Skewed print any ideas?

Posted by DjDemonD

|

Re: Skewed print any ideas? December 23, 2016 01:22PM |

Registered: 8 years ago Posts: 3,525 |

No I'm just joking I haven't had chance to change the belts yet, it prints okay at 50mm or higher so if it printed everything onto a 50mm raft it would work.

Edited 1 time(s). Last edit at 12/23/2016 01:25PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 12/23/2016 01:25PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? December 23, 2016 01:40PM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Skewed print any ideas? December 23, 2016 01:49PM |

Registered: 10 years ago Posts: 14,672 |

I was starting to suspect a firmware bug until you raised the bed 50mm and the problem went away. Now I think you may have a problem with your linear rails, sliders or carriages. Are you quite certain that none of your carriages is rotating about either its face or the Z axis over that bottom 50mm of height?

I recommend you put a bulls-eye spirit level on your effector if you don't have one already, to help detect effector tilt. I have a lot of spare ones, so if you are in the UK, drop me a PM.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I recommend you put a bulls-eye spirit level on your effector if you don't have one already, to help detect effector tilt. I have a lot of spare ones, so if you are in the UK, drop me a PM.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Skewed print any ideas? December 23, 2016 01:52PM |

Registered: 8 years ago Posts: 3,525 |

I've got one on there but thanks for the offer. It has a slight tilt but it's consistent at various x, y coordinates. I suspect it's the positioning of the spirit level or a lack of a genuinely flat level surface in the effector to place it.

None of the linear rail carriages have any play, the printed carriages on them are solid, so are the rods and now the effector after I beefed it up a bit. Belts might be the culprit as I tightened the x belt about 10 days ago, but now it's a bit loose again, so maybe the steel wires are snapping.

Might get chance to swap them out for non metal belts tonight.

Edited 2 time(s). Last edit at 12/23/2016 01:56PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

None of the linear rail carriages have any play, the printed carriages on them are solid, so are the rods and now the effector after I beefed it up a bit. Belts might be the culprit as I tightened the x belt about 10 days ago, but now it's a bit loose again, so maybe the steel wires are snapping.

Might get chance to swap them out for non metal belts tonight.

Edited 2 time(s). Last edit at 12/23/2016 01:56PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? December 23, 2016 03:56PM |

Registered: 7 years ago Posts: 154 |

The fact that it offset by the raised bed narrows the field significantly. Sadly that almost makes it worse, as it rules out most of what I thought it could be! Localized Mechanical binding and carriage issues wouldn't do it. The carriages only have to move 50mm in unison to get past your trouble zone, but much more to try the print on the other side of the bed.. If it was a troublesome area of v slot or something you wouldn't get the same result.

I've got no idea what's going on, but I DO know that when you figure it out the whole damn delta reprap crowd is gonna rejoice with you haha

I've got no idea what's going on, but I DO know that when you figure it out the whole damn delta reprap crowd is gonna rejoice with you haha

|

Re: Skewed print any ideas? December 24, 2016 03:57AM |

Registered: 8 years ago Posts: 312 |

|

Re: Skewed print any ideas? December 24, 2016 04:20AM |

Registered: 8 years ago Posts: 3,525 |

WOOOOOHOOOOOOOO !!!!

Sorry, was a bit overcome there. SOLVED......

