Zonestar D810B from AliExpress

Posted by frankvdh

|

Re: Zonestar D810B from AliExpress August 06, 2016 02:43PM |

Registered: 7 years ago Posts: 21 |

|

Re: Zonestar D810B from AliExpress August 07, 2016 06:53AM |

Registered: 7 years ago Posts: 58 |

Ok, I'll send it to you, need to update the design a bit before.

In the meantime for the hardware (for 1 clamp) :

- 2 x M4*12mm socket screw

- 2 x M4 boat nut

- 1 x M3*40mm socket screw (mine are partially threaded)

- 1 x M3 washer

- 1 x M3 nut

- 2 x M3*10mm socket screw (optional, only needed on 1 clamp to horizontaly clamp the glass to the other clamps, glass plate are often not perfeclty round, radius may vary a little)

- 1 x extended spring (I'm using a 3/8"x3/4")

I'm using different kind of modeling softwares,sometimes I mix them. Here's my top 3 ordered by my motivation to design a complex design :

1- Solidworks ($$)

2- 123D (Free)

3- TinkerCAD (Free)

For the spring I bought a box of ton's of spring (compressed or not) for nothing on aliexpress, so I have almost any kind of spring

Edited 2 time(s). Last edit at 08/07/2016 06:59AM by Hergonoway.

In the meantime for the hardware (for 1 clamp) :

- 2 x M4*12mm socket screw

- 2 x M4 boat nut

- 1 x M3*40mm socket screw (mine are partially threaded)

- 1 x M3 washer

- 1 x M3 nut

- 2 x M3*10mm socket screw (optional, only needed on 1 clamp to horizontaly clamp the glass to the other clamps, glass plate are often not perfeclty round, radius may vary a little)

- 1 x extended spring (I'm using a 3/8"x3/4")

I'm using different kind of modeling softwares,sometimes I mix them. Here's my top 3 ordered by my motivation to design a complex design :

1- Solidworks ($$)

2- 123D (Free)

3- TinkerCAD (Free)

For the spring I bought a box of ton's of spring (compressed or not) for nothing on aliexpress, so I have almost any kind of spring

Edited 2 time(s). Last edit at 08/07/2016 06:59AM by Hergonoway.

|

Re: Zonestar D810B from AliExpress August 07, 2016 06:47PM |

Registered: 9 years ago Posts: 978 |

Just published on Thingiverse my redesign of the triangles which support the spool.

These fit into the existing slots on the printer and disc, use the the same screw attachments, and increase the angle of the spool to 60 degrees to reduce friction.

These fit into the existing slots on the printer and disc, use the the same screw attachments, and increase the angle of the spool to 60 degrees to reduce friction.

|

Re: Zonestar D810B from AliExpress August 16, 2016 07:14PM |

Registered: 9 years ago Posts: 978 |

Oops... my redesign of the spool holder isn't quite right. The problem is that the bottom of the spool no longer lines up well with the extruder. The effect of this is that the filament is being pulled across the spool, which in turn means that a loop of the outgoing piece of filament may be pulled underneath another coil... if/when that coil is tightened as the filament feeds, it will jam.  This has happened a couple of times to me already. So I'm no longer using this spool holder (back to having the spool on a holder hanging from the ceiling), and suggest that others don't use it either.

This has happened a couple of times to me already. So I'm no longer using this spool holder (back to having the spool on a holder hanging from the ceiling), and suggest that others don't use it either.

I'm now thinking about a redesign.

The best solution would be to turn and move the extruder, or to move the mounting holes for the triangles, so that the feed into the extruder lines up with the spool again. But I'm loathe to do either of those things experimentally, since it would involve cutting into the acrylic top of the printer. But maybe Hally might think about redesigning the top for the next version.

Another plan I have was to replace the fixed extruder by a flying extruder, but I don't feel quite ready for that. Yet another, even longer term, plan is to replace the D810 extruder and hot-end with a Diamond... again, I'm not quite ready for that experiment.

So right now I'm thinking about changing the shape of the "triangles" to move the location of the disc back to being in-line with the extruder. Or maybe some kind of filament guide that would take the filament off the spool cleanly and lead it to the extruder. Maybe it might involve some PTFE tube.

This has happened a couple of times to me already. So I'm no longer using this spool holder (back to having the spool on a holder hanging from the ceiling), and suggest that others don't use it either.

