ball-cap rod-end concept pros and cons

Posted by shadowphile

|

ball-cap rod-end concept pros and cons September 09, 2017 12:44AM |

Registered: 9 years ago Posts: 280 |

Hello, after custom machining my effector and carriages I am now frequently getting .01 mm auto-levels on a machine with a 300mm print space, which I am pretty happy with.

However, the Traxxis rod-ends are definitely the weak link (no pun intended!) and I'm looking at alternatives.

The magnetic ball approach seems popular and easy to make accurate but I just don't trust magnets and shudder when I imagine my untended printer smashing itself to pieces.

Instead I recently learned about the ball-cap approach: the balls are mounted axially on the effector and the rod-ends are shaped to cap laterally on the ball, with a spring pulling the rod ends together.

My thought is that making the ball-cap end precisely centered on the ball itself is important, otherwise the effective rod-lengths will change with angle.

So far I have only encountered this design at Trick Laser

The parts are injected-molded Delrin so the accuracy is probably really good and likely to stay that way, IF you can find 3/8" ball studs. Most ball-studs I can find are 10mm, which differs from the Trick Laser parts by about 5%. Damn Americans using imperials units! (I am a damn American btw). A short ball-stud would directly replace the traxxis ball without any redesign (assuming the same M3 stud).

So far I have not found much hands-on or theoretical discussion of this idea so I am starting one now.

thanks

However, the Traxxis rod-ends are definitely the weak link (no pun intended!) and I'm looking at alternatives.

The magnetic ball approach seems popular and easy to make accurate but I just don't trust magnets and shudder when I imagine my untended printer smashing itself to pieces.

Instead I recently learned about the ball-cap approach: the balls are mounted axially on the effector and the rod-ends are shaped to cap laterally on the ball, with a spring pulling the rod ends together.

My thought is that making the ball-cap end precisely centered on the ball itself is important, otherwise the effective rod-lengths will change with angle.

So far I have only encountered this design at Trick Laser

The parts are injected-molded Delrin so the accuracy is probably really good and likely to stay that way, IF you can find 3/8" ball studs. Most ball-studs I can find are 10mm, which differs from the Trick Laser parts by about 5%. Damn Americans using imperials units! (I am a damn American btw). A short ball-stud would directly replace the traxxis ball without any redesign (assuming the same M3 stud).

So far I have not found much hands-on or theoretical discussion of this idea so I am starting one now.

thanks

|

Re: ball-cap rod-end concept pros and cons September 09, 2017 02:23AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: ball-cap rod-end concept pros and cons September 09, 2017 03:45AM |

Registered: 10 years ago Posts: 14,672 |

I recommend the magnetic rods and ball studs by Haydn Huntley. They have never come apart on me except when I applied force to the effector manually.

I've never used ball-end axles and caps, but user saffi on the Duet3D forum has used both the SeeMeCnc and the Tricklaser ones I believe and may be able to offer some advice. Here is one of saffi's posts: [www.duet3d.com].

Edited 1 time(s). Last edit at 09/09/2017 03:46AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I've never used ball-end axles and caps, but user saffi on the Duet3D forum has used both the SeeMeCnc and the Tricklaser ones I believe and may be able to offer some advice. Here is one of saffi's posts: [www.duet3d.com].

Edited 1 time(s). Last edit at 09/09/2017 03:46AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: ball-cap rod-end concept pros and cons September 09, 2017 07:51AM |

Registered: 9 years ago Posts: 1,159 |

Haydn also sells 3/8 Ball studs separately Haydn's Ball studs

|

Re: ball-cap rod-end concept pros and cons September 10, 2017 04:05PM |

Registered: 8 years ago Posts: 150 |

Would not be too hard to machine something that works like the Trick Laser-cups, I think. A countersinked hole in some slippery, reasenably hard material should do it. The trick is attaching the spring so the joints will self-center. A pure print might work too

Edited 1 time(s). Last edit at 09/10/2017 04:06PM by SlowFoot.

Edited 1 time(s). Last edit at 09/10/2017 04:06PM by SlowFoot.

|

Re: ball-cap rod-end concept pros and cons September 11, 2017 04:56AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: ball-cap rod-end concept pros and cons September 11, 2017 01:36PM |

Registered: 7 years ago Posts: 154 |

|

Re: ball-cap rod-end concept pros and cons September 12, 2017 09:03AM |

Registered: 8 years ago Posts: 3,525 |

+1 for Haydns magnets they won't disconnect unless you have a catastrophic impact with something and then you probably want them to.

