Large Kossel all metal delta build log

Posted by DjDemonD

|

Re: Large Kossel all metal delta build log October 24, 2016 06:19PM |

Registered: 10 years ago Posts: 293 |

|

Re: Large Kossel all metal delta build log October 24, 2016 06:19PM |

Registered: 10 years ago Posts: 293 |

|

Re: Large Kossel all metal delta build log October 24, 2016 06:36PM |

Registered: 8 years ago Posts: 3,525 |

Well I don't know about finding them but I will try some printed ones and then maybe get some made perhaps printed with dmls. I am surprised to find 3dhubs has no metal 3d printers in the UK. I know there are engineering firms who can do it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 25, 2016 04:15AM |

Registered: 8 years ago Posts: 3,525 |

I might first upgrade the magnets in the k800 setup, and re-orientate the magnets in the effector to be angled towards the carriages by 45 degrees. This will have to be done with printed parts. I am torn between spending/wasting any more time with this setup and going over to Haydens, or even some type of other joints/arms.

What do you all reckon will be mechanically more accurate - Hayden's magnets with a printed effector (I think I can use the metal carriages) or a metal effector with some other type of rod/joint.

Either of these options will enable me to extend the arms to 360mm which I think would be better for this bed size.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

What do you all reckon will be mechanically more accurate - Hayden's magnets with a printed effector (I think I can use the metal carriages) or a metal effector with some other type of rod/joint.

Either of these options will enable me to extend the arms to 360mm which I think would be better for this bed size.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 25, 2016 12:20PM |

Registered: 8 years ago Posts: 356 |

You can make your own effector in aluminum I did mine with a .125" plate, a little cutting and some bending (45 degree where the ball attach) and you are set. Its quite light take a look at berrybot effector I base mine on that and did it with a jigsaw and manual bending by hand, so far is doing the job.

Im using 10mm ball with thread inside and high temp 3/8 X 3/8 magnet in the arm, no disconnect so far, jerk at 1200 mm/min and I use 250 mm/sec at travel and print mostly at 60mm/sec ( never did a speed test so far so I dont know my max speed)

I have on the effector a e3d clone, 2X 40mm fan with double duct + the 30mm one

Im using 10mm ball with thread inside and high temp 3/8 X 3/8 magnet in the arm, no disconnect so far, jerk at 1200 mm/min and I use 250 mm/sec at travel and print mostly at 60mm/sec ( never did a speed test so far so I dont know my max speed)

I have on the effector a e3d clone, 2X 40mm fan with double duct + the 30mm one

|

Re: Large Kossel all metal delta build log October 25, 2016 02:25PM |

Registered: 8 years ago Posts: 3,525 |

That's a good solution, my home made metal constructions normally don't come out as good as that.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 25, 2016 04:30PM |

Registered: 8 years ago Posts: 3,525 |

So in an effort to keep the magnets from coming off so much I changed my autocalibration bed.g file to just probe the inner part of the bed and not the extremities. Managed to get a deviation after autocalibration of 0.006. This is more like it... and it shows what it should be capable of with decent arms that don't detach so much. Now to sort that out.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 25, 2016 10:37PM |

Registered: 8 years ago Posts: 916 |

I think that having the ball attached to the effector is a really good solution, from an engineering standpoint. I can't see how having the ball on the arms has any advantage.

Would it be possible to modify your existing effector to put the balls on the effector instead of the arms?

Good luck with your re-engineering.

Would it be possible to modify your existing effector to put the balls on the effector instead of the arms?

Good luck with your re-engineering.

|

Re: Large Kossel all metal delta build log October 26, 2016 02:22AM |

Registered: 8 years ago Posts: 3,525 |

Thanks. Yes it should be possible, that's probably what I will do if I try the Haydn magnets which are that way around.

But can you explain to me why it makes a difference? Unless I'm changing to stronger magnets surely reversing the components in the joint won't affect the strength of that joint or its range of movement.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

But can you explain to me why it makes a difference? Unless I'm changing to stronger magnets surely reversing the components in the joint won't affect the strength of that joint or its range of movement.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 26, 2016 03:42AM |

Registered: 8 years ago Posts: 916 |

The forces are always in line with the arms.

If the ball is fixed to the arm (like your current system) then the force can be up to 90 degrees away from the axis of the cup. This causes disconnects.