This has happened a couple of times to me already. So I'm no longer using this spool holder (back to having the spool on a holder hanging from the ceiling), and suggest that others don't use it either.I'm now thinking about a redesign.

The best solution would be to turn and move the extruder, or to move the mounting holes for the triangles, so that the feed into the extruder lines up with the spool again. But I'm loathe to do either of those things experimentally, since it would involve cutting into the acrylic top of the printer. But maybe Hally might think about redesigning the top for the next version.

Another plan I have was to replace the fixed extruder by a flying extruder, but I don't feel quite ready for that. Yet another, even longer term, plan is to replace the D810 extruder and hot-end with a Diamond... again, I'm not quite ready for that experiment.

So right now I'm thinking about changing the shape of the "triangles" to move the location of the disc back to being in-line with the extruder. Or maybe some kind of filament guide that would take the filament off the spool cleanly and lead it to the extruder. Maybe it might involve some PTFE tube.

|

Re: Zonestar D810B from AliExpress August 17, 2016 01:25PM |

Registered: 7 years ago Posts: 21 |

|

Re: Zonestar D810B from AliExpress August 18, 2016 05:29PM |

Registered: 9 years ago Posts: 978 |

I'm happy it works for you. The problem seemed to start happening to me when I put a fairly new spool on the printer. I haven't actually compared the two spools, but maybe it was because the new spool was wider or narrower, or had a smaller or larger hole. In any case, I have redesigned the triangles, and I'll print the new ones over the weekend.

In other news...

I've fitted three lights to the bottoms of the top frame of the printer. These light strips come with adhesive backing, and are the right length to fit neatly into place. I've wired them to run off the 10A 12V supply for the heated bed.

I've also added a 4-relay module to my Raspberry Pi 3 (running Octopi). I'm using 2 of the relays at the moment... one to turn on/off the lights, and one to turn on/off the heated bed. The third will control the 12V power to the printer itself. The fourth relay is spare. The reason for this (and the lights) is that the printer lives out in my garage. I watch it via the RPi's camera. In any kind of emergency, I'll be able to turn it off remotely. Also, I'll be able to turn off the heated bed (hopefully automatically) when the print finishes. I want to turn the lights on/off remotely so I can look at the printer without leaving the main garage lights on. Actually, whilst the lights + camera work OK, the colour that the camera shows is very blue. Maybe "warm white" LEDs would give a better colour? To make the relay board and RPi3 work together, I had to change the RPi 5V power supply... 1.6A wasn't quite enough, and the Pi would reboot each time it turned a relay on .

.

In other news...

I've fitted three lights to the bottoms of the top frame of the printer. These light strips come with adhesive backing, and are the right length to fit neatly into place. I've wired them to run off the 10A 12V supply for the heated bed.

I've also added a 4-relay module to my Raspberry Pi 3 (running Octopi). I'm using 2 of the relays at the moment... one to turn on/off the lights, and one to turn on/off the heated bed. The third will control the 12V power to the printer itself. The fourth relay is spare. The reason for this (and the lights) is that the printer lives out in my garage. I watch it via the RPi's camera. In any kind of emergency, I'll be able to turn it off remotely. Also, I'll be able to turn off the heated bed (hopefully automatically) when the print finishes. I want to turn the lights on/off remotely so I can look at the printer without leaving the main garage lights on. Actually, whilst the lights + camera work OK, the colour that the camera shows is very blue. Maybe "warm white" LEDs would give a better colour? To make the relay board and RPi3 work together, I had to change the RPi 5V power supply... 1.6A wasn't quite enough, and the Pi would reboot each time it turned a relay on

.

.

|

Re: Zonestar D810B from AliExpress August 21, 2016 09:47AM |

Registered: 7 years ago Posts: 58 |

Quote

frankvdh

I'm happy it works for you. The problem seemed to start happening to me when I put a fairly new spool on the printer. I haven't actually compared the two spools, but maybe it was because the new spool was wider or narrower, or had a smaller or larger hole. In any case, I have redesigned the triangles, and I'll print the new ones over the weekend.

In other news...

I've fitted three lights to the bottoms of the top frame of the printer. These light strips come with adhesive backing, and are the right length to fit neatly into place. I've wired them to run off the 10A 12V supply for the heated bed.

