Delta pulley and idler dimensions question

Posted by realthor

|

Delta pulley and idler dimensions question December 06, 2015 05:58PM |

Registered: 9 years ago Posts: 1,035 |

I am planning to replace MXL with GT2 on Delta and I would need some advice by answering the following questions:

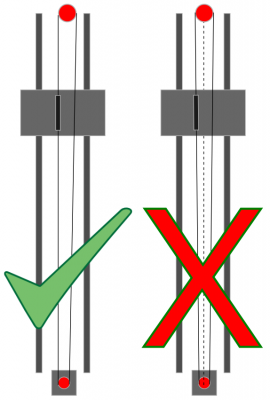

1) The sizes of pulley and idler don't have to be the same as long as the driving side of the loop is in a vertical line top-down right?

2) I plan to use 16 tooth pulleys that are about 13-14mm OD. If I were to look for 16tooth idlers I can't seem to find a bearing-based solution with toothed idler included. What do you guys use for idlers and how does the idler rotate on its shaft? Aluminum idler rotating on screw or even smooth shaft is going to wear off. What do you use for shaft?

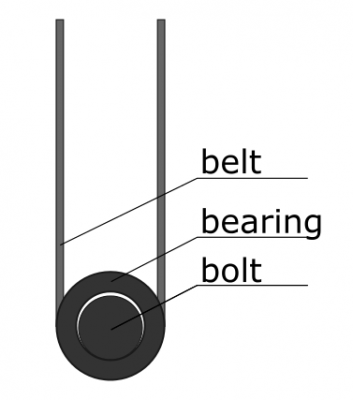

3) I've seen many bearings as idlers solutions that don't flip the belts along the way so that the smooth side rides the bearings. What would you suggest regarding:

a) bearings as idlers (have to be flanged? 2 non-flanged bearings side by side?)

b) is it better to let the teeth of the belt ride the bearing or flip it along the length of the tower so the smooth side of the belt ride the bearing?

Thanks.

Edited 6 time(s). Last edit at 12/07/2015 07:46PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

1) The sizes of pulley and idler don't have to be the same as long as the driving side of the loop is in a vertical line top-down right?

2) I plan to use 16 tooth pulleys that are about 13-14mm OD. If I were to look for 16tooth idlers I can't seem to find a bearing-based solution with toothed idler included. What do you guys use for idlers and how does the idler rotate on its shaft? Aluminum idler rotating on screw or even smooth shaft is going to wear off. What do you use for shaft?

3) I've seen many bearings as idlers solutions that don't flip the belts along the way so that the smooth side rides the bearings. What would you suggest regarding:

a) bearings as idlers (have to be flanged? 2 non-flanged bearings side by side?)

b) is it better to let the teeth of the belt ride the bearing or flip it along the length of the tower so the smooth side of the belt ride the bearing?

Thanks.

Edited 6 time(s). Last edit at 12/07/2015 07:46PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 06, 2015 06:31PM |

Registered: 10 years ago Posts: 14,672 |

My delta has the toothed side of the pulley running on Robotdigg smooth idler pulleys that are supported by bearings. But I am not happy with this solution. The teeth make a noise as they run on the pulleys at high speeds. This is sure to be causing belt vibration and loss of precision too.

So I want to switch to either toothed pulleys, or put a twist in the belt and run the back of the belt on the idler. Unfortunately the carriages are too narrow to accommodate a slot wide enough for the twist in the return belt. However, I currently use 4mm standoffs to widen the rod separation, so I can solve this by using printed wider carriages instead of the Robotdigg metal ones.

Edited 1 time(s). Last edit at 12/06/2015 06:32PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

So I want to switch to either toothed pulleys, or put a twist in the belt and run the back of the belt on the idler. Unfortunately the carriages are too narrow to accommodate a slot wide enough for the twist in the return belt. However, I currently use 4mm standoffs to widen the rod separation, so I can solve this by using printed wider carriages instead of the Robotdigg metal ones.