If the ball is fixed to the effector, then the force will always be in line with the axis of the cup, leading to much fewer disconnects.

If the ball is fixed to the arm (like your current system) then the force can be up to 90 degrees away from the axis of the cup. This causes disconnects.

If the ball is fixed to the effector, then the force will always be in line with the axis of the cup, leading to much fewer disconnects.

|

Re: Large Kossel all metal delta build log October 26, 2016 03:53AM |

Registered: 9 years ago Posts: 1,159 |

I'm thinking maybe use the Robot Digg alloy Effector and carriages with the balls mounted to them will have to do some experimenting to see what range of movement I would get by doing that think it could work quite well I'll mock one up with a printed effector (to use what I have) before commiting to purchasing some of Haydn's ball and delrin ends only thing is that I think I will need some bigger Carbon tube to what Haydn uses?

Doug

Doug

|

Re: Large Kossel all metal delta build log October 26, 2016 09:12AM |

Registered: 8 years ago Posts: 356 |

I dont know where hayden put his magnet but if its in the carbon tube so tube make contact with balls (you said you need bigger one) you should avoid that.

Having a proper cup made of nylon is a must and no need to have a cup surrounding the ball perfectly a 60 degree cone shape will do the trick , just calculate them with the right deep so the ball touch or even go through the back of the cone a little, then you adjust you magnet by shimming them or if they fit tight like me, just push them a little till the no more contact between ball and magnet this make sure you have a very minimal gap and maximum magnetic force. Trying to build a preset gap often turn not so precise and make a bigger gap .

Having a proper cup made of nylon is a must and no need to have a cup surrounding the ball perfectly a 60 degree cone shape will do the trick , just calculate them with the right deep so the ball touch or even go through the back of the cone a little, then you adjust you magnet by shimming them or if they fit tight like me, just push them a little till the no more contact between ball and magnet this make sure you have a very minimal gap and maximum magnetic force. Trying to build a preset gap often turn not so precise and make a bigger gap .

|

Re: Large Kossel all metal delta build log October 26, 2016 09:24AM |

Registered: 9 years ago Posts: 1,159 |

Quote

GroupB

I dont know where hayden put his magnet but if its in the carbon tube so tube make contact with balls (you said you need bigger one) you should avoid that.

Having a proper cup made of nylon is a must and no need to have a cup surrounding the ball perfectly a 60 degree cone shape will do the trick , just calculate them with the right deep so the ball touch or even go through the back of the cone a little, then you adjust you magnet by shimming them or if they fit tight like me, just push them a little till the no more contact between ball and magnet this make sure you have a very minimal gap and maximum magnetic force. Trying to build a preset gap often turn not so precise and make a bigger gap .

I was aware of this just trying to get a feel if Haydn's delrin cups will take 10 mm CF Tube I am contemplating getting some ends machined from PTFE which I think will be the most suitable material to use.

I can obtain magnets in all sorts of sizes etc locally so thats not an issue could go down to 8mm or even 7 on the cardon tube if need be but these arms will be 750mmm long?

Doug

|

Re: Large Kossel all metal delta build log October 26, 2016 09:45AM |

Registered: 10 years ago Posts: 14,672 |

Quote

nebbian

The forces are always in line with the arms.

Only if the arms have negligible mass and there is zero friction in the joints. I'm not convinced that zero friction is a valid assumption if you use magnetic joints with strong magnets.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Large Kossel all metal delta build log October 26, 2016 11:07AM |

Registered: 13 years ago Posts: 301 |

Quote

nebbian

I can't see how having the ball on the arms has any advantage.

When people put magnets on the rods the diameter of the magnet used is typically much smaller.

DJDemonD. If you put a ferrous set screw or other piece of metal in the bore of the countersunk magnet that is restrained to not quite touch the ball it will act as a pole piece to better direct the field. In my setup I get a doubling of attachment force.

|

Re: Large Kossel all metal delta build log October 26, 2016 01:09PM |

Registered: 9 years ago Posts: 1,159 |

DJ

I have found a localish supplier of magnets and can get 8mm dia x 8 long N42 with 2.5kG pull think that should do the job or there are plenty at 6dx10 long say with approx 1kG pull which may be safer.

