HotEnd mount between the heater block and the heatsink

Posted by realthor

|

HotEnd mount between the heater block and the heatsink January 10, 2016 04:38PM |

Registered: 9 years ago Posts: 1,035 |

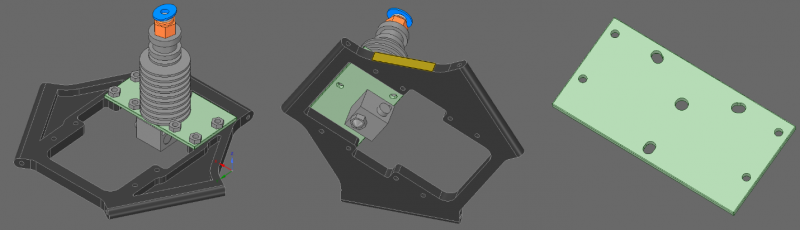

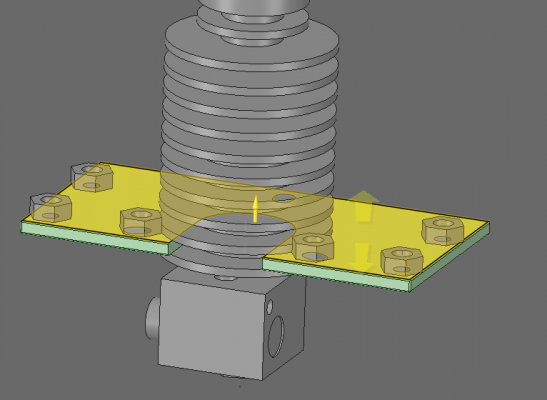

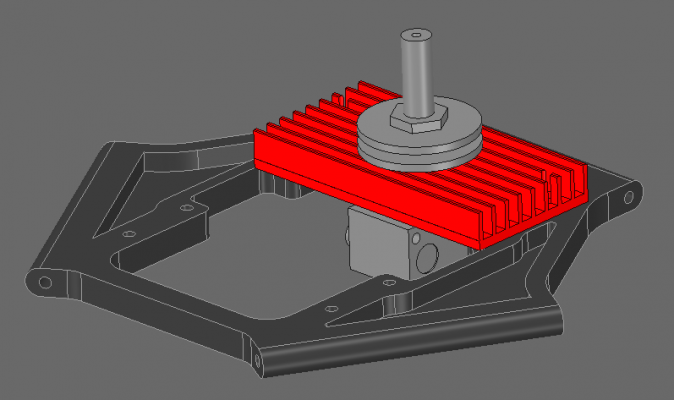

Hi, I am thinking of a hotend mount for a delta effector that would be a simple plate/pad that is fastened to the effector plate with bolts and sits on the hotend side in between the heater block and the heatsink, being clamped in between three nuts for additional support. The sketch below should be more explanatory of what I am thinking:

I get it that a metal plate would render the heatbreak useless and that it would bridge the heater block with the heatsink letting a whole lot of heat creep up but I am thinking that maybe there is some way to insulate the plate or use some sort of non-conducting material that can withstand the temperatures of the heater block.

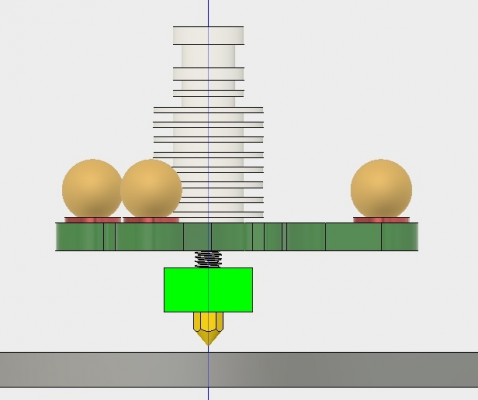

I like about this design that the nozzle is very close to the effector plate and that the clamping of the hotend is on the lower side (I compare drawing with a pencil by holding the pencil near the tip and drawing by holding it by its upper end).

Is this something worth pursuing or the normal way of clamping the hotend by its end is better? But for a delta effector it means either having the hotend way under the effector reducing the Z height or printing/making a part that would connect the effector to the hotend's "clamping area", which would introduce other issues down the road (a printed part can allow wiggle of the hotend in time).

