|

Re: Geeetech Rostock 301 first topic September 20, 2017 02:17PM |

Registered: 7 years ago Posts: 41 |

Hi suggi.

I'm sorry, but i still do not understand your problem. perhaps could you show us with a video or something like that.

Perhaps you could use repetier host, wich is an excellent program to control your printer... If you use easy print, i can believe it does not work, as it is full of bugssss....

Hi isralgs.

Happy you print well !

As i was satisfied with repetier + cura slicer, i only used them/ By the way, i'm sure that configuring Cura might not be a problem.

Just try ! and tell us !

Did you find a solution for the retract pbm (only one extruder retracts), and the stringing side effect ?.. I had no solution, and hope in 1.0.0.3 firmware version.... As i previously said, i had to downgrade...

I'm sorry, but i still do not understand your problem. perhaps could you show us with a video or something like that.

Perhaps you could use repetier host, wich is an excellent program to control your printer... If you use easy print, i can believe it does not work, as it is full of bugssss....

Hi isralgs.

Happy you print well !

As i was satisfied with repetier + cura slicer, i only used them/ By the way, i'm sure that configuring Cura might not be a problem.

Just try ! and tell us !

Did you find a solution for the retract pbm (only one extruder retracts), and the stringing side effect ?.. I had no solution, and hope in 1.0.0.3 firmware version.... As i previously said, i had to downgrade...

|

Re: Geeetech Rostock 301 first topic September 20, 2017 04:21PM |

Registered: 6 years ago Posts: 33 |

The fact is that the settings I've made on this printer have been minimal. Of course, the change from slic3 to curaengine is bestial, the first one gives errors of overmaterial especially in the corners, although I also have it ready.

What you say that only one extruder retracts and stringing side effect i dont know. Tell me more things for this please

What you say that only one extruder retracts and stringing side effect i dont know. Tell me more things for this please

|

Re: Geeetech Rostock 301 first topic September 20, 2017 04:25PM |

Registered: 6 years ago Posts: 33 |

hello suggyQuote

Suggy

238 not 288

what version firmware number have you?

Use repetier-host and forget EasyPrint, really.

That program lacks many features that if you bring Repetier-Host, so the functionality of your printer will be limited.

Tell me in detail what your problem is, together we can all help.

In fact, everyone who bought a 301 and went through here made it work, (Rene is my hero)

Edited 2 time(s). Last edit at 09/20/2017 05:01PM by isralgs.

|

Re: Geeetech Rostock 301 first topic October 05, 2017 06:40PM |

Registered: 6 years ago Posts: 3 |

Hello everyone. I thing this is a nice chalenge for my first 3d printer kkkkkk

The problem: Hotend is not heating up.

the LCD show 301°/0° (when the motor of extruder is conected on E0)

And when I plug OUT the extruder motor it shows 0°/0°

I don't know what to do.... someone have an idea?

Edited 2 time(s). Last edit at 10/05/2017 06:45PM by Marfreg.

The problem: Hotend is not heating up.

the LCD show 301°/0° (when the motor of extruder is conected on E0)

And when I plug OUT the extruder motor it shows 0°/0°

I don't know what to do.... someone have an idea?

Edited 2 time(s). Last edit at 10/05/2017 06:45PM by Marfreg.

Attachments:

open | download - 22154684_1491162060970991_7011718659638648926_n.jpg (26.2 KB)

open | download - 22196077_1491162057637658_2512190652479433160_n.jpg (60.4 KB)

open | download - 22228389_1491161937637670_6578498442043724630_n.jpg (20.4 KB)

open | download - 22279700_1491161977637666_2720568695778361013_n.jpg (59.5 KB)

open | download - 22154684_1491162060970991_7011718659638648926_n.jpg (26.2 KB)

open | download - 22196077_1491162057637658_2512190652479433160_n.jpg (60.4 KB)

open | download - 22228389_1491161937637670_6578498442043724630_n.jpg (20.4 KB)

open | download - 22279700_1491161977637666_2720568695778361013_n.jpg (59.5 KB)

|

Re: Geeetech Rostock 301 first topic October 11, 2017 07:00AM |

Registered: 6 years ago Posts: 33 |

hello marfreg

When you heat the extruder, the number on the left indicates the current temperature of the extruder by means of the thermistor (the thin cables that go to the extruder) and the one on the right indicates the temperature that you want to give it.

What version of the firmware do you use?

Did you check the connections?

Have you checked that the extruder doesn't really catch your temperature?

According to the images you send, the problem is that the extruder does catch temperature, but the thermistor does not tell you.

Let me know more

When you heat the extruder, the number on the left indicates the current temperature of the extruder by means of the thermistor (the thin cables that go to the extruder) and the one on the right indicates the temperature that you want to give it.

What version of the firmware do you use?

Did you check the connections?

Have you checked that the extruder doesn't really catch your temperature?

According to the images you send, the problem is that the extruder does catch temperature, but the thermistor does not tell you.

Let me know more

|

Re: Geeetech Rostock 301 first topic October 11, 2017 08:28PM |

Registered: 6 years ago Posts: 3 |

Hi.

the extruder doesn't catch the temperature.... so that 301°C is wrong.

I don't check the conections on the extruder because I don't know if it's possible tostrip then of the extruder ( looks like It can't )

but I will se it better, and send some pictures...

I dont tell, but the FANs are not working too... no one, they get hot, but dont move

Thank you for yous answer, I'll be back tomorrow with some news

the extruder doesn't catch the temperature.... so that 301°C is wrong.

I don't check the conections on the extruder because I don't know if it's possible tostrip then of the extruder ( looks like It can't )

but I will se it better, and send some pictures...

I dont tell, but the FANs are not working too... no one, they get hot, but dont move

Thank you for yous answer, I'll be back tomorrow with some news

|

Re: Geeetech Rostock 301 first topic October 11, 2017 08:45PM |

Registered: 6 years ago Posts: 3 |

|

Re: Geeetech Rostock 301 first topic October 12, 2017 05:43PM |

Registered: 6 years ago Posts: 33 |

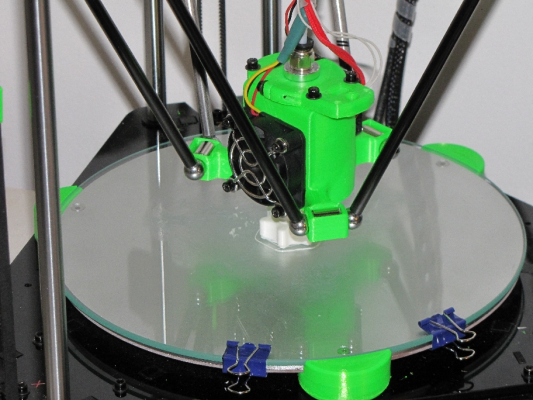

The cables attached to the second photo are the heating cartridge cables.

