Hexagon Hotend with Kossel Mini Review

Posted by DRTak

|

Hexagon Hotend with Kossel Mini Review April 09, 2016 03:40PM |

Registered: 8 years ago Posts: 319 |

My original Sintron Kossel hotend aluminum heater block broke. So instead of replacing it I bought a new different hotend. I searched the net and looked for a unique one. ie Not E3D I opted for the Hexagon Hotend. Its all metal and has a unique heatsink. Its the heatsink and the connection of the heatbreak tube to the heatsink that is different. It connects to the aluminum heaterblock the same as the E3D does.

I removed the E3D sintron hotend clone. Replaced it completely with the new Hexagon hotend. The hexagon is shorter than the E3D so all of the files on thingiverse will not work on the Hexagon that were meant for E3D. There are a few fan shrouds on thingiverse for the Hexagon. No IR holder premade for the Kossel. The hotend heats up really fast. Way faster than the E3D. But I am very pleased with it.It is very accurate. I love the all metal aspect. Before, I would have the filament get jammed between the PEET/ PTFE inner tubing within the heatbreak of the E3D. This is not the case for the Hexagon.

The Hexagon is sold as a kit. The kit comes with a very powerful 25mm and 40mm fan. The 25mm fan throws out a lot of air for its small size. However, I cannot find a print that will hold the 40mm fan vertically in place without it touching the glass bed since the Hexagon is so short. The 40mm fan would have to be placed at a steep angle. I want a 40mm fan to be used as an object fan. However, I am opting to use a 30mm fan I have laying around. The 25mm fan I have attached with a file I found on thingiverse that was made for the 25mm Hexagon fan.

I cannot find much info on the thermistor from the kit. It is an EPCOS 100k. I used my IR thermometer to try and get close readings of the nozzle temp vs real temp. I think I am close to the real temp. However, again, I am not sure. For me to print in PLA I have to go up to 220 C and for PETG its 250 C. On the high end of the scale. I have not tried ABS since I no longer use ABS.

Cons: The Hexagon nozzle that was shipped to me was a 0.4mm. I measured it and it is 0.4mm. I couldnt remove the tip to examine it. It was really really bolted on tightly to the aluminum heatblock. So instead of breaking the aluminum heatblock off of my new hotened, I decided not to remove it. So my issue will be if I ever have to remove the nozzle to replace it, I will be in for some fun . For whatever reason, I have had to slow my prints down to accomadate the Hexagon. It might heat the filament faster but appears to have issues extruding it fast enough without the extruder skipping.

Pros: Shorter than the E3D you will gain some z height on your prints. Super fast heating of the nozzle to temp.

Here is my custom Hexagon 30mm fan attachement for use as an Object Fan. Ill improve it as I go: [www.thingiverse.com]

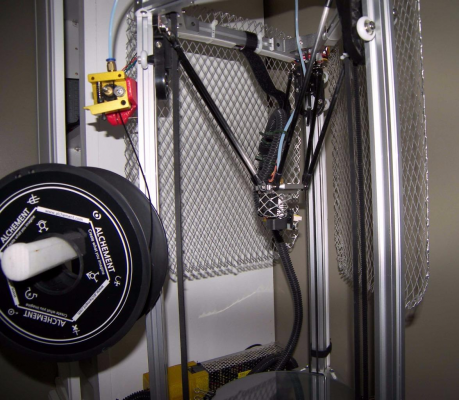

Metal Fan Shroud for Heatsink. I have upgraded to a PETG fan that attaches to the heatsink.

Edited 2 time(s). Last edit at 04/09/2016 05:33PM by DRTak.

I removed the E3D sintron hotend clone. Replaced it completely with the new Hexagon hotend. The hexagon is shorter than the E3D so all of the files on thingiverse will not work on the Hexagon that were meant for E3D. There are a few fan shrouds on thingiverse for the Hexagon. No IR holder premade for the Kossel. The hotend heats up really fast. Way faster than the E3D. But I am very pleased with it.It is very accurate. I love the all metal aspect. Before, I would have the filament get jammed between the PEET/ PTFE inner tubing within the heatbreak of the E3D. This is not the case for the Hexagon.

