Zonestar D810B from AliExpress

Posted by frankvdh

|

Re: Zonestar D810B from AliExpress September 04, 2016 04:47PM |

Registered: 9 years ago Posts: 978 |

Hmmmm... I don't know what's going on there. I didn't change the X,Z dimensions of the case from the original Thingiverse design... I only added 3mm to the Y dimension (thickness).

From my design at [cad.onshape.com] inside dimensions of the case are 41mm high by 49mm wide. Peg centres are 41mm apart horizontally, 33mm vertically.Peg diameters are 3mm, and I added a chamfer to the peg tops to make it easier to fit into the board. That fits my board perfectly (I'm at work, so can't measure it right now).

Are all the belts and screws tight on your printer?

If you don't want to throw that one away, you could try using boiling water to soften the PLA to allow you to bend the pegs enough to make it fit. Or just snap 2 or 3 of the pegs off... the board is a tight enough fit in the case anyway, I think.If not, a dot of hot-glue in the corners will stop it rattling about.

From my design at [cad.onshape.com] inside dimensions of the case are 41mm high by 49mm wide. Peg centres are 41mm apart horizontally, 33mm vertically.Peg diameters are 3mm, and I added a chamfer to the peg tops to make it easier to fit into the board. That fits my board perfectly (I'm at work, so can't measure it right now).

Are all the belts and screws tight on your printer?

If you don't want to throw that one away, you could try using boiling water to soften the PLA to allow you to bend the pegs enough to make it fit. Or just snap 2 or 3 of the pegs off... the board is a tight enough fit in the case anyway, I think.If not, a dot of hot-glue in the corners will stop it rattling about.

|

Re: Zonestar D810B from AliExpress September 06, 2016 02:36PM |

Registered: 7 years ago Posts: 21 |

|

Re: Zonestar D810B from AliExpress September 06, 2016 09:07PM |

Registered: 7 years ago Posts: 58 |

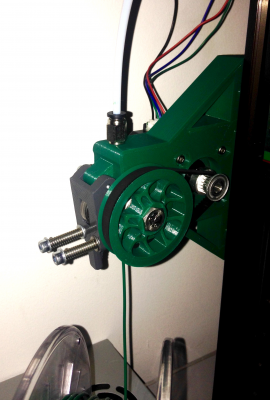

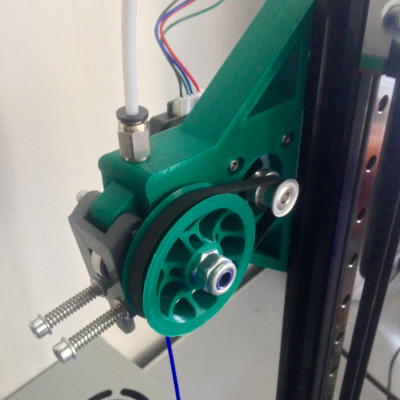

Finished my extruder prototype, works like charm. Added 4 time more torque, reduced the PTFE tube and changed the S shape for a U shape, which reduces friction. Need little "graphics" modification and go go to thingiverse.

Edited 2 time(s). Last edit at 09/06/2016 09:15PM by Hergonoway.

Edited 2 time(s). Last edit at 09/06/2016 09:15PM by Hergonoway.

|

Re: Zonestar D810B from AliExpress September 10, 2016 06:33PM |

Registered: 7 years ago Posts: 3 |

Hi Everyone,

I ordered the Zonestar D810 from aliexpress and then saw this forum and I thought I was going to regret it. I have to admit I'm totally surprised, it's really printing way better than I expected from the jump. I haven't even installed the separate heated bed yet but I'm getting pretty good prints on PLA. My favorite part is the hotend, it may be a copy of the e3d but a really good copy. Seriously prints almost as good as my Robo 3D which had been modified and upgraded. Of course nothing is perfect, and there are some things that need to be updated. I already used some of Frank's models on thingiverse (installed the LCD in the front and made the case for the bed controller). Going to print out Frank's tensioner also. So thanks Frank!!!. I'm going to put a separate power supply and connect bed heater to the board. It looks like some of you have done it, Has it been successful? I'm aware I would need to modify the firmware and it seems simple (done it with my other printers). Any other advice anyone can give me would be great. But I have to admit I'm happy with the D810

