Tomas's Kossel XL build log

Posted by tomasf

|

Re: Tomas's Kossel XL build log November 19, 2016 04:38PM |

Registered: 8 years ago Posts: 3,525 |

Quote

DjDemonD

Looking good, nice looking hot end that Dyze unit. Just ordered a Deltaprintr mini hot end for another project, looking forward to trying that.

Make sure to put something insulating over/around the IR sensor PCB, you've got a great location for it - the magnitude of observed effector tilt should be very low, mine is about this close to my heater block. However with mine if the fan shroud its attached to rotates slightly bringing the IR sensor closer to the heater block (despite silicone cover on the heater block and lots of kapton around the IR sensor) the sensor starts to perform erratically, not triggering etc, causing nozzle crashes.

Just an update partially the sensor issues I was having were from having the analogue threshold for the IR sensor to be triggered slightly above its normal trigger threshold of 535, I think I'd set 536 or something. Changed it to 480 and it triggers perfectly.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Tomas's Kossel XL build log November 19, 2016 05:23PM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Tomas's Kossel XL build log November 29, 2016 05:33AM |

Registered: 8 years ago Posts: 59 |

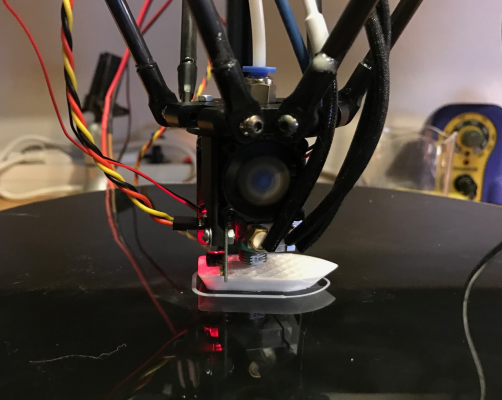

I finally ordered the remaining parts, and the Duet Wifi and IR sensor arrived last week. I replaced the temporary 0.8.5 board and everything went smoothly. The linear rails were estimated to arrive a few days ago, but have yet to appear. In the meantime, I mounted an old set of shorter (400 mm) rails that I already have, so I can at least get the machine up and running with a limited build height. The endstops are now mounted 300 mm from the top of the frame, which looks silly, but works.

The pushfit connector arrived from the states, so I can finally use my hotend. I had some problem with jamming, probably because I mounted the print cooling fan too close to the back of the heatsink, preventing airflow.

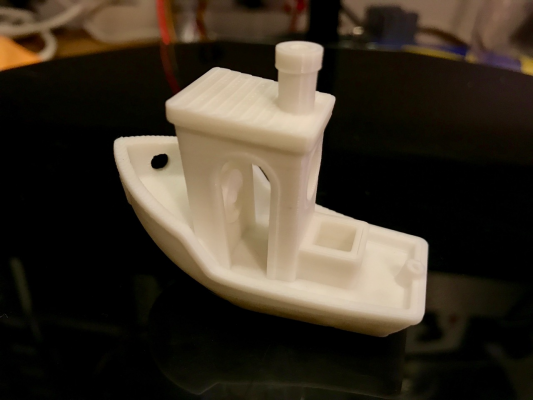

I increased the angle of the mounted part cooling fan to let more air through behind it, and I haven't had a jam since. The first thing I printed was a benchy in white PLA, and I'm very happy with the result. Not bad for a first print without any tuning beyond the probe Z offset.

The extruder is more noisy than the one on my old machine, which is of the exact same model. Not sure why yet.

The pushfit connector arrived from the states, so I can finally use my hotend. I had some problem with jamming, probably because I mounted the print cooling fan too close to the back of the heatsink, preventing airflow.

I increased the angle of the mounted part cooling fan to let more air through behind it, and I haven't had a jam since. The first thing I printed was a benchy in white PLA, and I'm very happy with the result. Not bad for a first print without any tuning beyond the probe Z offset.