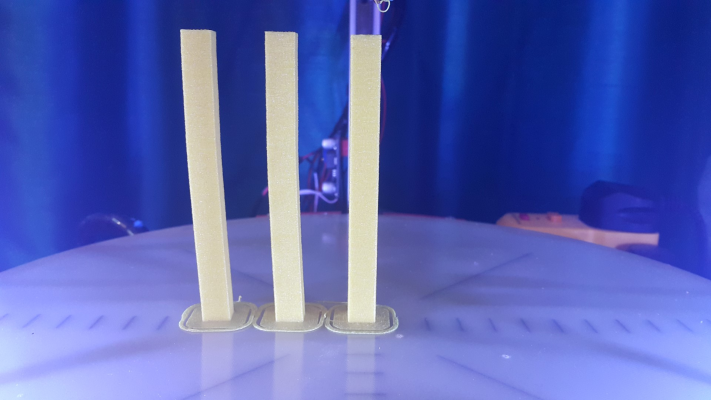

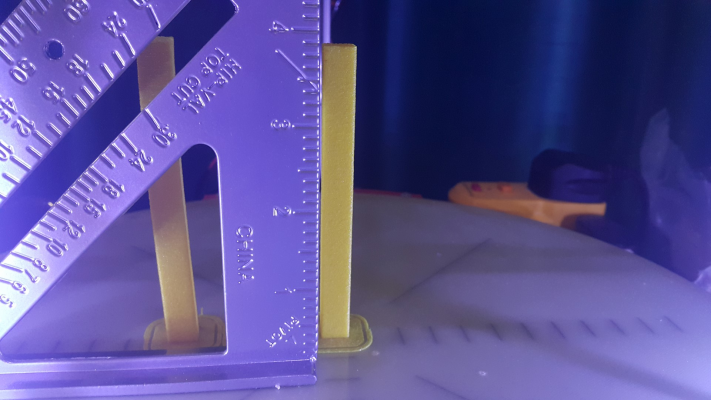

It was the belts. Now using common or garden black fibre reinforced GT2 belts and printing 100mm tall straight towers.

A massive thank you to everyone who has contributed here.

Steel reinforced belts and 16 tooth pulleys - maybe not such a good plan.

Merry Christmas and Happy New Year

ADMIN - could you change the title of the thread to include SOLVED?

Edited 1 time(s). Last edit at 12/24/2016 04:24AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, was a bit overcome there. SOLVED......

It was the belts. Now using common or garden black fibre reinforced GT2 belts and printing 100mm tall straight towers.

A massive thank you to everyone who has contributed here.

Steel reinforced belts and 16 tooth pulleys - maybe not such a good plan.

Merry Christmas and Happy New Year

ADMIN - could you change the title of the thread to include SOLVED?

Edited 1 time(s). Last edit at 12/24/2016 04:24AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? December 24, 2016 05:36AM |

Registered: 7 years ago Posts: 154 |

|

Re: Skewed print any ideas? December 24, 2016 05:44AM |

Registered: 8 years ago Posts: 3,525 |

Quote

clearlynotstefan

Woooooo! Odd, that it'd happen at the same height but with different xy positions seems very weird to me.

Yes it's strange. I admit when I tried test prints around the bed I didn't go to the extremities.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? December 24, 2016 06:05AM |

Registered: 8 years ago Posts: 916 |

|

Re: Skewed print any ideas? December 24, 2016 07:25AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Skewed print any ideas? December 24, 2016 09:35AM |

Registered: 8 years ago Posts: 312 |

|

Re: Skewed print any ideas? December 24, 2016 10:24AM |

Registered: 8 years ago Posts: 3,525 |

Congratulations. That's awesome news. Sounds mad but I've really enjoyed this problem thanks to this community. Have a great Christmas everyone.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 03, 2017 03:14PM |

Registered: 8 years ago Posts: 90 |

|

Re: Skewed print any ideas? January 03, 2017 03:17PM |

Registered: 8 years ago Posts: 3,525 |

Still on 16s swapped belts to more standard rubber & fibre glass with inline tensioners.

Autocalibration deviation dropped from 0.02 to 0.04 so there is something in those steel belts (steel obviously) would be keen to try polyurethane and kevlar/aramid to see how they compare to neoprene/fibreglass.

Edited 1 time(s). Last edit at 01/03/2017 03:26PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Autocalibration deviation dropped from 0.02 to 0.04 so there is something in those steel belts (steel obviously) would be keen to try polyurethane and kevlar/aramid to see how they compare to neoprene/fibreglass.

Edited 1 time(s). Last edit at 01/03/2017 03:26PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 03, 2017 03:27PM |

Registered: 10 years ago Posts: 14,672 |

16 tooth pulleys have the advantage that the Z height change per microstep is a nice round number, e.g. with 16x microstepping it's 0.005 or 0.01mm depending on your motors. With 20 tooth pulleys you get 0.00625 or 0.0125mm.

