The first beta machine based on DC42's Kossel XL

Posted by MightyMouth

|

The first beta machine based on DC42's Kossel XL December 03, 2015 05:15PM |

Registered: 10 years ago Posts: 104 |

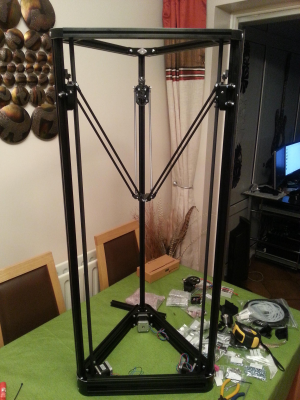

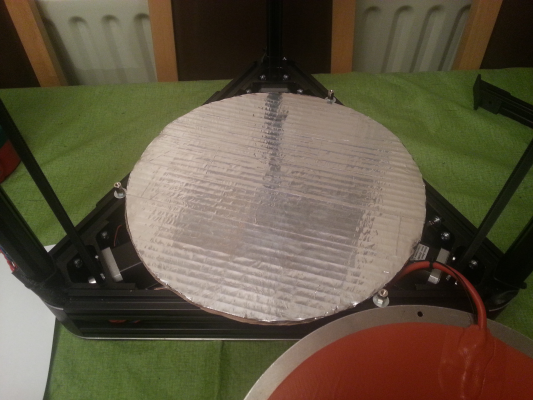

On DC42's recommendation I contacted Think3dPrint3d about their new Large Kossel and I have just recieved the first beta machine. I cannot wait to get started building but I am going to leave it until the weekend so I can concentrate on it properly. I opted for the black aluminium corners and black extrusions with black printed parts. I did want Yellow printed parts but it wasn't an option on the beta machines, I'll print them myself later. More pics to follow during the build.

Edited 1 time(s). Last edit at 12/03/2015 05:57PM by MightyMouth.

Edited 1 time(s). Last edit at 12/03/2015 05:57PM by MightyMouth.

|

Re: The first beta machine based on DC42's Kossel XL December 03, 2015 09:03PM |

Registered: 8 years ago Posts: 153 |

|

Re: The first beta machine based on DC42's Kossel XL December 04, 2015 04:32AM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 04, 2015 05:10AM |

Registered: 10 years ago Posts: 14,672 |

T3P3's kits normally come with all cables pre-crimped. If they said you need a crimper, then I guess for the beta they may not have worked out the correct lengths for all the cables yet.

Edited 2 time(s). Last edit at 12/04/2015 05:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 12/04/2015 05:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 04, 2015 05:33AM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 06, 2015 10:42AM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 06, 2015 11:50AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: The first beta machine based on DC42's Kossel XL December 06, 2015 12:38PM |

Registered: 8 years ago Posts: 1 |

|

Re: The first beta machine based on DC42's Kossel XL December 06, 2015 01:31PM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 11, 2015 05:03PM |

Registered: 10 years ago Posts: 104 |

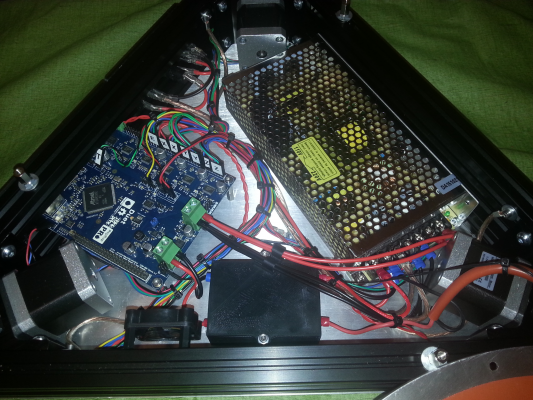

Ok so I have pretty much completed my build, I am kind of scared to power it up for fear of frying something. I have double checked all the connections but I am still hesitant.

|

Re: The first beta machine based on DC42's Kossel XL December 11, 2015 05:23PM |

Registered: 10 years ago Posts: 14,672 |

Good progress! A few suggestions:

- Double check that you have the + and - leads from the PSU connected to the Duet power input terminals the right way round.

- Make sure the stepper motor connections are good. An intermittent connection could damage the driver.

- If it uses an AC mains heated bed like mine, check all the mains connections and grounding of the frame. Use a multimeter to check the grounding, and to check for near infinite resistance between live and ground. Preferably use an RCD adapter to feed mains to the printer.

- There should also be continuity between mains ground and the -ve output terminal of the PSU.