With a polymeter and on the ohms scale check them. It should give about 5 ohms.

Therefore, in the nozzle has another pair of cable, are the thermistor ones, which checks the temperature.

Measure it on the omh scale, it should give 95 kohms (depending on the ambient temperature) approximately.

Finally, connect everything, and without closing the junction box, start repeater-host and heat the nozzle. Where this is connected, measure in volts with the polymeter, it has to indicate about 12 volts.

If you need help or indicative photos, please indicate this

Edited 1 time(s). Last edit at 10/12/2017 05:44PM by isralgs.

With a polymeter and on the ohms scale check them. It should give about 5 ohms.

Therefore, in the nozzle has another pair of cable, are the thermistor ones, which checks the temperature.

Measure it on the omh scale, it should give 95 kohms (depending on the ambient temperature) approximately.

Finally, connect everything, and without closing the junction box, start repeater-host and heat the nozzle. Where this is connected, measure in volts with the polymeter, it has to indicate about 12 volts.

If you need help or indicative photos, please indicate this

Edited 1 time(s). Last edit at 10/12/2017 05:44PM by isralgs.

|

Re: Geeetech Rostock 301 first topic December 10, 2017 04:52PM |

Registered: 7 years ago Posts: 13 |

Ref: [forums.reprap.org]

Heyhey... I do make nice prints with my printer, but I don't have a camera to record, nor do I see the need of sharing a printing video.

Have a look at my thingiverse page for things made myself! Some you already saw...

[www.thingiverse.com]

It's indeed not a Prusa MK3, but we all wanted lots of colors? No?!

Concerning settings: I recently deleted all of them, just using the defaults that came with Cura 3.1. https://ultimaker.com/en/products/ultimaker-cura-software

I can really advertise this slicer! It's only recently that I also configured Cura for real 3 extruder setup...

... and then you have to be very very careful as our Geeetech friends forgot to implement some things in their Marlin hacked code.

e.g. you have to remove the commands "M104 Tx S0" out of the Gcode - this appears in the end, after an extruder has done it's last print, then it gets switched off, but the exception is that this command should not have any effect when Tx is not the active extruder for the Rostock 301!

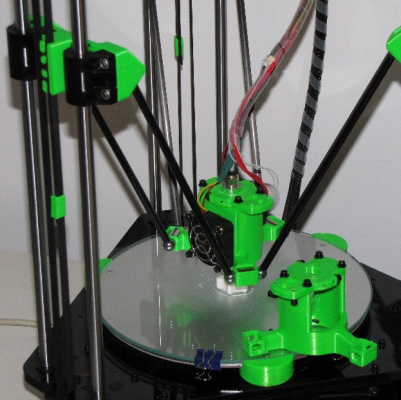

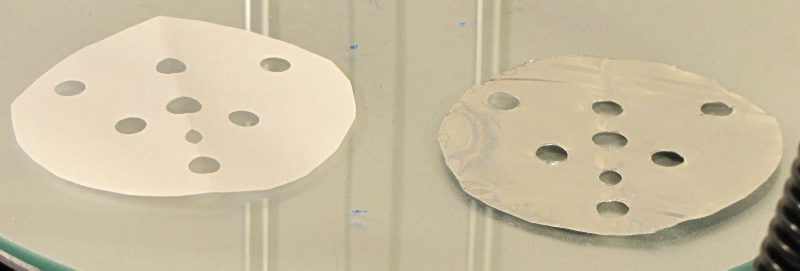

My next work is to try getting the retract better - as in fact it' really not working for me...

I want to cool the heatsinks better for this purpose, to increase the 'heatbreak', meaning filament has to stay as cold as possible up till the moment it enters the hotend.

I once made attached overview, but as you see the success is not so great. Also!! I should NOT have tried to do retract with a color mix. And then of course I do all to avoid retracts: Combing on - (Crossing perimeters off) - prints multiple parts in sequence - ...

Also I want to reset my printer to defaults soon (after writing all down so that I can re-enter) ; reason for this is that I've modified several things since the beginning that I don't know anymore if I didn't mess up some of the possibilities by my fiddling...

Still having fun! Nobody of my friends can print shaded like I do - I can't print fast or clean like any of my friends do neither, but everybody has his/her specialty, no?

- I can't print fast or clean like any of my friends do neither, but everybody has his/her specialty, no?

Edited 2 time(s). Last edit at 12/10/2017 05:18PM by MikaëlV.

Quote

L'ami René

Hello,

Bonjour,

...

Voici la totalité des sites YouTube des propriétaires Geeetech Rostock 301 à l'exception de celle du fabricant Geeetech. Le tout en date du 23 juillet 2017.

Je constate que la totalité des Youtubers non pas de vidéo d'impression réussi avec leur Geeetech Rostock 301 :

...

Mikael Vanherpe: https://www.youtube.com/user/MikaelVanherpe/videos

...

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello,

...

Here are all of the YouTube sites of the Geeetech Rostock 301 owners except for the Geeetech manufacturer. All on July 23, 2017.

I notice that the entire Youtubers not a successful print video with their Geeetech Rostock 301:

...

Mikael Vanherpe: https://www.youtube.com/user/MikaelVanherpe/videos

...

The friend René

Heyhey... I do make nice prints with my printer, but I don't have a camera to record, nor do I see the need of sharing a printing video.

Have a look at my thingiverse page for things made myself! Some you already saw...

[www.thingiverse.com]

It's indeed not a Prusa MK3, but we all wanted lots of colors? No?!

Concerning settings: I recently deleted all of them, just using the defaults that came with Cura 3.1. https://ultimaker.com/en/products/ultimaker-cura-software

I can really advertise this slicer! It's only recently that I also configured Cura for real 3 extruder setup...

... and then you have to be very very careful as our Geeetech friends forgot to implement some things in their Marlin hacked code.

e.g. you have to remove the commands "M104 Tx S0" out of the Gcode - this appears in the end, after an extruder has done it's last print, then it gets switched off, but the exception is that this command should not have any effect when Tx is not the active extruder for the Rostock 301!

