Trueing bed to towers proves quite difficult; Is it essential?

Posted by realthor

|

Trueing bed to towers proves quite difficult; Is it essential? December 10, 2015 04:20PM |

Registered: 9 years ago Posts: 1,035 |

Hi,

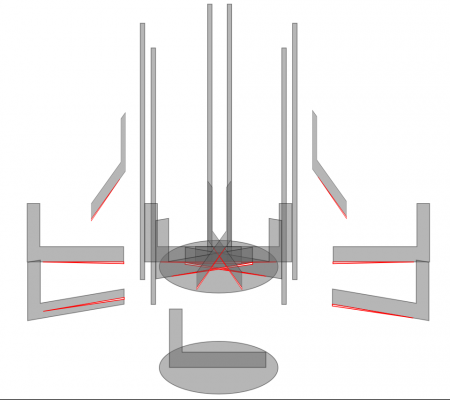

I am trying to calibrate my delta by first having the physical space as true as possible between components. In my delta (Overlord Pro), I have Rostock-like linear rods and I am trying to get them perfectly perpendicular to the aluminum bed. This is harder than i would have thought.

I have come pretty close to perfect perpendicularity (using a carpenters square) but I am at a quite baffling situation. Measured from all rods, there is a little gap at the end of the bed-side of the carpenters square, pointing to the conclusion that the bed is leaned towards that side. It's almost like all the rods see the other side of the bed lower than the point of contact between the carpenters square and the bed.

The bed can't be concave, it measures perfectly straight with the carpenters square laid across it. It's like all the rods are drawing a larger circle at the top of the delta printer than at the botom, making it not a cylinder bot more like a cone pointing downwards. Because this is a factory-made 3d printer, there is not much I can do if this was true. But, because of my inexperience, I assume I am doing something wrong. Moreover, all the plastic components of the printer are injection molded so they must be the same dimensions, rendering my speculation unlikely.

I didn't took pictures but will eventually. In the meantime the following sketch might prove explanatory enough:

Do I have it wrong and this can't happen? I am sure you have loads more experience than I have so maybe you went through this when you first started. Please let me know if there is a guide to trueing the bed against the towers because this very simple looking task doesn't seem to as simple in reality.

Right now I have about two millimeters gap at the end of the carpenters square, which goes past the center of the bed, more like 3/4 of the bed length.

Is it essential that this squareing/trueing of the towers to bed is perfect? I don't even want to go further with calibration before I get this perfect. There are so many other things that will drive the precision of the machine down I wouldn't like this to be yet another one.

Edited 2 time(s). Last edit at 12/10/2015 04:22PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am trying to calibrate my delta by first having the physical space as true as possible between components. In my delta (Overlord Pro), I have Rostock-like linear rods and I am trying to get them perfectly perpendicular to the aluminum bed. This is harder than i would have thought.

I have come pretty close to perfect perpendicularity (using a carpenters square) but I am at a quite baffling situation. Measured from all rods, there is a little gap at the end of the bed-side of the carpenters square, pointing to the conclusion that the bed is leaned towards that side. It's almost like all the rods see the other side of the bed lower than the point of contact between the carpenters square and the bed.

The bed can't be concave, it measures perfectly straight with the carpenters square laid across it. It's like all the rods are drawing a larger circle at the top of the delta printer than at the botom, making it not a cylinder bot more like a cone pointing downwards. Because this is a factory-made 3d printer, there is not much I can do if this was true. But, because of my inexperience, I assume I am doing something wrong. Moreover, all the plastic components of the printer are injection molded so they must be the same dimensions, rendering my speculation unlikely.

I didn't took pictures but will eventually. In the meantime the following sketch might prove explanatory enough:

Do I have it wrong and this can't happen? I am sure you have loads more experience than I have so maybe you went through this when you first started. Please let me know if there is a guide to trueing the bed against the towers because this very simple looking task doesn't seem to as simple in reality.

Right now I have about two millimeters gap at the end of the carpenters square, which goes past the center of the bed, more like 3/4 of the bed length.

Is it essential that this squareing/trueing of the towers to bed is perfect? I don't even want to go further with calibration before I get this perfect. There are so many other things that will drive the precision of the machine down I wouldn't like this to be yet another one.

