My first build, all metal delta "The Imp"

Posted by GroupB

|

Re: My first build, all metal delta "The Imp" March 04, 2016 10:59AM |

Registered: 8 years ago Posts: 356 |

|

Re: My first build, all metal delta "The Imp" March 04, 2016 11:26AM |

Registered: 8 years ago Posts: 916 |

Have you tried going down to 16 microsteps?

Maybe "Bandwidth" is the wrong word, what I meant was that you might be hitting the upper frequency limit of the 'step' input in the 8825 driver board. Going down to 16 microsteps shouldn't lose you any quality, but will halve the max frequency of that pin.

There's also the 8825 decay hack, but I'm not sure that this applies in your case.

Edited 1 time(s). Last edit at 03/04/2016 11:32AM by nebbian.

Maybe "Bandwidth" is the wrong word, what I meant was that you might be hitting the upper frequency limit of the 'step' input in the 8825 driver board. Going down to 16 microsteps shouldn't lose you any quality, but will halve the max frequency of that pin.

There's also the 8825 decay hack, but I'm not sure that this applies in your case.

Edited 1 time(s). Last edit at 03/04/2016 11:32AM by nebbian.

|

Re: My first build, all metal delta "The Imp" March 04, 2016 11:31AM |

Registered: 8 years ago Posts: 356 |

|

Re: My first build, all metal delta "The Imp" March 04, 2016 11:33AM |

Registered: 8 years ago Posts: 916 |

Quote

GroupB

not yet , Its kinda hard to reach the step setting , I have to remove the shield... I also chose radds and dvr8825 to be at 1/32 not to end up 1/16.

Ill put a a4988 in to check, so I dont have to change the step setting under the board

Good luck, don't forget to halve your steps/mm!

|

Re: My first build, all metal delta "The Imp" March 04, 2016 11:41AM |

Registered: 8 years ago Posts: 356 |

Just test out a a4988 in the X socket and its working fine at 6000

there must be a problem firmware wise with 1/32 driver. Im pretty sure the Due can handle ONE 1/32 driver going 6000 mm/min, heck they sale 1/128 driver for the radds right now , "raps128"

edit: Repetier on RADDS with 84MHz ARM Cortex-M3 (no FPU): 96 kHz. I dont know the KHz of reprap firmware but with 16 pulley ( im using 20) with 1/32 on repetier can reach 480mm/sec or 28800mm/min

Edited 2 time(s). Last edit at 03/04/2016 11:47AM by GroupB.

there must be a problem firmware wise with 1/32 driver. Im pretty sure the Due can handle ONE 1/32 driver going 6000 mm/min, heck they sale 1/128 driver for the radds right now , "raps128"

edit: Repetier on RADDS with 84MHz ARM Cortex-M3 (no FPU): 96 kHz. I dont know the KHz of reprap firmware but with 16 pulley ( im using 20) with 1/32 on repetier can reach 480mm/sec or 28800mm/min

Edited 2 time(s). Last edit at 03/04/2016 11:47AM by GroupB.

|

Re: My first build, all metal delta "The Imp" March 04, 2016 04:00PM |

Registered: 10 years ago Posts: 14,672 |

So it sounds that the problem is probably related to the longer step pulse width and interval needed by the DRV8825 drivers, compared to the A4982 that I was writing for when I rewrote the Move code several versions ago. AFAIR the DRV8825 needs 1.8us, and the A4982 only needs 1.0us.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My first build, all metal delta "The Imp" March 04, 2016 06:15PM |

Registered: 8 years ago Posts: 356 |

Yah, look like it, Im waiting on dan modification to the firmware to test them, if it work maybe adding that to a Gcode config can be useful, to allow more configuration to use this firmware. Look like we are only a few to use RRF with radds so far, I saw a couple users of dvr8825 radds on repetier, I bet they will be happy to try RRF if its working for they hardware.