They have zero backlash and are light.

My only suggestion would be thicker carbon rods/tubes for longer lengths I. E. 360mm plus as I can slightly bend my 360mm arms if I try, not that it seems to cause any practical issues, it just seems to make sense as length increases to increase stiffness.

Edited 1 time(s). Last edit at 09/12/2017 09:04AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

They have zero backlash and are light.

My only suggestion would be thicker carbon rods/tubes for longer lengths I. E. 360mm plus as I can slightly bend my 360mm arms if I try, not that it seems to cause any practical issues, it just seems to make sense as length increases to increase stiffness.

Edited 1 time(s). Last edit at 09/12/2017 09:04AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: ball-cap rod-end concept pros and cons September 15, 2017 07:49PM |

Registered: 9 years ago Posts: 280 |

|

Re: ball-cap rod-end concept pros and cons May 14, 2018 03:00PM |

Registered: 6 years ago Posts: 63 |

|

Re: ball-cap rod-end concept pros and cons May 14, 2018 03:40PM |

Registered: 9 years ago Posts: 280 |

Hi warbunniex.

I've been using the Trick Laser parts for a while. As expected they have great zero-backlash so the performance has been good.

Some things I have learned though:

-The springs required to pull the arm-ends together can get in the way of the either the carriages or the effector, depends on your designs. I like the springs in general for disassembly but their presence is really a con in the custom design of my own machine.

-The mounting axis of the balls must be lateral. For mag-ball rods, the mounting axis of the balls must be upright. They are incompatible so not easy to swap over without a redesign.

-I had no problem finding the correct ball size (Hadyns).

-The ball-cap design has to be very precise as the rotation center is in the middle of a hollow. The magnet-ball ends just have to be well centered which is a lot easier to fabricate. I'm sure Trick Laser knows this and has a precise design but I would have to build a test apparatus just to measure for myself.

-The Trick Laser rod-ends use little loops molded into the rod-ends to hold the spring ends.. They seemed fragile to me though and sure enough I had a metal extrusion fall on my effector and break one of the loops. I've been running with a pair of tiny cable-ties to hold the end of the spring (and the second tie to keep it from riding up the length of the arm). I suggested to Trick Laser they either remove the loops, or add in the ability to use a cable tie for the rod end (without allowing it ride up the rod), as cable ties are replaceable and generally tough (albeit not as pretty).

-The Trick Laser design also has pulling forces that do not align with the ball-cap center, which will cause the rods to bow together to some small degree. Another approach that pushes along the ball's mounting axis would be ideal (like a spring clip that presses on the backside of the rod end). The offset force also seems hard on the attachment of the rod-end to the rod cause it pulls sideways. The mag balls only direct tension in the same direction as the rods themselves.

Given the general interference of the springs, the non-ideal assymetric forces, and the fact that the increasingly-popular mag ball approach has not been reporting gripping problems I am designing my next effector platform for the mag-ball approach.

You have a fan on your cold end? I can't easily picture how a magball would cause a problem. Their are also ways to shield against magnetic fields although I can't comment on the effectiveness in this application. Google mu-metal or mu-shield for sources and tech details.

Hope this helps!

I've been using the Trick Laser parts for a while. As expected they have great zero-backlash so the performance has been good.

Some things I have learned though:

-The springs required to pull the arm-ends together can get in the way of the either the carriages or the effector, depends on your designs. I like the springs in general for disassembly but their presence is really a con in the custom design of my own machine.

-The mounting axis of the balls must be lateral. For mag-ball rods, the mounting axis of the balls must be upright. They are incompatible so not easy to swap over without a redesign.

-I had no problem finding the correct ball size (Hadyns).

-The ball-cap design has to be very precise as the rotation center is in the middle of a hollow. The magnet-ball ends just have to be well centered which is a lot easier to fabricate. I'm sure Trick Laser knows this and has a precise design but I would have to build a test apparatus just to measure for myself.

-The Trick Laser rod-ends use little loops molded into the rod-ends to hold the spring ends.. They seemed fragile to me though and sure enough I had a metal extrusion fall on my effector and break one of the loops. I've been running with a pair of tiny cable-ties to hold the end of the spring (and the second tie to keep it from riding up the length of the arm). I suggested to Trick Laser they either remove the loops, or add in the ability to use a cable tie for the rod end (without allowing it ride up the rod), as cable ties are replaceable and generally tough (albeit not as pretty).