Edited 2 time(s). Last edit at 12/10/2015 04:22PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 10, 2015 05:08PM |

Registered: 9 years ago Posts: 483 |

First, I'd verify your carpenters square is actually square. If it isn't, then you can try to correct it using a punch at the intersection of the two legs (flat side not edge). Punch towards the inside to increase the angle and towards the outside to decrease the angle.

Second, I'd make a story board to verify the distances between the towers are identical. To make one, cut a piece of wood (or extrusion) shorter than the distance between the towers. Drill and tap one end for a small bolt (CA glue on threads in wood will make them strong enough for this).

If the towers are not exactly the same distance apart top to bottom, send the printer back...

p.s. Or discuss it with the manufacturer

Second, I'd make a story board to verify the distances between the towers are identical. To make one, cut a piece of wood (or extrusion) shorter than the distance between the towers. Drill and tap one end for a small bolt (CA glue on threads in wood will make them strong enough for this).

If the towers are not exactly the same distance apart top to bottom, send the printer back...

p.s. Or discuss it with the manufacturer

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 10, 2015 06:39PM |

Registered: 9 years ago Posts: 346 |

Injection molding is not like CNC. Even for the best and despite very sophisticated simulation software it is still to some degree trial and error approach if you want a mold to hit exact dimensions. It is not unlikely that the time pressure the Overlord was under, did not allow for those last adjustment.

HOWEVER, if this was true, then I would expect there to be more experiences about this on the internet. On the other hand, many who bought the Overlord was first time buyers (pure guess) so maybe they never measured.

2 mm is too much. Are you sure it is that much? How is that measured?

Other then that etfrench, is 100% right. And do as he says, starts by checking the square is actually 90 deg....

HOWEVER, if this was true, then I would expect there to be more experiences about this on the internet. On the other hand, many who bought the Overlord was first time buyers (pure guess) so maybe they never measured.

2 mm is too much. Are you sure it is that much? How is that measured?

Other then that etfrench, is 100% right. And do as he says, starts by checking the square is actually 90 deg....

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 10, 2015 06:55PM |

Registered: 9 years ago Posts: 1,035 |

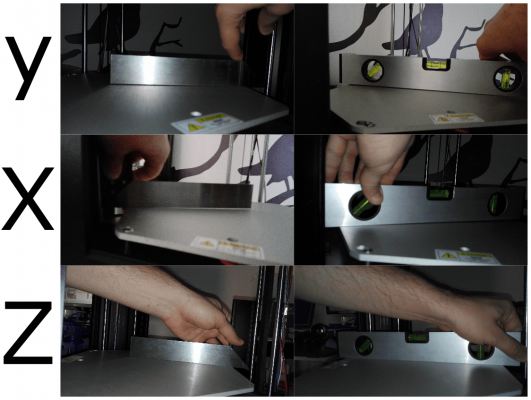

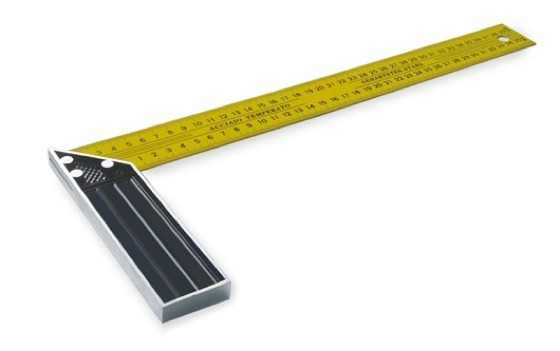

It is very possible that I am doing something wrong. I haven't seen anywhere a video of others doing it so my procedure was to put the thick side of the carpenters square (I have the IKEA one that is steel with aluminum short side just like this image) on the smooth rod, a few cm above the bed, and slide it down slowly until it touched the bed somewhere.

I do this for each of the six rods and adjust the 3 screws as I see fit and re-measure until i see the errors leveling out.

But at this point I can't seem to have anything else to do as all edges of the aluminum plate seem to be a bit higher than the other sides. I will redo the calibration tomorrow and report results. Maybe take some photos.

I would have thought that many more reports should have surfaced since the printer rolled out so I might be doing something wrong or overlooking something. But it should be a simple 10 minutes task really

Edited 1 time(s). Last edit at 12/10/2015 06:56PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I do this for each of the six rods and adjust the 3 screws as I see fit and re-measure until i see the errors leveling out.