I've also added a 4-relay module to my Raspberry Pi 3 (running Octopi). I'm using 2 of the relays at the moment... one to turn on/off the lights, and one to turn on/off the heated bed. The third will control the 12V power to the printer itself. The fourth relay is spare. The reason for this (and the lights) is that the printer lives out in my garage. I watch it via the RPi's camera. In any kind of emergency, I'll be able to turn it off remotely. Also, I'll be able to turn off the heated bed (hopefully automatically) when the print finishes. I want to turn the lights on/off remotely so I can look at the printer without leaving the main garage lights on. Actually, whilst the lights + camera work OK, the colour that the camera shows is very blue. Maybe "warm white" LEDs would give a better colour? To make the relay board and RPi3 work together, I had to change the RPi 5V power supply... 1.6A wasn't quite enough, and the Pi would reboot each time it turned a relay on.

+1 for the light a very good idea ! I tried octopie but I stopped when I saw that I'll have to import a cura profile :/ (#lazy I love repetier)

I've multiple issues with the extruder, already made a full bearing vertical spool holder, but the extruder basically doesn't have enough torque. Sometimes the extruder skip to push the filament so you have to inscrease the tension of the extruder spring which lead to bigger grooves on the filament.

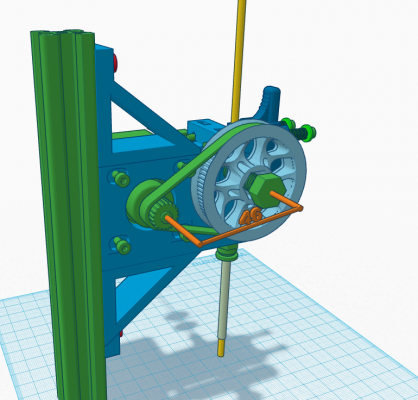

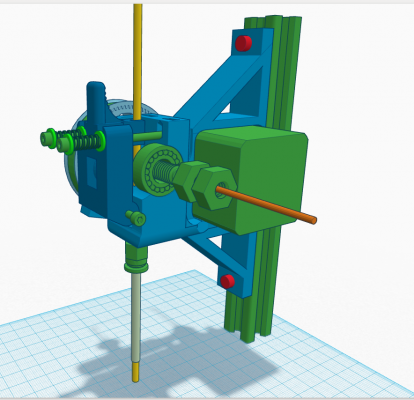

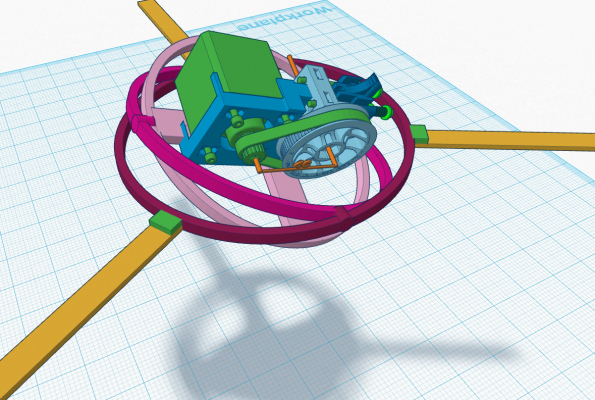

I'm currently designing a new extruder with a ratio of 4:1 which basicaly will give 4 times more torque, it will be mounted to the side of the printer so I'll be able to put the spool next to the printer and change the PTFE tube from an S shape to a shorter U shape which I assume will reduce friction.

Not finished yet but if people are interested I'll post pictures of it printed and share the STL file. Currently the cost of the hardware needed in under 15$. most of "greg wade based design are with gears, but I think it'll generate noise, so I design it to handle GT2 close belt of 200mm

current progress (green = hardware or existing stuff, blue = printed parts, yellow/orange = axes for work or filament simulation) :

Edited 1 time(s). Last edit at 08/21/2016 09:51AM by Hergonoway.

|

Re: Zonestar D810B from AliExpress August 21, 2016 01:28PM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress August 22, 2016 01:49AM |

Registered: 9 years ago Posts: 978 |

|

Re: Zonestar D810B from AliExpress August 22, 2016 03:48AM |

Registered: 7 years ago Posts: 58 |

Quote

frankvdh

Nice looking design. But if I'm going to change extruders, I'll have a flying extruder above the effector.

Yeah that's cool stuff too, Didn't try it yet.

I think I need more feedback from people using it, especially due to the pendulum law and rubber band during time.

If you jump into that please make a feedback.