The Hexagon is sold as a kit. The kit comes with a very powerful 25mm and 40mm fan. The 25mm fan throws out a lot of air for its small size. However, I cannot find a print that will hold the 40mm fan vertically in place without it touching the glass bed since the Hexagon is so short. The 40mm fan would have to be placed at a steep angle. I want a 40mm fan to be used as an object fan. However, I am opting to use a 30mm fan I have laying around. The 25mm fan I have attached with a file I found on thingiverse that was made for the 25mm Hexagon fan.

I cannot find much info on the thermistor from the kit. It is an EPCOS 100k. I used my IR thermometer to try and get close readings of the nozzle temp vs real temp. I think I am close to the real temp. However, again, I am not sure. For me to print in PLA I have to go up to 220 C and for PETG its 250 C. On the high end of the scale. I have not tried ABS since I no longer use ABS.

Cons: The Hexagon nozzle that was shipped to me was a 0.4mm. I measured it and it is 0.4mm. I couldnt remove the tip to examine it. It was really really bolted on tightly to the aluminum heatblock. So instead of breaking the aluminum heatblock off of my new hotened, I decided not to remove it. So my issue will be if I ever have to remove the nozzle to replace it, I will be in for some fun . For whatever reason, I have had to slow my prints down to accomadate the Hexagon. It might heat the filament faster but appears to have issues extruding it fast enough without the extruder skipping.

Pros: Shorter than the E3D you will gain some z height on your prints. Super fast heating of the nozzle to temp.

Here is my custom Hexagon 30mm fan attachement for use as an Object Fan. Ill improve it as I go: [www.thingiverse.com]

Metal Fan Shroud for Heatsink. I have upgraded to a PETG fan that attaches to the heatsink.

Edited 2 time(s). Last edit at 04/09/2016 05:33PM by DRTak.

|

Re: Hexagon Hotend with Kossel Mini Review May 03, 2016 03:24PM |

Registered: 8 years ago Posts: 319 |

Update. I have been working with the Hexagon Hotend now for several weeks. I think its a great hotend with PLA. However, since its an all metal hotend with NO PTFE liner it has issues with thermal creep with PETG filament. Different brands of PETG have different temps. I am using LD PETG. They no longer make this product and I think I know why. The temp is 265. The high end of spectrum. At this temp, the Hexagon cant handle it without multiple fans on the heatsink. The heat creeps up the heatbreak and heatsink and starts to expand the incoming filament. It expands the filament so much that it clogs the nozzle in a sense. I am using 2 fans on the heatsink right now. I am going to do further testing. I hope this cures my clogging issues.

|

Re: Hexagon Hotend with Kossel Mini Review May 03, 2016 05:40PM |

Registered: 11 years ago Posts: 528 |

|

Re: Hexagon Hotend with Kossel Mini Review May 09, 2016 11:12AM |

Registered: 8 years ago Posts: 319 |

There is no shroud on the pic above. But you can find them on thingiverse. I found one on thingiverse for the hexagon fan. I am using it now. [www.thingiverse.com]

I have also made a shroud for the included 30mm fan. Fan shroud link

I have also made a shroud for the included 30mm fan. Fan shroud link

|

Re: Hexagon Hotend with Kossel Mini Review March 26, 2017 04:51PM |

Registered: 8 years ago Posts: 319 |

I have been testing this Hexagon Hotend with Nylon 230. The Nylon is listed at 200-230 C but I have not had luck at that temp. I have tried 240, 245, and 250 but I get rough prints. Tried 260, 265 and looks better. Most promising so far are prints at 270 and 275. Ive increased the print speed to 50mm/s and increased the retraction to 4mm. The key to Nylon230 appears to be retraction. If you have NO retraction it will clog the nozzle. Ill post an update to see if I have anymore success.

Edited 1 time(s). Last edit at 03/26/2017 04:54PM by DRTak.

Edited 1 time(s). Last edit at 03/26/2017 04:54PM by DRTak.

|

Re: Hexagon Hotend with Kossel Mini Review April 08, 2017 10:39PM |

Registered: 8 years ago Posts: 319 |

Well nylon appears to be similar to PETG. I think I might have thermal creep issues when printing super long prints. At about 2 hours into a print my printer jams. I had to take apart the hotend and noted that plastic was stuck in the hotend. Also, I think there might be some thermal expansion of the nylon filament as it enters into the heatsink preventing it from moving deeper into the heating element.