The extruder is more noisy than the one on my old machine, which is of the exact same model. Not sure why yet.

|

Re: Tomas's Kossel XL build log November 29, 2016 05:47AM |

Registered: 8 years ago Posts: 3,525 |

Looks good, nice benchy.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Tomas's Kossel XL build log November 29, 2016 03:38PM |

Registered: 10 years ago Posts: 14,672 |

That looks excellent for a first print.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tomas's Kossel XL build log December 04, 2016 01:37PM |

Registered: 8 years ago Posts: 59 |

Ugh, this Dyze hotend is driving me crazy. I've had several jams for no apparent reason, and a lot of leakage for a "leak-proof" hotend. I've spent so many hours trying to get it to work again, only to have it jam again the next day. I might switch to the 1730 hotend, which I know to be reliable.

|

Re: Tomas's Kossel XL build log December 04, 2016 05:54PM |

Registered: 8 years ago Posts: 3,525 |

That's a shame. I've got the Deltaprintr mini hot end which I started using yesterday, no jams so far and its very small. Heats up quickly too. No thermistor table for it so had to make my own for Marlin. No documentation either, not really a problem but easier to mess it up if you were a beginner, you know attach the thermistor to the heater output etc....

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Tomas's Kossel XL build log December 05, 2016 04:42AM |

Registered: 8 years ago Posts: 59 |

Quote

DjDemonD

That's a shame. I've got the Deltaprintr mini hot end which I started using yesterday, no jams so far and its very small. Heats up quickly too. No thermistor table for it so had to make my own for Marlin. No documentation either, not really a problem but easier to mess it up if you were a beginner, you know attach the thermistor to the heater output etc....

I'd be interested in trying that one, but as far as I can tell, it's only available for 12V, and I'm using 24 :-/

Edited 1 time(s). Last edit at 12/05/2016 04:42AM by tomasf.

|

Re: Tomas's Kossel XL build log December 23, 2016 06:06AM |

Registered: 8 years ago Posts: 312 |

|

Re: Tomas's Kossel XL build log December 23, 2016 07:00PM |

Registered: 8 years ago Posts: 59 |

Quote

Lykle

For future reference, if you need V-slot profiles etc in Europe, try Ratrig.com

Based in Portugal I think. They supplied me with profiles and seem to be on the ball.

Interesting, thanks. I do remember visiting that site while googling around for extrusion suppliers in Europe. I probably passed on them since they don't seem to offer 2060 sizes.

|

Re: Tomas's Kossel XL build log December 24, 2016 03:56AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Tomas's Kossel XL build log January 02, 2017 01:14PM |

Registered: 8 years ago Posts: 59 |

|

Re: Tomas's Kossel XL build log January 03, 2017 05:37AM |

Registered: 8 years ago Posts: 3,525 |

How are you getting on with the hotend now? I had a genuine e3d v6 which jammed 3-4 times, in the end I tried a little oil and no problems since (groundnut oil). Feels wrong but it does seem to work. Mini hotend has been problem free so far, but I haven't put that many hours on it yet.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Tomas's Kossel XL build log January 03, 2017 05:54AM |

Registered: 8 years ago Posts: 3,525 |

Quote

dougal1957

Ooznest in the UK do all the OpenBuilds extrusions and will even cut to your size if you wish.

www.ooznest.co.uk

HTH

Doug

One thing to mention I ordered 4 x 500mm 2020 from them, they arrived but they were not all exactly 500mm as I presume they are a stock length, So I had much messing around to get them all the same length for my corexy frame. I am sure had I asked for 4x 499mm I would have got 4 at exactly 499mm.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Tomas's Kossel XL build log January 03, 2017 01:19PM |

Registered: 8 years ago Posts: 59 |

Quote

DjDemonD

How are you getting on with the hotend now? I had a genuine e3d v6 which jammed 3-4 times, in the end I tried a little oil and no problems since (groundnut oil). Feels wrong but it does seem to work. Mini hotend has been problem free so far, but I haven't put that many hours on it yet.