EDIT : I've red few articles and post about Flying Extruder. I think this kind of concept need to be tested

, I'll give a try

, I'll give a tryEdited 2 time(s). Last edit at 08/22/2016 10:36AM by Hergonoway.

|

Re: Zonestar D810B from AliExpress August 23, 2016 06:04PM |

Registered: 9 years ago Posts: 978 |

A quick question for people.... What's the largest size object you've successfully printed?

The reason I ask is that I'm struggling to print my redesigned spool-holder triangles. The problem is quite consistent and repeatable... when I print more than about 70mm from the centre of the bed, a motor skips. It appears that beyond about 70mm, there's too much force needed to move the head. Sometimes a belt tensioner breaks, and I think this was what caused my carriage lugs to break too. (I'm not making my belt tensioners any stronger, since they're easier to replace than a broken carriage.). Whether a motor skips (and which motor skips) depends on the motion of the head. Given Delta geometry, this means that subsequently, actual print height may be above or below the previous print height for the same layer). And of course this wreaks havoc on print quality.

Looking back through this thread [forums.reprap.org], I see @tidehunter apparently printing quite a bit further out than 70mm. How is that working for you?

The reason I ask is that I'm struggling to print my redesigned spool-holder triangles. The problem is quite consistent and repeatable... when I print more than about 70mm from the centre of the bed, a motor skips. It appears that beyond about 70mm, there's too much force needed to move the head. Sometimes a belt tensioner breaks, and I think this was what caused my carriage lugs to break too. (I'm not making my belt tensioners any stronger, since they're easier to replace than a broken carriage.). Whether a motor skips (and which motor skips) depends on the motion of the head. Given Delta geometry, this means that subsequently, actual print height may be above or below the previous print height for the same layer). And of course this wreaks havoc on print quality.

Looking back through this thread [forums.reprap.org], I see @tidehunter apparently printing quite a bit further out than 70mm. How is that working for you?

|

Re: Zonestar D810B from AliExpress August 23, 2016 08:12PM |

Registered: 7 years ago Posts: 58 |

Quote

frankvdh

A quick question for people.... What's the largest size object you've successfully printed?

The reason I ask is that I'm struggling to print my redesigned spool-holder triangles. The problem is quite consistent and repeatable... when I print more than about 70mm from the centre of the bed, a motor skips. It appears that beyond about 70mm, there's too much force needed to move the head. Sometimes a belt tensioner breaks, and I think this was what caused my carriage lugs to break too. (I'm not making my belt tensioners any stronger, since they're easier to replace than a broken carriage.). Whether a motor skips (and which motor skips) depends on the motion of the head. Given Delta geometry, this means that subsequently, actual print height may be above or below the previous print height for the same layer). And of course this wreaks havoc on print quality.

Looking back through this thread [forums.reprap.org], I see @tidehunter apparently printing quite a bit further out than 70mm. How is that working for you?

I've printed yesterday the main piece for my extruder prototype which is 154mm / 90 mm, I assume I would be in your case at 77mm from the center + a skirt distance at 15mm which mean I've print around 90~95 from the center. I remember that not so long ago I had a similar problem, it wasn't during a print but during auto-calibration when the "grid" came too close from the edge, especially area between vertical 2020, the sound was different, and motor skipped.

In my case the problem had multiple causes, took time to find a way to correct them all

, and I cannot say which cause had the bigger impact on this problem :

, and I cannot say which cause had the bigger impact on this problem : 1 - ball joint were blocked in there movement by the printed carriage when the nozzle reaches an edge which stress 1 or 2 motor because then can't move the way they should

-----> I've had 3mmID/4mmOD spacer of 2mm long between balljoint and mount point on the carriage and the effector, afterwards I've redesigned a new carriage and effector with narrow "cone" a mount point for the balljoints.

2 - I had a curvature effect (nozzle doesn't move perfectly horizontally, it moves like it was on a dome or inside a bowl. If the thickness of your first layer is not uniform in thickness (at the border or center the printed filament lose grip or change from flat and large to thick and narrow) you have a curvature effect. Combine with auto level, especially when you applies a correction matrix, the printer tried to do a non-natural movement, from the software point of view it's logical since the nozzle move on a perfect horizontal plate, but in reality it's not the case, which lead to high stress on the rods, so the carriage, so the belt, so the motor

-----> I've disabled autocorrection, put a borocilate glass plate on the bed, adjust manually the horizontal level of the bed, and corrected the curvature effect half millimeter per half millimeter and then disable auto calibration, (By the way I didn't touch the level of the bed ever since )

3 - Acceleration and jerk are too high by default. When you print close to the edge 1 or 2 arms are almost at 70-80°angle of the vector movement of their carriage which means it needs to move very quickly and very precisely compare to the other arms --> very stressfull.