Sonny

I ordered the Zonestar D810 from aliexpress and then saw this forum and I thought I was going to regret it. I have to admit I'm totally surprised, it's really printing way better than I expected from the jump. I haven't even installed the separate heated bed yet but I'm getting pretty good prints on PLA. My favorite part is the hotend, it may be a copy of the e3d but a really good copy. Seriously prints almost as good as my Robo 3D which had been modified and upgraded. Of course nothing is perfect, and there are some things that need to be updated. I already used some of Frank's models on thingiverse (installed the LCD in the front and made the case for the bed controller). Going to print out Frank's tensioner also. So thanks Frank!!!. I'm going to put a separate power supply and connect bed heater to the board. It looks like some of you have done it, Has it been successful? I'm aware I would need to modify the firmware and it seems simple (done it with my other printers). Any other advice anyone can give me would be great. But I have to admit I'm happy with the D810

Sonny

|

Re: Zonestar D810B from AliExpress September 12, 2016 03:15PM |

Registered: 9 years ago Posts: 978 |

A couple of additions...

I added a 1m strip of warm white LEDs, and I'm very pleased with the outcome (and the price... US$0.86!)... now I'm seeing good colour on my RPi cam. I left my cool white ones in place, and tuck the new ones on the other side of the 2020 rail. At the corners I went round the outside of the uprights to ensure it doesn't tangle with the belts if it comes loose.

And I just had the Bowden cable connector on my extruder fail... the blue plastic thing doesn't seem to lock onto the PTFE tube which just pops out when the extruder applies pressure The end of the tube seemed to be worn down/compressed, so I cut a cm or so off, but it still won't lock in place. I guess I need to replace the brass connector thing. And I guess the one down at the hot end is also liable to fail too. Does anyone know if these are just standard items to be got from AliExpress or eBay?

The end of the tube seemed to be worn down/compressed, so I cut a cm or so off, but it still won't lock in place. I guess I need to replace the brass connector thing. And I guess the one down at the hot end is also liable to fail too. Does anyone know if these are just standard items to be got from AliExpress or eBay?

I'm also interested in hearing whether others are successfully running the heated bed via the RIB board... I'm just a bit concerned about whether the MOSFET is up to 10A?

I added a 1m strip of warm white LEDs, and I'm very pleased with the outcome (and the price... US$0.86!)... now I'm seeing good colour on my RPi cam. I left my cool white ones in place, and tuck the new ones on the other side of the 2020 rail. At the corners I went round the outside of the uprights to ensure it doesn't tangle with the belts if it comes loose.

And I just had the Bowden cable connector on my extruder fail... the blue plastic thing doesn't seem to lock onto the PTFE tube which just pops out when the extruder applies pressure

The end of the tube seemed to be worn down/compressed, so I cut a cm or so off, but it still won't lock in place. I guess I need to replace the brass connector thing. And I guess the one down at the hot end is also liable to fail too. Does anyone know if these are just standard items to be got from AliExpress or eBay?

The end of the tube seemed to be worn down/compressed, so I cut a cm or so off, but it still won't lock in place. I guess I need to replace the brass connector thing. And I guess the one down at the hot end is also liable to fail too. Does anyone know if these are just standard items to be got from AliExpress or eBay?I'm also interested in hearing whether others are successfully running the heated bed via the RIB board... I'm just a bit concerned about whether the MOSFET is up to 10A?

|

Re: Zonestar D810B from AliExpress September 12, 2016 03:28PM |

Registered: 7 years ago Posts: 58 |

For the bowden plug, if you want to remove it, don't unscrew it, it is just put into the hole and there a tiny set screw which fit the plug in place.

I'm running the bed through the ZRIB, no problem at all, but you need to power up the board without using the barrel jack (extremly important).

Here's my configuration for the firmware (for the bed temp sensor, I used the pin next to the hotend sensor)

Edited 2 time(s). Last edit at 09/12/2016 03:30PM by Hergonoway.

