New delta drive

Posted by TTN

|

New delta drive June 07, 2016 08:40AM |

Registered: 9 years ago Posts: 52 |

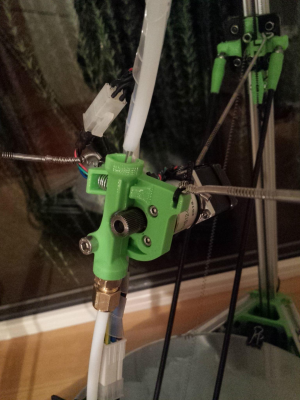

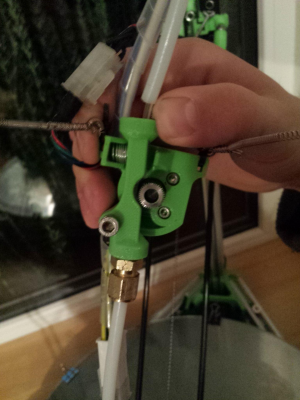

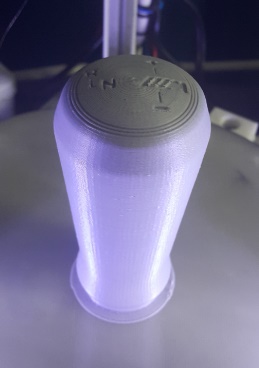

Thews made a new extruder drive last week. I've been testing it and it works great!

Best part about this drive is the quick release setup and being able to clean ground filament off the spur drive without having to disassemble anything.

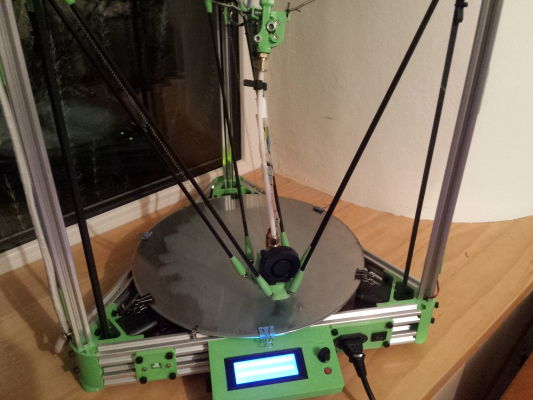

The whole idea of suspending the extruder like that is to reduce the length of the bowden tube. Like this I only need 2.1mm retracts and I don't get any blobbing or stringing anymore.

The stepper motor is a Nema11 with a 27:1 ratio gearbox on it. Can be bought here or from many other places: [www.omc-stepperonline.com]

STL files are attached but its on thingiverse too: [www.thingiverse.com]

Best part about this drive is the quick release setup and being able to clean ground filament off the spur drive without having to disassemble anything.

The whole idea of suspending the extruder like that is to reduce the length of the bowden tube. Like this I only need 2.1mm retracts and I don't get any blobbing or stringing anymore.

The stepper motor is a Nema11 with a 27:1 ratio gearbox on it. Can be bought here or from many other places: [www.omc-stepperonline.com]

STL files are attached but its on thingiverse too: [www.thingiverse.com]

|

Re: New delta drive June 07, 2016 10:20AM |

Registered: 8 years ago Posts: 42 |

|

Re: New delta drive June 07, 2016 11:11AM |

Registered: 10 years ago Posts: 14,672 |

27:1 gearing is very high. What retraction speed and acceleration are you able to achieve? Although I guess that with a short Bowden tube on a flying extruder, fast retraction is less important.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New delta drive June 07, 2016 11:25AM |

Registered: 13 years ago Posts: 268 |

I have both the 5:1 version of that motor and the 27:1. Either fit my extruder which is direct. I did not find the 27:1 to be any improvement, if anything it was slightly worse.Quote

dc42

27:1 gearing is very high. What retraction speed and acceleration are you able to achieve? Although I guess that with a short Bowden tube on a flying extruder, fast retraction is less important.

|

Re: New delta drive June 07, 2016 11:45AM |

Registered: 9 years ago Posts: 2 |

Depends on the voltage. With 12v you can do 12mm/s or 28.86mm^3/s at 3500mm/s^2 accel without any real concerns on 1.75mm filament. With 24v you can go up up to 20mm/s with the same accel, but you'll want to limit the unretract or prime to about 12mm/s still. I can extrude at about 19.2 cubic mm / s with completely even sheen, but if I push it beyond 24 cubic mm it will have some shiny spots at the end of accel and look matte on the rest.

This started off with the insane volumetric rate before I dropped it down. That's at 2mm width I think.

no retraction issues with normal printing

Edited 3 time(s). Last edit at 06/07/2016 12:11PM by thews.