My next work is to try getting the retract better - as in fact it' really not working for me...

I want to cool the heatsinks better for this purpose, to increase the 'heatbreak', meaning filament has to stay as cold as possible up till the moment it enters the hotend.

I once made attached overview, but as you see the success is not so great. Also!! I should NOT have tried to do retract with a color mix. And then of course I do all to avoid retracts: Combing on - (Crossing perimeters off) - prints multiple parts in sequence - ...

Also I want to reset my printer to defaults soon (after writing all down so that I can re-enter) ; reason for this is that I've modified several things since the beginning that I don't know anymore if I didn't mess up some of the possibilities by my fiddling...

Still having fun! Nobody of my friends can print shaded like I do

- I can't print fast or clean like any of my friends do neither, but everybody has his/her specialty, no?

- I can't print fast or clean like any of my friends do neither, but everybody has his/her specialty, no?

Edited 2 time(s). Last edit at 12/10/2017 05:18PM by MikaëlV.

|

Re: Geeetech Rostock 301 first topic December 11, 2017 12:12AM |

Registered: 7 years ago Posts: 236 |

Hello MikaëlV,

Bonjour MikaëlV,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

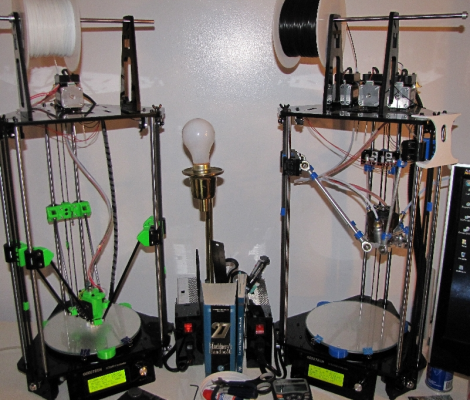

Avec mes modifications et améliorations et en réduisant la vitesse à 50 %, j'arrive à imprimer avec un mélange de deux couleurs (extrudeur # 2 et # 3, le # 1 n'a un débit que de 5 à 10 % de ce qu'il devrait). C'est super et étonnant le mélange des couleurs !

Comme j'ai le même problème sur mes deux imprimantes 3D à tête diamant, l'entrée de filament # 1 de 3 qui est presque totalement bouché, je présume qu'un des problèmes est l'usinage de cette tête diamant. Si le perçage de l'entrée # 1 de 3 ne va pas suffisamment profondément ou s'il va suffisamment profond, mais qu'il n'est pas aligné parfaitement avec la chambre de mélange des filaments, il y a blocage de la buse.

Comme l'entrée # 1 de 3 est l'entrée filament par défaut, et que la vitesse par défaut est 50 % trop rapide pour la puissance de poussée des trois extrudeurs pas-à-pas, tout le monde bloque dès le départ et vont dans tous les sens dans les réglages et paramètres.

De plus, les paramètres d'usine pour les dimensions physiques des pièces de trigonométries ne correspondent pas à la réalité dans le micrologiciel (Diagonal_Rod, etc.).

Pour toutes ces raisons, il est impossible d'imprimer avec cette imprimante telle que conçu et paramétré en usine.

Pourriez-vous tester mes paramètres de configurations de Repetier-Host sur votre imprimante 301 (voir les fichiers de configuration en pièces jointes) en vous assurant de n'utiliser que les extrudeurs # 2 et # 3 et pas le # 1 pour valider mon hypothèse de problèmes d'usinages de la tête diamant ?

Avec les traducteurs automatiques du genre Google Translator, les traductions ne sont pas très bonnes et donc je ne comprends pas si vous avez de belles impressions ou pas avec vos améliorations de pièce de ventilation. Pourriez-vous me le préciser avec une frase simple du genre « Oui, je fais de très belles impressions » ou « Non, je ne fais aucune belle impression » ?

Effectivement, pour la rétractation, j'ai aussi des gros problèmes et toujours pas trouvé la bonne vitesse de rétractation, distance de recul et température de buse, pour ne pas avoir de multiples cheveux partout sur et dans les pièces imprimées. Mais je n'y ai pas beaucoup travaillé faute des autres paramètres d'usine incorrects !

Pourquoi utilisez-vous Cura au lieu de Repetier-Host, pour une Geeetech 301, cela fait une différence ?

Pour mes conceptions et dessins aux formats STL et ipt (Autodesk Inventor Pro 2018) voir :

https://www.thingiverse.com/thing:2464177

Cordialement,

L'ami René

P. s. : Je suis sous Linux Kubuntu 17.10 64 bits avec Repetier-Host 2.0.5 et Slic3r 1.2.9.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello MikaëlV,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

With my modifications and improvements and reducing the speed to 50%, I can print with a mixture of two colors (extruder # 2 and # 3, the # 1 has a flow rate of only 5 to 10% of what 'He should). It's great and amazing the mix of colors!

As I have the same problem on my two diamond-head 3D printers, filament entry # 1 of 3 which is almost completely clogged, I assume that one of the problems is machining this diamond head. If hole # 1 of 3 does not go deep enough or goes deep enough, but is not perfectly aligned with the filament mixing chamber, the nozzle is blocked.

Since input # 1 of 3 is the default input filament, and the default speed is 50% too fast for the thrust power of the three step-by-step extruders, everyone blocks from the start and goes in all directions in the settings and parameters.

In addition, the factory settings for the physical dimensions of the trigonometry parts do not correspond to the reality in the firmware (Diagonal_Rod, etc.).

For all these reasons, it is impossible to print with this printer as designed and set at the factory.

Could you test my Repetier-Host configuration settings on your printer 301 (see attachment configuration files) making sure to use only extruders # 2 and # 3 and not # 1 to validate my hypothesis problems machining the diamond head?

With automatic translators like Google Translator, the translations are not very good and so I do not understand if you have nice impressions or not with your ventilation room improvements. Could you clarify it with a simple frease of the type "Yes, I make very beautiful impressions" or "No, I do not make any beautiful impression"?

Indeed, for the retraction, I also have big problems and still not found the right speed of retraction, distance of recoil and temperature of nozzle, not to have multiple hair all over and in the printed parts. But I did not work much because of other incorrect factory settings!

Why do you use Cura instead of Repetier-Host, for a Geeetech 301, it makes a difference?