-----> I've reduces the acceleration from 5000 to 2000-3000 and set the jerk from 20 to 10-15.

-3 bis- the printable area of a delta printer is not a disc shape, it's a Reuleaux triangle shape, which amplifies the effect I explain in point #3 when the printer reach an edge between 2 2020 vertical.

4 - "vertical offset of the carriages". Vertical endstops activates not precisely at the same height from each other. It results of an effector not totally parallel with the bed, so the nozzle is not perfectly perpendicular with the bed. The closer the nozzle is to the edge, the bigger this bad angle is, which false the real result of the autocalibration, create a false curvature effect, well .... TOP priority.

-----> Repetier explain how to correct it with M99 command on their auto calibration HOW TO page.

Hope it'll help

|

Re: Zonestar D810B from AliExpress August 23, 2016 09:50PM |

Registered: 9 years ago Posts: 978 |

Thank you very much!

Some good ideas for me to work on.

Some good news: I have (I think -- I very nearly got them right on the first attempt ) finished the design of some mounts to attach the LCD to the 2020 top frame. They're very straightforward and connect to the same mounting points as the existing acrylic legs... you use a couple of M3 screws and boat-nuts to attach them.

) finished the design of some mounts to attach the LCD to the 2020 top frame. They're very straightforward and connect to the same mounting points as the existing acrylic legs... you use a couple of M3 screws and boat-nuts to attach them.

Some good ideas for me to work on.

- Obviously Zonestar have never actually tried to print 180mm across, otherwise they would have run into this issue.

I'll look into this tonight.

I'll look into this tonight. - I have curvature issues too. For the time being, I've just added layers of tape to the bed so that it is curved to approximately the same shape as the nozzle path. (This works reasonably well, but does make the bottom surface of prints quite ugly. Fixing it properly is still on my to-do list... I'm also planning a borosilicate sheet. How did you "correct the curvature effect half millimeter per half millimeter"? Have you seen this page? I intend to use that as a starting point... hopefully it will be good enough to solve everything.

- Will look at reducing those... thanks.

3b. I knew that, but keep forgetting.

- Yes, I've noticed that too. And that an end-stop will trigger at slightly different positions. I'm thinking about removing the metal blades from the end-stops so that each carriage presses the button directly. Also thinking about making the end-stops adjustable so that they can be levelled. Incidentally, don't have any loose belt sticking out above the carriage, as that can trigger the end-stop.

Some good news: I have (I think -- I very nearly got them right on the first attempt

) finished the design of some mounts to attach the LCD to the 2020 top frame. They're very straightforward and connect to the same mounting points as the existing acrylic legs... you use a couple of M3 screws and boat-nuts to attach them.

) finished the design of some mounts to attach the LCD to the 2020 top frame. They're very straightforward and connect to the same mounting points as the existing acrylic legs... you use a couple of M3 screws and boat-nuts to attach them.

|

Re: Zonestar D810B from AliExpress August 24, 2016 07:24AM |

Registered: 7 years ago Posts: 58 |

Quote

frankvdh

Thank you very much!

Some good ideas for me to work on.

- Obviously Zonestar have never actually tried to print 180mm across, otherwise they would have run into this issue.

I'll look into this tonight.

- I have curvature issues too. For the time being, I've just added layers of tape to the bed so that it is curved to approximately the same shape as the nozzle path. (This works reasonably well, but does make the bottom surface of prints quite ugly. Fixing it properly is still on my to-do list... I'm also planning a borosilicate sheet. How did you "correct the curvature effect half millimeter per half millimeter"? Have you seen this page? I intend to use that as a starting point... hopefully it will be good enough to solve everything.

- Will look at reducing those... thanks.

3b. I knew that, but keep forgetting.

- Yes, I've noticed that too. And that an end-stop will trigger at slightly different positions. I'm thinking about removing the metal blades from the end-stops so that each carriage presses the button directly. Also thinking about making the end-stops adjustable so that they can be levelled. Incidentally, don't have any loose belt sticking out above the carriage, as that can trigger the end-stop.

Some good news: I have (I think -- I very nearly got them right on the first attempt) finished the design of some mounts to attach the LCD to the 2020 top frame. They're very straightforward and connect to the same mounting points as the existing acrylic legs... you use a couple of M3 screws and boat-nuts to attach them.