Ill wait till tonite to see if dan come up with a new firmware to test, if not Ill put in my spare A4988 and try to print a little. off course 1/16 on 1.8 motor look worst than 1/32 on 1.8 motor to me, and I have 1.8A motor and the a4988 take less Amperage than 8825. If its still problematic in the futur I may switch to 0.9 motor to get back the resolution. Or maybe try the rasp 128 and keep my motor( if they work nicely,Ill check before buying this time around if they compatible)

Ill wait till tonite to see if dan come up with a new firmware to test, if not Ill put in my spare A4988 and try to print a little. off course 1/16 on 1.8 motor look worst than 1/32 on 1.8 motor to me, and I have 1.8A motor and the a4988 take less Amperage than 8825. If its still problematic in the futur I may switch to 0.9 motor to get back the resolution. Or maybe try the rasp 128 and keep my motor( if they work nicely,Ill check before buying this time around if they compatible)

|

Re: My first build, all metal delta "The Imp" March 04, 2016 10:22PM |

Registered: 8 years ago Posts: 356 |

Did some print test again , with a4988, its fail ...

2 Problem :

1: filament still grinding whatever I tight or loose the spring ( airtripper v3) , it grind as soon as the extruder try to go a little bit faster, manual extract at 300mm/min work like a charm.

2: The printer print like a outside around the part and after 2-3 perimeter is just crash into the part and remove it from bed and start to move it around, I hear some scratch too, it look like it contact the bed ( the marking on the tape confirm it), maybe my calibration with a phone book paper while the hotend is heated not allow enough clearance ? should I use regular paper ?

2 Problem :

1: filament still grinding whatever I tight or loose the spring ( airtripper v3) , it grind as soon as the extruder try to go a little bit faster, manual extract at 300mm/min work like a charm.

2: The printer print like a outside around the part and after 2-3 perimeter is just crash into the part and remove it from bed and start to move it around, I hear some scratch too, it look like it contact the bed ( the marking on the tape confirm it), maybe my calibration with a phone book paper while the hotend is heated not allow enough clearance ? should I use regular paper ?

|

Re: My first build, all metal delta "The Imp" March 05, 2016 03:56AM |

Registered: 10 years ago Posts: 14,672 |

Have you performed delta calibration yet?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My first build, all metal delta "The Imp" March 05, 2016 01:13PM |

Registered: 8 years ago Posts: 356 |

Did 2 time while hotend was hot, the 7/10 point , but right now the grinding is my first concern I cant figure out to get ride of that, I try to almost lock the spring so tight they wont move at all , there still grinding, I try to lossen them , still happening, and I can push the filament with hand and its extrude but I have to put some kind of pressure, I guess pretty normal... I try to heat up the head a little more (220C).

Its always grinding a little but it work but when the mk8 try to get speed that where " the shit hit the fan" too much pressure in the head maybe.. I dont know

The filament I use is a white PLA/PHA colorfab ( figure a good brand will be less headache to start with)

Its always grinding a little but it work but when the mk8 try to get speed that where " the shit hit the fan" too much pressure in the head maybe.. I dont know

The filament I use is a white PLA/PHA colorfab ( figure a good brand will be less headache to start with)

|

Re: My first build, all metal delta "The Imp" March 05, 2016 01:27PM |

Registered: 8 years ago Posts: 356 |

|

Re: My first build, all metal delta "The Imp" March 05, 2016 02:31PM |

Registered: 8 years ago Posts: 356 |

I redid the calibration so this time Its -0.10 from my previous calibration. its still doing the same thing about 9 sec in , it start grinding and move the part on the bed. I dont know what to do honestly kinda loss.

I use DC42 calibration webpage and put a piece of paper ( printer paper) and get the head down till it hit the paper but I can still move it with some resistance, then enter the number I got from M114 into the webpage, did that for 10 point, then enter the new calibration into my config.g

I use DC42 calibration webpage and put a piece of paper ( printer paper) and get the head down till it hit the paper but I can still move it with some resistance, then enter the number I got from M114 into the webpage, did that for 10 point, then enter the new calibration into my config.g

|

Re: My first build, all metal delta "The Imp" March 05, 2016 03:04PM |

Registered: 10 years ago Posts: 14,672 |

If the extruder is reliable when extruding into free air but grinds filament sometimes during printing, then two things are wrong:

1. Your extruder motor current is too high. When the nozzle is obstructed, you want the extruder to skip steps instead of grinding the filament. That way, extrusion will restart when the obstruction is removed.

