New Hall endstop sensor design - views sought

Posted by dc42

|

New Hall endstop sensor design - views sought December 11, 2015 08:32AM |

Registered: 10 years ago Posts: 14,672 |

I intend to manufacture a small endstop switch board with am modern SMD Hall effect switch on it. The output will be low impedance in the not-triggered condition for high noise immunity, and there will be an LED on the board to indicate power and triggering. It will be proof against short circuited outputs and miswiring. It will be compatible with both 3.3V and 5V electronics.

The electrical design is done, but I need to finalise the mechanical design. I would like them to be easy to use on any delta, and to sacrifice little or no build height. My current plan is that they would normally be attached to the side of the tower extrusions and triggered by a magnet on the side of the carriage. When using wheeled carriages, there are usually 3 wheels; so if the endstop board is placed on the side with just one wheel, it will take up very little space as in this mock-up (this is not the actual PCB I will use, it will be smaller):

Does anyone have any other suggestions for a good mounting location and orientation that has little or no impact on build height?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The electrical design is done, but I need to finalise the mechanical design. I would like them to be easy to use on any delta, and to sacrifice little or no build height. My current plan is that they would normally be attached to the side of the tower extrusions and triggered by a magnet on the side of the carriage. When using wheeled carriages, there are usually 3 wheels; so if the endstop board is placed on the side with just one wheel, it will take up very little space as in this mock-up (this is not the actual PCB I will use, it will be smaller):

Does anyone have any other suggestions for a good mounting location and orientation that has little or no impact on build height?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New Hall endstop sensor design - views sought December 12, 2015 05:22AM |

Registered: 9 years ago Posts: 1,159 |

Dave

I will have a set when they are ready.

For me I can probably change things around to take whatever mounting you come up with.

On my more recent builds my endstop switches are mounted as yours are but my original delta they are mounted where you have the board positioned.

the new ones are using HIWIN Type linear rails tho so I would need to probably glue the magnets to the carriers in a suitable location (Will have to think on and make a 3 wire loom for them when I wire it up)

Doug

I will have a set when they are ready.

For me I can probably change things around to take whatever mounting you come up with.

On my more recent builds my endstop switches are mounted as yours are but my original delta they are mounted where you have the board positioned.

the new ones are using HIWIN Type linear rails tho so I would need to probably glue the magnets to the carriers in a suitable location (Will have to think on and make a 3 wire loom for them when I wire it up)

Doug

|

Re: New Hall endstop sensor design - views sought September 11, 2016 10:47PM |

Registered: 8 years ago Posts: 1,671 |

Are these derived from your work?

[www.ebay.co.uk]

[www.ebay.co.uk]

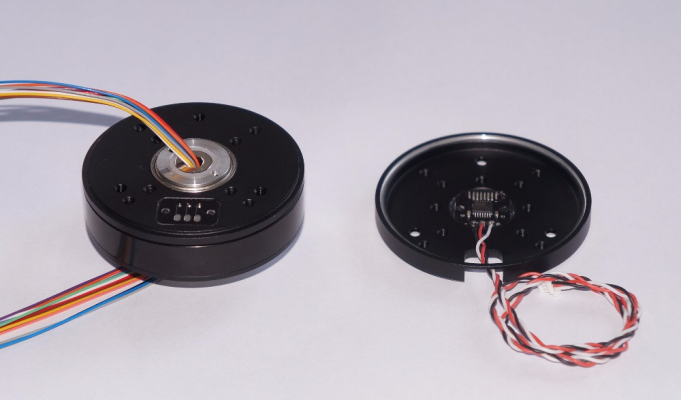

I'm thinking of trying to implement these hall sensors somewhere in the design, I've noticed gimbal motors are now using these as a way to improve the stabilization in conjuntion with newer 32bit controlers(though they are much more expensive $20 for the hall sensor board), [www.aliexpress.com]

so I was wondering if they could be used to also increase or count steps in a stepper motor for some kind of closed loop control..

perhaps thats not the way they work, just a thought.

Edited 2 time(s). Last edit at 09/12/2016 06:03AM by MechaBits.

[www.ebay.co.uk]

[www.ebay.co.uk]

I'm thinking of trying to implement these hall sensors somewhere in the design, I've noticed gimbal motors are now using these as a way to improve the stabilization in conjuntion with newer 32bit controlers(though they are much more expensive $20 for the hall sensor board), [www.aliexpress.com]

so I was wondering if they could be used to also increase or count steps in a stepper motor for some kind of closed loop control..

perhaps thats not the way they work, just a thought.

Edited 2 time(s). Last edit at 09/12/2016 06:03AM by MechaBits.

|

Re: New Hall endstop sensor design - views sought September 13, 2016 05:40AM |

Registered: 10 years ago Posts: 14,672 |

No, those are not derived from anything by me. I swill be using 3.3V SMD Hall sensors.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New Hall endstop sensor design - views sought September 13, 2016 09:18AM |

Registered: 8 years ago Posts: 42 |

|

Re: New Hall endstop sensor design - views sought September 13, 2016 12:19PM |

Registered: 10 years ago Posts: 14,672 |

Thanks, but the board will be very small anyway. The main design issue is what mounting arrangements to make for it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New Hall endstop sensor design - views sought September 13, 2016 12:54PM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.