I'm running the bed through the ZRIB, no problem at all, but you need to power up the board without using the barrel jack (extremly important).

Here's my configuration for the firmware (for the bed temp sensor, I used the pin next to the hotend sensor)

// ############# Heated bed configuration ######################## #define HAVE_HEATED_BED 1 #define HEATED_BED_MAX_TEMP 120 #define SKIP_M190_IF_WITHIN 3 #define HEATED_BED_SENSOR_TYPE 4 // Original Repetier : 1 | Hergonoway : 4 (resitance of 10K) #define HEATED_BED_SENSOR_PIN TEMP_1_PIN #define HEATED_BED_HEATER_PIN HEATER_1_PIN #define HEATED_BED_SET_INTERVAL 5000 #define HEATED_BED_HEAT_MANAGER 0 #define HEATED_BED_PID_INTEGRAL_DRIVE_MAX 255 #define HEATED_BED_PID_INTEGRAL_DRIVE_MIN 80 #define HEATED_BED_PID_PGAIN_OR_DEAD_TIME 196 #define HEATED_BED_PID_IGAIN 33 #define HEATED_BED_PID_DGAIN 290 #define HEATED_BED_PID_MAX 255 #define HEATED_BED_DECOUPLE_TEST_PERIOD 300000 #define MIN_EXTRUDER_TEMP 150 #define MAXTEMP 275 #define MIN_DEFECT_TEMPERATURE -10 #define MAX_DEFECT_TEMPERATURE 290

Edited 2 time(s). Last edit at 09/12/2016 03:30PM by Hergonoway.

|

Re: Zonestar D810B from AliExpress September 12, 2016 06:41PM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress September 12, 2016 11:06PM |

Registered: 9 years ago Posts: 978 |

Quote

Hergonoway

For the bowden plug, if you want to remove it, don't unscrew it, it is just put into the hole and there a tiny set screw which fit the plug in place.

Yeah, I discovered this months ago. I've replaced the little grub screw with an M3 socket cap since I often have to get it out to change filament.

But I think what's broken is the blue plastic bit that grips onto the PTFE tube. The PTFE tube just pops out whenever the extruder starts pushing.

|

Re: Zonestar D810B from AliExpress September 14, 2016 12:19AM |

Registered: 9 years ago Posts: 978 |

Bad news... those little brass & blue "pneumatic" connectors come in different sizes & shapes  And my spare ones are different from the one that came with my printer.

And my spare ones are different from the one that came with my printer.

Good news... you *can* hold a non-fitting pneumatic thing in place with twisted wire and still get acceptable print quality.

And my spare ones are different from the one that came with my printer.

And my spare ones are different from the one that came with my printer.

Good news... you *can* hold a non-fitting pneumatic thing in place with twisted wire and still get acceptable print quality.

|

Re: Zonestar D810B from AliExpress September 14, 2016 05:18PM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress September 15, 2016 03:15PM |

Registered: 7 years ago Posts: 3 |

|

Re: Zonestar D810B from AliExpress September 21, 2016 02:08PM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress September 21, 2016 07:19PM |

Registered: 7 years ago Posts: 1 |

Hi Guys,

I just bought this printer last 3 month but still cannot get good printing due to below issue. I really need your guys help

to guide me on this.

1) my printing cannot level during movement along bed heating. it always higher around 1mm between tower Y and tower Z.

2) When starting to print first layer, the thickness was not consistence which sometime the PLA come out higher more than 2mm.

I just bought this printer last 3 month but still cannot get good printing due to below issue. I really need your guys help

to guide me on this.

1) my printing cannot level during movement along bed heating. it always higher around 1mm between tower Y and tower Z.

2) When starting to print first layer, the thickness was not consistence which sometime the PLA come out higher more than 2mm.

|

Re: Zonestar D810B from AliExpress September 21, 2016 07:31PM |

Registered: 7 years ago Posts: 58 |

Honestly the simplest and most effective way is to buy a borosilicate glass and clamp it over your bed, you'll have a flat surface whatever the temperature is.

3mm aluminium bed is not flat and tend to be worse when heated.