1- Yes move manually the hotend to a border, 5mm per 5mm and look at the balljoint

2- I tried Escher. Very good tool, but with a big flaw, it's almost a paradox. Escher can correct endstop and curvature effect with precision BUT it assume that your bed is perfectly flat and your measurements are precise. Which is not the case with the D810 current bed and standard D810 proximity sensor, so the result will be inconsistent. What I can sugest you is my method, a bit longer, but after you won't have to touch anything.

-- A : install a borocillate glass

-- B : define 4 scripts (but you can send G0/1 manually if you prefer) to go to middle and 3 calibration positions : X0 Y0 Z10, and 3 point close to the edge at the opposite of each tower at a height of Z10 (I'm at work, I can give you these scripts with the coordinate I use when I'm back home)

-- C : reset every correction from G29, G32 or other autoleveling correction, I think it's M322 command but not sure.

-- D : make sure Tower offset are set correctly (look at point #4)

-- E : at this point go to each calibration point (in cycle), drop down the nozzle from Z10 to Z0 and level manually the bed (piece of paper or dirrectly look at the nozzle, with borocillate glasse it's easy to see if it touches or not). Do it multiple times until Z0 at each calibration point is perfectly the same.

-- F : go to middle and and do a Z calibration (Z=0)

-- Checkpoint : at this point from the point of view of the printer, the bed is perfectly flat, so you don't need to do the following steps on each calibration point.

-- G : go to a calibration point (at Z10 !!!!! not Z0 then Z10, directly Z10) carefullly lower the nozzle until it touches the bed. If the nozzle touch the bed before reaching Z0 then your curvature is a dome shape, so you'll have to increase the Printer RADIUS. Do it in eeprom (through Repetier) so you don't have to correct and re-upload the firmware each time ... increase it 1mm per 1mm until you have to opposite effect --> when you're at Z0 the nozzle doesn't touch the bed. Here, you have the 1mm frame you have to adjust, do the same process in this millimeter but with a correction of 0,2mm, then you can do at 0,1mm is you want

. Just remember : if the nozzle touch the bed before Z0 on a calibration point your on a dome shape, so increase printer radius, if the nozzle doesn't touch the bed on a calibration point at Z0 then you're on a bowl shape so decrease printer radius.

. Just remember : if the nozzle touch the bed before Z0 on a calibration point your on a dome shape, so increase printer radius, if the nozzle doesn't touch the bed on a calibration point at Z0 then you're on a bowl shape so decrease printer radius.-- E : check if Z0 is still Z0 in the middle (if not redo #F to #G process).

-- F : copy the printer radius value from your EEPROM in your configuration.h and flash the board with your correct printer radius. (don't forget to copy tower offset too, if not you have to redo #4)

Try to print a large objet with a skirt @ 50% speed and adjust manually the bed for final correction. --> this thing is perfect for that [www.thingiverse.com]

3- It slightly rise the printing time but it definitly corrects other painfull artifacts on printed stuff such as "echo" on printed walls, it also give higher quality print. But beware, too low value will result on possible blob and zits.

4- I tried what you say, I've removed the metal blade and made a new support for the endstop to make them adjustable with a screw. I even tried to add an adjustable screw on the carriage. It's very difficult to calibrate that way. But in the end adjusting “Tower X/Y/Z endstop offset [steps]” is definitly the best and easiest method to use. The idea it to place carriages at the same height (with a metal rod) and then let the printer calculte the offset in step after a homing, which is basically the error between endstop. Go there --> And search for the chapter called "Delta Printer" where you can find M99 command. I assure you it worth it.

Edited 2 time(s). Last edit at 08/24/2016 08:00AM by Hergonoway.

|

Re: Zonestar D810B from AliExpress August 24, 2016 08:12AM |

Registered: 7 years ago Posts: 58 |

An important thing : if your frame is rigid, belt are tensed, and a borosilicate bed well clamped to the frame, you don't need auto leveling before each print. It's been a month and half since my last manual calibration, and I print every day. Even if you change the nozzle because it's a matter of z calibration not bed leveling.

|

Re: Zonestar D810B from AliExpress August 25, 2016 05:08AM |

Registered: 9 years ago Posts: 978 |

Not having any spacers, as a workaround I've put an M3 nut between each arm and the carriage. That's made a huge difference... many thanks for that advice. There's still some issues left, which I think is partly due to the rod-ends also interfering with the effector. I'll put some nuts on there tomorrow.

|

Re: Zonestar D810B from AliExpress August 25, 2016 06:02AM |

Registered: 7 years ago Posts: 58 |

Yes nuts works great. Important thing : space between rods must be the same on every carriage. It must be the same also on every attachment points on the effector. You can have different space between effector and carriage like 40mm for the effector and 50mm on the carriage but beware it mechanicaly change the rod length and printer radius value because rods are not parallels. Bad rod length leads to travel distortion and bad printer radius leads to curvature effect, so keep space between rods the same everywhere it far more simple.