Awhile ago, my SD card became corrupted. I went back to a previous config.g file. Luckily I posted my config.g file from the past into the Mini Kossel thread in this forum. I noticed one difference.

M906 Command. The current I have now is 1000. I will increase it to 1200. It looks like this now:

M906 X1000 Y1000 Z1000 E1200 I60 ; Set motor currents (mA) and increase idle current to 60%

My config.g file is below for those that are interested or for my future reference.

; Configuration file for Mini Kossel kit from Think3DPrint3D

; Communication and general

M111 S0 ; Debug off

M550 PKosselMindy ; Machine name and Netbios name (can be anything you like)

M551 Preprap ; Machine password (used for FTP)

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address

;*** Adjust the IP address and gateway in the following 2 lines to suit your network

M552 P192.168.1.14 ; IP address (0 = use DHCP)

M554 P192.168.1.1 ; Gateway 71.8.194.37

M553 P255.255.255.0 ; Netmask

M555 P2 ; Set output to look like Marlin

M575 P1 B57600 S1 ;Comms parameters for Paneldue

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Axis and motor configuration

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forwards

M574 X2 Y2 Z2 S0 ; set endstop configuration (all endstops at high end, active high)

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration

M665 R108.99 L215.00 H237.63 B110.00 X-0.78 Y0.65 Z0.00 ;122.16 set delta radius, diagonal rod length, printable radius and homed height

M666 X0.21 Y0.27 Z-0.47 ; put your endstop adjustments here, or let auto calibration find them

M92 X80 Y80 Z80 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E1200 I60 ; Set motor currents (mA) and increase idle current to 60%

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min)

M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minute

M579 X1.001 Y1.03

; Thermistors

;*** If you have a Duet board stickered "4.7K", change R1000 to R4700 to the following M305 commands

M305 P0 T10000 B3950 R1000 H-10 L0 ; BED Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 T100000 B4036 R1000 H-10 L0 ; HOT END Put your own H and/or L values here to set the first nozzle thermistor ADC correction

;M305 P2 T100000 B3950 R1000 H10 L-30 ; Put your own H and/or L values here to set the second nozzle thermistor ADC correction

M570 S140 ; Hot end may be a little slow to heat up so allow it 180 seconds

; Tool definitions

M563 P0 D0 H1 ; Define tool 0

;M563 P1 H2 D1

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a dual-nozzle build, un-comment the next 2 lines

;M563 P1 D1 H2 ; Define tool 1

;G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M92 E100:100 ; Set extruder steps per mm

;Maximum Temperature control I added

M143 S295

;Heater Parameters I added

;M307 H0

; Z probe and compensation definition

;*** If you have an IR zprobe instead of a switch, change P4 to P1 in the following M558 command

M558 P1 X0 Y0 Z0 ; Z probe is a switch and is not used for homing any axes

G31 X0 Y0 Z1.29 P500 ; Set the zprobe height and threshold (put your own values here)

;*** If you are using axis compensation, put the figures in the following command

M556 S78 X0 Y0 Z0 ; Axis compensation here

M208 S1 Z-1.5 ; set minimum Z

;

T0 ; select first hot end

Edited 1 time(s). Last edit at 04/10/2017 02:36PM by DRTak.

Awhile ago, my SD card became corrupted. I went back to a previous config.g file. Luckily I posted my config.g file from the past into the Mini Kossel thread in this forum. I noticed one difference.

M906 Command. The current I have now is 1000. I will increase it to 1200. It looks like this now:

M906 X1000 Y1000 Z1000 E1200 I60 ; Set motor currents (mA) and increase idle current to 60%

My config.g file is below for those that are interested or for my future reference.