Edited 1 time(s). Last edit at 09/21/2016 07:33PM by Hergonoway.

3mm aluminium bed is not flat and tend to be worse when heated.

Edited 1 time(s). Last edit at 09/21/2016 07:33PM by Hergonoway.

|

Re: Zonestar D810B from AliExpress September 21, 2016 09:21PM |

Registered: 9 years ago Posts: 978 |

Quote

izlan

1) my printing cannot level during movement along bed heating. it always higher around 1mm between tower Y and tower Z.

2) When starting to print first layer, the thickness was not consistence which sometime the PLA come out higher more than 2mm.

Be very careful with this... if auto-leveling happens to use 3 low points on the bed, then the nozzle could crash into high points on the bed and cause damage.

This could be a geometry issue rather than a bed issue. Are all your end-stops triggering at the same height above the bed? If one end-stop is triggering slightly higher or lower than the others, you could try bending the little metal tongue on the switch to compensate. Or add a layer of tape or two to the top of the carriage.

My aluminium bed is also not level. I leveled it as best I could by hand. Even with 2 screws almost all the way out, and the third all the way in, I still couldn't use it all. I've added dozens of layers of tape (probably more than 2mm thick) to the bed, so that the top of the tape is now close enough to level to use as a print bed.

I am not using the auto-leveling at all... if the hot-end can move, then it just adds another variable into the problem.

I also have a borosilicate glass sheet, but haven't installed it yet... maybe this weekend.

If you are printing PLA, you don't need to turn on the heated bed unless you are printing large objects which could warp. PLA should stick just fine to painters tape.

|

Re: Zonestar D810B from AliExpress October 04, 2016 03:26PM |

Registered: 7 years ago Posts: 21 |

Quote

Hergonoway

Quote

frankvdh

I'm happy it works for you. The problem seemed to start happening to me when I put a fairly new spool on the printer. I haven't actually compared the two spools, but maybe it was because the new spool was wider or narrower, or had a smaller or larger hole. In any case, I have redesigned the triangles, and I'll print the new ones over the weekend.

In other news...

I've fitted three lights to the bottoms of the top frame of the printer. These light strips come with adhesive backing, and are the right length to fit neatly into place. I've wired them to run off the 10A 12V supply for the heated bed.

I've also added a 4-relay module to my Raspberry Pi 3 (running Octopi). I'm using 2 of the relays at the moment... one to turn on/off the lights, and one to turn on/off the heated bed. The third will control the 12V power to the printer itself. The fourth relay is spare. The reason for this (and the lights) is that the printer lives out in my garage. I watch it via the RPi's camera. In any kind of emergency, I'll be able to turn it off remotely. Also, I'll be able to turn off the heated bed (hopefully automatically) when the print finishes. I want to turn the lights on/off remotely so I can look at the printer without leaving the main garage lights on. Actually, whilst the lights + camera work OK, the colour that the camera shows is very blue. Maybe "warm white" LEDs would give a better colour? To make the relay board and RPi3 work together, I had to change the RPi 5V power supply... 1.6A wasn't quite enough, and the Pi would reboot each time it turned a relay on.

+1 for the light a very good idea ! I tried octopie but I stopped when I saw that I'll have to import a cura profile :/ (#lazy I love repetier)

I've multiple issues with the extruder, already made a full bearing vertical spool holder, but the extruder basically doesn't have enough torque. Sometimes the extruder skip to push the filament so you have to inscrease the tension of the extruder spring which lead to bigger grooves on the filament.