2. Either the nozzle is too close to the bed, or you are over extruding. Have you calibrated the extruder steps/mm?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Your extruder motor current is too high. When the nozzle is obstructed, you want the extruder to skip steps instead of grinding the filament. That way, extrusion will restart when the obstruction is removed.

2. Either the nozzle is too close to the bed, or you are over extruding. Have you calibrated the extruder steps/mm?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My first build, all metal delta "The Imp" March 05, 2016 03:20PM |

Registered: 8 years ago Posts: 356 |

yes I calibrated the extruder, take a 100mm mesurement, Ill reduce the current of the extruder driver a bit , but I really thing im printing too close , even after the recalibration. I print the outside just fine but then hit the part I guess

BTW I keep one of the drv8825 on the extruder for better resolution, change only the movement to 4988 while waiting for the firmware to have a fix for the dvr8825

In cura the amount of extruding is set a 100% default, should I try to lower this ?

Edited 4 time(s). Last edit at 03/05/2016 03:36PM by GroupB.

BTW I keep one of the drv8825 on the extruder for better resolution, change only the movement to 4988 while waiting for the firmware to have a fix for the dvr8825

In cura the amount of extruding is set a 100% default, should I try to lower this ?

Edited 4 time(s). Last edit at 03/05/2016 03:36PM by GroupB.

|

Re: My first build, all metal delta "The Imp" March 06, 2016 02:37AM |

Registered: 10 years ago Posts: 14,672 |

Yes, try a lower extrusion factor. In my experience, every roll of filament I print with needs a different extrusion factor for the best prints. You can adjust it on the fly using the M221 command.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My first build, all metal delta "The Imp" March 06, 2016 05:38PM |

Registered: 8 years ago Posts: 356 |

I just tried slic3r and no filament grinding at all, look like there something in cura that was forcing too much filament maybe, I looked at the extruder gear and under Slic3r it was giving way less filament

Now I cant get the print to stick while user slic3r , while cura for the 5 sec of printing before the filament grind was sticking ok.

Im gonna redo my calibration since I change back to dvr8825, thanks to Dan I got a hack for making the dvr8825 work past 5400 mm/min

Wish I had tried slic3r way before wasting a ton of filament

Now I cant get the print to stick while user slic3r , while cura for the 5 sec of printing before the filament grind was sticking ok.

Im gonna redo my calibration since I change back to dvr8825, thanks to Dan I got a hack for making the dvr8825 work past 5400 mm/min