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I get it that a metal plate would render the heatbreak useless and that it would bridge the heater block with the heatsink letting a whole lot of heat creep up but I am thinking that maybe there is some way to insulate the plate or use some sort of non-conducting material that can withstand the temperatures of the heater block.

I like about this design that the nozzle is very close to the effector plate and that the clamping of the hotend is on the lower side (I compare drawing with a pencil by holding the pencil near the tip and drawing by holding it by its upper end).

Is this something worth pursuing or the normal way of clamping the hotend by its end is better? But for a delta effector it means either having the hotend way under the effector reducing the Z height or printing/making a part that would connect the effector to the hotend's "clamping area", which would introduce other issues down the road (a printed part can allow wiggle of the hotend in time).

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: HotEnd mount between the heater block and the heatsink January 10, 2016 06:05PM |

Registered: 8 years ago Posts: 197 |

There are a few effector out there that place the heat block a few mm below the effector.

So the heat sink is mounted above the effector.

They normally do this in molded parts or metal and have a fan blowing on the heat sink and effector.

It will give you some more build space tho.

Is it worth it.... ah idk to each there own.

You can check out micromake, open beam kossel pro, and look on thingivers.

So the heat sink is mounted above the effector.

They normally do this in molded parts or metal and have a fan blowing on the heat sink and effector.

It will give you some more build space tho.

Is it worth it.... ah idk to each there own.

You can check out micromake, open beam kossel pro, and look on thingivers.

|

Re: HotEnd mount between the heater block and the heatsink January 11, 2016 02:15AM |

Registered: 9 years ago Posts: 1,035 |

I already have the printer and the effector and the hotend sits with the heatsink above the effector but the clamping of the hotend is on its upper side via another intermediary piece that raises above the effector and holds the hotend by its upper end. But that means one more part adding to the weight of the effector and then holding the hotend by its upper end is just like holding a pen by its end as opposed to holding it as close to its tip as possible. It allows the tip to have some play like it was on the circumference of a circle with a radius the same with the hotend's/pen's length.

With these 2 factors considered, I believe the design I proposed has some value but a metallic plate (the easiest to cut/drill) is the worst in terms of "breaking" the hotend parts' intent. The plate really has to keep the heater block and the heatsink disengaged.

I am thinking at two possibilities:

1) an insulating plate that can be used in between the heatblock and the heatsink, some sort of ceramic plate or some other such thing that I can't identify right now;

2) a metallic plate that would clamp the hotend after the heatbreak, somewhere in between the first and the second washers/fins of the heatsink. That gap is pretty small (<2mm) so even a metallic plate would be a stretch because of its flexibility.

Hopefully I will get more input from the community regarding material choice or placement to avoid breaking the hotend from the remperature transfer pov.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

With these 2 factors considered, I believe the design I proposed has some value but a metallic plate (the easiest to cut/drill) is the worst in terms of "breaking" the hotend parts' intent. The plate really has to keep the heater block and the heatsink disengaged.

I am thinking at two possibilities:

1) an insulating plate that can be used in between the heatblock and the heatsink, some sort of ceramic plate or some other such thing that I can't identify right now;

2) a metallic plate that would clamp the hotend after the heatbreak, somewhere in between the first and the second washers/fins of the heatsink. That gap is pretty small (<2mm) so even a metallic plate would be a stretch because of its flexibility.

Hopefully I will get more input from the community regarding material choice or placement to avoid breaking the hotend from the remperature transfer pov.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: HotEnd mount between the heater block and the heatsink January 11, 2016 04:03AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: HotEnd mount between the heater block and the heatsink January 11, 2016 06:17AM |

Registered: 9 years ago Posts: 1,035 |

Quote

o_lampe

Design a clamping piece, that grips the heatsink on its lower fins.

This way you have no issues with too much heat rising into the plate.

-Olaf

I have that in sight too but drilling holes is much easier than cutting notches into metal plates. I have the following design:

This will make it not much different than the existing ALU upper-heatsink-mounts and more tools will be needed to cut the metal plate (Dremel or similar).