They are about £1 each but in batches of 10.

Magnets and they are about 20 miles from me so can collect them.

What size are the ones on the K800 system?

Doug

I have found a localish supplier of magnets and can get 8mm dia x 8 long N42 with 2.5kG pull think that should do the job or there are plenty at 6dx10 long say with approx 1kG pull which may be safer.

They are about £1 each but in batches of 10.

Magnets and they are about 20 miles from me so can collect them.

What size are the ones on the K800 system?

Doug

|

Re: Large Kossel all metal delta build log October 27, 2016 03:50AM |

Registered: 8 years ago Posts: 3,525 |

@billyzelsnack - thanks for the tip, I will try that its a quick and simple fix.

@Dougal1957 - the k800 magnets are 12mm x3mm countersunk, I've ordered some N50 magnets in this size, which supposedly offer much higher holding force, but I think a big part of the problem is the orientation of the magnets in the effector.

So for now I am going to try to re-orientate the magnets in the effector using some printed additional parts. Change them for these newer (supposedly stronger - though I don't know the strength of the k800 magnets supplied), and I'll certainly try billyzelsnack's idea with the screws on the effector magnets, wont be able to do this on the carriages without removing the magnets which I am told is not very easy to do.

I've ordered a set of Haydn's arms/magnets which might necessitate a printed effector/carriages for now.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

@Dougal1957 - the k800 magnets are 12mm x3mm countersunk, I've ordered some N50 magnets in this size, which supposedly offer much higher holding force, but I think a big part of the problem is the orientation of the magnets in the effector.

So for now I am going to try to re-orientate the magnets in the effector using some printed additional parts. Change them for these newer (supposedly stronger - though I don't know the strength of the k800 magnets supplied), and I'll certainly try billyzelsnack's idea with the screws on the effector magnets, wont be able to do this on the carriages without removing the magnets which I am told is not very easy to do.

I've ordered a set of Haydn's arms/magnets which might necessitate a printed effector/carriages for now.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 27, 2016 06:30PM |

Registered: 8 years ago Posts: 3,525 |

Okay so I ordered some N50 strength 12mm countersunk magnets 3mm thick. When they arrived I tested them versus the magnets on the k800 effector by attaching one of the new magnets at one end of an arm and the old magnet at the other and pulled them apart. The old magnets won the tug of war everytime, even when I added a 12x2mm disc magnet to the new countersunk magnets.

So I decided to test the theory about the magnet on the effector being better at 45 deg to the build plate rather than 0.

I printed some small adaptors to change the angle of the magnets, bonded them into the effector with superglue. effectormod45degmagnets.stl

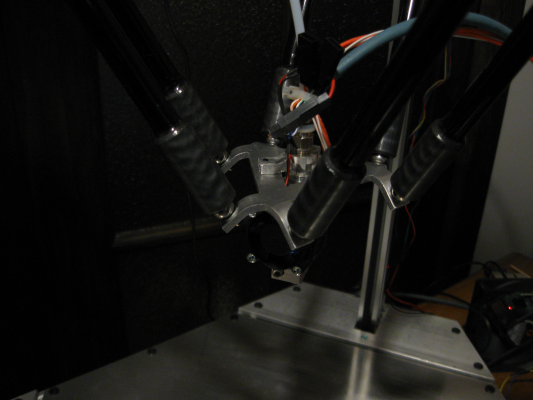

This is how it used to look.

This is how it looks now.

I am currently printing a cube to test it at 200% speed (120mm/s) and the magnets seem to be holding. So after very limited testing I would not recommend flat magnets in the effector, however flat balls as in Haydn's setup might work as the magnets are in the arms.

Worthy of note these extensions make the build height around 10mm less, so adjust your homed height before proceeding if you don't want a nasty divot in your print bite - first time I've actually managed to damage it (nozzle was at 250 when I smashed it into the printbite hard). No other damage thankfully.

I have some Haydn Huntley arms and magnets/balls on order so I will print an effector and carriages when they arrive and test them, that way I will have two alternative setups to use. I was intending to adapt the k800 setup to take Haydn's arms but I would not be able to go back (or sell the k800 setup on if Haydn's turns out to be better).

Looking at these makes me wonder if they would work even better if they were essentially cups and offered a degree of mechanical attachment to the balls also.