Edited 1 time(s). Last edit at 12/06/2015 06:32PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta pulley and idler dimensions question December 07, 2015 02:41AM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

My delta has the toothed side of the pulley running on Robotdigg smooth idler pulleys that are supported by bearings. But I am not happy with this solution. The teeth make a noise as they run on the pulleys at high speeds. This is sure to be causing belt vibration and loss of precision too.

So I want to switch to either toothed pulleys, or put a twist in the belt and run the back of the belt on the idler. Unfortunately the carriages are too narrow to accommodate a slot wide enough for the twist in the return belt. However, I currently use 4mm standoffs to widen the rod separation, so I can solve this by using printed wider carriages instead of the Robotdigg metal ones.

Dave

The robotdigg top corners can take a 10x5x4 bearing in them which means you can run a 5mm diam shaft with toothed gears on it. Guess you would want to put some spacers either side of the gear to keep everything aligned (I Did this on my first iteration as the first set came without the idler shafts he did supply them later tho).

Doug

Think I will go back to that idea as well as well as using steel cored belts.

|

Re: Delta pulley and idler dimensions question December 07, 2015 02:58AM |

Registered: 11 years ago Posts: 5,780 |

I am using a GT2 belt and bearings as a smooth pulley on the X axis in my printer. I used to twist the belt so the back side would would ride on the pulley but I found that the belt always wanted to walk off the pulley when I did that, even when I had the idler set up so I could tilt its axis. I could never adjust it to a stable point- the tilt that worked a high speed didn't work at low speeds and vice versa. It's easier to keep the belt on the pulley without the twist and I haven't been able to identify any loss of precision because of it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Delta pulley and idler dimensions question December 07, 2015 07:32AM |

Registered: 8 years ago Posts: 5,232 |

I didn't like the robotdigg alu idlers either. Especially their 3mm alu-shaft was way too brittle for my liking .

So I made some dummy 10 x 5 x 4 bearings from PLA and printed my own 22 tooth idler with real MF105 BBs.

It's a pretty close fit in the corners, next time I use 8x5x4 bearings and print smaller idlers.

-Olaf

Edited 1 time(s). Last edit at 12/07/2015 07:35AM by o_lampe.

So I made some dummy 10 x 5 x 4 bearings from PLA and printed my own 22 tooth idler with real MF105 BBs.

It's a pretty close fit in the corners, next time I use 8x5x4 bearings and print smaller idlers.

-Olaf

Edited 1 time(s). Last edit at 12/07/2015 07:35AM by o_lampe.

|

Re: Delta pulley and idler dimensions question December 07, 2015 08:45AM |

Registered: 9 years ago Posts: 1,035 |

Quote

o_lampe

So I made some dummy 10 x 5 x 4 bearings from PLA and printed my own 22 tooth idler with real MF105 BBs.

It's a pretty close fit in the corners, next time I use 8x5x4 bearings and print smaller idlers.

-Olaf

You have to print them on a pretty darn precise 3d printer otherwise you might get errors in printed parts isn't it? I am lately printing stuff at the library where they have ultimakers but I see errors in those as well, so unless I have myself another printer that i know I keep calibrated and well maintained I'd go straight to bearings and let the toothed side ride the bearing (I wouldn't want the twisted belt to try walking away on the bearings, I can use Spectra in that case, it too walks back and forth and at least in a predictable manner).

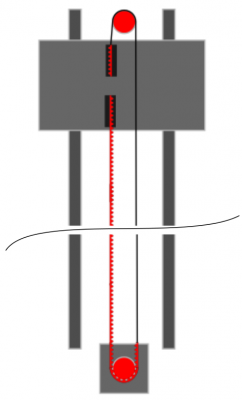

Regarding the driving side of the belt (the one clamped to the carriage): it is mandatory that this is perfectly vertical, like I have shown in my sketch attached to the first post?

