Large Kossel all metal delta build log

Posted by DjDemonD

|

Re: Large Kossel all metal delta build log January 18, 2017 10:41AM |

Registered: 8 years ago Posts: 3,525 |

No I bought about 20m from a German or Dutch ebay seller advertised as pu/kevlar but they were neoprene/fibre. Not too pricey and decent belts but not what was advertised, I suspect he/she doesn't know the difference. I'm using them now. Maybe from Gates direct?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log January 28, 2017 07:33PM |

Registered: 8 years ago Posts: 3,525 |

Now using piezo z-probe sensor [www.thingiverse.com]

Beta version now released. Looking to get some feedback on it from as many people as possible.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Beta version now released. Looking to get some feedback on it from as many people as possible.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log February 05, 2017 05:31PM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log February 05, 2017 05:32PM |

Registered: 8 years ago Posts: 3,525 |

What specifically of the piezo sensor?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log February 06, 2017 02:56PM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log February 06, 2017 03:05PM |

Registered: 8 years ago Posts: 3,525 |

Reasonable request but it isn't the best way to measure this. I was getting calibration deviation with the IR sensor of 0.05 and now I'm getting 0.02 with the piezo sensor. The real difference in print quality between these two levels of calibration is very small. You might notice the difference in terms of ability to print a good first layer at the extremities or the dimensions of objects printed near the extremities but print a cube or a marvin in the centre and you aren't going to see any difference at all.

The real reason for doing this is to use the nozzle as a probe for all the good reasons I have listed here/elsewhere: its independent of the surface being probed, its got no offset, effector tilt has no bearing on probing (but will still affect objects at the extremities where tilt is greatest), and its very sensitive.

The quest for a perfect z probe is ongoing and whilst this is not the perfect z-probe its closer IMO than any that have come before it. As has been pointed out, if the bed were metal, you could just send a 5v signal through the nozzle to the bed. That would be perfect, but the bed is usually covered in some sort of polymer like PEI, printbite etc.. or glue/hairpsray/3dlac which would render it non-conductive or poorly conductive.

If you have seen Thomas Sandladerer's review/Q&A on the Ultimaker 3 their new solution is to have sprung glass build plate, under neath it some sort of sensor which detects the glass being pushed down by the nozzle. Until full details of how this is done are available I wont know if the piezo approach is better or their new method is the best.

Edited 1 time(s). Last edit at 02/06/2017 03:08PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

The real reason for doing this is to use the nozzle as a probe for all the good reasons I have listed here/elsewhere: its independent of the surface being probed, its got no offset, effector tilt has no bearing on probing (but will still affect objects at the extremities where tilt is greatest), and its very sensitive.

The quest for a perfect z probe is ongoing and whilst this is not the perfect z-probe its closer IMO than any that have come before it. As has been pointed out, if the bed were metal, you could just send a 5v signal through the nozzle to the bed. That would be perfect, but the bed is usually covered in some sort of polymer like PEI, printbite etc.. or glue/hairpsray/3dlac which would render it non-conductive or poorly conductive.

If you have seen Thomas Sandladerer's review/Q&A on the Ultimaker 3 their new solution is to have sprung glass build plate, under neath it some sort of sensor which detects the glass being pushed down by the nozzle. Until full details of how this is done are available I wont know if the piezo approach is better or their new method is the best.

Edited 1 time(s). Last edit at 02/06/2017 03:08PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log February 06, 2017 03:47PM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log February 08, 2017 07:19AM |

Registered: 8 years ago Posts: 3,525 |

Update: Changed the flying extruder to a lighter and smarter bracket, thicker elastic. Have added these parts to thingiverse [www.thingiverse.com].

Tried RC car shock absorbers but unlike Nebbians shock design they are meant to be compressed not extended, so next step, make some like Nebbians.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Tried RC car shock absorbers but unlike Nebbians shock design they are meant to be compressed not extended, so next step, make some like Nebbians.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log February 08, 2017 03:51PM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log February 08, 2017 04:29PM |

Registered: 8 years ago Posts: 3,525 |

Fair enough, you could try a cable driven extruder, or use bowden but I've been down that route a few times and was thoroughly unsatisfied with time every time.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log February 18, 2017 08:56PM |

Registered: 8 years ago Posts: 601 |

|

Re: Large Kossel all metal delta build log February 19, 2017 03:34AM |

Registered: 8 years ago Posts: 3,525 |

I love cable driven extruders, I have a flex3drive and I have been very happy with it, and I've got a Nimble on order and looking forward to trying that too.