But at this point I can't seem to have anything else to do as all edges of the aluminum plate seem to be a bit higher than the other sides. I will redo the calibration tomorrow and report results. Maybe take some photos.

I would have thought that many more reports should have surfaced since the printer rolled out so I might be doing something wrong or overlooking something. But it should be a simple 10 minutes task really

Edited 1 time(s). Last edit at 12/10/2015 06:56PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 10, 2015 08:29PM |

Registered: 8 years ago Posts: 916 |

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 03:10AM |

Registered: 9 years ago Posts: 1,159 |

Quote

nebbian

Realthor,

Could you be measuring a twist in the top frame, relative to the bottom frame?

If your square isn't perpendicular to the two smooth rods, then you might be seeing a twist.

Alternatively your square might not be square.

To test the accuracy of your square place it against a straight edged board and draw a line down the rule part then flip the square over and check the line still lines up to the rule part?

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 08:25AM |

Registered: 9 years ago Posts: 1,035 |

Quote

dougal1957

To test the accuracy of your square place it against a straight edged board and draw a line down the rule part then flip the square over and check the line still lines up to the rule part?

Hmm, I am afraid I don't follow.

Ok, here we go with pictures and all. So I have this square and I thought of another supposedly square thing in my studio, which is an aluminum level. They both might not be square for all I know, but they were sold as square. Nevertheless this is what I have to work with.

So I have used both against the smooth vertical rods and observed the gap between the bed and the edge of the tool. The gap was consistent with both tools. Here are some pictures:

I am still trying to do a better job but I find myself cornered because even if I get one tower perfect (Z in this case), the other two towers show n increasing gap as the ruler/level extends towards the opposite side.

BTW, the OLP printer has rostock-style 2 rods per tower and on top of this the leveling screws aren't located between each tower's rods, like I would imagine, but they are offset to the side of the right rod. How is this squareing supposed to be done? From this right-side rod closest to the leveling screw towards both of the other screws?

I was trying to achieve some sort of squareing between each rod and the bed. But this is close to impossible in the current configuration.

If I am not able to achieve perfect squareness, is there any hope of adjusting these things in the software? As far as i know the auto-bed-leveling is only done at z=0 and translated for every Z up to the end stops, so if towers are leaned outwards or the upper rods' ends plane is somewhat rotated compared to the base plane the errors will increase as soon as you leave the calibrated Z=0 plane.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 08:47AM |

Registered: 10 years ago Posts: 14,672 |

I still don't understand exactly what problem you are describing. The bed is obviously slightly tilted with respect to the horizontal, but this could just mean that the printer is not standing on a level surface, or the feet at the bottom do not all have the same height. When you hold the spirit level against the rods, are they all exactly vertical, in both directions?

To a first approximation, towers leaning slightly in a radial direction can be compensated by shifting the tower positions, which will be done by auto calibration.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

To a first approximation, towers leaning slightly in a radial direction can be compensated by shifting the tower positions, which will be done by auto calibration.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 09:37AM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

I still don't understand exactly what problem you are describing. The bed is obviously slightly tilted with respect to the horizontal, but this could just mean that the printer is not standing on a level surface, or the feet at the bottom do not all have the same height. When you hold the spirit level against the rods, are they all exactly vertical, in both directions?

To a first approximation, towers leaning slightly in a radial direction can be compensated by shifting the tower positions, which will be done by auto calibration.

I can't really tell if the rods are perfectly vertical because I have no means to provide a perfectly flat and leveled surface. That would require another 3-point leveled surface which I don't have yet. I was thinking about building one though, a flat board with 3 8(10 maybe)mm screws would be enough. NOTE: I am not using the spirit as a leveler, I am only using the aluminum square body as a straight tool.

In my current setup I am trying to only compare bed to towers and to achieve 90 degrees between them. Which I seem to fail. It is quite conforting that you say the radial displacement that I seem to have can be compensated for in software.

My problem is exactly this. I can manage to make one tower perfectly perpendicular to the bed. But the remaining two towers remain slightly leaned radially outwards at the top and whatever screws adjustments I would make I can't but worsen the gap in favor of one or the other.

My options seem to be:

1) adjust in such a way that all 3 towers create the same gap between the tool and the bed;

2) adjust one tower to be 90deg with the bed and adjust the remaining towers to have a similar gap so that i can input that in firmware.