Wish I had tried slic3r way before wasting a ton of filament

|

Re: My first build, all metal delta "The Imp" March 06, 2016 08:57PM |

Registered: 8 years ago Posts: 356 |

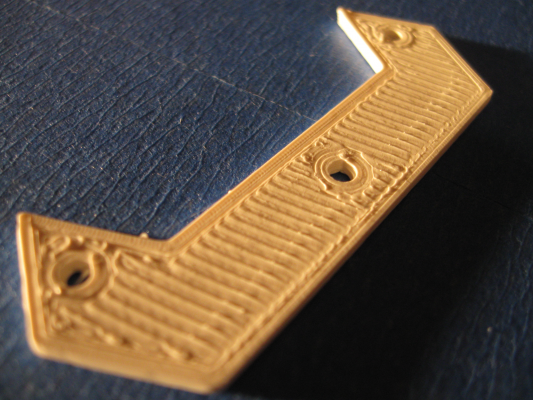

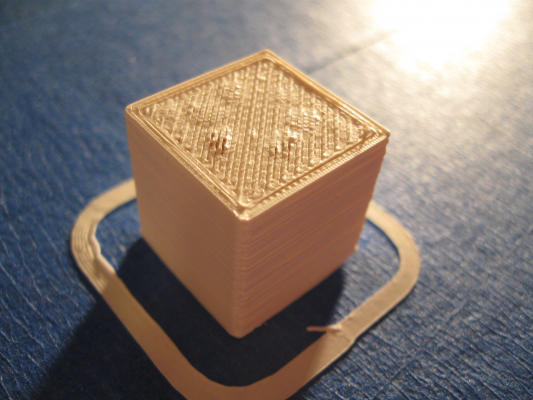

Manage to get my first print, using slicer and putting the Z correction to -0.2 and double up the tape on the bed to make it stick... I dont know why since I did the calibration multiple time with a piece of paper It should print with zero correction.

are there a similar z correction setting in Cura ? I would like to give it another try , But I dont feel like doing another calibration and spending HOURS and lot of plastic to get a setting that stick again

this is without a cooling fan, since im trying to print it the duct right now

Edited 1 time(s). Last edit at 03/06/2016 08:58PM by GroupB.

are there a similar z correction setting in Cura ? I would like to give it another try , But I dont feel like doing another calibration and spending HOURS and lot of plastic to get a setting that stick again

this is without a cooling fan, since im trying to print it the duct right now

Edited 1 time(s). Last edit at 03/06/2016 08:58PM by GroupB.

|

Re: My first build, all metal delta "The Imp" March 07, 2016 09:07AM |

Registered: 8 years ago Posts: 356 |

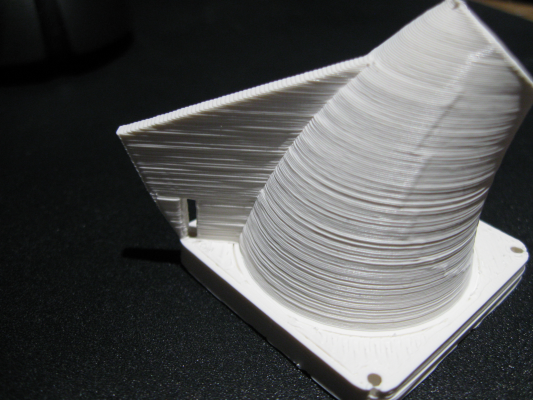

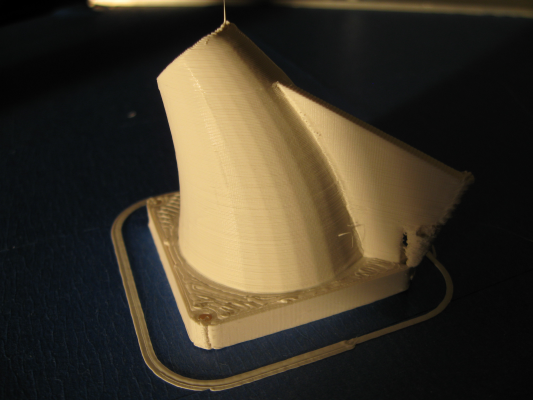

More print using slic3r, cura wont work at all, still grinding filament , but cura look like it dont need a z-0.2 to print and stick, no correction needed but try to inject too much pla and have too more pressure and grind

40mm/s ,0.2mm layer, perimeter overlap 15% ( leave a space between perimeter and infill)

60mm/s , 0.2mm layer , perimeter overlap 20% ( no space anymore)

Video of the 60mm/s printing:

[www.youtube.com]

Gonna print some cube to see if its accurate or not, Im now printing with dvr8825 1/32 micro, the 1/16 4988 were loud vs those

Edited 2 time(s). Last edit at 03/07/2016 09:10AM by GroupB.

