Maximum angle for arms? Is it actually 90 degrees???

Posted by patrickrio

|

Maximum angle for arms? Is it actually 90 degrees??? December 03, 2015 05:59PM |

Registered: 9 years ago Posts: 233 |

Hi, I know the minimum angle recommended is 20 degrees, maybe 15 degrees at the outside. For the highest angle, I have seen "nearly 90 degrees" but have not seen an actual recommended number. Is it actually 90 degrees or is it something like 85 degrees????

I am about to finalize my arm lengths and distances between linear guides, so I need to know this now...

Thanks!!!

I am about to finalize my arm lengths and distances between linear guides, so I need to know this now...

Thanks!!!

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 03, 2015 06:04PM |

Registered: 10 years ago Posts: 14,672 |

There is nothing wrong in principle with going to 90 degrees or even beyond. The practical limit is that the effector needs to remain clear of the belts.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 03, 2015 07:54PM |

Registered: 9 years ago Posts: 233 |

that is what I thought.... Wanted to make sure that there wasn't some unknown issue I did not know about....

Actually, thinking about the geometry, since all 6 arms are equal length, and since you want the shortest length of arms, 90 degrees is the angle that minimizes arm length for a given print diameter and effector size.

Actually, thinking about the geometry, since all 6 arms are equal length, and since you want the shortest length of arms, 90 degrees is the angle that minimizes arm length for a given print diameter and effector size.

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 04, 2015 01:14AM |

Registered: 9 years ago Posts: 483 |

Quote

patrickrio

that is what I thought.... Wanted to make sure that there wasn't some unknown issue I did not know about....

Actually, thinking about the geometry, since all 6 arms are equal length, and since you want the shortest length of arms, 90 degrees is the angle that minimizes arm length for a given print diameter and effector size.

I don't think that computes. I would say the minimum arm angle at the print diameter will determine the arm length.

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 04, 2015 04:11AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 04, 2015 05:08AM |

Registered: 10 years ago Posts: 14,672 |

Quote

patrickrio

Actually, thinking about the geometry, since all 6 arms are equal length, and since you want the shortest length of arms, 90 degrees is the angle that minimizes arm length for a given print diameter and effector size.

Surely you could use shorter arms if you went beyond 90 degrees, by standing the bearings off from the carriages. However, this would also require more sideways movement from the joints, so perhaps OK for ball-and-socket joints but not for Traxxas or Igus rod ends.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 04, 2015 06:35PM |

Registered: 9 years ago Posts: 233 |

OK, I think I can picture how to get equal arms shorter by extending past 90 degrees... However I am a ways past the age I studied geometry, so doing a geometry proof is beyond my current ability. But you would essentially have the joints on the carriages extend inward so the arms can swing past 90 without the effector hitting the vertical guides, rods or belts. Stiffness of the mounting points might decrease if you make the joints a long distance from the carriages, but in a small machine like mine, it might not matter much. I would like to attempt this.

Since a shorter arm would increase build height for a given machine height, especially in a small machine, it seems that there may be reason to calculate what construction would result in the shortest arms...

I will have to think about this in the morning while my brain is fresh if I am to have any hope of calculating what the shortest arms could be. Another thing to think about is that shortening the arms and allowing movement past 90 degrees will also increase the distance moved per step.... so smaller tooth counts on drive gears become more advantageous too.. I think.....

Edit: well, I guess my brain will HAVE to think about this tonight some more. Another effect of allowing movement past 90 degrees is that linear movement toward a tower from the far side will result in the slide on that tower moving upward till it's rods hit 90 degrees and then it will start moving downward again.... Can the math of the Duet calculate this in it's current form?????

Edit 2: And at a certain point, you have to worry about hitting the bowden tube too.....

Edit 3: It also increases arm angle sweep, so the only joints I have that can handle such large angles are the magnetic arms...... I am going to try this, but it may fail due to magnetic joint strength.....

Kind of a rabbit hole this is....

Edited 3 time(s). Last edit at 12/04/2015 06:56PM by patrickrio.

Since a shorter arm would increase build height for a given machine height, especially in a small machine, it seems that there may be reason to calculate what construction would result in the shortest arms...

I will have to think about this in the morning while my brain is fresh if I am to have any hope of calculating what the shortest arms could be. Another thing to think about is that shortening the arms and allowing movement past 90 degrees will also increase the distance moved per step.... so smaller tooth counts on drive gears become more advantageous too.. I think.....

Edit: well, I guess my brain will HAVE to think about this tonight some more. Another effect of allowing movement past 90 degrees is that linear movement toward a tower from the far side will result in the slide on that tower moving upward till it's rods hit 90 degrees and then it will start moving downward again.... Can the math of the Duet calculate this in it's current form?????