It's better now. It still jams every now and then, mostly when switching filaments, but it's acceptably rare. I'm getting more stringing than with my previous hotends, and increasing the retract length and decreasing temperature didn't help that much.

|

Re: Tomas's Kossel XL build log April 04, 2017 09:10AM |

Registered: 8 years ago Posts: 59 |

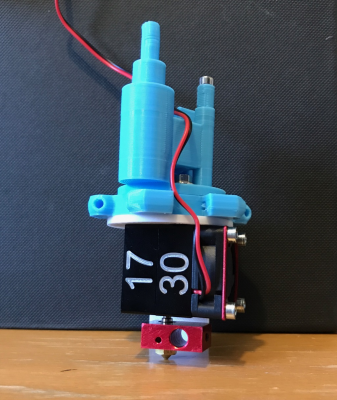

I'm now in the process of re-thinking the extruder/hotend setup. I have an early bird Zesty Nimble on order, which hopefully ships reasonably soon. I've also decided to take the opportunity to replace the DyzEnd-X with the 1730 hotend, which is so much better.

While the DyzEnd-X doesn't jam as often as it used to, it's still not great. It leaked quite a lot in the beginning for a "leak-free" hotend. Sure, if you tighten the nozzle repeatedly and do everything perfectly, I'm sure it doesn't leak, but with those criteria, any hotend could be considered leak-free. Meanwhile, the 1730 hotend literally can't leak, because the nozzle and the guiding tube is a single part (FNU). It also has a significantly more quiet fan, perhaps in part because it's a bit larger.

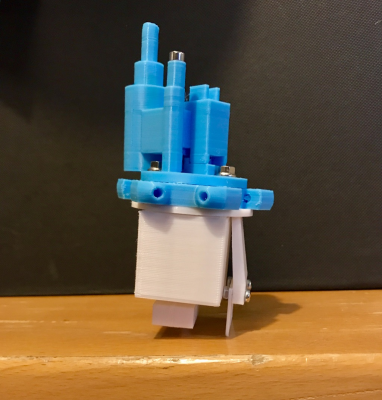

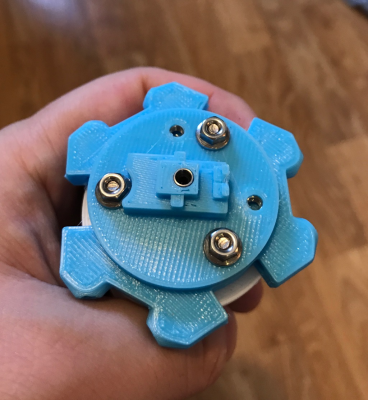

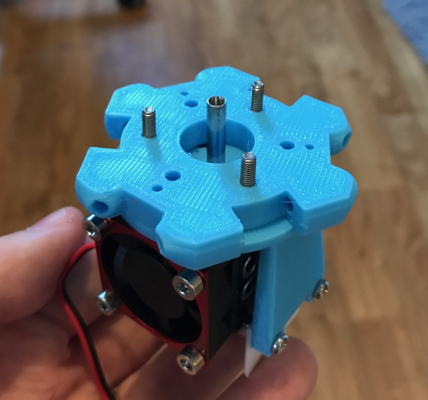

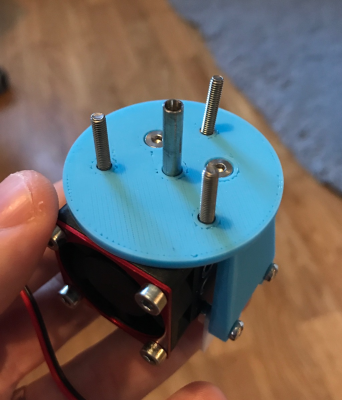

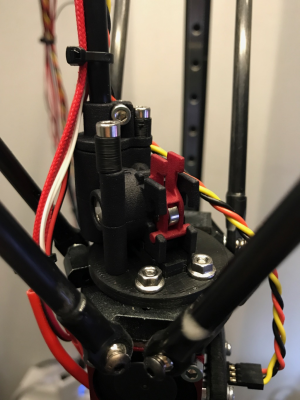

The combination of the Nimble and 1730 should be really sweet. The FNU shaft goes right up to the Nimble, so no intermediary PTFE tube is needed at all. I've made top/bottom mount prototypes for this combo (and dc42's IR sensor), and it seems very promising. Here's a photo of the mounts, together with mockups of the Nimble, hotend and a Kossel effector modified to match the thickness and hole layout of the Robotdigg effector:

I've ordered a 1730, which arrives tomorrow. Fingers crossed the mount fits!