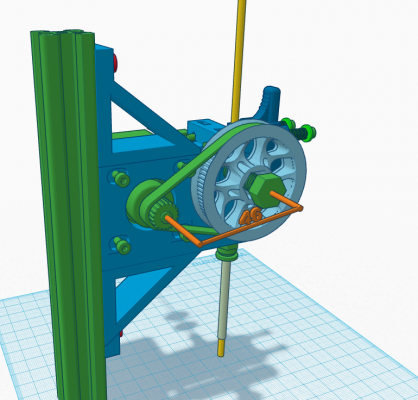

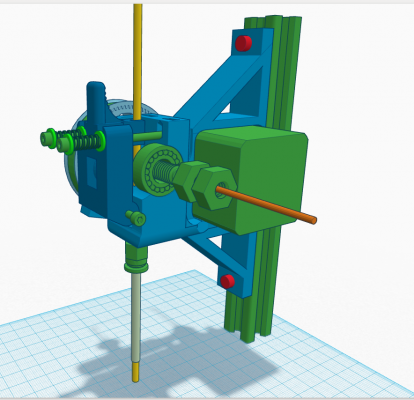

I'm currently designing a new extruder with a ratio of 4:1 which basicaly will give 4 times more torque, it will be mounted to the side of the printer so I'll be able to put the spool next to the printer and change the PTFE tube from an S shape to a shorter U shape which I assume will reduce friction.

Not finished yet but if people are interested I'll post pictures of it printed and share the STL file. Currently the cost of the hardware needed in under 15$. most of "greg wade based design are with gears, but I think it'll generate noise, so I design it to handle GT2 close belt of 200mm

current progress (green = hardware or existing stuff, blue = printed parts, yellow/orange = axes for work or filament simulation) :

Hi, Hergonoway!

Have you finished new extruder design? I'm very interested to try it.

|

Re: Zonestar D810B from AliExpress October 04, 2016 08:53PM |

Registered: 9 years ago Posts: 978 |

I'm interested in this extruder design too, although still thinking about a flying extruder, or maybe a cable-driven direct-drive one. I'm hearing a lot of clicks from the extruder motor.

News:

I still haven't got my glass plate mounted. I have a bowl-shaped nozzle locus, and I'm not sure about how to correct for that. I started out with [escher3d.com] but the Repetier firmware doesn't know about M665 or M666 commands. I'm still waiting for Zonestar support to reply about that. I don't want to go to Marlin, just because I gather that Repetier handles Deltas better.

I'm still waiting for Zonestar support to reply about that. I don't want to go to Marlin, just because I gather that Repetier handles Deltas better.

I've drilled out my extruder to take the larger Bowden connectors that I already had (the same as the one on the hot-end). If I knew what the thread on them was, I'd have tapped that into the extruder; instead, I'm still using the M3 screw to clamp it in place. Hint: Countersink the end of the Bowden connector that goes into your extruder... it will make loading filament *much* easier.

I have printed quite a few things that came out well, but recent results have been bad. I think this is because the (original) effector is now badly cracked through the rod attachments That in turn is because I've been progressively epoxying the rod-ends into the rods as they came loose, so the forces that were causing the rod-ends to break free from the rods are now being transferred to the effector. Fortunately, I had the foresight to print a replacement effector while things were going well.

News:

I still haven't got my glass plate mounted. I have a bowl-shaped nozzle locus, and I'm not sure about how to correct for that. I started out with [escher3d.com] but the Repetier firmware doesn't know about M665 or M666 commands.

I'm still waiting for Zonestar support to reply about that. I don't want to go to Marlin, just because I gather that Repetier handles Deltas better.

I'm still waiting for Zonestar support to reply about that. I don't want to go to Marlin, just because I gather that Repetier handles Deltas better.I've drilled out my extruder to take the larger Bowden connectors that I already had (the same as the one on the hot-end). If I knew what the thread on them was, I'd have tapped that into the extruder; instead, I'm still using the M3 screw to clamp it in place. Hint: Countersink the end of the Bowden connector that goes into your extruder... it will make loading filament *much* easier.

I have printed quite a few things that came out well, but recent results have been bad. I think this is because the (original) effector is now badly cracked through the rod attachments That in turn is because I've been progressively epoxying the rod-ends into the rods as they came loose, so the forces that were causing the rod-ends to break free from the rods are now being transferred to the effector. Fortunately, I had the foresight to print a replacement effector while things were going well.

|

Re: Zonestar D810B from AliExpress October 06, 2016 09:21AM |

Registered: 7 years ago Posts: 58 |

Quote

frankvdh

I'm interested in this extruder design too, although still thinking about a flying extruder, or maybe a cable-driven direct-drive one. I'm hearing a lot of clicks from the extruder motor.

