DeltaXY

Posted by PavloG

Hi everyone

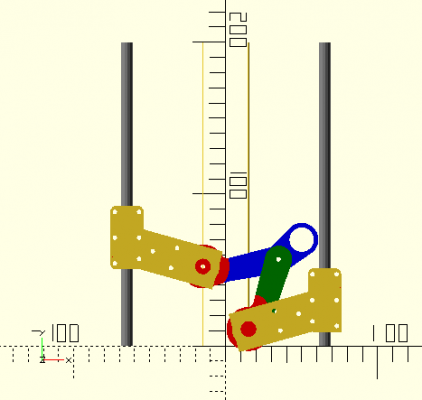

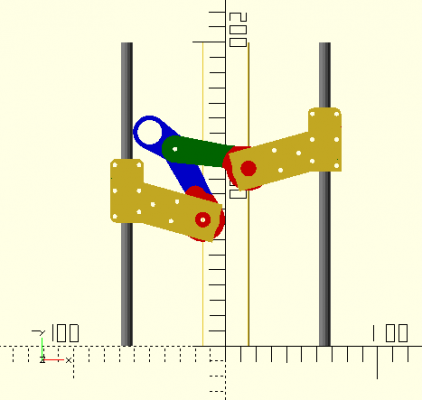

I started working on DeltaXY Kinematic

Idea descriped in images and video

Top view:

Video

Math and Web visualization

Current setup allows to have biggest reachability with shortest arms.

My targets:

Z-Axis seems like to be moved platform.

Thanks for your feedback...any suggestions, critique and discussion is appreciated.

P.S. I have printed a few parts of my printer - openscad file will be available a little bit later

My blog

I started working on DeltaXY Kinematic

Idea descriped in images and video

Top view:

Video

Math and Web visualization

Current setup allows to have biggest reachability with shortest arms.

My targets:

- 100x100x100mm build area with smallest possible box (approx 140x200x150mm)

- Closed build area

- Fast

- Cheap

- Opensource

- Software - Marlin (i have experience to modify source code)

Z-Axis seems like to be moved platform.

Thanks for your feedback...any suggestions, critique and discussion is appreciated.

P.S. I have printed a few parts of my printer - openscad file will be available a little bit later

My blog

|

Re: DeltaXY May 21, 2016 11:13PM |

Registered: 8 years ago Posts: 23 |

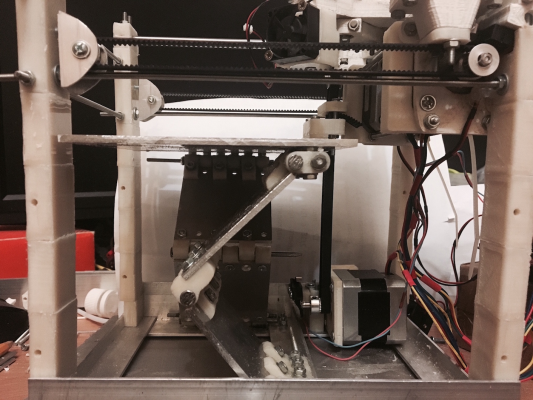

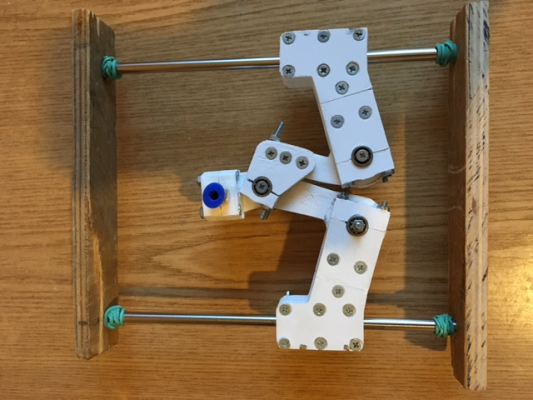

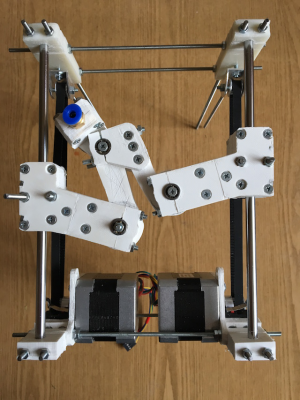

First printed prototype (e3d v6 mouned - not visible from this point of view)

4-LM6UU, 6-623 bearings, 2-200mm 6mm rods

My blog

4-LM6UU, 6-623 bearings, 2-200mm 6mm rods

My blog

|

Re: DeltaXY May 22, 2016 02:22AM |

Registered: 8 years ago Posts: 443 |

My biggest concerns with this idea is how are you going to achieve Z axis, and the deflection under load of the arm mechanism between the two rails. which will have a tendency to rotate on the rails, which will put cross axis load on the mid point bearings, I reckon your really going to suffer from a lack of rigidity.

Your could eliminate the rotation issues by having two pairs of parallel rails on each side and replace each mid point bearing with a pair of bearings separated vertically.