3? something I can't see because of my lack of experience and you can suggest.

Thanks.

Edited 3 time(s). Last edit at 12/11/2015 09:41AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 11:04AM |

Registered: 10 years ago Posts: 14,672 |

So it sounds as though your delta frame is slightly larger at the top than at the bottom. Can you measure it to check this? Can you do anything about it? If not, then I suggest you adjust it so that the towers lean out by approximately equal amounts.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 01:30PM |

Registered: 9 years ago Posts: 483 |

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 01:45PM |

Registered: 9 years ago Posts: 1,035 |

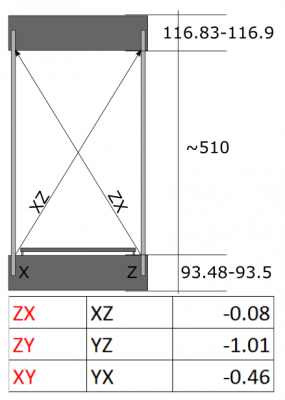

I have finished measuring and making notes on a sketch (attached). It seems the bottom and top planes are very similar (~0.1-0.2mm error, which can be caused by my caliper not being perfectly leveled while measuring - at the top I didn't have supporting surfaces to make it easy so I did the best I could). The XZ distance differs from the YZ distance by 1mm which will affect the angles too but I have no idea how much. BTW, it was impossible for me to measure the XY closest rods distance with the caliper in a form that would have ensured accurate reading (I could have turned the caliper 90 degrees but it would have been a too flimsy position to consider - I even tried).

My measurements were done at the maximum travel of the carriages, just above the glass plate (leaning the caliper on the glass) and just below the endstops at the top.

Either I have two left hands or there is a twist between the two planes, either they are rotated around the axis or they are shifted in their planes or a combinations of the latter two. I can't possibly measure rotation and it is quite unlikely considering the construction of the Overlord (injection molded frame and very sturdy aluminum extrusions; however, the aluminum extrusions slide on the injection molded parts so they could as well be decorative stuff).

Edited 2 time(s). Last edit at 12/11/2015 02:00PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

My measurements were done at the maximum travel of the carriages, just above the glass plate (leaning the caliper on the glass) and just below the endstops at the top.

Either I have two left hands or there is a twist between the two planes, either they are rotated around the axis or they are shifted in their planes or a combinations of the latter two. I can't possibly measure rotation and it is quite unlikely considering the construction of the Overlord (injection molded frame and very sturdy aluminum extrusions; however, the aluminum extrusions slide on the injection molded parts so they could as well be decorative stuff).

Edited 2 time(s). Last edit at 12/11/2015 02:00PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 02:08PM |

Registered: 9 years ago Posts: 483 |

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 02:21PM |

Registered: 9 years ago Posts: 1,159 |

Quote

realthor

Quote

dougal1957

To test the accuracy of your square place it against a straight edged board and draw a line down the rule part then flip the square over and check the line still lines up to the rule part?

Hmm, I am afraid I don't follow.

.

Ok

to test the accuracy of your square do the following place the square against a straight edge and draw a line on say a piece of paper Pic 1

then flip the square over and repeat pic 2

then check that the lines line up and if they don't like mine in pic 3 then your square is NOT Square

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 02:44PM |

Registered: 11 years ago Posts: 5,780 |

Aligning 3 linear guides would be tricky, putting 6 guide rails in parallel seems like a nightmare. You have quite a task ahead of you, but kudos for trying to measure and understand. You're ahead of 95% of 3D printers out there.

I use one of these to do the rough alignment in my printer. I don't trust its absolute accuracy down to 0.02 degrees, but it is much better than a bubble level and it actually gets my bed level enough to print on over most of its surface. I used it to roughly align the guide rails of the X and Z axes and had to make only minor shifts in the guide rail positions after I printed a test cube.

These things have many uses for leveling things around the house.

Edited 1 time(s). Last edit at 12/11/2015 02:57PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I use one of these to do the rough alignment in my printer. I don't trust its absolute accuracy down to 0.02 degrees, but it is much better than a bubble level and it actually gets my bed level enough to print on over most of its surface. I used it to roughly align the guide rails of the X and Z axes and had to make only minor shifts in the guide rail positions after I printed a test cube.