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: HotEnd mount between the heater block and the heatsink January 11, 2016 10:47AM |

Registered: 10 years ago Posts: 293 |

|

Re: HotEnd mount between the heater block and the heatsink January 11, 2016 01:10PM |

Registered: 9 years ago Posts: 483 |

Just tap 6mm (or 4mm for Prometheus) threads in the plate. Thread the nozzle into the plate leaving 2mm to 3mm exposed for the heatbreak. Thread the heatsink onto the top of the nozzle until it hits the plate.

|

Re: HotEnd mount between the heater block and the heatsink January 11, 2016 02:35PM |

Registered: 9 years ago Posts: 1,035 |

Quote

etfrench

Just tap 6mm (or 4mm for Prometheus) threads in the plate. Thread the nozzle into the plate leaving 2mm to 3mm exposed for the heatbreak. Thread the heatsink onto the top of the nozzle until it hits the plate

I'd have to have a much longer SS heatbreak which I currently don't and haven't even seen much longer heatbreaks to shop for. The sketch in the first post shows my hotend with the exact dimensions and there is room between the ALU heater block and the heatsink of exact 2.46mm, which is about a normal hardware store steel plate thickness but it would bridge, like i have mentioned above, the two hotend components, which is bad.

If I'd have the option for an arbitrarily long SS heatbreak I wouldn't have posted the question in the first place. Where do you get a longer heatbreak?

Quote

WZ9V

Why not just elevate the grove mount using some posts like they do on the Rostock Max from SeeMeCNC?

Because of stability issues when something is clamped too far away from the working end. See my pen example above.

Edited 3 time(s). Last edit at 01/11/2016 03:32PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: HotEnd mount between the heater block and the heatsink January 11, 2016 06:45PM |

Registered: 9 years ago Posts: 483 |

I'm currently using a Prometheus hot end. It uses a 4mm nozzle/heatbreak. I previously used a clone E3d with 6mm threads. It also worked quite well, that is until it jammed. The drawing is of the E3d hot end, not the Prometheus. There is a recess in the center of the effector, so it's only about 3mm thick where the threads are located. You may have to trim some of the heatsink off in order to fit it properly (only on an E3d, the Prometheus threads are long enough).

Edited 1 time(s). Last edit at 01/11/2016 06:47PM by etfrench.

Edited 1 time(s). Last edit at 01/11/2016 06:47PM by etfrench.

|

Re: HotEnd mount between the heater block and the heatsink January 12, 2016 03:29AM |

Registered: 8 years ago Posts: 5,232 |

Quote

realthor

Quote

o_lampe

Design a clamping piece, that grips the heatsink on its lower fins.

This way you have no issues with too much heat rising into the plate.

-Olaf

I have that in sight too but drilling holes is much easier than cutting notches into metal plates. I have the following design:

[attachment 69475 EffectorPlate_HotEnd-Mount_Between_Fins.png]

This will make it not much different than the existing ALU upper-heatsink-mounts and more tools will be needed to cut the metal plate (Dremel or similar).

You could design a printed clamping part. It wouldn't add cooling capabilities, but you don't have to CNC/dremel a big hole.

|

Re: HotEnd mount between the heater block and the heatsink January 12, 2016 07:44AM |

Registered: 9 years ago Posts: 1,035 |

Quote

o_lampe

Quote

realthor

Quote

o_lampe

Design a clamping piece, that grips the heatsink on its lower fins.

This way you have no issues with too much heat rising into the plate.

-Olaf

I have that in sight too but drilling holes is much easier than cutting notches into metal plates. I have the following design:

[attachment 69475 EffectorPlate_HotEnd-Mount_Between_Fins.png]

This will make it not much different than the existing ALU upper-heatsink-mounts and more tools will be needed to cut the metal plate (Dremel or similar).

You could design a printed clamping part. It wouldn't add cooling capabilities, but you don't have to CNC/dremel a big hole.

I am afraid of the small amount of heat creeping up into the first fins of the heatsink. That might soften the plastic enough to allow a small amount of play that I want to avoid by not clamping it up in the usual way.