Its Bowden extruders I don't like. I've softened my position on them lately as I realised I never really gave them a chance, and didn't tune them really well. Things like pressure advance in the firmware do make bowdens less bad.

But to sum it up:

-long tubes are exponentially worse than short ones

-friction is always more than you want

-the filament can't fit precisely in the bowden tube without too much friction

-the filament bends in the tube

-the filament depending on material stretches and compresses in the tube

So if there was a zero friction bowden tube, exactly 0.01mm larger than the filament, and the filament were not elastic then they would work perfectly.

Sorry got my rant on.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Its Bowden extruders I don't like. I've softened my position on them lately as I realised I never really gave them a chance, and didn't tune them really well. Things like pressure advance in the firmware do make bowdens less bad.

But to sum it up:

-long tubes are exponentially worse than short ones

-friction is always more than you want

-the filament can't fit precisely in the bowden tube without too much friction

-the filament bends in the tube

-the filament depending on material stretches and compresses in the tube

So if there was a zero friction bowden tube, exactly 0.01mm larger than the filament, and the filament were not elastic then they would work perfectly.

Sorry got my rant on.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log March 04, 2017 02:59AM |

Registered: 8 years ago Posts: 3,525 |

Also now using these carriages made by Dougal1957.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log March 05, 2017 11:01AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Large Kossel all metal delta build log March 05, 2017 11:04AM |

Registered: 8 years ago Posts: 3,525 |

Hi Doug. Fine, they are very nice. If I am honest they haven't changed anything, it calibrates and prints the same as before. But coupled with eventually a metal effector (be keen to hear how you get on with your nylon one), they would make a difference. I like the rod spacing it looks right on a machine this size.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log May 19, 2017 03:51AM |

Registered: 8 years ago Posts: 3,525 |

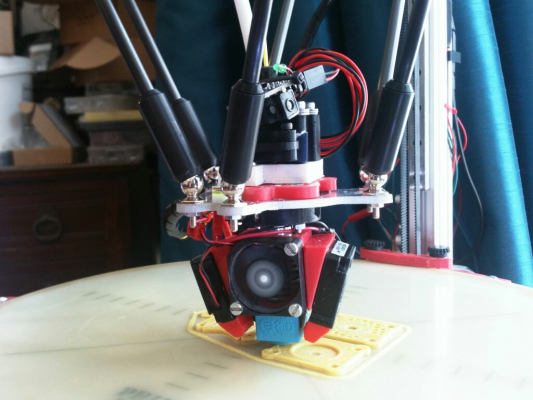

So just a little update, after Kraegar on Duet forum pointed out that he noticed a bit more effector tilt seemed to occur with flying extruders, I have done away with mine and put a flex3drive on the effector. This has been a great upgrade in that not only do I now have direct extrusion on the machine but I also got rid of the lateral forces being imparted from the flying extruder bowden tube. As such now the machine (over 200mm of its 300mm bed) calibrates on RRF to 0.009mm. Which is the lowest (and therefore most accurate) calibration I have ever achieved.

Plus with DuetWifi being able to happily run the flex3drive at 1/16th microstepping with interpolation, I have a very quiet extruder too.

I will post a photo later, so far its just a quick mash together of parts, but I will design a piezo-integrated base for the flex3drive (kossel mini version that I have) which fits the dougal1957 metal effector.

Edited 1 time(s). Last edit at 05/19/2017 03:53AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Plus with DuetWifi being able to happily run the flex3drive at 1/16th microstepping with interpolation, I have a very quiet extruder too.

I will post a photo later, so far its just a quick mash together of parts, but I will design a piezo-integrated base for the flex3drive (kossel mini version that I have) which fits the dougal1957 metal effector.