For my designs and drawings in STL and ipt formats (Autodesk Inventor Pro 2018) see:

https://www.thingiverse.com/thing:2464177

Cordially,

The friend René

P. s. : I am running Linux Kubuntu 17.10 64 bit with Repetier-Host 2.0.5 and Slic3r 1.2.9.

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

Bonjour MikaëlV,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

Avec mes modifications et améliorations et en réduisant la vitesse à 50 %, j'arrive à imprimer avec un mélange de deux couleurs (extrudeur # 2 et # 3, le # 1 n'a un débit que de 5 à 10 % de ce qu'il devrait). C'est super et étonnant le mélange des couleurs !

Comme j'ai le même problème sur mes deux imprimantes 3D à tête diamant, l'entrée de filament # 1 de 3 qui est presque totalement bouché, je présume qu'un des problèmes est l'usinage de cette tête diamant. Si le perçage de l'entrée # 1 de 3 ne va pas suffisamment profondément ou s'il va suffisamment profond, mais qu'il n'est pas aligné parfaitement avec la chambre de mélange des filaments, il y a blocage de la buse.

Comme l'entrée # 1 de 3 est l'entrée filament par défaut, et que la vitesse par défaut est 50 % trop rapide pour la puissance de poussée des trois extrudeurs pas-à-pas, tout le monde bloque dès le départ et vont dans tous les sens dans les réglages et paramètres.

De plus, les paramètres d'usine pour les dimensions physiques des pièces de trigonométries ne correspondent pas à la réalité dans le micrologiciel (Diagonal_Rod, etc.).

Pour toutes ces raisons, il est impossible d'imprimer avec cette imprimante telle que conçu et paramétré en usine.

Pourriez-vous tester mes paramètres de configurations de Repetier-Host sur votre imprimante 301 (voir les fichiers de configuration en pièces jointes) en vous assurant de n'utiliser que les extrudeurs # 2 et # 3 et pas le # 1 pour valider mon hypothèse de problèmes d'usinages de la tête diamant ?

Avec les traducteurs automatiques du genre Google Translator, les traductions ne sont pas très bonnes et donc je ne comprends pas si vous avez de belles impressions ou pas avec vos améliorations de pièce de ventilation. Pourriez-vous me le préciser avec une frase simple du genre « Oui, je fais de très belles impressions » ou « Non, je ne fais aucune belle impression » ?

Effectivement, pour la rétractation, j'ai aussi des gros problèmes et toujours pas trouvé la bonne vitesse de rétractation, distance de recul et température de buse, pour ne pas avoir de multiples cheveux partout sur et dans les pièces imprimées. Mais je n'y ai pas beaucoup travaillé faute des autres paramètres d'usine incorrects !

Pourquoi utilisez-vous Cura au lieu de Repetier-Host, pour une Geeetech 301, cela fait une différence ?

Pour mes conceptions et dessins aux formats STL et ipt (Autodesk Inventor Pro 2018) voir :

https://www.thingiverse.com/thing:2464177

Cordialement,

L'ami René

P. s. : Je suis sous Linux Kubuntu 17.10 64 bits avec Repetier-Host 2.0.5 et Slic3r 1.2.9.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello MikaëlV,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

With my modifications and improvements and reducing the speed to 50%, I can print with a mixture of two colors (extruder # 2 and # 3, the # 1 has a flow rate of only 5 to 10% of what 'He should). It's great and amazing the mix of colors!

As I have the same problem on my two diamond-head 3D printers, filament entry # 1 of 3 which is almost completely clogged, I assume that one of the problems is machining this diamond head. If hole # 1 of 3 does not go deep enough or goes deep enough, but is not perfectly aligned with the filament mixing chamber, the nozzle is blocked.

Since input # 1 of 3 is the default input filament, and the default speed is 50% too fast for the thrust power of the three step-by-step extruders, everyone blocks from the start and goes in all directions in the settings and parameters.

In addition, the factory settings for the physical dimensions of the trigonometry parts do not correspond to the reality in the firmware (Diagonal_Rod, etc.).

For all these reasons, it is impossible to print with this printer as designed and set at the factory.

Could you test my Repetier-Host configuration settings on your printer 301 (see attachment configuration files) making sure to use only extruders # 2 and # 3 and not # 1 to validate my hypothesis problems machining the diamond head?

With automatic translators like Google Translator, the translations are not very good and so I do not understand if you have nice impressions or not with your ventilation room improvements. Could you clarify it with a simple frease of the type "Yes, I make very beautiful impressions" or "No, I do not make any beautiful impression"?

Indeed, for the retraction, I also have big problems and still not found the right speed of retraction, distance of recoil and temperature of nozzle, not to have multiple hair all over and in the printed parts. But I did not work much because of other incorrect factory settings!

Why do you use Cura instead of Repetier-Host, for a Geeetech 301, it makes a difference?

For my designs and drawings in STL and ipt formats (Autodesk Inventor Pro 2018) see:

https://www.thingiverse.com/thing:2464177

Cordially,

The friend René

P. s. : I am running Linux Kubuntu 17.10 64 bit with Repetier-Host 2.0.5 and Slic3r 1.2.9.

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

|

Re: Geeetech Rostock 301 first topic December 11, 2017 02:12AM |

Registered: 8 years ago Posts: 193 |

|

Re: Geeetech Rostock 301 first topic December 11, 2017 04:41AM |

Registered: 7 years ago Posts: 236 |

[forums.reprap.org]

Hello Suggy,

Bonjour Suggy,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

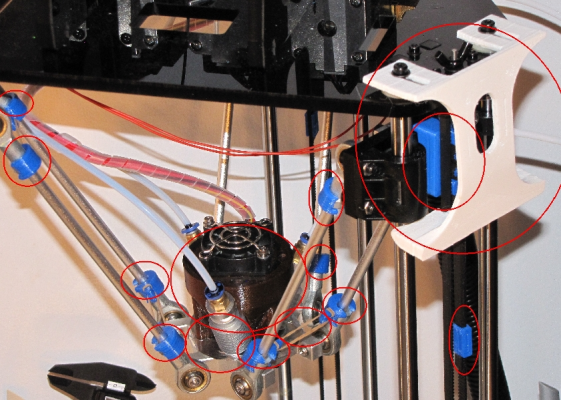

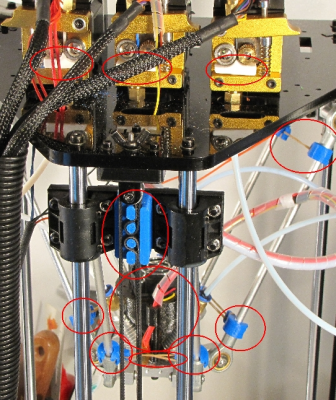

C'est dans ma signature, mais pour plus de précision (Néodime ∅10mm x 12mm) et le lien direct a la réponse :

http://forums.reprap.org/read.php?110,786337,786618#msg-786618

Donc :

https://www.banggood.com/fr/200MM-4x6-MM-Diagonal-Push-Rod-L200-With-Magnetic-Ball-Joint-And-Steel-Ball-For-Kossel-3D-Printer-p-1090223.html