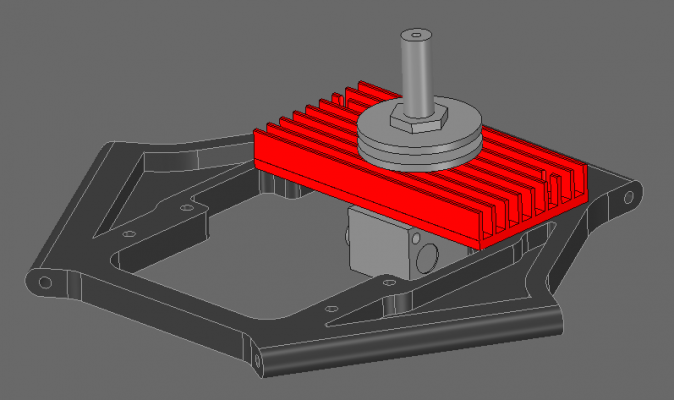

I have thought about this more than I should have and I actually considered using a rectangular heatsink/radiator instead of the normal round finned heatsink. I have found such radiators that are exactly the size I need (30x60mm)...and came up with this design:

With all the parts I would get around 7-10Eur from Aliexpress which is about the same with a complete hotend clone.

The radiator's aluminum meat is only 2 mm which I believe it's too little to tap for an M6 that's why I have added a clamping system made of thin M6 nuts (~3.5mm thick) both above and below the radiator and washers, at least one, atop of the fins side. I wish I could find such a radiator with a thicker meat or at least having the center portion fin-less and full metal, a small rectangle 10x10mm would have been great. Anyways, this design only needs drilling the holes in the radiator, which can be done from the smooth part down into the finned side. I wish I was lucky enough to have the effector plate's holes spaced such that they are in between ribs/fins on the radiator but I can only have one hole avoid the rib, the other must go through.

Another aspect that is important is that the ribbed construction has no flex , making it a very rigid and light component.

Is there any female push-in pneumatic fitting that can go straight over the SS barrel?

Edit: I have just found that there are such pushin fittings that can go straight over the SS barrel, they were just a bit harder to find. On Aliexpress search for "PCF 4-M6".

Edited 7 time(s). Last edit at 01/12/2016 02:11PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: HotEnd mount between the heater block and the heatsink January 12, 2016 09:18AM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

You could design a printed clamping part. It wouldn't add cooling capabilities, but you don't have to CNC/dremel a big hole.

That's what I have in mind. The temperature of the heatsink fins should not exceed 40C when printing PLA and maybe 60C when printing ABS, so a PETG or ABS printed part would be OK. The print would also accommodate the cooling fan. The only thing I haven't worked out yet is how to mount the IR sensor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: HotEnd mount between the heater block and the heatsink January 12, 2016 09:26AM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

Quote

o_lampe

You could design a printed clamping part. It wouldn't add cooling capabilities, but you don't have to CNC/dremel a big hole.

That's what I have in mind. The temperature of the heatsink fins should not exceed 40C when printing PLA and maybe 60C when printing ABS, so a PETG or ABS printed part would be OK. The print would also accommodate the cooling fan. The only thing I haven't worked out yet is how to mount the IR sensor.

Does PET-G or ABS remain perfectly rigid at these temperatures? If evena bit soft it could affect the hotend's vertical axis during the print.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: HotEnd mount between the heater block and the heatsink January 13, 2016 05:06AM |

Registered: 8 years ago Posts: 5,232 |

This design would have a too small contact area between M6 heatbarrier and the rectangular heatsink. This would make the melting zone very long.

IMHO the cold zone would start above the fins.

Furthermore, you don't use commonly available parts. E3d clones unfortunately are commonly available, so we have to make the best of it

|

Re: HotEnd mount between the heater block and the heatsink January 14, 2016 04:42PM |

Registered: 9 years ago Posts: 1,035 |

Quote

o_lampe

This design would have a too small contact area between M6 heatbarrier and the rectangular heatsink. This would make the melting zone very long.

IMHO the cold zone would start above the fins.

Furthermore, you don't use commonly available parts. E3d clones unfortunately are commonly available, so we have to make the best of it

Fair points. I was wary also that the contact of the SS barrel to the aluminum heatsink is not sufficient. I am trying to find alternatives that I can rep-strap to my specific effector plate but the alu heatsink was a too good match to dismiss from the start.

@dc42: do you have yet any design or it's just a thought?

Edited 1 time(s). Last edit at 01/14/2016 04:55PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.