; Configuration file for Mini Kossel kit from Think3DPrint3D

; Communication and general

M111 S0 ; Debug off

M550 PKosselMindy ; Machine name and Netbios name (can be anything you like)

M551 Preprap ; Machine password (used for FTP)

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address

;*** Adjust the IP address and gateway in the following 2 lines to suit your network

M552 P192.168.1.14 ; IP address (0 = use DHCP)

M554 P192.168.1.1 ; Gateway 71.8.194.37

M553 P255.255.255.0 ; Netmask

M555 P2 ; Set output to look like Marlin

M575 P1 B57600 S1 ;Comms parameters for Paneldue

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Axis and motor configuration

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forwards

M574 X2 Y2 Z2 S0 ; set endstop configuration (all endstops at high end, active high)

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration

M665 R108.99 L215.00 H237.63 B110.00 X-0.78 Y0.65 Z0.00 ;122.16 set delta radius, diagonal rod length, printable radius and homed height

M666 X0.21 Y0.27 Z-0.47 ; put your endstop adjustments here, or let auto calibration find them

M92 X80 Y80 Z80 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E1200 I60 ; Set motor currents (mA) and increase idle current to 60%

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min)

M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minute

M579 X1.001 Y1.03

; Thermistors

;*** If you have a Duet board stickered "4.7K", change R1000 to R4700 to the following M305 commands

M305 P0 T10000 B3950 R1000 H-10 L0 ; BED Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 T100000 B4036 R1000 H-10 L0 ; HOT END Put your own H and/or L values here to set the first nozzle thermistor ADC correction

;M305 P2 T100000 B3950 R1000 H10 L-30 ; Put your own H and/or L values here to set the second nozzle thermistor ADC correction

M570 S140 ; Hot end may be a little slow to heat up so allow it 180 seconds

; Tool definitions

M563 P0 D0 H1 ; Define tool 0

;M563 P1 H2 D1

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a dual-nozzle build, un-comment the next 2 lines

;M563 P1 D1 H2 ; Define tool 1

;G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M92 E100:100 ; Set extruder steps per mm

;Maximum Temperature control I added

M143 S295

;Heater Parameters I added

;M307 H0

; Z probe and compensation definition

;*** If you have an IR zprobe instead of a switch, change P4 to P1 in the following M558 command

M558 P1 X0 Y0 Z0 ; Z probe is a switch and is not used for homing any axes

G31 X0 Y0 Z1.29 P500 ; Set the zprobe height and threshold (put your own values here)

;*** If you are using axis compensation, put the figures in the following command

M556 S78 X0 Y0 Z0 ; Axis compensation here

M208 S1 Z-1.5 ; set minimum Z

;

T0 ; select first hot end

Edited 1 time(s). Last edit at 04/10/2017 02:36PM by DRTak.

|

Re: Hexagon Hotend with Kossel Mini Review April 28, 2017 01:43PM |

Registered: 8 years ago Posts: 319 |

After updating my Duet 0.6 to Firmware 1.18 the temperature readings I think are accurate. So I am able to print Nylon 230 at the recommended 230 deg C. I have slowly increased the speed of the prints from 15 mm/s to 40 mm/s. This speed works fine for the small test cube 20 x 20mm. However, when I try the same setting for a larger print (over 5hrs long), the object looks horrible with underfilled areas from underextrusion. So I am going to try printing Nylon230 at 15 mm/s for a very large object.

So far here are my basic info for printing with Nylon230

Hexagon Hotend temp: 230 deg C

Heated bed Temp: 87 deg C

Heated bed has glass with PVA glue stick coating.

Edited 1 time(s). Last edit at 04/28/2017 01:45PM by DRTak.

So far here are my basic info for printing with Nylon230

Hexagon Hotend temp: 230 deg C

Heated bed Temp: 87 deg C

Heated bed has glass with PVA glue stick coating.

Edited 1 time(s). Last edit at 04/28/2017 01:45PM by DRTak.

|

Re: Hexagon Hotend with Kossel Mini Review May 31, 2017 06:23PM |

Registered: 8 years ago Posts: 319 |

Well my ethernet chip on my Duet 0.6 is not working. I bought and I am now running Duet Ethernet. My temps are off when using Nylon230. Currently the working temperature is 200-230 C. I have to narrow it down to a workable temp.

Edited 1 time(s). Last edit at 05/31/2017 06:35PM by DRTak.

Edited 1 time(s). Last edit at 05/31/2017 06:35PM by DRTak.

Sorry, only registered users may post in this forum.