Mais comme les aimants de ce kit sont trop faibles, je les remplace par des :

http://www.dx.com/p/diy-10-10mm-cylindrical-ndfeb-magnets-silver-10pcs-433439

ou par ce qui suit, mais il vous faudra modifier les dessins 3D :

https://www.banggood.com/fr/Big-Super-Strong-Round-Disc-Cylinder-Magnet-D-15-x-20-mm-p-947979.html

Ou :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

Ou :

http://www.dx.com/p/15-x-20mm-cylindrical-ndfeb-magnet-silver-10pcs-395982

Je vais ajouter tout cela au sujet « Aide pour la configuration d'une delta Geeetech Rostock 301 » prochainement.

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello Suggy,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

It's in my signature, but for more precision (Néodime ∅10mm x 12mm) and the direct link to the answer :

http://forums.reprap.org/read.php?110,786337,786618#msg-786618

So :

https://www.banggood.com/fr/200MM-4x6-MM-Diagonal-Push-Rod-L200-With-Magnetic-Ball-Joint-And-Steel-Ball-For-Kossel-3D-Printer-p-1090223.html

But as the magnets of this kit are too weak, I replace them with :

http://www.dx.com/p/diy-10-10mm-cylindrical-ndfeb-magnets-silver-10pcs-433439

or what follows, but you will need to modify the 3D drawings :

https://www.banggood.com/fr/Big-Super-Strong-Round-Disc-Cylinder-Magnet-D-15-x-20-mm-p-947979.html

or :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

or :

http://www.dx.com/p/15-x-20mm-cylindrical-ndfeb-magnet-silver-10pcs-395982

I will add all this about« Aide pour la configuration d'une delta Geeetech Rostock 301 » shortly.

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

Hello Suggy,

Bonjour Suggy,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

C'est dans ma signature, mais pour plus de précision (Néodime ∅10mm x 12mm) et le lien direct a la réponse :

http://forums.reprap.org/read.php?110,786337,786618#msg-786618

Donc :

https://www.banggood.com/fr/200MM-4x6-MM-Diagonal-Push-Rod-L200-With-Magnetic-Ball-Joint-And-Steel-Ball-For-Kossel-3D-Printer-p-1090223.html

Mais comme les aimants de ce kit sont trop faibles, je les remplace par des :

http://www.dx.com/p/diy-10-10mm-cylindrical-ndfeb-magnets-silver-10pcs-433439

ou par ce qui suit, mais il vous faudra modifier les dessins 3D :

https://www.banggood.com/fr/Big-Super-Strong-Round-Disc-Cylinder-Magnet-D-15-x-20-mm-p-947979.html

Ou :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

Ou :

http://www.dx.com/p/15-x-20mm-cylindrical-ndfeb-magnet-silver-10pcs-395982

Je vais ajouter tout cela au sujet « Aide pour la configuration d'une delta Geeetech Rostock 301 » prochainement.

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello Suggy,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

It's in my signature, but for more precision (Néodime ∅10mm x 12mm) and the direct link to the answer :

http://forums.reprap.org/read.php?110,786337,786618#msg-786618

So :

https://www.banggood.com/fr/200MM-4x6-MM-Diagonal-Push-Rod-L200-With-Magnetic-Ball-Joint-And-Steel-Ball-For-Kossel-3D-Printer-p-1090223.html

But as the magnets of this kit are too weak, I replace them with :

http://www.dx.com/p/diy-10-10mm-cylindrical-ndfeb-magnets-silver-10pcs-433439

or what follows, but you will need to modify the 3D drawings :

https://www.banggood.com/fr/Big-Super-Strong-Round-Disc-Cylinder-Magnet-D-15-x-20-mm-p-947979.html

or :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

or :

http://www.dx.com/p/15-x-20mm-cylindrical-ndfeb-magnet-silver-10pcs-395982

I will add all this about« Aide pour la configuration d'une delta Geeetech Rostock 301 » shortly.

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

|

Re: Geeetech Rostock 301 first topic December 11, 2017 07:26AM |

Registered: 7 years ago Posts: 236 |

[www.dx.com]

Hello,

Bonjour,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

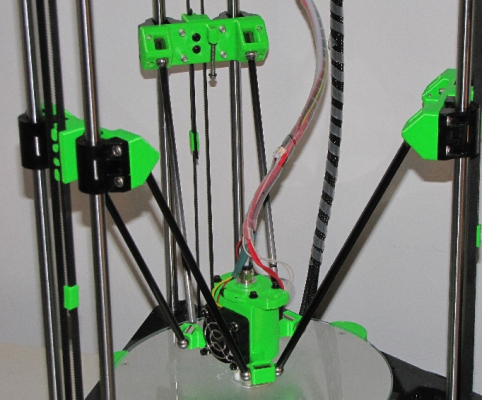

Mon système actuel de rotule magnétique n'est pas suffisamment fort et c'est pourquoi je vous recommande de passer à des aimants néodyme plus fort du genre ∅12x12mm ou ∅10x15mm avec des rotules d'acier plus grosses de ∅12mm avec dégagement et portion filetée de 15mm du genre « Vis sphérique à boule de joint d'aimant pour imprimante 3D M4x15mm, ∅12mm » :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

https://www.banggood.com/fr/20pcs-N50-Super-Strong-Round-Rare-Earth-Neodymium-10mm-x-15mm-p-952669.html

https://www.banggood.com/fr/K800-Magnet-Joint-Spherical-Ball-Screw-For-3D-Printer-Accessories-12mm-M4-15mm-p-1031850.html

Pour des raisons de sécurités (désolidarisation d'une ou de plusieurs rotules magnétique, vous ne pouvez laisser l'imprimante 3D ainsi modifiée sans surveillance constante. Il faut penser qu'une tête d'impression qui se désolidarise va se retrouver à écraser durant le reste de l'impression la matière déjà déposée et faire un gros gâchis qui pourrait prendre feu avec ces températures de fonctionnement de plus de 200°C.