-The Trick Laser design also has pulling forces that do not align with the ball-cap center, which will cause the rods to bow together to some small degree. Another approach that pushes along the ball's mounting axis would be ideal (like a spring clip that presses on the backside of the rod end). The offset force also seems hard on the attachment of the rod-end to the rod cause it pulls sideways. The mag balls only direct tension in the same direction as the rods themselves.

Given the general interference of the springs, the non-ideal assymetric forces, and the fact that the increasingly-popular mag ball approach has not been reporting gripping problems I am designing my next effector platform for the mag-ball approach.

You have a fan on your cold end? I can't easily picture how a magball would cause a problem. Their are also ways to shield against magnetic fields although I can't comment on the effectiveness in this application. Google mu-metal or mu-shield for sources and tech details.

Hope this helps!

|

Re: ball-cap rod-end concept pros and cons June 15, 2018 06:17PM |

Registered: 8 years ago Posts: 3,525 |

If your only concern before was the magnets becoming detached then try them. They work very well, and if it does come apart it will be a good thing, less damage will occur as the effector will stop crashing into things and just wobble back and to attached to the 2 or 3 arms which are not disconnected.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: ball-cap rod-end concept pros and cons June 16, 2018 03:48AM |

Registered: 10 years ago Posts: 150 |

Shameless self-promotion: so use Zatsit's polypropylene hinged system, which is ultra-light, extremely accurate without any adjustment, and performs very well against ringing.

Look at the photo I published on this post:

[reprap.org]

Edited 1 time(s). Last edit at 06/16/2018 04:16AM by M_Xeno.

Look at the photo I published on this post:

[reprap.org]

Edited 1 time(s). Last edit at 06/16/2018 04:16AM by M_Xeno.

|

Re: ball-cap rod-end concept pros and cons June 16, 2018 04:59AM |

Registered: 9 years ago Posts: 978 |

|

Re: ball-cap rod-end concept pros and cons June 16, 2018 05:29AM |

Registered: 10 years ago Posts: 150 |

|

Re: ball-cap rod-end concept pros and cons June 16, 2018 05:31PM |

Registered: 9 years ago Posts: 978 |

|

Re: ball-cap rod-end concept pros and cons June 16, 2018 08:00PM |

Registered: 9 years ago Posts: 280 |

I checked the Zatsit site and it seems like a great novel approach. One thing about 3D printing that fascinates me is how fertile it is for innovation. Like the very early days of computers.

My only complaint about the Hylite material is that it's no good for us without access to a precision 2D router table. Buying that service would get expensive and any time I need to make a small part I can't do it myself. So for hobbyists it seems useless, but great for engineering a device at low cost and high performance for those willing to invest into something that will return the costs, like Zatsit.

My only complaint about the Hylite material is that it's no good for us without access to a precision 2D router table. Buying that service would get expensive and any time I need to make a small part I can't do it myself. So for hobbyists it seems useless, but great for engineering a device at low cost and high performance for those willing to invest into something that will return the costs, like Zatsit.

|

Re: ball-cap rod-end concept pros and cons June 17, 2018 01:22AM |

Registered: 8 years ago Posts: 5,232 |

Quote

So for hobbyists it seems useless...[Hylite]

I thought the same, but VDX already made an remark about using PP as hinges and clamp it in you own design.

If we'd find a way to glue or bond PP to a printed part or aluminum surface, we wouldn't need milling machines.

Edited 1 time(s). Last edit at 06/17/2018 01:22AM by o_lampe.

|

Re: ball-cap rod-end concept pros and cons June 17, 2018 05:23AM |

Registered: 10 years ago Posts: 150 |

@o_lampe, shadowphile, VDX

Hinges to glue: that's a very good idea!

During the KS campaign, I will propose, among the goodies offered to bakers who want to support the project, but do not want to buy a complete kit, hinges ready to glue.

For example, a Ø30mm disc, with one hinge along a diameter, and another, with two perpendicular hinges, to make a joint.

This would allow Makers to easily integrate this technology into various DIY projects. I could also sell that stuff online after the KS campaign, next to Zatsit, and other Hylite applications.

But if it is to make a linear delta robot, believe me, nothing will ever be worth the simultaneous cutting of all the hinges of an elementary deformable parallelogram, as the Zatsit kit proposes it!

Edited 1 time(s). Last edit at 06/17/2018 05:28AM by M_Xeno.

