Calibration problem

Posted by Neutrino

|

Calibration problem January 27, 2016 08:24AM |

Registered: 8 years ago Posts: 28 |

Hi All,

i spent weeks to find the source of the problem.

My printer is a Delta:

- HIWIN linear guides

- 0.9° Steppers, 64 microstepps on RAPPS128

- running repetier

- e3d hotend and RADDS electronics.

- Aluminium Heatspreader

This one was printed at 60mm/s and the "errors" are only very very small, but i belive there is a problem.

It was hard to take a picture cause you only see those "lines" in the right angle. It was printed with the throat for the 2040 to the top.

Does anyone have an idea ?

[drive.google.com]

Edited 1 time(s). Last edit at 01/27/2016 08:25AM by Neutrino.

i spent weeks to find the source of the problem.

My printer is a Delta:

- HIWIN linear guides

- 0.9° Steppers, 64 microstepps on RAPPS128

- running repetier

- e3d hotend and RADDS electronics.

- Aluminium Heatspreader

This one was printed at 60mm/s and the "errors" are only very very small, but i belive there is a problem.

It was hard to take a picture cause you only see those "lines" in the right angle. It was printed with the throat for the 2040 to the top.

Does anyone have an idea ?

[drive.google.com]

Edited 1 time(s). Last edit at 01/27/2016 08:25AM by Neutrino.

|

Re: Calibration problem January 27, 2016 05:37PM |

Registered: 10 years ago Posts: 14,672 |

Which firmware are you running on the Due/RADDS? Several possible causes come to mind:

1. Incorrect decay mode causing uneven microsteps around the point where the motor changes direction. I believe the RAPS128 has a second pot to adjust the decay mode.

2. The combination of 0.9deg motors and x64 microstepping demands very high step rates. You may be overloading the processor.

3. Segmentation banding. If the firmware you are running uses segmentation, work out whether the pattern has a repeat interval that corresponds to the print speed divided by the configured segments per second.

4. Some other firmware issue.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Incorrect decay mode causing uneven microsteps around the point where the motor changes direction. I believe the RAPS128 has a second pot to adjust the decay mode.

2. The combination of 0.9deg motors and x64 microstepping demands very high step rates. You may be overloading the processor.

3. Segmentation banding. If the firmware you are running uses segmentation, work out whether the pattern has a repeat interval that corresponds to the print speed divided by the configured segments per second.

4. Some other firmware issue.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Calibration problem January 28, 2016 06:59AM |

Registered: 8 years ago Posts: 28 |

Hi,

i am running repetier 0.92 latest firmware currently.

1. how do i check the decay on the raps ? how should they be set ?

2. he processor seems fine, even on a 16 microsteps it does those artifacts.

3. the segments do not follow a patter, printing a 20x20x20 cube resulted in different patterns not any repeated ones. i also went from 360 to 10 segments without any luck.

Thanks for your help.

i am running repetier 0.92 latest firmware currently.

1. how do i check the decay on the raps ? how should they be set ?

2. he processor seems fine, even on a 16 microsteps it does those artifacts.

3. the segments do not follow a patter, printing a 20x20x20 cube resulted in different patterns not any repeated ones. i also went from 360 to 10 segments without any luck.

Thanks for your help.

|

Re: Calibration problem January 28, 2016 07:28AM |

Registered: 8 years ago Posts: 71 |

I have very similar problem. Parts are looking nearly the same like yours.

I´m using a Duet 0.8.5 with davids latest firmware, 0.9° steppers.

Although I have a very accurate Built and quality linear rails, Layers sometimes "shifting" like yours. But next Layer going back to normal, so no missing steps I guess.

Is there a gcode where I can play with the decay mode on the duets firmware as well?

I recognized that lowering the amps for the steppers making things better, but still not 100%

I´m using a Duet 0.8.5 with davids latest firmware, 0.9° steppers.

Although I have a very accurate Built and quality linear rails, Layers sometimes "shifting" like yours. But next Layer going back to normal, so no missing steps I guess.

Is there a gcode where I can play with the decay mode on the duets firmware as well?

I recognized that lowering the amps for the steppers making things better, but still not 100%

|

Re: Calibration problem January 28, 2016 03:25PM |

Registered: 8 years ago Posts: 28 |

Hi Everyone, it seems i got the "patterns" fixed. the Jerk i increased a little and printed this with 150mm/s at 0.2mm layer height. Also it seems my belts where a little too tight, loosened them slightly

the only problem i see is on the side where Z lifts it gets a nasty corner. Did anyone expirienced that as well ?

[drive.google.com]

[drive.google.com]

Thanks for your help so far, runnin now on 360 segments, 64microsteps and jerk of 50 Acceleration of 1000.

Edited 1 time(s). Last edit at 01/28/2016 04:43PM by Neutrino.

the only problem i see is on the side where Z lifts it gets a nasty corner. Did anyone expirienced that as well ?