Donc à vos risques !

Est-ce que l'un ou l'une d'entre vous pourrait nous fournir ici une référence pour l'achat de 6 tiges de carbone de longueur parfaitement égale aux alentours de 200 mm (±10mm) avec un diamètre intérieur pour les rotules si dessus (réf. : vis de 12mm-M4-15mm : #1031850) soit de ∅4mm et entre ∅5 et ∅6mm extérieurs.

Merci d'avance !

Si vous testez ce type de rotule magnétique, s'il vous plaît nous informé de ce que vous utilisez (où acheter vos pièces, lien Web) et des résultats d'impression obtenus.

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

My current magnetic ball joint system is not strong enough and that's why I recommend switching to stronger neodymium magnets of the ∅12x12mm or ∅10x15mm type with ∅12mm larger steel ball joints with clearance and serving 15mm Threaded Screw Type Magnetic Seal Ball Screw for 3D Printer M4x15mm, ∅12mm " :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

https://www.banggood.com/fr/20pcs-N50-Super-Strong-Round-Rare-Earth-Neodymium-10mm-x-15mm-p-952669.html

https://www.banggood.com/fr/K800-Magnet-Joint-Spherical-Ball-Screw-For-3D-Printer-Accessories-12mm-M4-15mm-p-1031850.html

For security reasons (disconnection of one or more magnetic ball joints, you can not leave the 3D printer thus modified without constant monitoring.It must be thought that a print head that disengages will end up crushing during the Remain of the already deposited material matter and make a big mess that could catch fire with these operating temperatures of over 200 ° C.

So at your risk!

Could one of you here give us a reference for the purchase of 6 carbon rods of perfectly equal length around 200 mm (± 10mm) with an inside diameter for the kneecaps if on (ref .: 12mm-M4-15mm screw: # 1031850) is ∅4mm and between ∅5 and ∅6mm outside.

Thank you in advance !

If you are testing this type of magnetic ball head, please inform us of what you are using (where to buy your parts, web link) and print results obtained.

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

Hello,

Bonjour,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

Mon système actuel de rotule magnétique n'est pas suffisamment fort et c'est pourquoi je vous recommande de passer à des aimants néodyme plus fort du genre ∅12x12mm ou ∅10x15mm avec des rotules d'acier plus grosses de ∅12mm avec dégagement et portion filetée de 15mm du genre « Vis sphérique à boule de joint d'aimant pour imprimante 3D M4x15mm, ∅12mm » :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

https://www.banggood.com/fr/20pcs-N50-Super-Strong-Round-Rare-Earth-Neodymium-10mm-x-15mm-p-952669.html

https://www.banggood.com/fr/K800-Magnet-Joint-Spherical-Ball-Screw-For-3D-Printer-Accessories-12mm-M4-15mm-p-1031850.html

Pour des raisons de sécurités (désolidarisation d'une ou de plusieurs rotules magnétique, vous ne pouvez laisser l'imprimante 3D ainsi modifiée sans surveillance constante. Il faut penser qu'une tête d'impression qui se désolidarise va se retrouver à écraser durant le reste de l'impression la matière déjà déposée et faire un gros gâchis qui pourrait prendre feu avec ces températures de fonctionnement de plus de 200°C.

Donc à vos risques !

Est-ce que l'un ou l'une d'entre vous pourrait nous fournir ici une référence pour l'achat de 6 tiges de carbone de longueur parfaitement égale aux alentours de 200 mm (±10mm) avec un diamètre intérieur pour les rotules si dessus (réf. : vis de 12mm-M4-15mm : #1031850) soit de ∅4mm et entre ∅5 et ∅6mm extérieurs.

Merci d'avance !

Si vous testez ce type de rotule magnétique, s'il vous plaît nous informé de ce que vous utilisez (où acheter vos pièces, lien Web) et des résultats d'impression obtenus.

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

My current magnetic ball joint system is not strong enough and that's why I recommend switching to stronger neodymium magnets of the ∅12x12mm or ∅10x15mm type with ∅12mm larger steel ball joints with clearance and serving 15mm Threaded Screw Type Magnetic Seal Ball Screw for 3D Printer M4x15mm, ∅12mm " :

http://www.dx.com/p/n35-12-x-12mm-round-style-ndfeb-magnet-silver-10-pcs-378878

https://www.banggood.com/fr/20pcs-N50-Super-Strong-Round-Rare-Earth-Neodymium-10mm-x-15mm-p-952669.html

https://www.banggood.com/fr/K800-Magnet-Joint-Spherical-Ball-Screw-For-3D-Printer-Accessories-12mm-M4-15mm-p-1031850.html

For security reasons (disconnection of one or more magnetic ball joints, you can not leave the 3D printer thus modified without constant monitoring.It must be thought that a print head that disengages will end up crushing during the Remain of the already deposited material matter and make a big mess that could catch fire with these operating temperatures of over 200 ° C.

So at your risk!

Could one of you here give us a reference for the purchase of 6 carbon rods of perfectly equal length around 200 mm (± 10mm) with an inside diameter for the kneecaps if on (ref .: 12mm-M4-15mm screw: # 1031850) is ∅4mm and between ∅5 and ∅6mm outside.

Thank you in advance !

If you are testing this type of magnetic ball head, please inform us of what you are using (where to buy your parts, web link) and print results obtained.

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

|

Re: Geeetech Rostock 301 first topic December 11, 2017 10:01AM |

Registered: 10 years ago Posts: 14,672 |

I recommend the magnetic arms supplied by Haydn Huntley. They are not cheap, but they are very accurate and the magnets are strong. They are available direct from Haydn via [groups.google.com] (USA), from [www.blueeaglelabs.com] (also USA), and from [www.duet3d.com] (UK, 360mm long only, look at the addons section).

Edited 2 time(s). Last edit at 12/11/2017 10:02AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 12/11/2017 10:02AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Geeetech Rostock 301 first topic December 12, 2017 04:29AM |

Registered: 7 years ago Posts: 236 |

Hello,

Bonjour,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

DC42, merci pour tous ces liens !