News:

I still haven't got my glass plate mounted. I have a bowl-shaped nozzle locus, and I'm not sure about how to correct for that. I started out with [escher3d.com] but the Repetier firmware doesn't know about M665 or M666 commands.I'm still waiting for Zonestar support to reply about that. I don't want to go to Marlin, just because I gather that Repetier handles Deltas better.

I've drilled out my extruder to take the larger Bowden connectors that I already had (the same as the one on the hot-end). If I knew what the thread on them was, I'd have tapped that into the extruder; instead, I'm still using the M3 screw to clamp it in place. Hint: Countersink the end of the Bowden connector that goes into your extruder... it will make loading filament *much* easier.

I have printed quite a few things that came out well, but recent results have been bad. I think this is because the (original) effector is now badly cracked through the rod attachments That in turn is because I've been progressively epoxying the rod-ends into the rods as they came loose, so the forces that were causing the rod-ends to break free from the rods are now being transferred to the effector. Fortunately, I had the foresight to print a replacement effector while things were going well.

I tried Marlin, not so good I went back to repetier like most of people, when you say "bowl-shaped nozzle locus" do you mean that at Z=0 in the center if you move the nozzle to the border of the place the nozzle is higher than at Z=0 in the middle ? If yes, I gave you my procedure to correct this effect few post ago.

For the extruder mine is working great but the current design (in the middle of the vertical 2020) doesn't work with a pulley system, because it is attached to the vertical 2020. I can made a version to be fixed at the top of the printer like the original extruder if you want. Tell me which version do you want.

|

Re: Zonestar D810B from AliExpress October 06, 2016 10:43AM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress October 07, 2016 12:18PM |

Registered: 7 years ago Posts: 21 |

|

Re: Zonestar D810B from AliExpress October 15, 2016 04:41PM |

Registered: 7 years ago Posts: 3 |

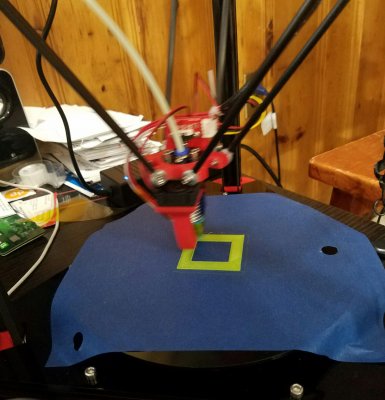

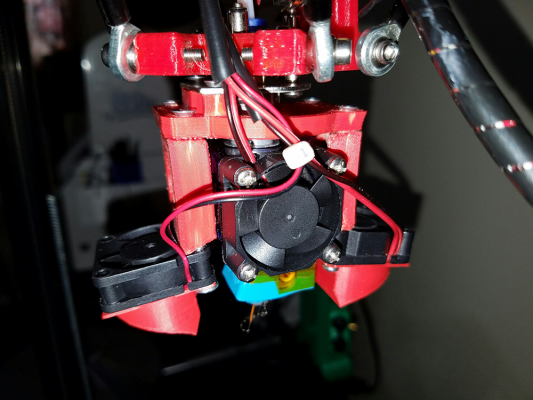

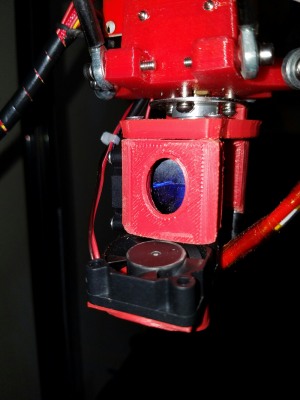

So like most of you have figured out - that one cooling fan just isn't enough. I created this new holder that attaches to the hotend carriage

to hold 2 cooling fans. My prints were coming out good but this allows more details to show through and less strings. Look at the attached Benchy images.

If you want the files (STL), you can get them on Thingiverse: [www.thingiverse.com]

Edited 1 time(s). Last edit at 10/16/2016 12:00AM by SonnyDR.

to hold 2 cooling fans. My prints were coming out good but this allows more details to show through and less strings. Look at the attached Benchy images.

