Proper way of assembling Traxxs ball ends.

Posted by janpenguin

|

Proper way of assembling Traxxs ball ends. October 05, 2016 05:06AM |

Registered: 9 years ago Posts: 189 |

Delta robot 3D printers ›

Traxxas join assembly magic

By Doug LaRue

Press fitting will create premature failure of the ball end.

Traxxas join assembly magic

By Doug LaRue

- Put all metal balls in freeze compartment of the refrigirator for ten to twenty minutes. - Prepare hot water in a cup where you will put the plasic rod end - Put couple plastic rod ends in the cup to warm up and take out equal number of metal balls from the refrigirator - Gently press one metal ball into a rod end

Press fitting will create premature failure of the ball end.

|

Re: Proper way of assembling Traxxs ball ends. October 05, 2016 07:39AM |

Registered: 10 years ago Posts: 14,672 |

I found it helpful to print this assembly tool [www.thingiverse.com]. If I were doing it again, I would buy and assemble 24 joints, then pick 12 with no play in them to use.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Proper way of assembling Traxxs ball ends. October 05, 2016 10:07PM |

Registered: 8 years ago Posts: 916 |

Also ensure that you press the ball into the correct side of the rod end. There is a side that doesn't have as thick a lip -- you need to insert the ball into that side. Inserting into the wrong side will damage the rod end.

I wrote a full write-up halfway down this page:

[forums.reprap.org]

I wrote a full write-up halfway down this page:

[forums.reprap.org]

|

Re: Proper way of assembling Traxxs ball ends. October 07, 2016 03:04AM |

Registered: 9 years ago Posts: 483 |

|

Re: Proper way of assembling Traxxs ball ends. October 07, 2016 02:17PM |

Registered: 10 years ago Posts: 732 |

|

Re: Proper way of assembling Traxxs ball ends. October 12, 2016 10:51PM |

Registered: 7 years ago Posts: 21 |

|

Re: Proper way of assembling Traxxs ball ends. October 16, 2016 12:28PM |

Registered: 8 years ago Posts: 23 |

|

Re: Proper way of assembling Traxxs ball ends. October 16, 2016 09:00PM |

Registered: 8 years ago Posts: 916 |

TheHebs,

Yes I saw that, and winced. Why would you put the balls into the rod end _after_ you glue the rod ends to the carbon? Also the top picture shows the ball being inserted into the wrong side of the rod end.

I don't know about yours, but a couple of my traxxas ends had a bit of slop, even after assembling them correctly. I had to use 14 ends to make 12 good ones. There's no way of telling before you put the balls in. I know that others have had the same problem.

Do any of your ends have any slop? Perhaps it's not such a big deal on a large printer.

Edited 2 time(s). Last edit at 10/16/2016 09:02PM by nebbian.

Yes I saw that, and winced. Why would you put the balls into the rod end _after_ you glue the rod ends to the carbon? Also the top picture shows the ball being inserted into the wrong side of the rod end.

I don't know about yours, but a couple of my traxxas ends had a bit of slop, even after assembling them correctly. I had to use 14 ends to make 12 good ones. There's no way of telling before you put the balls in. I know that others have had the same problem.

Do any of your ends have any slop? Perhaps it's not such a big deal on a large printer.

Edited 2 time(s). Last edit at 10/16/2016 09:02PM by nebbian.

|

Re: Proper way of assembling Traxxs ball ends. October 16, 2016 10:52PM |

Registered: 8 years ago Posts: 23 |

|

Re: Proper way of assembling Traxxs ball ends. October 16, 2016 11:04PM |

Registered: 8 years ago Posts: 23 |

|

Re: Proper way of assembling Traxxs ball ends. October 17, 2016 09:27PM |

Registered: 7 years ago Posts: 21 |

I just came here to say I discovered something useful with the driver end but someone already posted it.

But, I do have my own addition to it that maybe is useful. I have one of these short multibit stanley screwdrivers, the socket is only 10mm deep to the magnet. Combined with a m3 x 16mm screw this creates a fool proof press for putting them on. Combined with the freezing the metal balls in the freezer plus heating the plastic in hot water, they go on super easy. And the added bonus of the shallow screwdriver is it hits the M3 screw just after it pops the plastic over the ball. So even if you ham fisted it with conan the barbarian strength or something, you can't possibly press down too hard. They came out pretty snug.

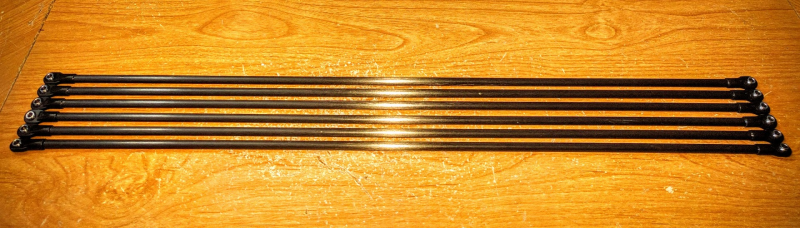

Pictured below.

Edited 2 time(s). Last edit at 10/17/2016 09:31PM by feistylemur.

But, I do have my own addition to it that maybe is useful. I have one of these short multibit stanley screwdrivers, the socket is only 10mm deep to the magnet. Combined with a m3 x 16mm screw this creates a fool proof press for putting them on. Combined with the freezing the metal balls in the freezer plus heating the plastic in hot water, they go on super easy. And the added bonus of the shallow screwdriver is it hits the M3 screw just after it pops the plastic over the ball. So even if you ham fisted it with conan the barbarian strength or something, you can't possibly press down too hard. They came out pretty snug.

Pictured below.

Edited 2 time(s). Last edit at 10/17/2016 09:31PM by feistylemur.

|

Re: Proper way of assembling Traxxs ball ends. October 17, 2016 11:05PM |

Registered: 7 years ago Posts: 21 |

As I'm epoxying my ends, I just had an interesting thought, I wonder if putting them on with double wall adhesive shrink tubing would be solid enough. That stuff is really stiff and solid, but can also be removed. You can barely bend it when you put it on a cable, if it's on something like a carbon fiber rod, it should shrink and pull it right into place snug, and never budge.

Edited 1 time(s). Last edit at 10/17/2016 11:05PM by feistylemur.

Edited 1 time(s). Last edit at 10/17/2016 11:05PM by feistylemur.

|

Re: Proper way of assembling Traxxs ball ends. November 07, 2016 01:47PM |

Registered: 9 years ago Posts: 280 |

This is all good to know! I thought just hammering them in was a little brutal but figured that was expected.

Some of my rods seem a little loose now, how much printing wear can they take before they start to stretch? I have had a few high-speed (70mm/sec) 10-hour jobs but otherwise my machine sees very low usage.

Some of my rods seem a little loose now, how much printing wear can they take before they start to stretch? I have had a few high-speed (70mm/sec) 10-hour jobs but otherwise my machine sees very low usage.

Sorry, only registered users may post in this forum.