These things have many uses for leveling things around the house.

Edited 1 time(s). Last edit at 12/11/2015 02:57PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 03:21PM |

Registered: 9 years ago Posts: 1,035 |

Quote

dougal1957

Quote

realthor

Quote

dougal1957

To test the accuracy of your square place it against a straight edged board and draw a line down the rule part then flip the square over and check the line still lines up to the rule part?

Hmm, I am afraid I don't follow.

.

Ok

to test the accuracy of your square do the following place the square against a straight edge and draw a line on say a piece of paper Pic 1

then flip the square over and repeat pic 2

then check that the lines line up and if they don't like mine in pic 3 then your square is NOT Square

Oh such a simple technique. So much for my straight carpenters square

) ...attached.

) ...attached.I believe that my square has a smaller than 90deg inner angle, which would explain the gap I get while measuring.

So, summarizing, the dimensions are quite accurate and the manual bed leveling can get to maybe half the error I showed earlier.

I have to think of a way to measure the diagonals like I've been advised. I am thinking the same technique: some sort of caliper extender so I can reach the longer distance between diagonals.

Will update when I get the measurements.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 04:04PM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

Aligning 3 linear guides would be tricky, putting 6 guide rails in parallel seems like a nightmare. You have quite a task ahead of you, but kudos for trying to measure and understand. You're ahead of 95% of 3D printers out there.

I use one of these to do the rough alignment in my printer. I don't trust its absolute accuracy down to 0.02 degrees, but it is much better than a bubble level and it actually gets my bed level enough to print on over most of its surface. I used it to roughly align the guide rails of the X and Z axes and had to make only minor shifts in the guide rail positions after I printed a test cube.

These things have many uses for leveling things around the house.

Yes I agree about the less than fortunate idea to have 6 rods perfectly parallel with one another and perfectly perpendicular to the bed ... I see the practicality of Kossel's alu extrusion and steel rail with bearing blocks, but that's not the reality - unfortunately. I don't know how the Rostocks out there deal with all this. Maybe that's why the auto-calibration is much more advanced on Deltas than other printers.

On a side note, I have a crazy idea: did you see how the Overlord is skinned with the aluminum extrusions? They are slid over the injection molded structure and 4 puny screws keep it in place. I personally don't believe they add to the stiffness of the frame much more than the rods themselves. They aren't even a perfect fit while sliding in the injection molded channels, you can rock them back and forth with the hand and they would move 1 mm in those channels.

Now my idea: strip the Overlord of these Aluminum extrusions and use them to build another Delta printer with them, Rep-Rap Style

- one printer builds another one

- one printer builds another one  -. The channels can be used to bolt a linear rail like some Kossels do or go even wilder and have some sort of carriages made with some bearings riding the three channels to provide stability or even some PFTE/UHMWPE sliding blocks. Barebone bearings would be pretty loud I guess.

-. The channels can be used to bolt a linear rail like some Kossels do or go even wilder and have some sort of carriages made with some bearings riding the three channels to provide stability or even some PFTE/UHMWPE sliding blocks. Barebone bearings would be pretty loud I guess.I have photographed the alu extrusion with some bearings to illustrate the idea

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 11, 2015 05:17PM |

Registered: 9 years ago Posts: 483 |

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 13, 2015 01:45PM |

Registered: 9 years ago Posts: 1,035 |

Quote

etfrench

You don't need to measure the length of the diagonals, just verify their relative lengths. A story board will do this.

Didn't yet got to do that. I don't mean to measure by all means but it could help down the road to have the numbers. And anyway I am planning to use the digital caliper for this ... it could be just as easy to throw together such a contraption as to make a wood with a screw in its head but I could make notes and assess my situation easier with the caliper and knowing the numbers.

Regarding the slightly not-perpendicular carpenters square I seem to have, how can i punch this to open up the angle? I have the type that has a steel "ruler" and an aluminum shorter "handle", like this one:

I can clamp it on a surface at the steel ruler's height and hit it with a puncher as closed to the diagonal between the two components, but never right on the diagonal because of the riveted aluminum "handle". What do you suggest? Maybe another "square" that is all-steel and maybe even having the "hypotenuse" - I just can't seem to find one of these later ones.