Edited 1 time(s). Last edit at 01/03/2017 03:30PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 01/03/2017 03:30PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Skewed print any ideas? January 03, 2017 03:35PM |

Registered: 8 years ago Posts: 3,525 |

Yeah I definitely prefer them with 0.9 degree motors,but this combination certainly requires the improved processing power of 32 bit boards. Plan to move to 0.9 degree motors on the corexy too trying the rearm board.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 03, 2017 03:39PM |

Registered: 8 years ago Posts: 90 |

|

Re: Skewed print any ideas? January 03, 2017 03:41PM |

Registered: 8 years ago Posts: 3,525 |

My Chinese copies of them come with smooth 16t diameter idlers so possibly.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 03, 2017 03:47PM |

Registered: 8 years ago Posts: 90 |

|

Re: Skewed print any ideas? January 03, 2017 04:15PM |

Registered: 8 years ago Posts: 3,525 |

If you put the twist below the carriage down to the drive pulley this should work but you'll need to ensure if your carriages have toothed belt grips that they face the right way.

I'm running the toothed side of the belt over the idler whether this is detrimental to print quality or not is hard to tell if it is, it's marginal.

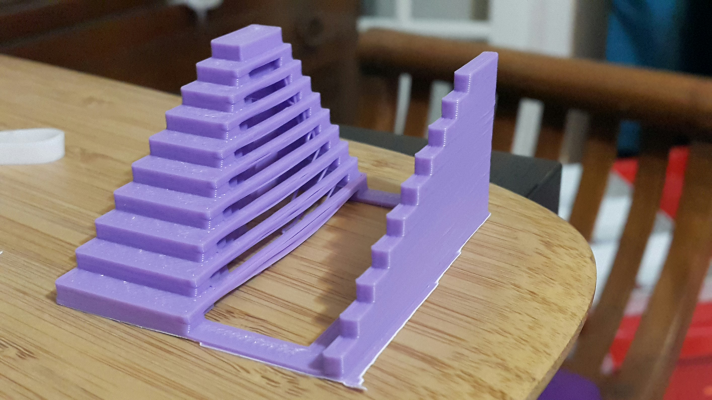

This is the sort of print quality it's turning out

I tried flanged toothed idlers on my kossel mini, I'd say probably noisier and the belt seemed to bump over the teeth and interfere with the flanges.

Edited 1 time(s). Last edit at 01/03/2017 04:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I'm running the toothed side of the belt over the idler whether this is detrimental to print quality or not is hard to tell if it is, it's marginal.

This is the sort of print quality it's turning out

I tried flanged toothed idlers on my kossel mini, I'd say probably noisier and the belt seemed to bump over the teeth and interfere with the flanges.

Edited 1 time(s). Last edit at 01/03/2017 04:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 03, 2017 04:33PM |

Registered: 8 years ago Posts: 90 |

|

Re: Skewed print any ideas? January 03, 2017 05:11PM |

Registered: 8 years ago Posts: 3,525 |

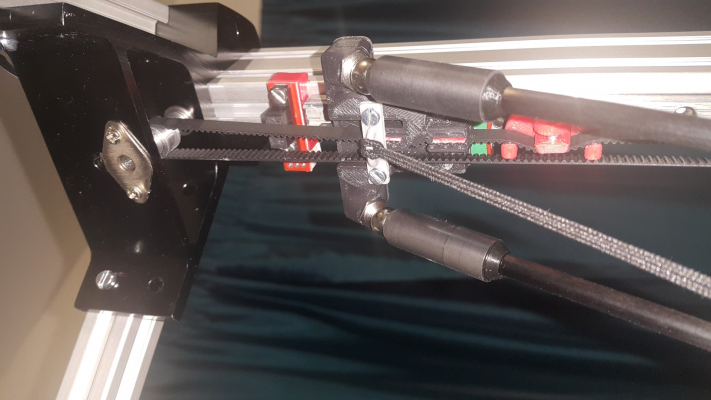

Yes but I changed carriages from metal k800 to printed Haydn magnets and the belt grips are the "normal" way around.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 03, 2017 05:27PM |

Registered: 8 years ago Posts: 3,525 |

This is how it currently looks.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 03, 2017 07:53PM |

Registered: 8 years ago Posts: 916 |

Quote

Andreas15

I know it's not really the topic here, but do you think there is an advantage in using an idler with teeth instead of a smooth one and running the back (twisting) of the belt on it?