Edit 2: And at a certain point, you have to worry about hitting the bowden tube too.....

Edit 3: It also increases arm angle sweep, so the only joints I have that can handle such large angles are the magnetic arms...... I am going to try this, but it may fail due to magnetic joint strength.....

Kind of a rabbit hole this is....

Edited 3 time(s). Last edit at 12/04/2015 06:56PM by patrickrio.

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 04, 2015 08:28PM |

Registered: 9 years ago Posts: 233 |

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 05, 2015 02:10PM |

Registered: 9 years ago Posts: 233 |

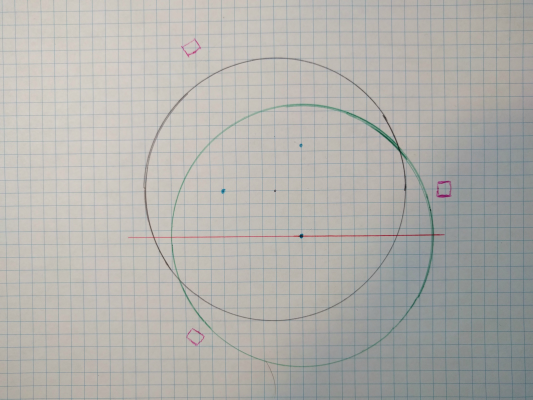

Ok, here is the drawing.

in the drawing each square=5mm per side

The Pink squares represent the limit of movement for the carriage at the tower points.

The Black circle represents the build area circle.

The Blue dots represent the center points of the effector joints in a 3 ball system.

The Green circle represents the path traced by one of the effector joint center points when the nozzle traces the edge of the build area

The Red line represents the possible locations of the corresponding carriage joint center point as you lengthen the attach distance from the carriage.

From the drawing, the theoretically shortest arm results when the carriage ball center is directly above the effector ball center when the nozzle is centered in the build circle.

The theoretical minimum arm length in the case of this effector size and bed diameter, would be 53.21mm for 20 degrees and 51.76mm for 15 degrees minimum angle. of course you can't actually put the arms at this point because arms from two towers would occupy the same space in the real world, as they are not really lines or points... also, the center of the carriage balls would need to be located about 60mm from the towers which would look pretty awkward...

I guess all this work shows is that if you extend the carriage joint centers away from the carriage, you will shorten the arms.

Some might say this was a lot of circular thinking, and running around in circles just to circle back to where I started. But to those who would doubt the value of this, I say "the proof is in the circles, jerk!!" (HA!)

in the drawing each square=5mm per side

The Pink squares represent the limit of movement for the carriage at the tower points.

The Black circle represents the build area circle.

The Blue dots represent the center points of the effector joints in a 3 ball system.

The Green circle represents the path traced by one of the effector joint center points when the nozzle traces the edge of the build area

The Red line represents the possible locations of the corresponding carriage joint center point as you lengthen the attach distance from the carriage.

From the drawing, the theoretically shortest arm results when the carriage ball center is directly above the effector ball center when the nozzle is centered in the build circle.

The theoretical minimum arm length in the case of this effector size and bed diameter, would be 53.21mm for 20 degrees and 51.76mm for 15 degrees minimum angle. of course you can't actually put the arms at this point because arms from two towers would occupy the same space in the real world, as they are not really lines or points... also, the center of the carriage balls would need to be located about 60mm from the towers which would look pretty awkward...

I guess all this work shows is that if you extend the carriage joint centers away from the carriage, you will shorten the arms.

Some might say this was a lot of circular thinking, and running around in circles just to circle back to where I started. But to those who would doubt the value of this, I say "the proof is in the circles, jerk!!" (HA!)

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 10, 2015 03:44PM |

Registered: 8 years ago Posts: 31 |

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 10, 2015 11:09PM |

Registered: 9 years ago Posts: 233 |

|

Re: Maximum angle for arms? Is it actually 90 degrees??? December 11, 2015 03:07AM |

Registered: 9 years ago Posts: 1,159 |

Quote

DrDoggy

going past 90deg would be impractical , since the nozzle position of 91deg would be the same as 89 deg (trig stuff)

We are talking here of the angle that the arm subtends to the bed so an angle of 91 is NOT the same nozzle position as an angle of 89 (I think you are thinking of the angle in relation to the towers in which case you would be correct). ie an angle of 90 degrees would be parallel to the tower.

Doug

Edited 1 time(s). Last edit at 12/11/2015 03:07AM by dougal1957.

Sorry, only registered users may post in this forum.