RIP large Kossel and Rostock deltas - C beam Deltas are next big thing

Posted by newbob

|

RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 11, 2017 09:12AM |

Registered: 7 years ago Posts: 270 |

I predict once openbuild C channel deltas become popular, Kossel and Rostock designs will be history. Example of C-beam design: TEVO little monster:

Three 1000m long C channel profiles from Openbuilds are about $100 shipped (in USA). Add top and bottom plates for $60 (estimating) and you have a complete and sturdy large frame that is easy to align (as long as C channel profiles are cut square). Another advantage is no wasted space at the bottom or top easily adding 10cm to vertical print area.

Problem right now is that there top and bottom plates are not available but I'm sure some enterprising laser cutting shops will start selling them on ebay soon ( so I hope ).

PS.: plate 4.5mm thick from eMachineShop would cost $60 each (400mm build area) so I underestimated the cost of plates. Nonetheless, it is still cheaper (and surdier) considering that 2040 Kossel corners alone cost around $100.

Edited 2 time(s). Last edit at 05/11/2017 10:11AM by newbob.

Three 1000m long C channel profiles from Openbuilds are about $100 shipped (in USA). Add top and bottom plates for $60 (estimating) and you have a complete and sturdy large frame that is easy to align (as long as C channel profiles are cut square). Another advantage is no wasted space at the bottom or top easily adding 10cm to vertical print area.

Problem right now is that there top and bottom plates are not available but I'm sure some enterprising laser cutting shops will start selling them on ebay soon ( so I hope ).

PS.: plate 4.5mm thick from eMachineShop would cost $60 each (400mm build area) so I underestimated the cost of plates. Nonetheless, it is still cheaper (and surdier) considering that 2040 Kossel corners alone cost around $100.

Edited 2 time(s). Last edit at 05/11/2017 10:11AM by newbob.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 11, 2017 10:41AM |

Registered: 8 years ago Posts: 916 |

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 11, 2017 11:39AM |

Registered: 7 years ago Posts: 270 |

Quote

nebbian

Looks interesting!

How do you mount linear rails to this? Is this meant for dual linear rails, or wheels?

Good question - mentioned TEVO is using rollers. Personally I think linear guides are great for Delta printers so I would try to mount them by drilling through the middle profile...

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 12, 2017 02:18AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 12, 2017 03:22AM |

Registered: 8 years ago Posts: 916 |

I think you could mount dual linear rails on there, which would give you a lot of torsional rigidity on the carriage. This is because you're not depending on the distance between bearing surfaces on the one bearing (12mm for MGN12 I think), you're depending on the distance between rails (60mm). I have noticed that my robotdigg carriages do have a tiny bit of slop. For a bigger, faster delta it might resolve this issue. It would be twice as expensive (obviously) with regard to cost of linear rails. I think that industrial systems usually have at least two, if not four, bearing carriages per thing that's being moved.

This might also be a good solution for the Z axis on cartesian printers, you could mount two linear rails (and four bearing carriages) and not have any issues keeping them lined up. That would be as close to slop-free as I think it's possible to get.

This might also be a good solution for the Z axis on cartesian printers, you could mount two linear rails (and four bearing carriages) and not have any issues keeping them lined up. That would be as close to slop-free as I think it's possible to get.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 12, 2017 01:11PM |

Registered: 7 years ago Posts: 270 |

Usually linear rails have no detectable slop. When two are used in parallel one is high precision and other normal precision so they don't lock up. Maybe with some Chinese linear rails there's more play - mine are solid ( I have MGN15H)

Edited 1 time(s). Last edit at 05/12/2017 01:29PM by newbob.

Edited 1 time(s). Last edit at 05/12/2017 01:29PM by newbob.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 13, 2017 02:53AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 13, 2017 11:13AM |

Registered: 7 years ago Posts: 270 |

Below is the link to the review of the tevo printer, probably one of the best reviews of any printer. As much as I'm not a big fan of rollers they seem to perform ok and big issue are stepper drivers of all things (it's tevo's big mistake since it's widely known that 8225 do not work well above 12V)

[youtu.be]

Here's sister design with 2060 I found on reprap (apparently the frame was on a kickstarter in 2016):

[reprap.org]

Edited 2 time(s). Last edit at 05/13/2017 11:34AM by newbob.

[youtu.be]

Here's sister design with 2060 I found on reprap (apparently the frame was on a kickstarter in 2016):

[reprap.org]

Edited 2 time(s). Last edit at 05/13/2017 11:34AM by newbob.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 13, 2017 09:33PM |

Registered: 10 years ago Posts: 293 |

If you don't want to use wheels you would be way better off using 60x40 extrusions instead. That would give you the nice big verticals and proper alignment of the linear rail. The top/bottom plate approach does make for an easy assembly and seems pretty stiff even at the Little Monster's 1.2M height.