Edited 2 time(s). Last edit at 10/28/2016 09:13AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So I decided to test the theory about the magnet on the effector being better at 45 deg to the build plate rather than 0.

I printed some small adaptors to change the angle of the magnets, bonded them into the effector with superglue. effectormod45degmagnets.stl

This is how it used to look.

This is how it looks now.

I am currently printing a cube to test it at 200% speed (120mm/s) and the magnets seem to be holding. So after very limited testing I would not recommend flat magnets in the effector, however flat balls as in Haydn's setup might work as the magnets are in the arms.

Worthy of note these extensions make the build height around 10mm less, so adjust your homed height before proceeding if you don't want a nasty divot in your print bite - first time I've actually managed to damage it (nozzle was at 250 when I smashed it into the printbite hard). No other damage thankfully.

I have some Haydn Huntley arms and magnets/balls on order so I will print an effector and carriages when they arrive and test them, that way I will have two alternative setups to use. I was intending to adapt the k800 setup to take Haydn's arms but I would not be able to go back (or sell the k800 setup on if Haydn's turns out to be better).

Looking at these makes me wonder if they would work even better if they were essentially cups and offered a degree of mechanical attachment to the balls also.

Edited 2 time(s). Last edit at 10/28/2016 09:13AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 28, 2016 12:28PM |

Registered: 8 years ago Posts: 356 |

Be aware that N50 or N42 only go to 80C and after that they will lose they magnetic and wont be magnet anymore... Since your magnet are closer to the bed because they are on effector watch out for that. That the reason I chose 42SH magnet they pull (7.86lbs) 2 lbs less than the N42 version of the same size but go to 150C if I want to enclose or something.

Im pretty sure you will go for the plastic cup magnet and ball on the effector they are superior and can be adjust ( drill a bigger hole and you can move the ball on the effector for perfect alignement, right now you have what magnet to magnet contact ? I suppose your countersunk are magnet.. that not good on friction and wear.

Those K800 magnectic and others exotic configuration joint are one reason why people think magnetic joint are a poor choice, but when its done properly magnetic joint are quite good and offer no backlash.

So good on you for keep trying and not put them in garbage already and then call magnetic joint bad

Im pretty sure you will go for the plastic cup magnet and ball on the effector they are superior and can be adjust ( drill a bigger hole and you can move the ball on the effector for perfect alignement, right now you have what magnet to magnet contact ? I suppose your countersunk are magnet.. that not good on friction and wear.

Those K800 magnectic and others exotic configuration joint are one reason why people think magnetic joint are a poor choice, but when its done properly magnetic joint are quite good and offer no backlash.

So good on you for keep trying and not put them in garbage already and then call magnetic joint bad

|

Re: Large Kossel all metal delta build log October 28, 2016 12:35PM |

Registered: 8 years ago Posts: 3,525 |

I love the idea of magnetic joints and I'm looking forwards to trying the other variant. The theory is sound regarding backlash. I grease the magnets and balls to lower friction.To be honest despite only very basic testing yesterday this new configuration is much better I'd would definitely have had magnets disconnecting at 120mm/s before. So for now I'm reasonably happy.

As for heat my effector is nowhere near 80 deg C, but I'll check how hot it is later on.

If the Haydn setup works well, I might see about getting metal versions of his effector and carriages made.

Edited 2 time(s). Last edit at 10/28/2016 12:44PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

As for heat my effector is nowhere near 80 deg C, but I'll check how hot it is later on.

If the Haydn setup works well, I might see about getting metal versions of his effector and carriages made.

Edited 2 time(s). Last edit at 10/28/2016 12:44PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 28, 2016 06:39PM |

Registered: 8 years ago Posts: 356 |

I did my first speed test about 10 minute ago just for the fun of it see what I get. Acel 2500 mm/m, max speed 1200 (reprapfirmware for jerk I guess) travel at 230mm/sec. I did some small half cube at 60,80,100 and 120 mm/sec 100% speed on everything wall,infill only first layer was cut down to 50%. The result are great the wall are still perfect even at 120mm/sec the problem are the corner they are not sharp anymore kinda elephant feet ( maybe my jerk at 1200 is too low I hear it should be half the max speed) and at 120 the last infill was not looking as good as 60 or even 100.