- Set the stepper motor currents in the M906 command to a low value initially e.g. 500 mA until the printer is at least homing correctly.

- Don't apply mains power until you are getting good readings from the thermistors, IR probe and endstop switches with just USB power supplied.

Some of this may already be in the build instructions.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- Double check that you have the + and - leads from the PSU connected to the Duet power input terminals the right way round.

- Make sure the stepper motor connections are good. An intermittent connection could damage the driver.

- If it uses an AC mains heated bed like mine, check all the mains connections and grounding of the frame. Use a multimeter to check the grounding, and to check for near infinite resistance between live and ground. Preferably use an RCD adapter to feed mains to the printer.

- There should also be continuity between mains ground and the -ve output terminal of the PSU.

- Set the stepper motor currents in the M906 command to a low value initially e.g. 500 mA until the printer is at least homing correctly.

- Don't apply mains power until you are getting good readings from the thermistors, IR probe and endstop switches with just USB power supplied.

Some of this may already be in the build instructions.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 11, 2015 07:38PM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 05:00AM |

Registered: 8 years ago Posts: 28 |

Lol, I just installed a Azteeg X5 mini and had the same feelings. There is something crazy either in the board design or smoothieware. My power supply is a development unit I got from my job, with knobs to adjust volts and amps, and amps were turned way down. WHen I set the hot end temp the speaker/buzzer started making a scary hissing noise that sounded like something shorted !! With the supply amperage set correctly it made no sound. I'm sure of the cause, but what was going on I have no clue. I'm making a seperate post about the board.

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 11:12AM |

Registered: 10 years ago Posts: 104 |

OK So my printer is now powered on and I can access the web interface. I have homed the axes successfully and have been reading DC42's blog post Upgrading the Mini Kossel to Duet Electronics Part 4: the Z probe but am confused what M558 parameter I should be using. My kit comes with David's IR Probe so do I use P1 or P2? My config is currently set to M558 P1 X0 Y0 Z0 which was configure by t3p3 as default I suppose but it seems to me it should possibly be M558 P2 X0 Y0 Z0.

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 11:32AM |

Registered: 9 years ago Posts: 1,159 |

Quote

MightyMouth

OK So my printer is now powered on and I can access the web interface. I have homed the axes successfully and have been reading DC42's blog post Upgrading the Mini Kossel to Duet Electronics Part 4: the Z probe but am confused what M558 parameter I should be using. My kit comes with David's IR Probe so do I use P1 or P2? My config is currently set to M558 P1 X0 Y0 Z0 which was configure by t3p3 as default I suppose but it seems to me it should possibly be M558 P2 X0 Y0 Z0.

this is my M558 line and it works (Have now got 3 of these working)

M558 P1 X0 Y0 Z0 H5 F300 T10000

So P1 is correct

HTH

Doug

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 11:39AM |

Registered: 10 years ago Posts: 14,672 |

M558 with P1 is correct. P2 is for a dumb but modulated sensor, where the modulation signal is generated by the Duet. My IR sensor has an on-board microcontroller that generates the modulation.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 01:57PM |

Registered: 10 years ago Posts: 104 |

Thanks DC42, I worked it out in the end, I just confused myself reading modulated and un-modulated.

I am at 1605.4 Check Z-probe offsets at 4 points in the Mini documentation because the docs for the XL (or Maxi as it is to be called) aren't complete yet but I don't have the macros listed there. I have

E motors off

Origin

X-tower

Y-tower

Z-10u

Z-tower

Z+10u

Where do I get the correct macros or how do I use these if the procedure has changed?

I am at 1605.4 Check Z-probe offsets at 4 points in the Mini documentation because the docs for the XL (or Maxi as it is to be called) aren't complete yet but I don't have the macros listed there. I have

E motors off

Origin

X-tower

Y-tower

Z-10u

Z-tower

Z+10u

Where do I get the correct macros or how do I use these if the procedure has changed?

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 02:51PM |

Registered: 10 years ago Posts: 14,672 |

I suggest you don't bother with the macros, because if you have the IR sensor working well then you can auto calibrate. Here's how:

1. Check that the Z probe is working by moving the head to about 5mm above bed centre and executing G30. It should stop at the trigger height.