[drive.google.com]

[drive.google.com]

Thanks for your help so far, runnin now on 360 segments, 64microsteps and jerk of 50 Acceleration of 1000.

Edited 1 time(s). Last edit at 01/28/2016 04:43PM by Neutrino.

|

Re: Calibration problem January 28, 2016 05:03PM |

Registered: 8 years ago Posts: 28 |

|

Re: Calibration problem January 29, 2016 04:18PM |

Registered: 8 years ago Posts: 28 |

Hi All,

now after the "patterns" are fixed i expirience an issue at the corner where it Z lifts.

[drive.google.com]

Does anyone know where this comes from ?

last days this printer makes me angry ... it lessen's when i move slower, i wonder where that comes off

Edited 1 time(s). Last edit at 01/29/2016 04:25PM by Neutrino.

now after the "patterns" are fixed i expirience an issue at the corner where it Z lifts.

[drive.google.com]

Does anyone know where this comes from ?

last days this printer makes me angry ... it lessen's when i move slower, i wonder where that comes off

Edited 1 time(s). Last edit at 01/29/2016 04:25PM by Neutrino.

|

Re: Calibration problem January 30, 2016 06:31AM |

Registered: 10 years ago Posts: 732 |

One possibility is:

If your slicer generates filament retracts and un-retracts at the corner(*) than your problem is that your retract speed (or also acceleration) is too low for the length of the retract you use. You should try to retract in less than 0.1 s to minimize small blobs of plastic at the retract location.

(*) Some slicers generate retract also at layer change. Configure slicer so that it does not do it or replace the slicer.

Also if some other people get that strange layer banding problem discussed before then there is one more possible reason: Unstable temperature of hotend (bed) leads to change in change in hotend length (bed thickness) which leads to regular layer height at the same extrusion speed which leads to the bands on vertical walls.

If your slicer generates filament retracts and un-retracts at the corner(*) than your problem is that your retract speed (or also acceleration) is too low for the length of the retract you use. You should try to retract in less than 0.1 s to minimize small blobs of plastic at the retract location.

(*) Some slicers generate retract also at layer change. Configure slicer so that it does not do it or replace the slicer.

Also if some other people get that strange layer banding problem discussed before then there is one more possible reason: Unstable temperature of hotend (bed) leads to change in change in hotend length (bed thickness) which leads to regular layer height at the same extrusion speed which leads to the bands on vertical walls.

|

Re: Calibration problem January 30, 2016 09:07AM |

Registered: 8 years ago Posts: 28 |

Hi Hercek,

i completely switched of retracts to check whether it is a problem. Even after disabled retracts its there. Also when watching the printer it looks like a "move" at that corner. it shakes a little... but just that corner where the Zlift occurs.

i'm pretty much lost

Edit:

okay now reprinted the whole with infill and closed top/bottom at 150mm/s without any issue ...... totaly fine ... will post a picture in 5 min when its complete

Edited 1 time(s). Last edit at 01/30/2016 09:13AM by Neutrino.

i completely switched of retracts to check whether it is a problem. Even after disabled retracts its there. Also when watching the printer it looks like a "move" at that corner. it shakes a little... but just that corner where the Zlift occurs.

i'm pretty much lost

Edit:

okay now reprinted the whole with infill and closed top/bottom at 150mm/s without any issue ...... totaly fine ... will post a picture in 5 min when its complete

Edited 1 time(s). Last edit at 01/30/2016 09:13AM by Neutrino.

|

Re: Calibration problem January 30, 2016 02:48PM |

Registered: 10 years ago Posts: 732 |

I do not know then. Looks like a problem in slicer. It looks like slicer thinks there is an infill and generates those small "tails" pointing into infill to keep the outer surface clean. But when you do not have any infill, top, and bottom then those "tails" make things worse. If you want to print only the outer surface then select the spiralize option.

You can try to study the gcode of your bad print to know for sure.

You can try to study the gcode of your bad print to know for sure.

|

Re: Calibration problem January 31, 2016 05:14PM |

Registered: 10 years ago Posts: 580 |

One clue is how the problem is increasing with height, where a slight delay happens due to layer change, and also that it doesn't happen with an infilled shape. It's a very small object, I think it's just overheating there. You've got lots of options to test that - multiply the object, make a larger object of same wall thickness, etc. Best to test that first.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Calibration problem February 02, 2016 03:44PM |

Registered: 8 years ago Posts: 28 |

ok i retried it on a couple of things.... stuff looks good without patterns, but i get these "ugly's" every not and then

[drive.google.com]

[drive.google.com]

printed at 40mm/s Jerk 10 and the other with jerk 50 .... cant get rid of it.

Edited 1 time(s). Last edit at 02/02/2016 03:47PM by Neutrino.

[drive.google.com]

[drive.google.com]

printed at 40mm/s Jerk 10 and the other with jerk 50 .... cant get rid of it.