Im gonna boost my acel to 3000 or 3500 and keep trying those 60,80,100,120 see what happen with the magnet or my frame if everything go right I will go higher than 120 till I hit the wall or something crap on me. My guess will be the hotend will not be able to follow the speed before the magnet crap on me.

Im gonna boost my acel to 3000 or 3500 and keep trying those 60,80,100,120 see what happen with the magnet or my frame if everything go right I will go higher than 120 till I hit the wall or something crap on me. My guess will be the hotend will not be able to follow the speed before the magnet crap on me.

|

Re: Large Kossel all metal delta build log October 29, 2016 03:43AM |

Registered: 8 years ago Posts: 3,525 |

I'd check your values, when you say max speed 1200 reprap for jerk that's not correct.

This part of my config.g which deals with speeds.

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z15000 E3600 ; Maximum speeds (mm/min)

M566 X800 Y800 Z800 E1200 ; Maximum instant speed changes mm/minute (JERK)

So jerk is the one at the bottom maximum instant speed changes.

So if you have max speed at 1200, an acceleration of 2500 isnt going to do much you'll never go that fast anyway.

I am not getting rounded corners with the settings above.

Printed at 120mm/s.

Edited 2 time(s). Last edit at 10/29/2016 03:46AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

This part of my config.g which deals with speeds.

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z15000 E3600 ; Maximum speeds (mm/min)

M566 X800 Y800 Z800 E1200 ; Maximum instant speed changes mm/minute (JERK)

So jerk is the one at the bottom maximum instant speed changes.

So if you have max speed at 1200, an acceleration of 2500 isnt going to do much you'll never go that fast anyway.

I am not getting rounded corners with the settings above.

Printed at 120mm/s.

Edited 2 time(s). Last edit at 10/29/2016 03:46AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 29, 2016 05:05AM |

Registered: 8 years ago Posts: 916 |

|

Re: Large Kossel all metal delta build log October 29, 2016 05:41AM |

Registered: 8 years ago Posts: 3,525 |

Edit ought to say that's a 40x40x20 cube.

Thanks Nebbian, that's 0.2mm layers. It is really precise, and now the magnets are holding I can start pushing it a bit.

I'd be disappointed if I were getting less precision, although my best calibration deviation is 0.02 now I have the printed magnet holders, before the best I managed was 0.006.

Its the combination of very stiff frame, linear rails, steel belts and metal carriages/effector, there just isn't any lash/backlash/play in anything. I think the TMC2100s help too. It's nice to see it performing as it should.

What's interesting though is although my mini kossel now seems to have all the rigidity of a wet noodle in comparison, it still produces parts that are only marginally less good than this new machine, the law of dimishing returns being demonstrated very clearly there.

I'm also pleased the new machine will go fast too, as you know I'm not an advocate of the super precise printer achieved by over-engineering, with axes so heavy they barely move. That's why I love deltas (and corexy's) - fast and accurate.

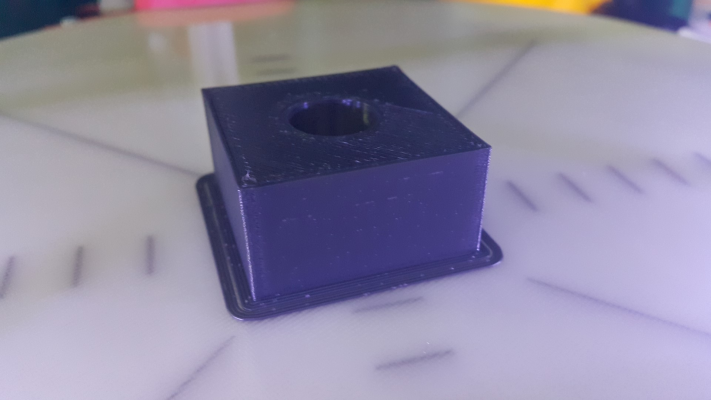

Printed these for my son this morning again 0.2mm layers, abs, 90mm/s, these are 20x20 at the base, slightly under extruding around the perimeter on the base but otherwise fairly pleased. Printed some thumb wheels for the bed clamps, m4 slotted machine screws and they literally just fit perfectly over the screw heads.