Hinges to glue: that's a very good idea!

During the KS campaign, I will propose, among the goodies offered to bakers who want to support the project, but do not want to buy a complete kit, hinges ready to glue.

For example, a Ø30mm disc, with one hinge along a diameter, and another, with two perpendicular hinges, to make a joint.

This would allow Makers to easily integrate this technology into various DIY projects. I could also sell that stuff online after the KS campaign, next to Zatsit, and other Hylite applications.

But if it is to make a linear delta robot, believe me, nothing will ever be worth the simultaneous cutting of all the hinges of an elementary deformable parallelogram, as the Zatsit kit proposes it!

Edited 1 time(s). Last edit at 06/17/2018 05:28AM by M_Xeno.

|

Re: ball-cap rod-end concept pros and cons June 17, 2018 01:19PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: ball-cap rod-end concept pros and cons June 17, 2018 06:10PM |

Registered: 9 years ago Posts: 280 |

Sounds good, I can see buying modular pieces.

It seems to have a limited strength though. I'm designing version three of my delta to carry multiple extruders and swappable with other types of hot-ends so the entire frame is getting thicker parts which will load the joints more when trying to go fast. I can't seem to avoid designing away from light airy printers that can move really fast.

It seems to have a limited strength though. I'm designing version three of my delta to carry multiple extruders and swappable with other types of hot-ends so the entire frame is getting thicker parts which will load the joints more when trying to go fast. I can't seem to avoid designing away from light airy printers that can move really fast.

|

Re: ball-cap rod-end concept pros and cons November 11, 2018 06:27PM |

Registered: 9 years ago Posts: 978 |

I've done a bit more thinking about magnetic joints (as well as backing the Zatsit  ) and thought I'd share my methods and conclusions.

) and thought I'd share my methods and conclusions.

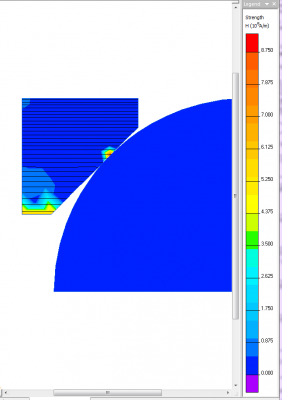

Firstly, I searched around the Net for a magnetic field analysis program, and used QuickField Student, because it's free, gave me the analysis I wanted, and I was able to figure out how to drive it. I modelled a 90-degree countersunk magnet with a 10mm steel ball. Below is a screenshot of the Field Strength (which I just realised I'm assuming is proportional to the attractive force between the magnet and ball). The model is axissymmetric along the X axis... imagine it is revolved around that axis.

So, QuickField tells me that the diameter and thickness of the magnet are pretty much irrelevant to the attractive force; the force decreases so quickly with distance that it's really only the contact area that's relevant.

The contact point shown is in fact a circle, so you can increase the force by increasing the circumference of the contact circle.

Given this, I wonder whether countersunk magnets are any better than ring magnets? However, if the ball is tangential to the sides of the countersink (rather than just contacting at the rim), you get force on both sides of the contact point. For a 10mm steel ball, this means the magnet should have a hole diameter a bit over 4mm, and it need only have an outer diameter of about 9mm.

Incidentally, I think that having the contact point on the sloping face of the countersink, rather than at its rim, will also mechanically reduce the ball's inclination to jump away from the magnet, since any lateral force will push it against the side of the magnet.

) and thought I'd share my methods and conclusions.

) and thought I'd share my methods and conclusions.Firstly, I searched around the Net for a magnetic field analysis program, and used QuickField Student, because it's free, gave me the analysis I wanted, and I was able to figure out how to drive it. I modelled a 90-degree countersunk magnet with a 10mm steel ball. Below is a screenshot of the Field Strength (which I just realised I'm assuming is proportional to the attractive force between the magnet and ball). The model is axissymmetric along the X axis... imagine it is revolved around that axis.

So, QuickField tells me that the diameter and thickness of the magnet are pretty much irrelevant to the attractive force; the force decreases so quickly with distance that it's really only the contact area that's relevant.

The contact point shown is in fact a circle, so you can increase the force by increasing the circumference of the contact circle.

Given this, I wonder whether countersunk magnets are any better than ring magnets? However, if the ball is tangential to the sides of the countersink (rather than just contacting at the rim), you get force on both sides of the contact point. For a 10mm steel ball, this means the magnet should have a hole diameter a bit over 4mm, and it need only have an outer diameter of about 9mm.