Edited 1 time(s). Last edit at 02/02/2016 03:47PM by Neutrino.

|

Re: Calibration problem February 02, 2016 04:55PM |

Registered: 10 years ago Posts: 580 |

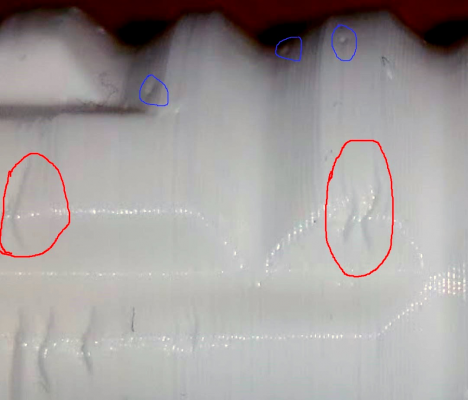

I blew up one of the photos and took a look, posted here so others can comment.

I see two kinds of artifacts:

- Circled in blue are little craters or skips, these appear all over.

- Circled in red look like short segments of over extrusion. These seem to occur more around corners.

Does this agree with what you are seeing first hand?

1) The craters could have at least a couple of causes

a) moisture in the filament could cause a steam bubble

b) perhaps a perimeter start point? Hard to tell without looking at the gcode.

2) The over extrusions (in red) - hmm, there are a lot of things that could cause that..

Anyone else have thoughts on those? I'll list a few that come to mind:

a) Large changes in extrusion rate from one area to another. For instance if infill is printed using a combination of high feedrate and wide extrusion, and then immediately the outside perimeter is printed at a lower feedrate and narrower width. The excess pressure has to go somewhere (a short dump of extra extrusion). A solution is to slow down the infill, and not use "External perimeters first".

b) Printed too hot, or need a fan (if PLA)?

c) Extruder not feeding evenly? Could be from driver settings or bad driver (missed and regained microsteps like the DRV8825 problem), partially clogged extruder gear (doubt it here)

d) ???

3) Are you using Slic3r? If so, you can turn on Verbose gcode in Output settings, and link the file here. I can run it through my gcode analyzer.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I see two kinds of artifacts:

- Circled in blue are little craters or skips, these appear all over.

- Circled in red look like short segments of over extrusion. These seem to occur more around corners.

Does this agree with what you are seeing first hand?

1) The craters could have at least a couple of causes

a) moisture in the filament could cause a steam bubble

b) perhaps a perimeter start point? Hard to tell without looking at the gcode.

2) The over extrusions (in red) - hmm, there are a lot of things that could cause that..

Anyone else have thoughts on those? I'll list a few that come to mind:

a) Large changes in extrusion rate from one area to another. For instance if infill is printed using a combination of high feedrate and wide extrusion, and then immediately the outside perimeter is printed at a lower feedrate and narrower width. The excess pressure has to go somewhere (a short dump of extra extrusion). A solution is to slow down the infill, and not use "External perimeters first".

b) Printed too hot, or need a fan (if PLA)?

c) Extruder not feeding evenly? Could be from driver settings or bad driver (missed and regained microsteps like the DRV8825 problem), partially clogged extruder gear (doubt it here)

d) ???

3) Are you using Slic3r? If so, you can turn on Verbose gcode in Output settings, and link the file here. I can run it through my gcode analyzer.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Calibration problem February 03, 2016 08:17AM |

Registered: 8 years ago Posts: 28 |

Hi you observed it completely correct. there are small craters and somehow "overextrusions " ?!

Its pla printed here at 205°C. One of your thoughts i will verify tonight, maybe its overheating. I have no print fan attached YET, will do that tonight as well as trying a smaller heaterblock. I use Cura to produce gcode. The extrucer is clean and using an airtripper V3 with a geared stepper

Its pla printed here at 205°C. One of your thoughts i will verify tonight, maybe its overheating. I have no print fan attached YET, will do that tonight as well as trying a smaller heaterblock. I use Cura to produce gcode. The extrucer is clean and using an airtripper V3 with a geared stepper

|

Re: Calibration problem February 03, 2016 03:01PM |

Registered: 10 years ago Posts: 732 |

Head speed changes are the common reason for over/under extrusion. Especially with bowden systems it is good to print everything at the same speed (infills as well as perimeters). I think a bowden printer should use only two speeds: one for all printing moves and another one for non-printing moves.

|

Re: Calibration problem February 03, 2016 03:12PM |

Registered: 10 years ago Posts: 14,672 |

As you are running RADDS electronics, you have the option of running RepRapFirmware on it as an alternative to Repetier. Trying it would tell you whether it is a firmware issue, or a slicer or hardware issue. If you do put RRF on it, then I suggest you set the microstepping to x16 initially and limit the travel speed to not more than 300mm/sec.

See [reprap.org] for how to configure RRF for your printer.

Edited 1 time(s). Last edit at 02/03/2016 03:14PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

See [reprap.org] for how to configure RRF for your printer.

Edited 1 time(s). Last edit at 02/03/2016 03:14PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.