One more: I am looking at "685 685ZZW3 MR115ZZ deep groove ball bearing 5x11x3mm miniature bearing" to use for the idlers. They are pretty close to the 13mm OD of the 16-tooth GT2 pulley. The problem is that they are not flanged and being 3mm deep, a 6mm wide GT2 will require 2 of them side by side. How would you setup flanges? Washers maybe? Are the flanges absolutely necessary? AFAIK the tension on the belt will arrange it to be exactly under/over the motor pulley. The Overlord currently uses a 5mm bolt and a 20-tooth MXL brass idler pulley that rotates on the bolt.

Thanks.

Edited 2 time(s). Last edit at 12/07/2015 12:20PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 07, 2015 02:45PM |

Registered: 9 years ago Posts: 483 |

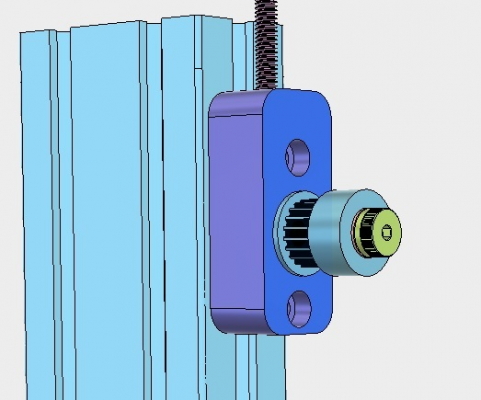

I use a 20 tooth pulley with an 8mm bore riding on two 8mmx5mm bearings on a 5mm shoulderbolt. The shoulderbolt is recessed a couple of millimeters into the spacer block so the threads aren't being side loaded. It's hard to see the bearings in the drawing, but they are there.

|

Re: Delta pulley and idler dimensions question December 07, 2015 07:46PM |

Registered: 9 years ago Posts: 1,035 |

Does it matter for a Delta if you use 16 or 20 tooth pulley on the motor? I was thinking the lower tooth count the better resolution but with 20 tooth we get 0.2mm (200micron) resolution per full step while the 16tooth can get us to 0.16 (160micron) resolution, a 25% improvement, which is substantial. Yet we usually do 16x microstepping and here the 25% difference somehow washes out because we get 0.0125mm (12.5micron) from 20tooth GT2 pulley while the 16tooth gets us to 0.01mm (10 micron). Now both 12.5micron and 10micron possible resolution is plenty enough to offer good results with FFF.

I don't know for Deltas how do these values compound considering that for every move all 3 motors rotate, but with the calculated values, at 16x microstepping does it still matter if I choose 16 or 32 tooth pulleys?

@etfrench: did you choose 5mm shoulderbolt because the M5 bolt is more 4.87mm and not 5mm? I would think that even if you have 4.87mm bolt, the 5mm ID bearings will ride well on it after the tension is applied to the belt because the tension will cause a permanent contact on one side of the bolt at all times. I don't think there will be any noise caused by this or other secondary effects as long as there is enough tension on the belt. Please let me know if you do.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I don't know for Deltas how do these values compound considering that for every move all 3 motors rotate, but with the calculated values, at 16x microstepping does it still matter if I choose 16 or 32 tooth pulleys?

@etfrench: did you choose 5mm shoulderbolt because the M5 bolt is more 4.87mm and not 5mm? I would think that even if you have 4.87mm bolt, the 5mm ID bearings will ride well on it after the tension is applied to the belt because the tension will cause a permanent contact on one side of the bolt at all times. I don't think there will be any noise caused by this or other secondary effects as long as there is enough tension on the belt. Please let me know if you do.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 07, 2015 08:40PM |

Registered: 9 years ago Posts: 483 |

|

Re: Delta pulley and idler dimensions question December 07, 2015 08:50PM |

Registered: 9 years ago Posts: 1,035 |

Quote

etfrench

Shoulder bolts were designed for applications like this. It isn't good practice to allow bearings to flop around on their axles. It may work with standard bolts, but it won't be as good as it can be. Why introduce a source for errors when it's not necessary?