I've got some 0.2mm nozzles now so I might have a try printing some really tiny stuff. Seems ironic that the best printer I have for really small stuff is also the largest. I fancy making a micro delta printer now. Be interesting to see if I use all the same precision components for a delta 60% scale of a mini kossel how precise it might print.

Edited 1 time(s). Last edit at 10/29/2016 05:47AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Thanks Nebbian, that's 0.2mm layers. It is really precise, and now the magnets are holding I can start pushing it a bit.

I'd be disappointed if I were getting less precision, although my best calibration deviation is 0.02 now I have the printed magnet holders, before the best I managed was 0.006.

Its the combination of very stiff frame, linear rails, steel belts and metal carriages/effector, there just isn't any lash/backlash/play in anything. I think the TMC2100s help too. It's nice to see it performing as it should.

What's interesting though is although my mini kossel now seems to have all the rigidity of a wet noodle in comparison, it still produces parts that are only marginally less good than this new machine, the law of dimishing returns being demonstrated very clearly there.

I'm also pleased the new machine will go fast too, as you know I'm not an advocate of the super precise printer achieved by over-engineering, with axes so heavy they barely move. That's why I love deltas (and corexy's) - fast and accurate.

Printed these for my son this morning again 0.2mm layers, abs, 90mm/s, these are 20x20 at the base, slightly under extruding around the perimeter on the base but otherwise fairly pleased. Printed some thumb wheels for the bed clamps, m4 slotted machine screws and they literally just fit perfectly over the screw heads.

I've got some 0.2mm nozzles now so I might have a try printing some really tiny stuff. Seems ironic that the best printer I have for really small stuff is also the largest. I fancy making a micro delta printer now. Be interesting to see if I use all the same precision components for a delta 60% scale of a mini kossel how precise it might print.

Edited 1 time(s). Last edit at 10/29/2016 05:47AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 29, 2016 01:15PM |

Registered: 8 years ago Posts: 356 |

My M566 its at 1200 and my max speed is 20000 I think good for 333 mm/sec acel its a 2500 and im planing to go higher to see what happen. Off course with an accel of 1000 I should not have round corner, even at 2500 and print 80mm/sec I dont have them.

Im at 2500 acel since a couple month but I usally print at 70 and lower the last wall to 65% and top bottom infill to 60% , those test where I end up with last wall overextend the axe were down without reduce the % of last walls.

The print you done at 120mm\sec probably never get close to 120 with a 1000 acel , you dont have time to reach it on a small part like that even on a large part you will slowly acel get to 120 for a limited time then decel. Get your acel a least to 2000 or 2500 must delta aim for 3000 but dont go 3000 @ 120mm/sec right away its start to get crazy fast at that acel and your frame may wooble around or magnet detach.

That the reason i do 60,80,100,120 test at each acel setting. When I know the limit of the magnet or extruder (my frame wont wooble im sure) I will dial down the % of wall and top and bottom infill a little or play with jerk to regain corner and top surface quality.

Keep an eye on those metal filled belt , i hear they no good on tight pulley like 20 tooth, they will break quicker than carbon fillled one and may require to be replace more often.

Edited 2 time(s). Last edit at 10/30/2016 05:22PM by GroupB.

Im at 2500 acel since a couple month but I usally print at 70 and lower the last wall to 65% and top bottom infill to 60% , those test where I end up with last wall overextend the axe were down without reduce the % of last walls.

The print you done at 120mm\sec probably never get close to 120 with a 1000 acel , you dont have time to reach it on a small part like that even on a large part you will slowly acel get to 120 for a limited time then decel. Get your acel a least to 2000 or 2500 must delta aim for 3000 but dont go 3000 @ 120mm/sec right away its start to get crazy fast at that acel and your frame may wooble around or magnet detach.

That the reason i do 60,80,100,120 test at each acel setting. When I know the limit of the magnet or extruder (my frame wont wooble im sure) I will dial down the % of wall and top and bottom infill a little or play with jerk to regain corner and top surface quality.

Keep an eye on those metal filled belt , i hear they no good on tight pulley like 20 tooth, they will break quicker than carbon fillled one and may require to be replace more often.