While the DyzEnd-X doesn't jam as often as it used to, it's still not great. It leaked quite a lot in the beginning for a "leak-free" hotend. Sure, if you tighten the nozzle repeatedly and do everything perfectly, I'm sure it doesn't leak, but with those criteria, any hotend could be considered leak-free. Meanwhile, the 1730 hotend literally can't leak, because the nozzle and the guiding tube is a single part (FNU). It also has a significantly more quiet fan, perhaps in part because it's a bit larger.

The combination of the Nimble and 1730 should be really sweet. The FNU shaft goes right up to the Nimble, so no intermediary PTFE tube is needed at all. I've made top/bottom mount prototypes for this combo (and dc42's IR sensor), and it seems very promising. Here's a photo of the mounts, together with mockups of the Nimble, hotend and a Kossel effector modified to match the thickness and hole layout of the Robotdigg effector:

I've ordered a 1730, which arrives tomorrow. Fingers crossed the mount fits!

|

Re: Tomas's Kossel XL build log April 05, 2017 05:36AM |

Registered: 8 years ago Posts: 59 |

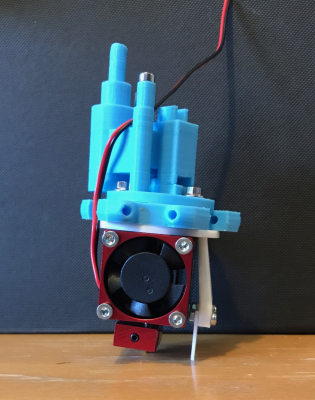

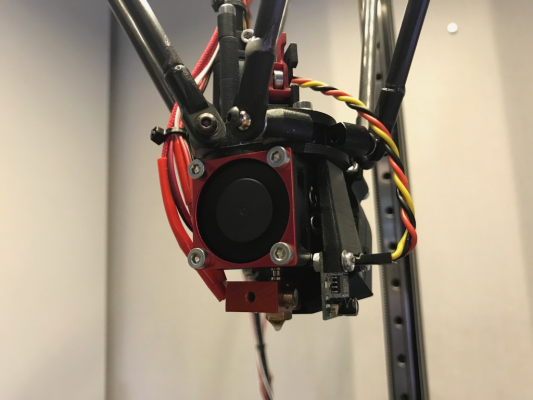

The 1730 arrived today, and it fits. I needed to fine-tune the Z offset of the IR sensor, but that's it. They've added a red metal cover to the fan, which wasn't present in my previous Kickstarted unit. This is most likely to prevent overtightened bolts from cracking the fan plastic.

|

Re: Tomas's Kossel XL build log May 18, 2017 03:08PM |

Registered: 8 years ago Posts: 59 |

A few days ago, my Nimble finally arrived! I'm apparently the first customer to receive it. The adapter I designed and prototyped using the mock Nimble model actually fit the real thing. I later had to adjust the adapter slightly to avoid Nimble touching my delta rods.

Nimble looks solid, with a nice grainy surface finish. The breech block was in a darker red color than I expected from the photos. Assembling it was fairly easy. The strands of the drive cable kept flaring, so sliding it into the worm gear was tricky. Cutting a few of the problematic strands and re-shaping the cable end into a square helped. No biggie.

I also installed the 1730 hotend I received previously. I had some problems pushing filament through easily, but some thermal paste on the FNU fixed it.

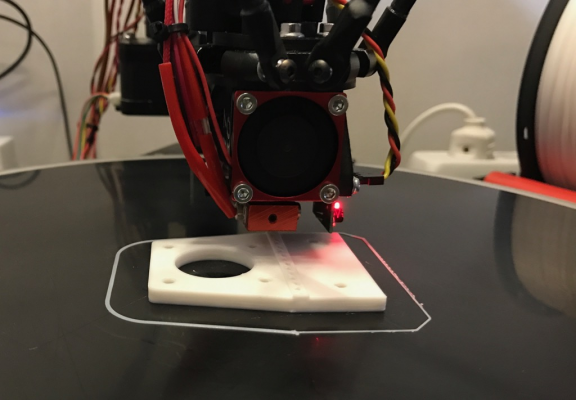

The new setup works very well. Nimble is a joy to use. It pretty much just works. After adjusting steps per mm, acceleration, jerk and retraction settings, everything works as expected. It's fantastic to finally get rid of the bowden tube.