If you want the files (STL), you can get them on Thingiverse: [www.thingiverse.com]

Edited 1 time(s). Last edit at 10/16/2016 12:00AM by SonnyDR.

|

Re: Zonestar D810B from AliExpress November 04, 2016 05:50PM |

Registered: 7 years ago Posts: 21 |

|

Re: Zonestar D810B from AliExpress May 21, 2017 07:47PM |

Registered: 9 years ago Posts: 978 |

Despite this thread having been dormant for about 6 months, I'll just add on here with a bit of a progress report....

For some time I've been struggling with print quality, and I now suspect that the cause is a couple of cracks I just found in the acrylic top triangle. One crack is on the left hand side near the front, between the edge and a square cutout. The other on the right hand side near the rear, between an M5 screw hole and the edge. People might want to do some pre-emptive strengthening on their triangles. I've epoxied mine together, and glued strips of plywood to the top of the acrylic to add strength. But its a bit concerning that the acrylic is taking some stress... I'd have thought that the 2020 extrusions should be taking the forces. I guess it means that the attachment of the extrusions to the corners must also be moving a bit, despite me regularly tightening all the M5 screws.

One crack is on the left hand side near the front, between the edge and a square cutout. The other on the right hand side near the rear, between an M5 screw hole and the edge. People might want to do some pre-emptive strengthening on their triangles. I've epoxied mine together, and glued strips of plywood to the top of the acrylic to add strength. But its a bit concerning that the acrylic is taking some stress... I'd have thought that the 2020 extrusions should be taking the forces. I guess it means that the attachment of the extrusions to the corners must also be moving a bit, despite me regularly tightening all the M5 screws.

Improvements:

For some time I've been struggling with print quality, and I now suspect that the cause is a couple of cracks I just found in the acrylic top triangle.

One crack is on the left hand side near the front, between the edge and a square cutout. The other on the right hand side near the rear, between an M5 screw hole and the edge. People might want to do some pre-emptive strengthening on their triangles. I've epoxied mine together, and glued strips of plywood to the top of the acrylic to add strength. But its a bit concerning that the acrylic is taking some stress... I'd have thought that the 2020 extrusions should be taking the forces. I guess it means that the attachment of the extrusions to the corners must also be moving a bit, despite me regularly tightening all the M5 screws.

One crack is on the left hand side near the front, between the edge and a square cutout. The other on the right hand side near the rear, between an M5 screw hole and the edge. People might want to do some pre-emptive strengthening on their triangles. I've epoxied mine together, and glued strips of plywood to the top of the acrylic to add strength. But its a bit concerning that the acrylic is taking some stress... I'd have thought that the 2020 extrusions should be taking the forces. I guess it means that the attachment of the extrusions to the corners must also be moving a bit, despite me regularly tightening all the M5 screws.Improvements:

- I've mounted my processor board vertically on the outside of the top 2020... that seems to have alleviated the stepper driver cooling issues, even without a fan.

- I'm refining my carriage design... there's only one original carriage still on my printer; the rod attachments just keep breaking. Lots of epoxy has gone into repairing these, without lasting success. New carriages are stronger, have better attachment lugs, and will align the belt attachment with the pulleys better.

- On one of my top corners, the endstop lever kept falling off, so on that corner the carriage (with a little extension) just presses the switch directly. That works well, and I think is more accurate than via the lever. My refined carriage will include a vertical M3 screw to press the switch, which will make the Z-stops height adjustable.

- Until now, I've just been Z-calibrating by hand. Zonestar's original bed-detector was a disaster, and I don't have any faith in Zonestar's revised probe-microswitch bed-detector either, so didn't even try that. Manual calibration works well, except for large (say 100mm+ diameter) objects, where out-of-level and non-flat build plate effects start to become an issue. I'm printing on a 3mm borosilicate glass heated bed, but still have nozzle height variation (and consequent adhesion) issues. I've ordered a piezo bed detector, and will mount that when it arrives, which hopefully will allow me to use auto-bed-levelling.