2. In config.g make sure you have the following parameters:

M665 L parameter - accurately set to your diagonal rod length, measured between bearing centres (mine is 349.5, I don't know what T3P3 uses on that kit)

M665 R parameter - set to your approximate delta radius (mine is about 172)

M665 H parameter - set to the approximate height of the nozzle above the bed when the carriages are all activating the homing switches (mine is about 493)

G31 Z parameter - measure the IR sensor trigger height (between nozzle and bed) at bed centre and use that

M558 H parameter - temporarily set to a higher value than the default 5mm, e.g. 25 (this is the height form which probing starts)

M558 T parameter - temporarily set to a lower value than the default, e.g. 500 (this is the travel speed between probe points)

3. Use [escher3d.com] to generate your bed.g file and put it in /sys/bed.g (or perhaps t3p3 has done this already). I suggest 6 factor and 10 or 13 points.

4. Run G32 to execute auto calibration. Look at the Console page of the web interface to see what the deviation is. Repeat a few times until the deviation stabilises.

5. Run M665 and M666 without parameters, and copy the reported values back into the M665 and M666 commands in config.g. Remove the M558 T and H parameters, or set them to more sensible values to speed up bed probing in future. Upload the new config.g.

6. Reboot and run G32 again, check that everything is OK.

The final G32 should be done with the hot end end bed at printing temperature.

Edited 1 time(s). Last edit at 12/12/2015 04:28PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Check that the Z probe is working by moving the head to about 5mm above bed centre and executing G30. It should stop at the trigger height.

2. In config.g make sure you have the following parameters:

M665 L parameter - accurately set to your diagonal rod length, measured between bearing centres (mine is 349.5, I don't know what T3P3 uses on that kit)

M665 R parameter - set to your approximate delta radius (mine is about 172)

M665 H parameter - set to the approximate height of the nozzle above the bed when the carriages are all activating the homing switches (mine is about 493)

G31 Z parameter - measure the IR sensor trigger height (between nozzle and bed) at bed centre and use that

M558 H parameter - temporarily set to a higher value than the default 5mm, e.g. 25 (this is the height form which probing starts)

M558 T parameter - temporarily set to a lower value than the default, e.g. 500 (this is the travel speed between probe points)

3. Use [escher3d.com] to generate your bed.g file and put it in /sys/bed.g (or perhaps t3p3 has done this already). I suggest 6 factor and 10 or 13 points.

4. Run G32 to execute auto calibration. Look at the Console page of the web interface to see what the deviation is. Repeat a few times until the deviation stabilises.

5. Run M665 and M666 without parameters, and copy the reported values back into the M665 and M666 commands in config.g. Remove the M558 T and H parameters, or set them to more sensible values to speed up bed probing in future. Upload the new config.g.

6. Reboot and run G32 again, check that everything is OK.

The final G32 should be done with the hot end end bed at printing temperature.

Edited 1 time(s). Last edit at 12/12/2015 04:28PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 03:55PM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 04:29PM |

Registered: 10 years ago Posts: 14,672 |

Quote

MightyMouth

Ah great thanks, I thought you had to do the macros to get close before using the auto calibration.

The trick is to increase the M558 H parameter so that it probes from a great height, to avoid the risk of crashing into the bed before probing or while transiting between probe points. However, if you see it probing with the IR sensor not over the bed, then stop and change things, e.g. reduce the probing radius.

Edited 1 time(s). Last edit at 12/12/2015 04:30PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 05:37PM |

Registered: 10 years ago Posts: 104 |

OK so I don't have an H or T parameter beside M558, I assume I just add them to override defaults?

Mine looks like

Should I make it look like

Also where you say "G31 Z parameter - measure the IR sensor trigger height (between nozzle and bed) at bed centre and use that" is that with or without the copy paper in place?

Edited 1 time(s). Last edit at 12/12/2015 05:54PM by MightyMouth.

Mine looks like

M558 P1 X0 Y0 Z0

Should I make it look like

M558 P1 X0 Y0 Z0 H25 T500?

Also where you say "G31 Z parameter - measure the IR sensor trigger height (between nozzle and bed) at bed centre and use that" is that with or without the copy paper in place?

Edited 1 time(s). Last edit at 12/12/2015 05:54PM by MightyMouth.

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 06:03PM |

Registered: 10 years ago Posts: 14,672 |

Quote

MightyMouth

OK so I don't have an H or T parameter beside M558, I assume I just add them to override defaults?

Mine looks likeM558 P1 X0 Y0 Z0

Should I make it look likeM558 P1 X0 Y0 Z0 H25 T500?

Yes.

Quote

MightyMouth

Also where you say "G31 Z parameter - measure the IR sensor trigger height (between nozzle and bed) at bed centre and use that" is that with or without the copy paper in place?

One way to measure trigger height:

1. Jog the nozzle down until it is just touching the bed or just gripping a sheet of paper (whatever your preferred method of setting Z=0 is).