Edited 1 time(s). Last edit at 05/19/2017 03:53AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log May 19, 2017 08:47AM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log May 19, 2017 12:14PM |

Registered: 8 years ago Posts: 3,525 |

At present piezo board is just lashed on. Planning to also raise the hotend, integrate the flex3drive and the piezo disc, and have a mounting point for the piezo board.

Edited 1 time(s). Last edit at 05/19/2017 12:14PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log May 24, 2017 01:04PM |

Registered: 9 years ago Posts: 425 |

Looking good there DJDemonD, if you need files or support just ping me.

Flex3Drive.com

Quote

DjDemonD

[attachment 94332 CameraZOOM-2017051913574128701.jpg]

At present piezo board is just lashed on. Planning to also raise the hotend, integrate the flex3drive and the piezo disc, and have a mounting point for the piezo board.

Flex3Drive.com

|

Re: Large Kossel all metal delta build log May 27, 2017 04:56PM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log May 27, 2017 05:39PM |

Registered: 8 years ago Posts: 3,525 |

It should be and I think it's just that kossel corners (in my case) come with 6mm smooth pulleys. Plus 6mm drive pulleys are much more common and probably cheaper. 9mm belts must offer some improvement

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log May 27, 2017 06:26PM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log May 27, 2017 06:51PM |

Registered: 7 years ago Posts: 232 |

|

Re: Large Kossel all metal delta build log July 11, 2017 05:42AM |

Registered: 8 years ago Posts: 3,525 |

Just a quick update to say I ordered from Keenovo (ali/ebay) a 260mm 400w silicone heater. The shenzen alibrother one I have fiftted now (decided to buy it just following DC42's build) is not great, the adhesive was not 3M as advertised but a Chinese brand, which has peeled away centrally creating a potentially dangerous hot spot, where the heat from the pad doesn't dissipate into the aluminium plate. I solved it by having a metal plate underneath to press it upwards.

Its smaller so the edges won't interfere with the bed mounts, although I will have to check the edges of the bed are not too much cooler than the centre. Also 400w rather than 500w as my current heater heats very rapidly and is probably a little overpowered for its size.

Also I recently ordered a keenovo heater for another printer and the build quality and attention to detail was excellent, the price difference is barely noticeable.

Edited 1 time(s). Last edit at 07/11/2017 06:05AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Its smaller so the edges won't interfere with the bed mounts, although I will have to check the edges of the bed are not too much cooler than the centre. Also 400w rather than 500w as my current heater heats very rapidly and is probably a little overpowered for its size.

Also I recently ordered a keenovo heater for another printer and the build quality and attention to detail was excellent, the price difference is barely noticeable.

Edited 1 time(s). Last edit at 07/11/2017 06:05AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log July 20, 2017 03:23PM |

Registered: 8 years ago Posts: 3,525 |

Keenovo heater fitted and I am very pleased with it. Quality is awesome, keeping it away from the edges has made mounting it easier, it heats up nicely. Might have to calculate the b value for the thermistor as I am not sure what brand it is, but thats easy enough. Quite an effort scraping away the old adhesive and some nasty burn marks on the underside of the old heater, so watch out.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log July 25, 2017 04:01AM |

Registered: 9 years ago Posts: 1,159 |

Simon

I have the data sheet for the Keenovo Thermistor if you need it the B Value is 3950 25/50 I did work it out for a 25/100 which was IIRC 4008.

My new build has a 320mm diam one on it with a 10mm hole in the Centre Which allows me to fir the Temp sensor directly in the Bed material in the centre of the bed (The Keenovo ones tend to be the other side of the pad and the shenzen ones right at the edge is also not ideal)

Doug

I have the data sheet for the Keenovo Thermistor if you need it the B Value is 3950 25/50 I did work it out for a 25/100 which was IIRC 4008.

My new build has a 320mm diam one on it with a 10mm hole in the Centre Which allows me to fir the Temp sensor directly in the Bed material in the centre of the bed (The Keenovo ones tend to be the other side of the pad and the shenzen ones right at the edge is also not ideal)

Doug

|

Re: Large Kossel all metal delta build log July 25, 2017 04:43AM |

Registered: 8 years ago Posts: 3,525 |

Thanks Doug.