Edited 1 time(s). Last edit at 12/13/2015 01:46PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 13, 2015 02:46PM |

Registered: 9 years ago Posts: 483 |

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 13, 2015 03:27PM |

Registered: 9 years ago Posts: 1,035 |

Quote

realthor

On a side note, I have a crazy idea: did you see how the Overlord is skinned with the aluminum extrusions? They are slid over the injection molded structure and 4 puny screws keep it in place. I personally don't believe they add to the stiffness of the frame much more than the rods themselves. [...]

Now my idea: strip the Overlord of these Aluminum extrusions and use them to build another Delta printer with them, Rep-Rap Style- one printer builds another one

-. The channels can be used to bolt a linear rail like some Kossels do or go even wilder and have some sort of carriages made with some bearings riding the three channels to provide stability or even some PFTE/UHMWPE sliding blocks. Barebone bearings would be pretty loud I guess.

I know you guys who happen to be living in areas where V/T-slot/openbeam/etc extrusions can be found aplenty don't care much about these "rep-strap" ideas but where I am (yeah, maybe I have some extraordinary conditions that don't happen too often -being delegated with work in a place where I don't know the language and where even square alu tubes are Eur9/m etc etc) having two sets of "slide-able" components on a single printer looks like too much wasting.

I also agree that "home-brew" sliding mechanisms can't really be done professionally and it would end up with a "hobby" 3d printer at best but I would even use it for a chocolate 3d printer or for vases and stuff tha desn't require much precision or repetability so if you have any "alike" minded comments don't refrain from posting

. I can take criticism but I also believe strange ideas can be valuable if shared, may click other ideas in somebody's else brain, etc.

. I can take criticism but I also believe strange ideas can be valuable if shared, may click other ideas in somebody's else brain, etc.The same idea goes for IKEA Kvartal triple rail curtain aluminum extrusion that seems cheaper in this area than square alu tube too.

So I am only asking for some ideas or your expertise or confirmation that something can be done about this.

Regarding the main subject of this thread: I need a new square, I have to get as close to 90 deg sharp between towers and bed as possible and there might be settings in the software to adjust for leaned/angled/rotated towers. If there are, what are those and how can I adjust for them?

Thanks.

Edited 2 time(s). Last edit at 12/13/2015 03:32PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 13, 2015 06:59PM |

Registered: 9 years ago Posts: 1,035 |

Ok, nevermind, I can't see a home-brew solution that would work for these unconventional extrusions and keep some degree of precision. I guess open-beam and linear rails and other solutions are the right way to go afterall

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Trueing bed to towers proves quite difficult; Is it essential? December 17, 2015 05:51PM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

So it sounds as though your delta frame is slightly larger at the top than at the bottom. Can you measure it to check this? Can you do anything about it? If not, then I suggest you adjust it so that the towers lean out by approximately equal amounts.

Quote

etfrench

What was the result of using a story board to verify the distances between the towers?

I have just measured as accurate as I could (digital caliper clamped to a metal extender) and the differences seem minimal. Moreover, the top and bottom platforms can be also sub-millimetrically different in height (they are injection molded and should be fairly accurate in dimensions). I have made an excel with my measurements and i put together a sketch with the differences. The values are not important as they were relative to the extender piece.

The dimensions are measured from the "down-side" of first letter tower to the "up"-side of the second letter tower and are in mm.

Where do these errors rank in the error spectrum of delta 3D printers? They seem quite minimal to me.

I am sure I have errors in my measurements that are related to the caliper's own precision, due to manually positioning the caliper without any jug to constrain the tool in the same position for all metrics, etc etc.

I am wondering if we should define a set of metrics which are important for a machine's squareness and design a jig that would help us achieve repeatable measurements and then input those measurements in a tool (online php form/ excel/etc) to have an analysis and some output values that we can do a better calibration with.

I see that as much as Delta printers have advanced in calibration, it's always focused on the Z=0 plane and then assumed upwards to be the same, considering the build volume a perfect cylinder. And I believe it's not like that. We should try some volumetric calibration. either manual or automatic.

The easiest would be to measure it and input the values in a program that would approximate the build volume just like we do with bed leveling. And for each Z increase the current position should be corrected by the deviation calculated from the printer's shape. Just some thoughts.

Edited 3 time(s). Last edit at 12/18/2015 11:30AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.