Edited 2 time(s). Last edit at 08/25/2016 06:06AM by Hergonoway.

Edited 2 time(s). Last edit at 08/25/2016 06:06AM by Hergonoway.

|

Re: Zonestar D810B from AliExpress August 26, 2016 06:33PM |

Registered: 9 years ago Posts: 978 |

My variant of the heated bed thermostat case is now on Thingiverse

Some variations on the original...

Mounting lugs, to attach to the 2020 extrusion bottom rail of a Zonestar D810 delta printer. Attach with M3x25mm screws nd M3 boat nuts

Opened up the viewing angles to the LED

Added labels underneath each button (need to print on a good flat bed for these to be legible)

Added labels on the top of each button.

Source is publicly available at

[cad.onshape.com]

With thanks to Hergonoway who originally did the lugs.

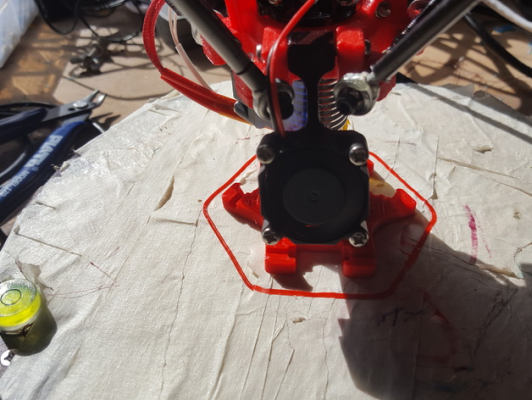

And a replacement fan duct

And LCD mounts

[Edit] Oops, forgot...

And V2 of the spool holder triangle.

Edited 1 time(s). Last edit at 08/26/2016 07:03PM by frankvdh.

Some variations on the original...

Mounting lugs, to attach to the 2020 extrusion bottom rail of a Zonestar D810 delta printer. Attach with M3x25mm screws nd M3 boat nuts

Opened up the viewing angles to the LED

Added labels underneath each button (need to print on a good flat bed for these to be legible)

Added labels on the top of each button.

Source is publicly available at

[cad.onshape.com]

With thanks to Hergonoway who originally did the lugs.

And a replacement fan duct

And LCD mounts

[Edit] Oops, forgot...

And V2 of the spool holder triangle.

Edited 1 time(s). Last edit at 08/26/2016 07:03PM by frankvdh.

|

Re: Zonestar D810B from AliExpress August 26, 2016 06:47PM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress August 27, 2016 06:09AM |

Registered: 7 years ago Posts: 21 |

|

Re: Zonestar D810B from AliExpress August 27, 2016 05:23PM |

Registered: 9 years ago Posts: 978 |

|

Re: Zonestar D810B from AliExpress August 30, 2016 03:05PM |

Registered: 7 years ago Posts: 21 |

Quote

frankvdh

Added photos to each of the things on Thingiverse

Frank,

The fan duct model you uploaded on thingiverse can not be installed on d810 because top part is very wide.

But there is other model with other top part on your photo.

Edited 2 time(s). Last edit at 08/30/2016 10:26PM by tidehunter.

|

Re: Zonestar D810B from AliExpress August 31, 2016 12:30AM |

Registered: 9 years ago Posts: 978 |

|

Re: Zonestar D810B from AliExpress August 31, 2016 07:40AM |

Registered: 8 years ago Posts: 6 |

|

Re: Zonestar D810B from AliExpress August 31, 2016 08:40AM |

Registered: 7 years ago Posts: 58 |

Model seems good, I think you can get a bigger printer area for 235$.

Moulded corner are better, metal one are far greater, robotdigg ones are the best.

EDIT : found it at a better price on AliExpress without really searching, you find at a better I think. (And I don't know I you can have taxes from your link)

[s.aliexpress.com]

Edited 2 time(s). Last edit at 08/31/2016 08:46AM by Hergonoway.

