than a gusset with multiple bolts- I know more bolts is stronger than fewer, but what force will be applied that will require the added strength at the joints? My machine's frame is made without any corner gussets and I routinely move its 60 kg bulk around in my car and on wheeled carts and I only rarely have to make any adjustments. I'm surprised by the gusseted corners construction technique because many people try to cut costs without much regard for performance and those little gussets are pretty expensive parts (unless they are printed, in which case they probably aren't doing anything). I would think that if you did away with the gussets you could spend that money on larger cross section extrusions and end up with a stiffer frame. On much smaller, lower mass machines it seems unlikely you'd need all that extra strength in the joints. It would be much better to have stiffness in the frame.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

How is one bolt through the part weaker than a gusset with multiple bolts- I know more bolts is stronger than fewer, but what force will be applied that will require the added strength at the joints? My machine's frame is made without any corner gussets and I routinely move its 60 kg bulk around in my car and on wheeled carts and I only rarely have to make any adjustments. I'm surprised by the gusseted corners construction technique because many people try to cut costs without much regard for performance and those little gussets are pretty expensive parts (unless they are printed, in which case they probably aren't doing anything). I would think that if you did away with the gussets you could spend that money on larger cross section extrusions and end up with a stiffer frame. On much smaller, lower mass machines it seems unlikely you'd need all that extra strength in the joints. It would be much better to have stiffness in the frame.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aligning linear guides December 02, 2015 09:33PM |

Registered: 9 years ago Posts: 483 |

I think this discussion is more related to Cartesian printers than delta as there are no 90 degree angles in a (standard) delta frame. That said, the single bolt won't stop the horizontal member from twisting whereas the gusset will. If you make your own gussets they are quite inexpensive.

Sorry, only registered users may post in this forum.