Incidentally, I think that having the contact point on the sloping face of the countersink, rather than at its rim, will also mechanically reduce the ball's inclination to jump away from the magnet, since any lateral force will push it against the side of the magnet.

|

Re: ball-cap rod-end concept pros and cons November 12, 2018 03:58AM |

Registered: 10 years ago Posts: 732 |

I think you need to do a vector integral of magnetic pressure over the contact surface: [en.wikipedia.org]

|

Re: ball-cap rod-end concept pros and cons November 12, 2018 08:43AM |

Registered: 10 years ago Posts: 14,672 |

The magnetic rods supplied by Haydn Huntley don't work like that. The rod ends contain a magnet with a flat face, and a non-magnetic (Delrin) concave cap on top of the magnet is what is in contact with the ball. There is a hole in the centre of the Delrin cap, however the magnet end is kept at a small distance from the ball by the cap.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: ball-cap rod-end concept pros and cons November 12, 2018 01:01PM |

Registered: 10 years ago Posts: 732 |

Delrin is diamagnetic. It's relative magnetic permeability is somewhat less than 1 (the specification states <~1; not sure how exactly to interpret it).

frankvdh can assume it is the same as air or somewhat worse with Delrin (compared to air). That may be also the reason why the Delrin cup has a hole in the middle - not to disrupt the magnetic flow there. If we wants to increase the overall attractive force then we need to add some ferric cup around to provide better conduction for magnetic flow. Without a ferric cup the magnetic field B may be very strong but at a very small area S and we need to optimize S * B². The surface direction should be considered too.

[www.rolling-components.com]

Edited 1 time(s). Last edit at 11/12/2018 01:04PM by hercek.

frankvdh can assume it is the same as air or somewhat worse with Delrin (compared to air). That may be also the reason why the Delrin cup has a hole in the middle - not to disrupt the magnetic flow there. If we wants to increase the overall attractive force then we need to add some ferric cup around to provide better conduction for magnetic flow. Without a ferric cup the magnetic field B may be very strong but at a very small area S and we need to optimize S * B². The surface direction should be considered too.

[www.rolling-components.com]

Edited 1 time(s). Last edit at 11/12/2018 01:04PM by hercek.

|

Re: ball-cap rod-end concept pros and cons November 12, 2018 04:31PM |

Registered: 9 years ago Posts: 280 |

nice to see a technically accurate depiction of the magball design but what is the issue that motivates a closer analysis?

-Delrin, like most plastics, has little response to magnetic fields, plus or minus. The hole in the middle is perhaps THE critical part of the design that results in zero play because it provides a stable load configuration. A full cup would need to be absolutely perfect and any wear would induce play in the joint.

-Magnetics, being dipoles, have a net field strength that falls off very fast to virtually nothing. Multipling a magnet's strength by adding more magnets raises the strength of the field linearly but the exponential-like fall-off of a dipole field shape quickly erases any advantage.

The contact-surface area you mentioned is indeed an important factor, for several reasons:

--it increases the contact force linearly for the same strength magnet

-- less trivial to describe is that the fall-off shape of the dipole field of a disk magnet is mathematically zero at center of the magnet and falls off as you move away from the center. so in fact a WIDER magnet with the same thickness will have more grab, but only if the ball is wider as well. Ideally the ball would be just a piece of the surface of a much bigger ball, depending on the range of motion required. however, this only adds a linear increase to pull force that is still extinguished by the dipole fall off.

bottom line though is you cant escape the dipole-nature of magnets. in fact, the ONLY reason a magball joint even works at all is the strength of the force of the magnet, NOT how far the ball moves away (as your observation about needing contact was noted). as long as the forces on the joint do not exceed the contact force of the joint, you get zero play. the instant the ball starts to separate its game over, because the restoring force becomes less than the impact force, which allows the gap to widen even further...

in the world of mechanical engineering the tendency for something to break with little deflection pretty much describes 'brittle' who wants a brittle joint? the question I havent resolved in my head is not a technical one: a stronger joint is required to drive a delta harder but at what point do you WANT it to separate? a joint that breaks apart will actually protect the rest of the printer in case of an accidental impact, but then a printer that doesnt stop immediate may continue to drag a broken effector all over the place, damaging the print job AND potentially the hot end. ive been leaning back toward the spring-loaded ball-cap design but its harder to manufacture precisely and its ability to absorb an impact is great because the spring force gets STRONGER as the joint separates. this would be described as a 'tough' joint, but then the energy of an accidental impact would be transferred to non-tough parts of the printer, possibly breaking them.