It's quite difficult to find them at least I haven't been able to find a shop around that has them. I am in Finland so it might be different in US.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 07, 2015 09:11PM |

Registered: 9 years ago Posts: 483 |

|

Re: Delta pulley and idler dimensions question December 08, 2015 05:10AM |

Registered: 9 years ago Posts: 445 |

|

Re: Delta pulley and idler dimensions question December 08, 2015 05:21AM |

Registered: 9 years ago Posts: 1,035 |

This dimensional difference between standardized bolts and bearings is very annoying. Why can't the bolts be the exact diameter they describe? M5 is not 5mm but less. Just annoying.

Now we have to buy another specialty product to add up to the vitamins of a 3D printer.

However, I don't see any issue that would arise down the road from an imperfect fit of the bolt/bearing because the tension in the belt would always load it from a single side. I know this is not "the way it's done" but neither is running the belt with the teeth on the bearing and there is no degradation in performance, as the doctor reports a few posts above. There might be applications where this would be detrimental but in this case I just don't see any downside.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Now we have to buy another specialty product to add up to the vitamins of a 3D printer.

However, I don't see any issue that would arise down the road from an imperfect fit of the bolt/bearing because the tension in the belt would always load it from a single side. I know this is not "the way it's done" but neither is running the belt with the teeth on the bearing and there is no degradation in performance, as the doctor reports a few posts above. There might be applications where this would be detrimental but in this case I just don't see any downside.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 11, 2015 04:28PM |

Registered: 10 years ago Posts: 469 |

I run 20T pulleys on my delta with 5mm id flanged bearings in a sandwitch. It works, however I am not happy with the arangement. I would like to run a 20T pulley with built in bearings, however I have not found any yet.

With that said, I still run rubber belts even with a heated chamber and 45-50C in there they seem to have settled down. I think a redesign of the idler side of a delta is necessary.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

With that said, I still run rubber belts even with a heated chamber and 45-50C in there they seem to have settled down. I think a redesign of the idler side of a delta is necessary.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Delta pulley and idler dimensions question December 11, 2015 04:37PM |

Registered: 9 years ago Posts: 1,035 |

Quote

jaguarking11

I run 20T pulleys on my delta with 5mm id flanged bearings in a sandwitch. It works, however I am not happy with the arangement. I would like to run a 20T pulley with built in bearings, however I have not found any yet.

With that said, I still run rubber belts even with a heated chamber and 45-50C in there they seem to have settled down. I think a redesign of the idler side of a delta is necessary.

I have considered 20T GT2 pulley with 8mm bore and 2x MR84ZZ (4x8x3mm) bearings but I have decided that inserting those miniature bearings in the bore was too complicated and opted out for 2 flanged F694ZZ (4x11x4mm). The difference in diameter from a 20T pulley with the belt ontop is 0.3 or 0.4mm when you put the belt riding on the bearings with the teeth on the smooth surface of the bearing's OD.

I also believe that this resulting smooth pulley will be quieter than a toothed pulley but I don't know by how much (a good read here: http://www.pfeiferindustries.com/troubleshooting/timing-belt-unusual-excessive-noise.html).

I guess I'll see when they arrive.

Why are you unhappy of that arrangement? Did you notice any loss in quality on the prints?

Edited 1 time(s). Last edit at 12/11/2015 04:38PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 11, 2015 04:47PM |

Registered: 10 years ago Posts: 14,672 |

The toothed belt running on the smooth pulley is one of the noisiest components of my delta. I think it excites the resonant frequency of the belt at some speeds. That's why I want a better solution.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta pulley and idler dimensions question December 11, 2015 05:20PM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

The toothed belt running on the smooth pulley is one of the noisiest components of my delta. I think it excites the resonant frequency of the belt at some speeds. That's why I want a better solution.

But the belt's teeth entering at high speeds into their recess on the motor pulley have an apparently worse effect of compressing the air and evacuating it at high speeds as they fill the gap, making basically a pop sound that is multiplied with speed creating the "drrrrrr" sound of the belt. I fail to see where or how can the teeth create a similar noise on the smooth pulleys.There is no place where the air would be compressed.