- I also have built an improved effector, which has a mount for a blower fan. The effector uses an M3 screw to clamp the heatsink collar to the effector. That costs a few mm of height, but I haven't printed anything 300mm tall anyway. The big benefit is that the Bowden attachment to the hotend is easy to access and undo, which makes it *much* easier to clear a jam. It's also much easier to remove the hot-end entirely.

Not that I have a lot of jams... the hot-end and extruder seem to be the best parts of this printer. But, for example, I've had spaghetti due to bed-attachment and layer-to-layer-attachment failure (due to cracked/broken carriage lugs and maybe the cracked top triangle) where the spaghetti has jammed the hot-end cooling fan and consequently the filament has jammed the hot-end itself.

|

Re: Zonestar D810B from AliExpress May 22, 2017 01:50AM |

Registered: 7 years ago Posts: 58 |

Hello,

Good news, I've also encounter similar issues with mine so I'm currently upgrading it seriously.

so I'm currently upgrading it seriously.

I've lost my HDD with all my 3D model so it take me times to redo them, but I take this chance to switch to fusion 360, so I started to model my future printer annnnd it's already 7 month past.

I seriously thinking about pression probe, but there's still feedback I need to gather. In the mean time I'm currently talking with zonestar about how to connect a solenoid probe to the Zrib, I'll keep you posted.

Do you go for the piezo under the bed or above the hotend version?

Edited 3 time(s). Last edit at 05/22/2017 02:11AM by Hergonoway.

Good news, I've also encounter similar issues with mine

so I'm currently upgrading it seriously.

so I'm currently upgrading it seriously. I've lost my HDD with all my 3D model so it take me times to redo them, but I take this chance to switch to fusion 360, so I started to model my future printer annnnd it's already 7 month past.

I seriously thinking about pression probe, but there's still feedback I need to gather. In the mean time I'm currently talking with zonestar about how to connect a solenoid probe to the Zrib, I'll keep you posted.

Do you go for the piezo under the bed or above the hotend version?

Edited 3 time(s). Last edit at 05/22/2017 02:11AM by Hergonoway.

|

Re: Zonestar D810B from AliExpress May 22, 2017 03:08PM |

Registered: 9 years ago Posts: 978 |

|

Re: Zonestar D810B from AliExpress May 22, 2017 03:24PM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress May 22, 2017 09:01PM |

Registered: 9 years ago Posts: 978 |

Sorry, thought you would be following this thread.

|

Re: Zonestar D810B from AliExpress May 23, 2017 01:10AM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress May 27, 2017 06:08AM |

Registered: 7 years ago Posts: 58 |

|

Re: Zonestar D810B from AliExpress May 28, 2017 05:36AM |

Registered: 9 years ago Posts: 978 |

A bit more on the piezo, now that I have it installed...

I haven't figured out how to make it work

A G29 (or G30) command results in the nozzle moving down to 5.10mm above the bed, and a message on the LCD saying "G29 failed" (or similar... I don't recall exactly). I just connected the piezo to the old bed-detection microswitch wires. I'm wondering whether the microswitch was wired up in the opposite polarity to the piezo?

Also see my post in the piezo thread... you need somewhere for your Bowden connector to screw into, since it can't screw into the heatsink when the piezo is installed. I screwed a block of plastic (a failed print) to the top of the effector, and epoxied a Bowden connector into that (I have lots of spare Bowden connectors... they're cheap). A properly designed effector would be better.

I haven't figured out how to make it work

A G29 (or G30) command results in the nozzle moving down to 5.10mm above the bed, and a message on the LCD saying "G29 failed" (or similar... I don't recall exactly). I just connected the piezo to the old bed-detection microswitch wires. I'm wondering whether the microswitch was wired up in the opposite polarity to the piezo?

Also see my post in the piezo thread... you need somewhere for your Bowden connector to screw into, since it can't screw into the heatsink when the piezo is installed. I screwed a block of plastic (a failed print) to the top of the effector, and epoxied a Bowden connector into that (I have lots of spare Bowden connectors... they're cheap). A properly designed effector would be better.

Sorry, only registered users may post in this forum.