40mm/s ,0.2mm layer, perimeter overlap 15% ( leave a space between perimeter and infill)

60mm/s , 0.2mm layer , perimeter overlap 20% ( no space anymore)

Video of the 60mm/s printing:

[www.youtube.com]

Gonna print some cube to see if its accurate or not, Im now printing with dvr8825 1/32 micro, the 1/16 4988 were loud vs those

Edited 2 time(s). Last edit at 03/07/2016 09:10AM by GroupB.

|

Re: My first build, all metal delta "The Imp" March 07, 2016 11:06AM |

Registered: 8 years ago Posts: 916 |

Hey good to see that you're making progress!

Regarding those prints, you're overextruding there. In the filament section of Slic3r, lower the extrusion multiplier from 1 down to something like 0.95. It's normal to tweak the multiplier when you've got new filament.

I take it you're printing a fan duct for your extruder? When you get it installed that will help with the curling issues you're having with the bottom piece.

I'm surprised that you're getting such inaccurate walls on your prints, knowing how fastidious you were with your build. About the only thing I can put it down to is extrusion issues, if you're occasionally grinding or skipping steps in your extruder then this might be the cause.

Edited 1 time(s). Last edit at 03/07/2016 11:08AM by nebbian.

Regarding those prints, you're overextruding there. In the filament section of Slic3r, lower the extrusion multiplier from 1 down to something like 0.95. It's normal to tweak the multiplier when you've got new filament.

I take it you're printing a fan duct for your extruder? When you get it installed that will help with the curling issues you're having with the bottom piece.

I'm surprised that you're getting such inaccurate walls on your prints, knowing how fastidious you were with your build. About the only thing I can put it down to is extrusion issues, if you're occasionally grinding or skipping steps in your extruder then this might be the cause.

Edited 1 time(s). Last edit at 03/07/2016 11:08AM by nebbian.

|

Re: My first build, all metal delta "The Imp" March 07, 2016 11:51AM |

Registered: 8 years ago Posts: 356 |

You talking about the bottom walls of the duct ? yah its not so straight at I dont know why and what can cause this but the one I print at 60mm/s look better and were print at 210C ( first one was 220C, colorfab recommand 190C), One thing I saw is the nozzle dont extrude the plastic straight it got a small little curve to the left/ Also I read somewhere that the White color colorfab is one of the hard one to get good print with.

I dont thing my extruder is skipping at least there no grinding at all on slic3r , I lower the current as DC42 recommend but that was for the cura problem, maybe I should ramp it up a little , im like.900A on 1.8A stepper on extruder and 1.33A on movement

I wish I can try cura and see if it do better but im tired of waste filament trying to figure it out

I dont thing my extruder is skipping at least there no grinding at all on slic3r , I lower the current as DC42 recommend but that was for the cura problem, maybe I should ramp it up a little , im like.900A on 1.8A stepper on extruder and 1.33A on movement

I wish I can try cura and see if it do better but im tired of waste filament trying to figure it out

|

Re: My first build, all metal delta "The Imp" March 07, 2016 12:08PM |

Registered: 13 years ago Posts: 268 |

As others have said, you are extruding too much plastic. There are several methods to fix it, either via adjusting the extrusion multiplier, extruder steps per mm, or the filament size in your slicer. There are a number of objects floating around which are like a series of steps. You set your infill to 95% and watch to see that the infill sections have tiny gaps, but top layers have none. You adjust steps per mm or extrusion factor while printing to get where you need to go, then modify your configs to suit after. Simply measuring that 100mm comes out when you tell the extruder to move 100mm will not be enough to get good results here.

As for wasting filament you are going to go through a good portion of your first roll just getting things dialed in. You will go through more of it if you don't fix problems early and insist on pushing forward before your stuff is set up right. Print some calibration objects till you get things right where you want them, then move on to functional parts.