When I first built my mini, I twisted the belt and had the smooth side running over the smooth idler.

Then I went to linear rails, and due to the carriage design had to remove the twist. I can't say that I notice the belt teeth in the print, but I have a set of toothed idlers sitting here that will be installed in the next few days. There is a resonance in my frame which means that I can't print at over 50 mm/s without seeing the vibrations in my print (and hearing the loud resonance). Whether this is due to the toothed belt running over the smooth idler, or something to do with my motors I can't say.

Interesting that DJDemonD had issues with those toothed idlers. I'll see how they go on my mini.

|

Re: Skewed print any ideas? January 03, 2017 08:06PM |

Registered: 8 years ago Posts: 3,525 |

They might have been (were) cheap badly made idlers.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 04, 2017 04:24AM |

Registered: 8 years ago Posts: 5,232 |

Quote

dc42

16 tooth pulleys have the advantage that the Z height change per microstep is a nice round number, e.g. with 16x microstepping it's 0.005 or 0.01mm depending on your motors. With 20 tooth pulleys you get 0.00625 or 0.0125mm.

Is that really an advantage?

I know from gearboxes, that they intentionally use gears with prime numbers. ( eg,17 tooth ) Don't know, if there are similar effects seen with belts'n pulleys, but it would be worth trying 17 toothed pulleys.

Has anyone seen herringbone belts and pulleys?

|

Re: Skewed print any ideas? January 04, 2017 04:58AM |

Registered: 8 years ago Posts: 3,525 |

Why do they use gears with prime numbers?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Skewed print any ideas? January 04, 2017 08:56AM |

Registered: 9 years ago Posts: 1,159 |

Quote

o_lampe

Quote

dc42

16 tooth pulleys have the advantage that the Z height change per microstep is a nice round number, e.g. with 16x microstepping it's 0.005 or 0.01mm depending on your motors. With 20 tooth pulleys you get 0.00625 or 0.0125mm.

Is that really an advantage?

I know from gearboxes, that they intentionally use gears with prime numbers. ( eg,17 tooth ) Don't know, if there are similar effects seen with belts'n pulleys, but it would be worth trying 17 toothed pulleys.

Has anyone seen herringbone belts and pulleys?

Yes it is you can step one microstep at a time for Calibration purposes much easier with they come out at a nice even number jogging the head .01 mm is possible with 16 tooth pulley but not with 17 or 20 for that matter

Doug

|

Re: Skewed print any ideas? January 04, 2017 10:23AM |

Registered: 8 years ago Posts: 5,232 |

OK, I see the benefit during calibration.

Using prime numbers in gears means, you'll NEVER have a repeating pressure pattern. That leads to a more even wear on the teeth and prevents damages.

Worst case would be: every time a cylinder fires, the same tooth is on duty.

Having a belt/step ratio with even numbers means, you probably see repeating patterns on the print.

Many people use toothed idler bearings, because the belt rolls smoother.

Using 17 toothed pulleys falls in the same category.

Edited 1 time(s). Last edit at 01/04/2017 10:25AM by o_lampe.

Using prime numbers in gears means, you'll NEVER have a repeating pressure pattern. That leads to a more even wear on the teeth and prevents damages.

Worst case would be: every time a cylinder fires, the same tooth is on duty.

Having a belt/step ratio with even numbers means, you probably see repeating patterns on the print.

Many people use toothed idler bearings, because the belt rolls smoother.

Using 17 toothed pulleys falls in the same category.

Edited 1 time(s). Last edit at 01/04/2017 10:25AM by o_lampe.

Sorry, only registered users may post in this forum.