Pour le site Blue Eagle Labs, les tiges de toute longueur :

https://www.blueeaglelabs.com/collections/parts-accesories/products/haydns-carbon-fiber-arms-with-cnc-precision-machined-delrin-sockets

Il y a :

215mm (75 USD)

288mm (75 USD)

304mm (75 USD)

360mm (80 USD)

Longueur personnalisée jusqu'à 490mm (115 USD)

Pour ce qui est de « Delta robot 3D printers » adresse Web :

https://groups.google.com/forum/#!topic/deltabot/485cfVFrFFU%5B51-75%5D

Je voudrais commander, mais je ne trouve pas de lien sur cette page. Vous pouvez m'aider pour une commande pour le Canada ?

Pour le site Web : https://www.filastruder.com/collections/electronics/products/12-magballs-6-360mm-arms-for-delta-smarteffector

Dommage qu'ils n'ont que du 360mm de longueur à 79.99 USD !

Et pour ce qui est d'acheter que des tubes de carbone de ∅4mm intérieurs et ∅5 à ∅6mm extérieurs, de longueur précise, disons 190mm ou 200mm ?

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

DC42, thanks for all these links!

For the Blue Eagle Labs website, stems of any length:

https://www.blueeaglelabs.com/collections/parts-accesories/products/haydns-carbon-fiber-arms-with-cnc-precision-machined-delrin-sockets

There is :

215mm (75 USD)

288mm (75 USD)

304mm (75 USD)

360mm (80 USD)

Custom length up to 490mm (115 USD)

With regard to "Delta robot 3D printers" web address:

https://groups.google.com/forum/#!topic/deltabot/485cfVFrFFU%5B51-75%5D

I would like to order, but I can not find a link on this page. Can you help me for an order for Canada?

For the website: https://www.filastruder.com/collections/electronics/products/12-magballs-6-360mm-arms-for-delta-smarteffector

Too bad they only have 360mm length at 79.99 USD!

And when it comes to buying only ∅4mm carbon tubes inside and ∅5 to ∅6mm outside, of precise length, say 190mm or 200mm?

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

Bonjour,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

DC42, merci pour tous ces liens !

Pour le site Blue Eagle Labs, les tiges de toute longueur :

https://www.blueeaglelabs.com/collections/parts-accesories/products/haydns-carbon-fiber-arms-with-cnc-precision-machined-delrin-sockets

Il y a :

215mm (75 USD)

288mm (75 USD)

304mm (75 USD)

360mm (80 USD)

Longueur personnalisée jusqu'à 490mm (115 USD)

Pour ce qui est de « Delta robot 3D printers » adresse Web :

https://groups.google.com/forum/#!topic/deltabot/485cfVFrFFU%5B51-75%5D

Je voudrais commander, mais je ne trouve pas de lien sur cette page. Vous pouvez m'aider pour une commande pour le Canada ?

Pour le site Web : https://www.filastruder.com/collections/electronics/products/12-magballs-6-360mm-arms-for-delta-smarteffector

Dommage qu'ils n'ont que du 360mm de longueur à 79.99 USD !

Et pour ce qui est d'acheter que des tubes de carbone de ∅4mm intérieurs et ∅5 à ∅6mm extérieurs, de longueur précise, disons 190mm ou 200mm ?

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

DC42, thanks for all these links!

For the Blue Eagle Labs website, stems of any length:

https://www.blueeaglelabs.com/collections/parts-accesories/products/haydns-carbon-fiber-arms-with-cnc-precision-machined-delrin-sockets

There is :

215mm (75 USD)

288mm (75 USD)

304mm (75 USD)

360mm (80 USD)

Custom length up to 490mm (115 USD)

With regard to "Delta robot 3D printers" web address:

https://groups.google.com/forum/#!topic/deltabot/485cfVFrFFU%5B51-75%5D

I would like to order, but I can not find a link on this page. Can you help me for an order for Canada?

For the website: https://www.filastruder.com/collections/electronics/products/12-magballs-6-360mm-arms-for-delta-smarteffector

Too bad they only have 360mm length at 79.99 USD!

And when it comes to buying only ∅4mm carbon tubes inside and ∅5 to ∅6mm outside, of precise length, say 190mm or 200mm?

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

|

Re: Geeetech Rostock 301 first topic December 12, 2017 05:38AM |

Registered: 10 years ago Posts: 14,672 |

To order direct from Haydn, join the Google group I gave a link to and post a message to, it saying what you want to order.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Geeetech Rostock 301 first topic December 12, 2017 02:53PM |

Registered: 7 years ago Posts: 236 |

Hello,

Bonjour,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

J'ai une bonne et une mauvaise nouvelle et c'est la même nouvelle !

Avec un ventilateur de CPU 12 volts comme ce qui suit et une gaine de ventilation comme ce qui suit aussi, vous pourrez imprimer un mélange de trois filaments dans les proportions de votre choix pour un arc-en-ciel de couleur :

https://www.banggood.com/fr/12V-Internal-Desktop-Computer-CPU-Case-Cooling-Cooler-Master-Silent-Fan-6cm-p-997474.html

https://www.ebay.com/itm/AVC-F6015B12LY-DC12V-0-1A-3-Pin-60X60X15mm-Ball-Bearing-Fan/132025703610?epid=1418877560&hash=item1ebd585cba:g:eGMAAOSwImRYRi5X

https://www.newegg.com/Product/Product.aspx?Item=9SIA4RE67X7817&cm_re=60mm_12v_fan-_-1YF-003V-00072-_-Product

https://www.thingiverse.com/thing:2464177

(Voir les dessins « Gaine de ventilation V60 mm 01.stl » ou « Gaine de ventilation V60 mm 01.ipt »).

J'imprime avec des températures pour du PLA de 205°C en montant, mais j'en suis à mes balbutiements. Pour ce qui est des réglages avec cette tête d'impression diamant.

Mais enfin, ça imprimer des mélanges des trois filaments.

Mais chez moi pour les autres paramètres d'impression tout est à faire, il me faudra du courage et de la patience !!!

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

I have good and bad news and it's the same news!