Could it be that each tooth, not finding a perfectly matched recess to dissipate its energy is banging into the pulley with all force? I really can't see the smooth pulley being a source of noise.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 12, 2015 01:59PM |

Registered: 8 years ago Posts: 28 |

I had not considered the additional resolution using a 16 tooth vs 20 tooth pulley, but it is there, you have to change steps per mm to compensate. My idlers are two flanged bearings riding on a cheap bolt, but they seem to work. A belt is never going to be your most consistent drive, but it looks like they are more than accurate enough to not be the limiting factor for a delta bot. The extruder is far less accurate, and I don't see huge efforts being made in that area yet, like feed forward pressure control. I come from an automotive background and I think there has been extensive research done on fuel injectors that we can , er, borrow. Hmmmmm, a plastic injector ....

|

Re: Delta pulley and idler dimensions question December 13, 2015 11:46AM |

Registered: 9 years ago Posts: 1,035 |

Liquefying plastic to that viscosity to be able to pass through an injector would require a too high of a temperature which would burn the plastic and i believe that they are already doing injection-style printing with the XJet technology but I don't think that can be applied to FDM 3D printing.

Myself, I miss designing fro spectra line for its advantages but I am so sad that no development is going for the "spectra drive" that was once a hot topic in the reprap discussions, before everybody got confy and settled for timing belts. Yes, spectra drive has some disadvantages compared to timing belts but it's also silent and doesn't need toothed pulleys and some more. But the big disadvantage is its "walking" effect which is bad for precision/repetability. Synchromesh is the new kid that could but it's proprietary technology and it's difficult to source and its quite expensive so timing belts are the de facto for their ubiquity and cost effectiveness.

I went for 20tooth 5mm bore pulleys and F694ZZ flanged bearings (4x11x4mm). The difference in diameter between the two when they have belts on is 0.4mm on a 600mm height loop between the two. I too will have a 4mm smooth bolt for the idler to ride and that is 0.13mm smaller than the 4mm bearing hole but, being always forced but the tension in the belt, it will never be loose and will always have contact with the bolt.

I still have my doubts at high speeds where the belt resonates heavily, maybe that will introduce a play in the tension and will make the flanged bearing loose some of its contact with the bolt.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Myself, I miss designing fro spectra line for its advantages but I am so sad that no development is going for the "spectra drive" that was once a hot topic in the reprap discussions, before everybody got confy and settled for timing belts. Yes, spectra drive has some disadvantages compared to timing belts but it's also silent and doesn't need toothed pulleys and some more. But the big disadvantage is its "walking" effect which is bad for precision/repetability. Synchromesh is the new kid that could but it's proprietary technology and it's difficult to source and its quite expensive so timing belts are the de facto for their ubiquity and cost effectiveness.

I went for 20tooth 5mm bore pulleys and F694ZZ flanged bearings (4x11x4mm). The difference in diameter between the two when they have belts on is 0.4mm on a 600mm height loop between the two. I too will have a 4mm smooth bolt for the idler to ride and that is 0.13mm smaller than the 4mm bearing hole but, being always forced but the tension in the belt, it will never be loose and will always have contact with the bolt.

I still have my doubts at high speeds where the belt resonates heavily, maybe that will introduce a play in the tension and will make the flanged bearing loose some of its contact with the bolt.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 13, 2015 01:02PM |

Registered: 10 years ago Posts: 14,672 |

Quote

voi9viper

...The extruder is far less accurate, and I don't see huge efforts being made in that area yet, like feed forward pressure control..

I implemented pressure advance in RepRapFirmware about a year ago. Sadly, it didn't improve my print quality much. I intend to try adding extruder time advance as well sometime.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta pulley and idler dimensions question December 13, 2015 01:05PM |

Registered: 8 years ago Posts: 28 |

|

Re: Delta pulley and idler dimensions question December 13, 2015 01:28PM |

Registered: 9 years ago Posts: 1,035 |

Quote

voi9viper

I just hate imprecission too. syncromesh as in trasmissions? Or is it something new, which I suspect if patents apply. I'm dating myself, but my 71 firebird had a syncromesh tranny I think.