Moulded corner are better, metal one are far greater, robotdigg ones are the best.

EDIT : found it at a better price on AliExpress without really searching, you find at a better I think. (And I don't know I you can have taxes from your link)

[s.aliexpress.com]

Edited 2 time(s). Last edit at 08/31/2016 08:46AM by Hergonoway.

|

Re: Zonestar D810B from AliExpress August 31, 2016 12:15PM |

Registered: 7 years ago Posts: 21 |

found some parts models for flsun delta [www.thingiverse.com]

Edited 1 time(s). Last edit at 08/31/2016 12:18PM by tidehunter.

Edited 1 time(s). Last edit at 08/31/2016 12:18PM by tidehunter.

|

Re: Zonestar D810B from AliExpress August 31, 2016 09:06PM |

Registered: 9 years ago Posts: 978 |

Quote

Joey

I cam across similar Delta Kit on a Store here for $235 with shipping and the parts looks moulded .

You've got to know that, at that price, it's not going to be a good 3D printer until you've done a *lot* of work on it. *Everything* about it will be at the lowest possible price. There will be no quality control at all. See my first few posts in this thread for the issues I found with the D810.

Quote

Do you guys think its worth a buy?

Without knowing you, I couldn't make a recommendation. If you're looking for a plug-and-play printer, I'd suggest that you need to be in the $1000+ price bracket. If you're handy and like fiddling and have time to spare and want to learn about 3D printing, then a cheap printer could be a good buy.

I'd consider buying that, except that I already have a D810, which I got for $225 incl shipping. That one has a single power supply (I think) which is better (but it seems to be only 5A, which is useless), and RAMPS (which I think is better than the proprietary board that the D810 has). But the real questions are about the geometry of the printer, the effectiveness of the extruder, how good the hot-end is, the power of the motors, the rigidity of the whole thing, the accuracy of the parts, the usability of the spool holder (looks like nothing to me) and the bed-leveling sensor. None of these things is mentioned by the seller. There's an FLSUN thread in this forum which seems to have lots of messages... I suggest you ask there.

|

Re: Zonestar D810B from AliExpress September 03, 2016 05:42PM |

Registered: 9 years ago Posts: 978 |

Next issue solved, I hope.

Short story: I believe the stepper drivers need better cooling. I'll design a proper mount and duct for a fan in that area.

Long story: I've been intermittently having my machine going into a "stuttering" mode, where after 20+ minutes it started moving the nozzle around in the wrong places, and didn't seem to extrude. Sometimes this seemed to be associated with communication errors to Octopi. Yesterday it happened again, but this time seemed quite consistent. I switched to printing directly from Repetier Host, and it did the same thing, so I could eliminate my RPi3. I then checked the ZRIB board and found that the stepper driver heatsinks were very hot... too hot to touch. So I taped one of my failed fan ducts to a blower fan and directed it at the heatsinks. After that, for quite a while there was a stinky molten plastic smell from that area. I think that indicates that it's been overheating for a while, and there was a lot of stale hot air in that area. I also suspect the comms errors were caused by the overheating... hopefully there's no long-term damage. Since installing the fan, I've had a couple of good long prints.

Short story: I believe the stepper drivers need better cooling. I'll design a proper mount and duct for a fan in that area.

Long story: I've been intermittently having my machine going into a "stuttering" mode, where after 20+ minutes it started moving the nozzle around in the wrong places, and didn't seem to extrude. Sometimes this seemed to be associated with communication errors to Octopi. Yesterday it happened again, but this time seemed quite consistent. I switched to printing directly from Repetier Host, and it did the same thing, so I could eliminate my RPi3. I then checked the ZRIB board and found that the stepper driver heatsinks were very hot... too hot to touch. So I taped one of my failed fan ducts to a blower fan and directed it at the heatsinks. After that, for quite a while there was a stinky molten plastic smell from that area. I think that indicates that it's been overheating for a while, and there was a lot of stale hot air in that area. I also suspect the comms errors were caused by the overheating... hopefully there's no long-term damage. Since installing the fan, I've had a couple of good long prints.

|

Re: Zonestar D810B from AliExpress September 03, 2016 05:54PM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress September 04, 2016 08:18AM |

Registered: 7 years ago Posts: 21 |

What are the dimensions of your board? mine is 48x40 mm, but printed 1:1 case has 51x42 mm inside and holes positions don't match. Standard one was ok.

Sorry, only registered users may post in this forum.