When it comes to printing you are going to need some methodology to accurately calibrate the position of the tool point and take into account any eccentricity between the axis of rotation and the toolpoint position, especially if you plan on using an E3D style hot end

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Your could eliminate the rotation issues by having two pairs of parallel rails on each side and replace each mid point bearing with a pair of bearings separated vertically.

When it comes to printing you are going to need some methodology to accurately calibrate the position of the tool point and take into account any eccentricity between the axis of rotation and the toolpoint position, especially if you plan on using an E3D style hot end

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: DeltaXY May 22, 2016 05:16AM |

Registered: 8 years ago Posts: 23 |

Rigidity is ok (I checked it on real printed prototype) - it is only 130 mm beetween rods.

Also it is possible to use MGN type rails for bigger sizes or 2 rods on each size (as your said)

Calibration seems to be even simpler than regular delta (of course some surprises are possible but I don't afraid)

My blog

Also it is possible to use MGN type rails for bigger sizes or 2 rods on each size (as your said)

Calibration seems to be even simpler than regular delta (of course some surprises are possible but I don't afraid)

My blog

|

Re: DeltaXY May 24, 2016 02:28AM |

Registered: 8 years ago Posts: 916 |

|

Re: DeltaXY May 25, 2016 11:14AM |

Registered: 8 years ago Posts: 23 |

|

Re: DeltaXY May 25, 2016 02:23PM |

Registered: 8 years ago Posts: 17 |

|

Re: DeltaXY May 26, 2016 11:43AM |

Registered: 8 years ago Posts: 23 |

|

Re: DeltaXY May 27, 2016 03:44AM |

Registered: 8 years ago Posts: 23 |

Firmware on git hub

Openscad sources on git hub

Edited 3 time(s). Last edit at 05/27/2016 05:34AM by PavloG.

My blog

Openscad sources on git hub

Edited 3 time(s). Last edit at 05/27/2016 05:34AM by PavloG.

My blog

|

Re: DeltaXY May 30, 2016 03:56AM |

Registered: 9 years ago Posts: 189 |

|

Re: DeltaXY June 08, 2016 09:23PM |

Registered: 8 years ago Posts: 23 |

Progress a little bit delayed due to:

Hotend sink with impeller

Edited 1 time(s). Last edit at 06/09/2016 10:36AM by PavloG.

My blog

Hotend sink with impeller

Edited 1 time(s). Last edit at 06/09/2016 10:36AM by PavloG.

My blog

|

Re: DeltaXY June 08, 2016 09:47PM |

Registered: 8 years ago Posts: 916 |

|

Re: DeltaXY June 08, 2016 09:51PM |

Registered: 8 years ago Posts: 23 |

|

Re: DeltaXY June 08, 2016 10:30PM |

Registered: 8 years ago Posts: 916 |

|

Re: DeltaXY June 09, 2016 04:24AM |

Registered: 8 years ago Posts: 23 |

|

Re: DeltaXY June 11, 2016 04:17PM |

Registered: 8 years ago Posts: 23 |

|

Re: DeltaXY June 11, 2016 09:34PM |

Registered: 8 years ago Posts: 443 |

Well your clearly not afraid to do things your own way, but the more I see of this design the more I'm convinced that this is not a delta, more of an oddball Cartesian/CoreXY hybrid....and looking at this I wonder why a Cartesian XY rack would be considered an inferior design choice

Really can't fathom the rational behind any of your design decisions, if this were me I'd make those uprights 16mm rod and mount the plate with linear bearings, or even affix 4 pieces of linear rail

Any lack of precision in the distance between the pivots on that bed elevation mechanism is going to result in XY and AB shift errors, however, its possible that the right angle orientation of the lift plates will help eliminate this....but that's not necessarily a good thing, it just means you have an over constrained mechanism. so you either have play in the mechanism to overcome the over constraints or the over constraint will cause wear and you will have play

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Really can't fathom the rational behind any of your design decisions, if this were me I'd make those uprights 16mm rod and mount the plate with linear bearings, or even affix 4 pieces of linear rail

Any lack of precision in the distance between the pivots on that bed elevation mechanism is going to result in XY and AB shift errors, however, its possible that the right angle orientation of the lift plates will help eliminate this....but that's not necessarily a good thing, it just means you have an over constrained mechanism. so you either have play in the mechanism to overcome the over constraints or the over constraint will cause wear and you will have play

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: DeltaXY June 12, 2016 06:17AM |

Registered: 8 years ago Posts: 23 |

About delta - XY axes math is a delta.

About Sarrus - it is just prototype, and required testing (one week later I hope)

Generally speaking I try experimenting as much as possible - because I can.

My current Scara printer became good only after third revision, and now I am happy with it.

Of course current DeltaXY pure experimental setup and I don't afraid to get failed.

About Sarrus - it is just prototype, and required testing (one week later I hope)

Generally speaking I try experimenting as much as possible - because I can.

My current Scara printer became good only after third revision, and now I am happy with it.

Of course current DeltaXY pure experimental setup and I don't afraid to get failed.

Sorry, only registered users may post in this forum.

, please keep the updates coming and good luck

, please keep the updates coming and good luck