No idea how old this is but this is it:

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 15, 2015 02:39PM |

Registered: 10 years ago Posts: 469 |

Quote

realthor

Quote

jaguarking11

I run 20T pulleys on my delta with 5mm id flanged bearings in a sandwitch. It works, however I am not happy with the arangement. I would like to run a 20T pulley with built in bearings, however I have not found any yet.

With that said, I still run rubber belts even with a heated chamber and 45-50C in there they seem to have settled down. I think a redesign of the idler side of a delta is necessary.

I have considered 20T GT2 pulley with 8mm bore and 2x MR84ZZ (4x8x3mm) bearings but I have decided that inserting those miniature bearings in the bore was too complicated and opted out for 2 flanged F694ZZ (4x11x4mm). The difference in diameter from a 20T pulley with the belt ontop is 0.3 or 0.4mm when you put the belt riding on the bearings with the teeth on the smooth surface of the bearing's OD.

I also believe that this resulting smooth pulley will be quieter than a toothed pulley but I don't know by how much (a good read here: http://www.pfeiferindustries.com/troubleshooting/timing-belt-unusual-excessive-noise.html).

I guess I'll see when they arrive.

Why are you unhappy of that arrangement? Did you notice any loss in quality on the prints?

Its not the quality that suffers. I have rarely gone to .1mm layers let along sub .1mm stuff as I 3d print larger stuff and that kind of resolution would give me print times measured in days, not hours.

With that said I am unhappy with the solution as it will create wear on the belt, I have observed that my belt lost a bit of tension creating some slack. A toothed pulley preferably of the same diameter would hold the teeth in a proper grove and increase surface area and belt life with the possible down side of increasing friction. However friction limitations are not a concern for me at this time due to the fact that I run a ramps, anything over 150mm/s causes the cpu to peg giving very jerky movements and bad prints.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Delta pulley and idler dimensions question December 15, 2015 02:44PM |

Registered: 10 years ago Posts: 469 |

Quote

realthor

Quote

voi9viper

I just hate imprecission too. syncromesh as in trasmissions? Or is it something new, which I suspect if patents apply. I'm dating myself, but my 71 firebird had a syncromesh tranny I think.

No idea how old this is but this is it:

I have also been thinking of these kinds of chains. [www.amazon.co.uk]

They may work in our setup and they could be stronger, although not necessarily more precise.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Delta pulley and idler dimensions question December 15, 2015 03:45PM |

Registered: 9 years ago Posts: 1,035 |

Precision is in 3D printers' case of essential importance and everything that happens in the realm of consumer grade 3D printing is slowly going towards improvements in precision/repetability/performance. I don't particularly like the means of getting there, which is to be late adopters of whatever made the commercial 3D printers precise 15 years ago. This is fine on one hand, because mass production of said components is driving down the prices but this is ridiculous because 3D printing is supposed to break mass production and to improve localized production, less harmful to the environment, personalized to the specific needs of customers, etc. But we are trying to beat the mass production with more mass production.

Philosophy aside, having some experience with both belts and spectra fishing line, and having read a lot about Spectra/Dyneema (at least read this Wikipedia section on Ultra High Molecular Weight Polyethylene), I can see a good approach in combining the belt for the exact portion that will roll across the toothed pulley and Spectra/Dyneema,Kevlar, UHMWP fibers for everything else, all the pulleys and 3D routing is better with spectra but the driving portion.

I am going to experiment with this approach which, by the way, is nothing new. There are a couple of videos on youtube sporting this approach, one of them (I don't remember any other) being about a Delta of all.

I know that a new variable will be introduced into the system, the tensioning of the combo, but we are clueless anyway about the right way to tension belts and we go by "feeling", so nothing new there.

Edit reason: Wow, I just learned how to link to a section of a page that doesn't got an anchor. Super cool, I have sent you right to the right section on the wikipedia page.

Edited 1 time(s). Last edit at 12/15/2015 03:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Philosophy aside, having some experience with both belts and spectra fishing line, and having read a lot about Spectra/Dyneema (at least read this Wikipedia section on Ultra High Molecular Weight Polyethylene), I can see a good approach in combining the belt for the exact portion that will roll across the toothed pulley and Spectra/Dyneema,Kevlar, UHMWP fibers for everything else, all the pulleys and 3D routing is better with spectra but the driving portion.