Almost two years ago, I bought a roll of flexible TPE filament. The printer I used back then was crap, and I've only used bowden machines since, so the filament has been sitting unused in a drawer. Yesterday, I tried printing a hollow vase with it, and Nimble handled it beautifully.

Nimble looks solid, with a nice grainy surface finish. The breech block was in a darker red color than I expected from the photos. Assembling it was fairly easy. The strands of the drive cable kept flaring, so sliding it into the worm gear was tricky. Cutting a few of the problematic strands and re-shaping the cable end into a square helped. No biggie.

I also installed the 1730 hotend I received previously. I had some problems pushing filament through easily, but some thermal paste on the FNU fixed it.

The new setup works very well. Nimble is a joy to use. It pretty much just works. After adjusting steps per mm, acceleration, jerk and retraction settings, everything works as expected. It's fantastic to finally get rid of the bowden tube.

Almost two years ago, I bought a roll of flexible TPE filament. The printer I used back then was crap, and I've only used bowden machines since, so the filament has been sitting unused in a drawer. Yesterday, I tried printing a hollow vase with it, and Nimble handled it beautifully.

|

Re: Tomas's Kossel XL build log May 20, 2017 09:44AM |

Registered: 8 years ago Posts: 312 |

Hey Tomas,

Nice to see the flexible vase finally being printed.

Happy with the fact that you are happy with the Nimble. Thank you for the great photo's.

Also, I like the fact that you are using the 1730 hot end. It had kind of slipped my mind, so it was good to get reminded.

Nice to see that the flexibility of the Nimble makes it possible to fit any hot end.

One more thing that can help you with the 1730. When you remove the breech block you can really feel exactly how much force is needed to push the filament through the hot nozzle. Especially as it completely opens up the filament path. It is a great way to determine what is happening inside your nozzle. You can instantly feel if there is a blockage or if something else is wrong. It is a great diagnostic tool for melt zones.

Lykle

Nice to see the flexible vase finally being printed.

Happy with the fact that you are happy with the Nimble. Thank you for the great photo's.

Also, I like the fact that you are using the 1730 hot end. It had kind of slipped my mind, so it was good to get reminded.

Nice to see that the flexibility of the Nimble makes it possible to fit any hot end.

One more thing that can help you with the 1730. When you remove the breech block you can really feel exactly how much force is needed to push the filament through the hot nozzle. Especially as it completely opens up the filament path. It is a great way to determine what is happening inside your nozzle. You can instantly feel if there is a blockage or if something else is wrong. It is a great diagnostic tool for melt zones.

Lykle

|

Re: Tomas's Kossel XL build log May 20, 2017 01:07PM |

Registered: 15 years ago Posts: 8 |

|

Re: Tomas's Kossel XL build log May 20, 2017 01:57PM |

Registered: 8 years ago Posts: 59 |

Quote

perolalars

I am really interested of what brand the linkage heads are (if thats the right word for it) at the ends of your carbon fiber rods?

And maybe where you bought them?

Regards

Per

They're Traxxas 5347 rod ends, bought at Kullagergrossisten: [www.kullagergrossisten.se]

|

Re: Tomas's Kossel XL build log May 27, 2017 03:19AM |

Registered: 7 years ago Posts: 232 |

why did you buy yours extrusion in china if you live in eu?

best price are here(dc42guide)

[www.motedis.fr]

what is you print size max?

great looking machine

Edited 1 time(s). Last edit at 05/27/2017 03:26AM by titeuf007.

best price are here(dc42guide)

[www.motedis.fr]

what is you print size max?

great looking machine

Edited 1 time(s). Last edit at 05/27/2017 03:26AM by titeuf007.

Sorry, only registered users may post in this forum.