As for wasting filament you are going to go through a good portion of your first roll just getting things dialed in. You will go through more of it if you don't fix problems early and insist on pushing forward before your stuff is set up right. Print some calibration objects till you get things right where you want them, then move on to functional parts.

|

Re: My first build, all metal delta "The Imp" March 07, 2016 12:48PM |

Registered: 8 years ago Posts: 356 |

|

Re: My first build, all metal delta "The Imp" March 07, 2016 01:10PM |

Registered: 13 years ago Posts: 268 |

|

Re: My first build, all metal delta "The Imp" March 08, 2016 04:13PM |

Registered: 8 years ago Posts: 356 |

I figure out how to print with cura, I add a M82 in the start code, so set the extruder in absolute, turn out its set to relative by default in the firmware sd image you start with in the git, slic3r work with relative and cura use absolute, that why my filament was ginding.

Im printing test piece and test diff temperature , turn out 190-195 is the sweet spot for that filament , exactly the " printing tip" temps they recommend when I get my filament

Now im looking around diff guide to calibrate the print, there so many

Im printing test piece and test diff temperature , turn out 190-195 is the sweet spot for that filament , exactly the " printing tip" temps they recommend when I get my filament

Now im looking around diff guide to calibrate the print, there so many

|

Re: My first build, all metal delta "The Imp" March 08, 2016 05:24PM |

Registered: 10 years ago Posts: 651 |

Quote

GroupB

Now im looking around diff guide to calibrate the print, there so many

http://reprap.org/wiki/Triffid_Hunter's_Calibration_Guide

Do the E Steps section, then the E Steps Fine Tuning

|

Re: My first build, all metal delta "The Imp" March 08, 2016 07:16PM |

Registered: 8 years ago Posts: 356 |

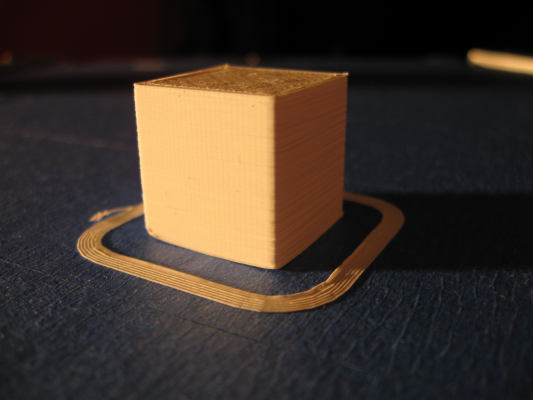

I print a 20X20X20 cube and got 20.15 X 20.15 and Z at 20.07 I still got those horrible walls, even if I print the last perimeter at 30mm/sec, the one in front of the printer between the X and Y tower are really the worst, Maybe I should try to calibrate again without using the 7 point that play with delta radius and arm length. I dont know whats to look to fix that walls thing.

Using Slic3r , 0.2 height , 25% infill ,60 mm/sec, infill 80mm/s, travel 180mm/s, 195C ,0.95 extruder multi , nozzle 0.4

Ill do the E step calibration then maybe try cura, and see if the walls are mess up too

I think my cooling fan start too late , you can see the 4 corner curl up a little, I set it to start at layer 3

Edited 1 time(s). Last edit at 03/08/2016 07:19PM by GroupB.

Using Slic3r , 0.2 height , 25% infill ,60 mm/sec, infill 80mm/s, travel 180mm/s, 195C ,0.95 extruder multi , nozzle 0.4

Ill do the E step calibration then maybe try cura, and see if the walls are mess up too

I think my cooling fan start too late , you can see the 4 corner curl up a little, I set it to start at layer 3

Edited 1 time(s). Last edit at 03/08/2016 07:19PM by GroupB.

|

Re: My first build, all metal delta "The Imp" March 08, 2016 11:27PM |

Registered: 8 years ago Posts: 916 |

Try turning off your heated bed after the first layer and see if that fixes your walls.

Some heated beds flex badly when they turn on and off, making the nozzle either closer or further away from the print. Worth a try.

Also 20mm is way too small to get an accurate feel for how close your dimensions are in the X and Y dimensions. Try a 100mm cube instead (only print the first 20 layers or so).

Edited 1 time(s). Last edit at 03/08/2016 11:28PM by nebbian.

Some heated beds flex badly when they turn on and off, making the nozzle either closer or further away from the print. Worth a try.