I am going to experiment with this approach which, by the way, is nothing new. There are a couple of videos on youtube sporting this approach, one of them (I don't remember any other) being about a Delta of all.

I know that a new variable will be introduced into the system, the tensioning of the combo, but we are clueless anyway about the right way to tension belts and we go by "feeling", so nothing new there.

Edit reason: Wow, I just learned how to link to a section of a page that doesn't got an anchor. Super cool, I have sent you right to the right section on the wikipedia page.

Edited 1 time(s). Last edit at 12/15/2015 03:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 16, 2015 02:20AM |

Registered: 8 years ago Posts: 916 |

When I built my printer, I read up about how the best way to do things was to flip the belt so that the smooth side ran over the idler bearing, so that's how I built mine.

Then when upgrading my roller carriages to linear bearings, I changed from the belt riding on the smooth side of the idler bearings to the toothed side due to the way that the robotdigg carriages were set up.

This resulted in a noticeable degradation in quality. Sides of the piece that used to be dead flat now have slight diagonal ridges on them.

They're only noticeable in the right light, but they're definitely there. I've also noticed a bit more 'ringing' in the print, which might be due to the teeth of the belt compressing more than if the belt were flipped.

I'm going to get out the dremel and attack those robotdigg carriages to allow a half-twist in the long side of the belt, and see if I can get my old print quality back. Incidentally the reason I went to the linear slides turned out to be unrelated to what was actually going on. It turned out to be a slic3r setting.

Then when upgrading my roller carriages to linear bearings, I changed from the belt riding on the smooth side of the idler bearings to the toothed side due to the way that the robotdigg carriages were set up.

This resulted in a noticeable degradation in quality. Sides of the piece that used to be dead flat now have slight diagonal ridges on them.

They're only noticeable in the right light, but they're definitely there. I've also noticed a bit more 'ringing' in the print, which might be due to the teeth of the belt compressing more than if the belt were flipped.

I'm going to get out the dremel and attack those robotdigg carriages to allow a half-twist in the long side of the belt, and see if I can get my old print quality back. Incidentally the reason I went to the linear slides turned out to be unrelated to what was actually going on. It turned out to be a slic3r setting.

|

Re: Delta pulley and idler dimensions question December 16, 2015 04:31AM |

Registered: 9 years ago Posts: 1,035 |

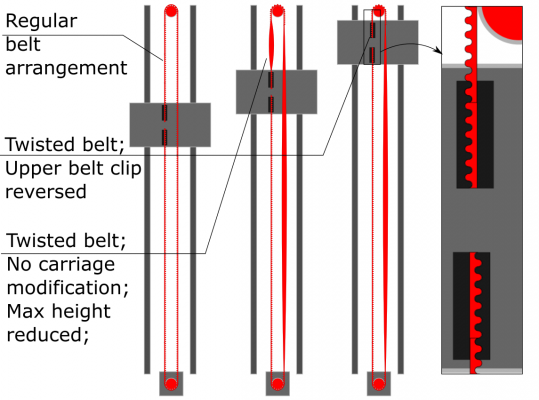

Did you ever notice the "walking" attempts of the inverted belt like was reported on this thread? And I confess I don't see why there would be impediments in twisting it. I would think that the problems arise when the twisted belt approaches the pulley or idler because the twist would have to turn 180 in a very short distance and that would stress the belt.

Do you have any idea what is the shortest distance the 180deg twist can be safely done without degradation in belt's life? DigitalDentist reported that he has seen no degradation of the prints done with teeth running on the smooth idler. I don't know about the belt lifespan due to the teeth being compressed more than in a toothed idler. My test would suggest that the minimum distance for the 180deg twist without too much stress on the belt is 100mm for the complete twist. And I have much less than that between the carriage and the idler when it is at the end of its upper stroke. Depending on Delta design, if the upper pulley is too close to the carriage at the top position of the carriage this will reduce the life of the belt.