This started off with the insane volumetric rate before I dropped it down. That's at 2mm width I think.

no retraction issues with normal printing

Edited 3 time(s). Last edit at 06/07/2016 12:11PM by thews.

|

Re: New delta drive June 07, 2016 04:19PM |

Registered: 9 years ago Posts: 52 |

Quote

DC42

What retraction speed and acceleration are you able to achieve?

I had to set microstepping to 2x to be able to get fast enough retracts on my RAMPS 1.4. I was able to go up to 20mm/s but use 10mm/s because 20mm/s retracts weren't always reliable.

The 3mm filament I use is really stiff so if you run thinner filament I'm sure you could use a higher speed. It works beautifully! I'm retracting 2.1mm and coasting 0.3mm before doing retracts.

It has loads of torque, easily enough torque for a longer bowden tube.Quote

BuildAThing

With a nema 11 motor and the 27 to 1 box would your torque be about 36 Nm? Do you think that is enough for longer bowden tubes?

|

Re: New delta drive June 07, 2016 10:58PM |

Registered: 8 years ago Posts: 177 |

Hey TTN,

Couldn't you shorten that Bowden tube further? Not sure how long your arms are but there seems like plenty of leeway to suspend the extruder lower down.

Very tempted to print one and try.

I'm down to 1.2mm retracts on my set up with a 200mm Bowden tube from the flying extruder on 674mm long arms

Couldn't you shorten that Bowden tube further? Not sure how long your arms are but there seems like plenty of leeway to suspend the extruder lower down.

Very tempted to print one and try.

I'm down to 1.2mm retracts on my set up with a 200mm Bowden tube from the flying extruder on 674mm long arms

|

Re: New delta drive June 07, 2016 11:06PM |

Registered: 9 years ago Posts: 52 |

|

Re: New delta drive August 02, 2016 07:39AM |

Registered: 8 years ago Posts: 312 |

Nice and simple.

What is the total weight of the extruder?

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

What is the total weight of the extruder?

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: New delta drive August 02, 2016 09:44PM |

Registered: 9 years ago Posts: 978 |

Sorry, coming in late on this...

Who/what is 'Thews'? Something to do with thews-wo_ ?

I'm curious about the thinking behind a NEMA11 + 27:1 gearbox... they're quite pricey. Why not (say) a NEMA17 or NEMA14 pancake motor? Is it that you can't get the torque for the low weight?

According to the website, the holding torque = 1.3Nm (cf 0.43Nm for a 48mm NEMA17 direct drive).

Who/what is 'Thews'? Something to do with thews-wo_ ?

I'm curious about the thinking behind a NEMA11 + 27:1 gearbox... they're quite pricey. Why not (say) a NEMA17 or NEMA14 pancake motor? Is it that you can't get the torque for the low weight?

According to the website, the holding torque = 1.3Nm (cf 0.43Nm for a 48mm NEMA17 direct drive).

|

Re: New delta drive August 02, 2016 10:00PM |

Registered: 9 years ago Posts: 52 |

Thews is a user on IRC in #bigdelta on freenode.net aka thews-wo or thews-work

If you can get the torque, why not use it. The point of the nema11 was to reduce weight, while still being able to do the extruding functions.

He's made a newer fully parametric version of the filament drive: [cad.onshape.com]

Since I run 3mm filament I had to resize some parts and thicken them.

If you can get the torque, why not use it. The point of the nema11 was to reduce weight, while still being able to do the extruding functions.

He's made a newer fully parametric version of the filament drive: [cad.onshape.com]

Since I run 3mm filament I had to resize some parts and thicken them.

|

Re: New delta drive August 11, 2016 09:28AM |

Registered: 8 years ago Posts: 3,525 |

Whats the total mass of your extruder+motor/gearbox? I only say this as I am using a flying e3d titan and 20mm nema 17 and its 250g, and the results are stunning.

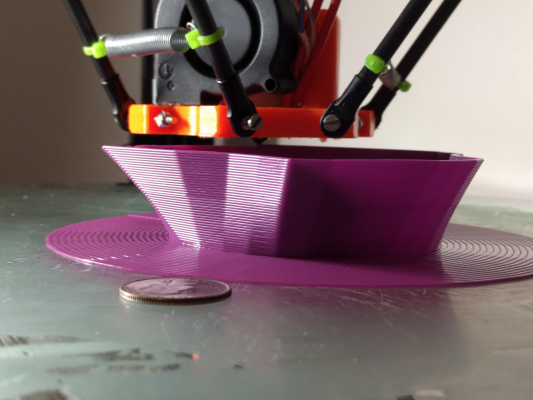

A part I recently printed for someone with 150 micron layers until the top section with 100micron layers.

Edited 1 time(s). Last edit at 08/11/2016 09:32AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

A part I recently printed for someone with 150 micron layers until the top section with 100micron layers.

Edited 1 time(s). Last edit at 08/11/2016 09:32AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: New delta drive August 11, 2016 04:32PM |

Registered: 9 years ago Posts: 52 |

Sorry, only registered users may post in this forum.