Also 20mm is way too small to get an accurate feel for how close your dimensions are in the X and Y dimensions. Try a 100mm cube instead (only print the first 20 layers or so).

Edited 1 time(s). Last edit at 03/08/2016 11:28PM by nebbian.

|

Re: My first build, all metal delta "The Imp" March 09, 2016 10:14AM |

Registered: 8 years ago Posts: 356 |

I have no heated bed, I read somewhere belts can cause shift in the layer , I will try to loose them a little , see if the walls thing still there or maybe tight them more.

Other thing that can cause that is backslash but I have none with the magnetic joint and the frame dont move and dont vibrate

Other thing that can cause that is backslash but I have none with the magnetic joint and the frame dont move and dont vibrate

|

Re: My first build, all metal delta "The Imp" March 10, 2016 08:35AM |

Registered: 8 years ago Posts: 356 |

I tried to fine tune the E step but the grinding problem start again... IF I try to go to fast ..E step 300, 50mm/s perimeter is the limit, I often hear a bit of grinding going 60+.. so If I reduce the step It grind the filament. Manual extruding at 50mm/sec cause grinding all the time even at 215C

There must be something wrong somewhere, I wont settle for a 30mm/sec print all the time, I build a delta for speed. I can extude by hand but its kinda hard.

Im gonna change to the e3d clone #2 and test again see if its better, if not, gonna try the clone Jhead, or change the nozzle on the e3d clone ( got a couple spare, maybe they have a shorter orifice length so less pressure)

I have to fix that extruder before trying to fix the walls problem, or It will always come back to bite me.

There must be something wrong somewhere, I wont settle for a 30mm/sec print all the time, I build a delta for speed. I can extude by hand but its kinda hard.

Im gonna change to the e3d clone #2 and test again see if its better, if not, gonna try the clone Jhead, or change the nozzle on the e3d clone ( got a couple spare, maybe they have a shorter orifice length so less pressure)

I have to fix that extruder before trying to fix the walls problem, or It will always come back to bite me.

|

Re: My first build, all metal delta "The Imp" March 10, 2016 02:11PM |

Registered: 8 years ago Posts: 356 |

Im rebuilding the second clone right now and I got a couple spare nozzle and im wondering should I use them or the original clone nozzle.. the spare one are the MK8 0.4mm from robotdigg ( claim to have the best nozzle in china), the ID is a little bigger 2.40mm vs the original one that came 2mm BUT the mk8 one have a far superior finish its polish smooth inside, the original is not so much , kinda rough ( I find a piece of metal inside too , drilling scrap), the mk8 is also a little bit shorter but whatever block I will be using with the ptfe will NOT be inside the block but right at the edge of the block if I chose the higher block and the mk8 nozzle.

Also the second clone had the heatbreak in the wrong way... The ptfe linner were on the bottom so in the heating block and the 2mm metal bore in the aluminum heatsink...

Also im wondering if I should use the original heater block, or a mk7 one I have, the original is smaller but is higher weight 6 gram, the mk7 bigger but lower height at 8gram. but the mk7 block dont have hole for the thermistor, but screw hole , those are clone of the makerbot I guess where they just tape a thermistor/coupler directly on the block, but I can always drill me a proper thermistor hole.

So guys what you think ?

Original nozzle or mk8 nozzle ?

Original or MK7 Block ?

Also the second clone had the heatbreak in the wrong way... The ptfe linner were on the bottom so in the heating block and the 2mm metal bore in the aluminum heatsink...

Also im wondering if I should use the original heater block, or a mk7 one I have, the original is smaller but is higher weight 6 gram, the mk7 bigger but lower height at 8gram. but the mk7 block dont have hole for the thermistor, but screw hole , those are clone of the makerbot I guess where they just tape a thermistor/coupler directly on the block, but I can always drill me a proper thermistor hole.

So guys what you think ?

Original nozzle or mk8 nozzle ?

Original or MK7 Block ?

Sorry, only registered users may post in this forum.