I went about it slightly differently I placed a k-type thermocouple under some insulation with a heavy object on top of it, on the bed top surface (printbite in my case) , heated it up to the actual 115 deg C I normally print abs at and then adjusted the B value on the fly to match the indicated temperature to the actual bed surface temperature. It works out at around B 4350.

Now I know this isn't the "proper" way to do it, but it means when I ask for 115 deg C I get 115 deg C. I do not get very accurate temperatures at lower ranges, so my 70 degrees setting is actually about 75, but I can live with that.

I am probably going to use AndOrNot's surface a lot more in the future it really holds ABS and everything else at much lower temperatures i.e. 60-70 deg C. It just doesnt release quite as easily as Printbite but its cheap £14.50 per 12x12" sheet, with 3m adhesive.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I went about it slightly differently I placed a k-type thermocouple under some insulation with a heavy object on top of it, on the bed top surface (printbite in my case) , heated it up to the actual 115 deg C I normally print abs at and then adjusted the B value on the fly to match the indicated temperature to the actual bed surface temperature. It works out at around B 4350.

Now I know this isn't the "proper" way to do it, but it means when I ask for 115 deg C I get 115 deg C. I do not get very accurate temperatures at lower ranges, so my 70 degrees setting is actually about 75, but I can live with that.

I am probably going to use AndOrNot's surface a lot more in the future it really holds ABS and everything else at much lower temperatures i.e. 60-70 deg C. It just doesnt release quite as easily as Printbite but its cheap £14.50 per 12x12" sheet, with 3m adhesive.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log July 25, 2017 05:36AM |

Registered: 9 years ago Posts: 1,159 |

Ah LokBuild yes it is made not to far from me and in fact I did contact them for larger pieces some time ago and they were looking into it but never did come back to me so maybe worth me dropping them another line.

I would need 16x16 inch piece for this new machine. (360mm diam bed). Ah on further checking see that AndOrNot do a 17inch square one now maybe worth a try

Currently getting deviation's of 6-7 microns using a pre-production DC42 PCB Effector.

Doug

Edited 1 time(s). Last edit at 07/25/2017 05:59AM by dougal1957.

I would need 16x16 inch piece for this new machine. (360mm diam bed). Ah on further checking see that AndOrNot do a 17inch square one now maybe worth a try

Currently getting deviation's of 6-7 microns using a pre-production DC42 PCB Effector.

Doug

Edited 1 time(s). Last edit at 07/25/2017 05:59AM by dougal1957.

|

Re: Large Kossel all metal delta build log July 25, 2017 06:13AM |

Registered: 8 years ago Posts: 3,525 |

This is the stuff I have been trying [www.andornot.co.uk]

Not sure if he can do it in larger sheets, 12x12 is big enough for me. I wrote up my findings on his thread here, and Jinx did a test and linked to the write up. PLA sticks to it cold. PETG and ABS need a surface temperature of about 55-60 degrees and not too much squash down or they are hard to remove.

I think I will keep it as a reserve to place on the bed when I need extra adhesion for a difficult part. A bit like the PEI I tested for you, its very strong adhesion is great when you really need it, and at this price it might be almost considered disposable under some circumstances. Shame its very tricky to debond it and clean up the adhesive afterwards, with any of these surfaces.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Not sure if he can do it in larger sheets, 12x12 is big enough for me. I wrote up my findings on his thread here, and Jinx did a test and linked to the write up. PLA sticks to it cold. PETG and ABS need a surface temperature of about 55-60 degrees and not too much squash down or they are hard to remove.

I think I will keep it as a reserve to place on the bed when I need extra adhesion for a difficult part. A bit like the PEI I tested for you, its very strong adhesion is great when you really need it, and at this price it might be almost considered disposable under some circumstances. Shame its very tricky to debond it and clean up the adhesive afterwards, with any of these surfaces.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Large Kossel all metal delta build log July 29, 2017 09:44AM |

Registered: 10 years ago Posts: 651 |

Sorry, only registered users may post in this forum.