If Openbuilds would start making 100x40 C-Beam that would be fun because you could then easily mount the linear rail in the channel.

Edited 1 time(s). Last edit at 05/13/2017 09:35PM by WZ9V.

If Openbuilds would start making 100x40 C-Beam that would be fun because you could then easily mount the linear rail in the channel.

Edited 1 time(s). Last edit at 05/13/2017 09:35PM by WZ9V.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 14, 2017 09:50AM |

Registered: 7 years ago Posts: 270 |

Quote

WZ9V

If you don't want to use wheels you would be way better off using 60x40 extrusions instead. That would give you the nice big verticals and proper alignment of the linear rail. The top/bottom plate approach does make for an easy assembly and seems pretty stiff even at the Little Monster's 1.2M height.

If Openbuilds would start making 100x40 C-Beam that would be fun because you could then easily mount the linear rail in the channel.

One of the reasons I went with 15mm rails for my delta was to increase surface contact for rails siting on top of the V-slot.

On the other hand - if you don't mind drilling through to attach linear rail to the flat portion of extrusion - you'll get even more support - even with 9mm rail. So there are advantages and disadvantages to both.

Edited 1 time(s). Last edit at 05/14/2017 09:53AM by newbob.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 18, 2017 06:03AM |

Registered: 8 years ago Posts: 3,525 |

I like the idea, and if I built another large delta I'd seriously look into it, it does simplify the frame (never a bad thing) and I am sure with decent top and bottom plates, makes for a rigid printer. Not inclined to dismantle my Kossel XL just yet though.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 18, 2017 01:27PM |

Registered: 8 years ago Posts: 5,232 |

The top and bottom plates are what keeps my excitement low.

The bad thing about the way they are mounted is: the center holes of the extrusion don't hold much. They are meant to direct tap a thread with the screw.

I'd put some horizontal extrusions between the towers anyway to keep the plates from bending.

The bad thing about the way they are mounted is: the center holes of the extrusion don't hold much. They are meant to direct tap a thread with the screw.

I'd put some horizontal extrusions between the towers anyway to keep the plates from bending.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 20, 2017 08:22PM |

Registered: 10 years ago Posts: 169 |

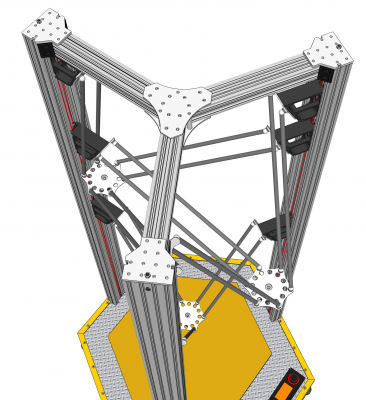

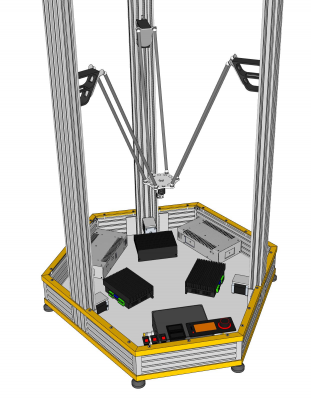

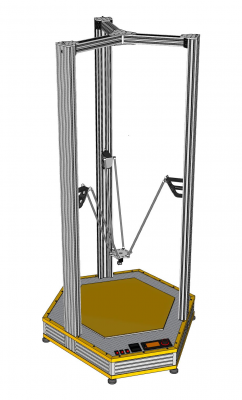

Here is a C-Beam Delta design I drew up a year or two ago. This would use 1000mm C-Beams for the verticals and 4040 extrusions for the triangulated top. The base uses 8020 for the base perimeters. The usable bed space is 500mm dia.

Edited 1 time(s). Last edit at 05/20/2017 08:31PM by simspeed.

|

Re: RIP large Kossel and Rostock deltas - C beam Deltas are next big thing May 24, 2017 08:18PM |

Registered: 7 years ago Posts: 270 |

Quote

simspeed

[attachment 94386 C-BeamDelta3.JPG][attachment 94385 C-BeamDelta2.JPG][attachment 94384 C-BeamDelta.JPG]

Here is a C-Beam Delta design I drew up a year or two ago. This would use 1000mm C-Beams for the verticals and 4040 extrusions for the triangulated top. The base uses 8020 for the base perimeters. The usable bed space is 500mm dia.

Nice. I'm building delta that has top and bottom like your design's top (except that plates in the corners go on the sides to counteract slanting of towers).

Edited 1 time(s). Last edit at 05/24/2017 08:18PM by newbob.

Sorry, only registered users may post in this forum.