On the other hand, if the carriage is 3D printed, the upper belt clamp can be redesigned so that it catches the belt in its 180deg twisted position. My carriages are injection molded so not much luck here.

Here's a quick sketch with all 3 situations:

I assume that rarely one will print such a tall object as to reach max Z position so I guess even in my case twisting the belt on one side would be acceptable.

Another option is to use spectra for half of the loop:

Because of the difference in width between the belt and the spectra, the idler should be larger to compensate for the size so that the vertical lines are still parallel. I have sketched the situation where the spectra is used on the existing pulley (I will have 2 flanged bearings so if/when i change to spectra I can run it in the groove between the two bearings)

Edited 1 time(s). Last edit at 12/16/2015 05:00AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Do you have any idea what is the shortest distance the 180deg twist can be safely done without degradation in belt's life? DigitalDentist reported that he has seen no degradation of the prints done with teeth running on the smooth idler. I don't know about the belt lifespan due to the teeth being compressed more than in a toothed idler. My test would suggest that the minimum distance for the 180deg twist without too much stress on the belt is 100mm for the complete twist. And I have much less than that between the carriage and the idler when it is at the end of its upper stroke. Depending on Delta design, if the upper pulley is too close to the carriage at the top position of the carriage this will reduce the life of the belt.

On the other hand, if the carriage is 3D printed, the upper belt clamp can be redesigned so that it catches the belt in its 180deg twisted position. My carriages are injection molded so not much luck here.

Here's a quick sketch with all 3 situations:

I assume that rarely one will print such a tall object as to reach max Z position so I guess even in my case twisting the belt on one side would be acceptable.

Another option is to use spectra for half of the loop:

Because of the difference in width between the belt and the spectra, the idler should be larger to compensate for the size so that the vertical lines are still parallel. I have sketched the situation where the spectra is used on the existing pulley (I will have 2 flanged bearings so if/when i change to spectra I can run it in the groove between the two bearings)

Edited 1 time(s). Last edit at 12/16/2015 05:00AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 16, 2015 04:42AM |

Registered: 10 years ago Posts: 14,672 |

If you have a half twist over a length of the belt that varies as in your second diagram, then the belt tension will vary with that length, and hence with carriage position. So the arrangement in the third diagram is better. This also lets you lock the teeth of the belt together in the carriage, which avoids the tension in the belt putting stress on the printed carriage parts. RepRapPro does this in the X carriage of their Ormerod printer.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta pulley and idler dimensions question December 16, 2015 05:09AM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

If you have a half twist over a length of the belt that varies as in your second diagram, then the belt tension will vary with that length, and hence with carriage position. So the arrangement in the third diagram is better. This also lets you lock the teeth of the belt together in the carriage, which avoids the tension in the belt putting stress on the printed carriage parts. RepRapPro does this in the X carriage of their Ormerod printer.

I agree with you. However, in my situation, the carriage is injection molded so I can't really see a way to adopt the third diagram, which involves re-printing the carriage. I don't know if there is a way to securely stitch/clamp/bolt two sections of belt so I can cut 20mm of belt, reverse it and clamp/stitch/whatever to the other length of belt. This solution might be too stretched to work an i might opt for the spectra-belt combo instead.

Edited 3 time(s). Last edit at 12/16/2015 05:21AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Delta pulley and idler dimensions question December 16, 2015 05:18AM |

Registered: 10 years ago Posts: 14,672 |

Quote

realthor

Quote

dc42

I don't know if there is a way to securely stitch/clamp/bolt two sections of belt so I can cut 20mm of belt, reverse it and clamp/stitch/whatever to the other length of belt. This solution might be too stretched to work an i might opt for the spectra-belt combo instead.

I assume that 20mm section will never have to run over a pulley, so that it can be rigid. I suggest you lock the teeth of the two sections together, then hold them together in one of several ways:

- epoxy them in that position;

- clamp them between two small metal plates;

- print a plastic part with a slot in it, and push the belts into that slot - as on the Ormerod X-carriage.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.