With a 12-volt CPU fan like the following and a ventilation duct as the following also, you will be able to print a mixture of three filaments in the proportions of your choice for a rainbow of color:

https://www.banggood.com/fr/12V-Internal-Desktop-Computer-CPU-Case-Cooling-Cooler-Master-Silent-Fan-6cm-p-997474.html

https://www.ebay.com/itm/AVC-F6015B12LY-DC12V-0-1A-3-Pin-60X60X15mm-Ball-Bearing-Fan/132025703610?epid=1418877560&hash=item1ebd585cba:g:eGMAAOSwImRYRi5X

https://www.newegg.com/Product/Product.aspx?Item=9SIA4RE67X7817&cm_re=60mm_12v_fan-_-1YF-003V-00072-_-Product

https://www.thingiverse.com/thing:2464177

(Voir les dessins « Gaine de ventilation V60 mm 01.stl » ou « Gaine de ventilation V60 mm 01.ipt »).

I print with temperatures for PLA of 205 ° C up, but I'm in my infancy. For the settings with this diamond print head.

But finally, it prints blends of the three filaments.

But at home for the other print settings everything is to be done, it will take me courage and patience !

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

Bonjour,

You can find the original text translated into English following this original French text.

Vous trouverez le texte original traduit en anglais à la suite du présent texte original en français.

J'ai une bonne et une mauvaise nouvelle et c'est la même nouvelle !

Avec un ventilateur de CPU 12 volts comme ce qui suit et une gaine de ventilation comme ce qui suit aussi, vous pourrez imprimer un mélange de trois filaments dans les proportions de votre choix pour un arc-en-ciel de couleur :

https://www.banggood.com/fr/12V-Internal-Desktop-Computer-CPU-Case-Cooling-Cooler-Master-Silent-Fan-6cm-p-997474.html

https://www.ebay.com/itm/AVC-F6015B12LY-DC12V-0-1A-3-Pin-60X60X15mm-Ball-Bearing-Fan/132025703610?epid=1418877560&hash=item1ebd585cba:g:eGMAAOSwImRYRi5X

https://www.newegg.com/Product/Product.aspx?Item=9SIA4RE67X7817&cm_re=60mm_12v_fan-_-1YF-003V-00072-_-Product

https://www.thingiverse.com/thing:2464177

J'imprime avec des températures pour du PLA de 205°C en montant, mais j'en suis à mes balbutiements. Pour ce qui est des réglages avec cette tête d'impression diamant.

Mais enfin, ça imprimer des mélanges des trois filaments.

Mais chez moi pour les autres paramètres d'impression tout est à faire, il me faudra du courage et de la patience !!!

Cordialement,

L'ami René

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Hello,

Excuse me, I am unilingual francophone and I use Google translator to translate the texts of the forum in French and to write to you in English. Thank you for your understanding and your indulgence for these texts translated mechanically!

I have good and bad news and it's the same news!

With a 12-volt CPU fan like the following and a ventilation duct as the following also, you will be able to print a mixture of three filaments in the proportions of your choice for a rainbow of color:

https://www.banggood.com/fr/12V-Internal-Desktop-Computer-CPU-Case-Cooling-Cooler-Master-Silent-Fan-6cm-p-997474.html

https://www.ebay.com/itm/AVC-F6015B12LY-DC12V-0-1A-3-Pin-60X60X15mm-Ball-Bearing-Fan/132025703610?epid=1418877560&hash=item1ebd585cba:g:eGMAAOSwImRYRi5X

https://www.newegg.com/Product/Product.aspx?Item=9SIA4RE67X7817&cm_re=60mm_12v_fan-_-1YF-003V-00072-_-Product

https://www.thingiverse.com/thing:2464177

I print with temperatures for PLA of 205 ° C up, but I'm in my infancy. For the settings with this diamond print head.

But finally, it prints blends of the three filaments.

But at home for the other print settings everything is to be done, it will take me courage and patience !

Cordially,

The friend René

Un pour tous et tous pour un !

One for all and all for one !

Imprimante 3D : Geeetech Rostock 301 dysfonctionnelle modifiée

Aide pour la configuration d'une delta Geeetech Rostock 301

|

Re: Geeetech Rostock 301 first topic April 11, 2018 11:30AM |

Registered: 6 years ago Posts: 13 |

Hi, I thank everyone for the information you have written to enable and set up the printer.

Now I find myself ahead of an extrusion problem, very little thread comes out.

I looked for the same problem in my discussion, but I did not find anything similar.

The printer has all the original parts and the extruder is metallic.

As firmware there is v1.0.03

As a program I use both Cura and Repetier Host v2.0 with Slic3r slicer

If you need more information let me know.

Thanks for those who will give me a hand.

P.s: I'm italian and I've used google translator.

Prima stampante 3d: Prusa I3 Pro B Mk8

Now I find myself ahead of an extrusion problem, very little thread comes out.

I looked for the same problem in my discussion, but I did not find anything similar.

The printer has all the original parts and the extruder is metallic.

As firmware there is v1.0.03

As a program I use both Cura and Repetier Host v2.0 with Slic3r slicer

If you need more information let me know.

Thanks for those who will give me a hand.

P.s: I'm italian and I've used google translator.

Prima stampante 3d: Prusa I3 Pro B Mk8

|

Re: Geeetech Rostock 301 first topic May 03, 2018 02:28AM |

Registered: 5 years ago Posts: 1 |

Hi, I wanted to comment that in the geeetech easyprint software I have seen a new firmware version for the M301, it is V1.0.04. I do not know what's new, if someone has tried it, please indicate if it's better or worse.

I still have not updated because I do not have news of if something improves in the printing.

Greetings.

I still have not updated because I do not have news of if something improves in the printing.

Greetings.

|

Re: Geeetech Rostock 301 first topic June 02, 2018 01:33PM |

Registered: 8 years ago Posts: 193 |

Hi all

Got a week to get this working. Updated to firmware v1.0.04

All motors move in the correct direction but I cannot make it go in a - direction, will go in a + direction then back in a - direction but cannot go past 0 which is what it is when homed. Any ideas what to alter to make it do a - direction?

Got a week to get this working. Updated to firmware v1.0.04

All motors move in the correct direction but I cannot make it go in a - direction, will go in a + direction then back in a - direction but cannot go past 0 which is what it is when homed. Any ideas what to alter to make it do a - direction?

|

Re: Geeetech Rostock 301 first topic June 03, 2018 04:45PM |

Registered: 8 years ago Posts: 193 |

|

Re: Geeetech Rostock 301 first topic August 22, 2018 08:57PM |

Registered: 5 years ago Posts: 3 |

Sorry, only registered users may post in this forum.