2. Send G92 Z0

3. Send G1 Z5 F1000 and remove the paper.

4. Send G30 S-1 and then read off the trigger heigh from the web interface or by sending M114,

In theory the paper is 0.1mm thick. In practice there is some elasticity in the print head, so when it is gripping the paper more than slightly, you can take that position as Z=0.

Edited 1 time(s). Last edit at 12/12/2015 06:03PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 06:11PM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 12, 2015 06:59PM |

Registered: 10 years ago Posts: 104 |

ok so after 4 runs it settled down so I ran M665 and M666 which came back

I don't know what to do with the X 0.15°, Y 0.12°, Z 0.00° after the bed radius.

Also these are the numbers when cold, should I use these or the numbers after the hot run.

Edited 1 time(s). Last edit at 12/12/2015 07:11PM by MightyMouth.

Diagonal 350.00, delta radius 178.05, homed height 495.90, bed radius 140.0, X 0.15°, Y 0.12°, Z 0.00°

Endstop adjustments X-0.28 Y0.44 Z-0.17

I don't know what to do with the X 0.15°, Y 0.12°, Z 0.00° after the bed radius.

Also these are the numbers when cold, should I use these or the numbers after the hot run.

Edited 1 time(s). Last edit at 12/12/2015 07:11PM by MightyMouth.

|

Re: The first beta machine based on DC42's Kossel XL December 13, 2015 03:30AM |

Registered: 10 years ago Posts: 14,672 |

Quote

MightyMouth

ok so after 4 runs it settled down so I ran M665 and M666 which came back

Diagonal 350.00, delta radius 178.05, homed height 495.90, bed radius 140.0, X 0.15°, Y 0.12°, Z 0.00°Endstop adjustments X-0.28 Y0.44 Z-0.17

I don't know what to do with the X 0.15°, Y 0.12°, Z 0.00° after the bed radius.

Also these are the numbers when cold, should I use these or the numbers after the hot run.

The XYZ numbers after the bed radius should be added to the M665 command i.e. X0.15 Y0.12 Z0

I do a single autocalibration before I print but after heating the bed and hot end to operating temperature. Then it doesn't matter whether I have hot or cold values in config.g, or what temperatures I am using.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 13, 2015 06:51AM |

Registered: 10 years ago Posts: 104 |

|

Re: The first beta machine based on DC42's Kossel XL December 13, 2015 07:04AM |

Registered: 9 years ago Posts: 131 |

|

Re: The first beta machine based on DC42's Kossel XL December 13, 2015 07:09AM |

Registered: 10 years ago Posts: 104 |

Thanks. There seems to be quite a lot of noise from something while moving and some resonance from something, possibly the belts. I am ready to print something but I don't really no how to configure slicer and no config file was supplied with the beta kit.

Video of the printer calibrating.

Video of the printer calibrating.

|

Re: The first beta machine based on DC42's Kossel XL December 13, 2015 12:54PM |

Registered: 10 years ago Posts: 14,672 |

Sadly I had to give up using slic3r because it crashes almost every time I try to slice anything with it. I now use S3D instead. Here is a summary of the settings I use for PLA:

Bed: 70C (it is quite a lot cooler than that on top of the glass)

Hot end: 200 or 205C first layer, 195C remaining layers

Layer height: 0.2mm

Speed: perimeters 50mm/sec, infill 100mm/sec, small perimeters 10mm/sec, travel 200mm/sec, first layer speed 50%, external perimeters 80%.

Retraction: this is critical. To little and you will get a small blob at the start of each travel move. Too much and the E3D hot end will jam. So increase it until the blobs disappear. My printer has a 660mm Bowden tube and needs 8mm retraction. I use retraction speed 100mm/sec and lift Z 0.5mm.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Bed: 70C (it is quite a lot cooler than that on top of the glass)

Hot end: 200 or 205C first layer, 195C remaining layers

Layer height: 0.2mm

Speed: perimeters 50mm/sec, infill 100mm/sec, small perimeters 10mm/sec, travel 200mm/sec, first layer speed 50%, external perimeters 80%.

Retraction: this is critical. To little and you will get a small blob at the start of each travel move. Too much and the E3D hot end will jam. So increase it until the blobs disappear. My printer has a 660mm Bowden tube and needs 8mm retraction. I use retraction speed 100mm/sec and lift Z 0.5mm.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The first beta machine based on DC42's Kossel XL December 13, 2015 01:54PM |

Registered: 10 years ago Posts: 104 |

Sorry, only registered users may post in this forum.