Edited 2 time(s). Last edit at 10/30/2016 05:22PM by GroupB.

|

Re: Large Kossel all metal delta build log October 29, 2016 02:59PM |

Registered: 13 years ago Posts: 301 |

|

Re: Large Kossel all metal delta build log October 29, 2016 04:19PM |

Registered: 8 years ago Posts: 356 |

|

Re: Large Kossel all metal delta build log October 30, 2016 04:25PM |

Registered: 8 years ago Posts: 3,525 |

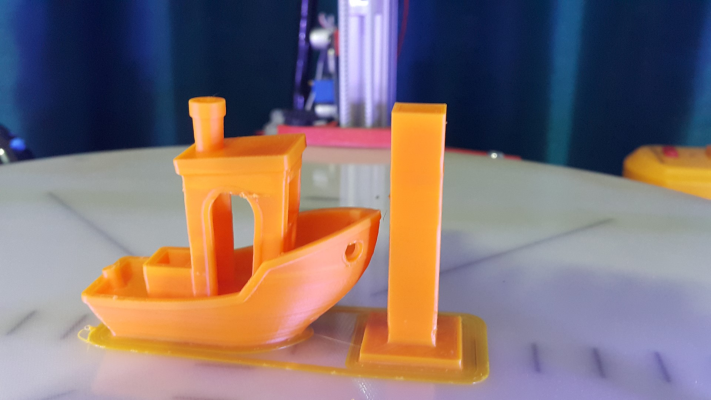

Well I did increase my acceleration to 2500 and it was a lot quicker. Attempted a Benchy at 90mm/s and it made it to nearly the funnel/chimney on top before knocking the part off the build plate and a magnet becoming detached. So back to some detailed extrusion tuning and it was over extruding by a few %.

So here's another this time at 60mm/s, in ABS, 0.1mm layer height.

A few slight blemishes in places.

Might get to work printing some carriages and an effector for the Haydn magnets, although these K800 ones are better now, they have zero tolerance for slight over-extrusion or blobs, which there are going to be a few of.

Edited 1 time(s). Last edit at 10/30/2016 04:34PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So here's another this time at 60mm/s, in ABS, 0.1mm layer height.

A few slight blemishes in places.

Might get to work printing some carriages and an effector for the Haydn magnets, although these K800 ones are better now, they have zero tolerance for slight over-extrusion or blobs, which there are going to be a few of.

Edited 1 time(s). Last edit at 10/30/2016 04:34PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log October 30, 2016 05:21PM |

Registered: 8 years ago Posts: 356 |

Wait till you try 3500+ its start to get crazy fast, I think I have to play with jerk a little since my circle are very bad at that accel , its like its stopping at each little section of the circle

2500 accel , 60mm/sec is the speed I used for several month, for me its a perfect print all the time.

Try printing the benchy in PLA in .2mm, pla show the detail better than ABS, its easier to see whats up and what to tune.

So far there couple blob all around the benchy you may work a little on your retraction whats software are you using ? 5mm at 60mm/sec ( if direct drive) is a good starting value for a e3d original or clone.

Make use of the M221 SXXX command to modify the extruder flow in real time when you see you over or under extrude its quite useful and will give you a multi value to use next time in your software base on the % add or remove.

2500 accel , 60mm/sec is the speed I used for several month, for me its a perfect print all the time.

Try printing the benchy in PLA in .2mm, pla show the detail better than ABS, its easier to see whats up and what to tune.

So far there couple blob all around the benchy you may work a little on your retraction whats software are you using ? 5mm at 60mm/sec ( if direct drive) is a good starting value for a e3d original or clone.

Make use of the M221 SXXX command to modify the extruder flow in real time when you see you over or under extrude its quite useful and will give you a multi value to use next time in your software base on the % add or remove.

|

Re: Large Kossel all metal delta build log October 30, 2016 05:45PM |

Registered: 8 years ago Posts: 3,525 |

Thanks for the tips. Yeah I think until I have better arms/magnets I will give 3500 accel. a miss.

I can print one in PLA @ 0.2mm sure.

The retraction is 1.8mm at 50mm/s as its an E3D v6 genuine but a flying extruder so my bowden tube is only 15cm.

I think its extruding fairly close to the optimum.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I can print one in PLA @ 0.2mm sure.

The retraction is 1.8mm at 50mm/s as its an E3D v6 genuine but a flying extruder so my bowden tube is only 15cm.

I think its extruding fairly close to the optimum.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.