who wants a brittle joint? the question I havent resolved in my head is not a technical one: a stronger joint is required to drive a delta harder but at what point do you WANT it to separate? a joint that breaks apart will actually protect the rest of the printer in case of an accidental impact, but then a printer that doesnt stop immediate may continue to drag a broken effector all over the place, damaging the print job AND potentially the hot end. ive been leaning back toward the spring-loaded ball-cap design but its harder to manufacture precisely and its ability to absorb an impact is great because the spring force gets STRONGER as the joint separates. this would be described as a 'tough' joint, but then the energy of an accidental impact would be transferred to non-tough parts of the printer, possibly breaking them.

a good analogy is an electrical fuse. you want it big enough to handle the expected load but weak enough to blow before the excess current starts a fire somewhere. a perfect fuse allows just enough power for the intended use of the circuitn and no more. the value of that fuse totally depends on the designed performance of the system.

sorry if this got long-winded and a little off-topic. ive tried the sprung-ball-cap design and right now I have magballs. im irritated by the tendency of the magballs to pop apart when Im fiddling with the effector (which should be considered an expected force) but without a lot of design calculations of the desired/expected performance of the entire system I have no way to design the optimal joint (other than what most people do: adjust things until they meet their needs)

-Delrin, like most plastics, has little response to magnetic fields, plus or minus. The hole in the middle is perhaps THE critical part of the design that results in zero play because it provides a stable load configuration. A full cup would need to be absolutely perfect and any wear would induce play in the joint.

-Magnetics, being dipoles, have a net field strength that falls off very fast to virtually nothing. Multipling a magnet's strength by adding more magnets raises the strength of the field linearly but the exponential-like fall-off of a dipole field shape quickly erases any advantage.

The contact-surface area you mentioned is indeed an important factor, for several reasons:

--it increases the contact force linearly for the same strength magnet

-- less trivial to describe is that the fall-off shape of the dipole field of a disk magnet is mathematically zero at center of the magnet and falls off as you move away from the center. so in fact a WIDER magnet with the same thickness will have more grab, but only if the ball is wider as well. Ideally the ball would be just a piece of the surface of a much bigger ball, depending on the range of motion required. however, this only adds a linear increase to pull force that is still extinguished by the dipole fall off.

bottom line though is you cant escape the dipole-nature of magnets. in fact, the ONLY reason a magball joint even works at all is the strength of the force of the magnet, NOT how far the ball moves away (as your observation about needing contact was noted). as long as the forces on the joint do not exceed the contact force of the joint, you get zero play. the instant the ball starts to separate its game over, because the restoring force becomes less than the impact force, which allows the gap to widen even further...

in the world of mechanical engineering the tendency for something to break with little deflection pretty much describes 'brittle'

who wants a brittle joint? the question I havent resolved in my head is not a technical one: a stronger joint is required to drive a delta harder but at what point do you WANT it to separate? a joint that breaks apart will actually protect the rest of the printer in case of an accidental impact, but then a printer that doesnt stop immediate may continue to drag a broken effector all over the place, damaging the print job AND potentially the hot end. ive been leaning back toward the spring-loaded ball-cap design but its harder to manufacture precisely and its ability to absorb an impact is great because the spring force gets STRONGER as the joint separates. this would be described as a 'tough' joint, but then the energy of an accidental impact would be transferred to non-tough parts of the printer, possibly breaking them.

who wants a brittle joint? the question I havent resolved in my head is not a technical one: a stronger joint is required to drive a delta harder but at what point do you WANT it to separate? a joint that breaks apart will actually protect the rest of the printer in case of an accidental impact, but then a printer that doesnt stop immediate may continue to drag a broken effector all over the place, damaging the print job AND potentially the hot end. ive been leaning back toward the spring-loaded ball-cap design but its harder to manufacture precisely and its ability to absorb an impact is great because the spring force gets STRONGER as the joint separates. this would be described as a 'tough' joint, but then the energy of an accidental impact would be transferred to non-tough parts of the printer, possibly breaking them.a good analogy is an electrical fuse. you want it big enough to handle the expected load but weak enough to blow before the excess current starts a fire somewhere. a perfect fuse allows just enough power for the intended use of the circuitn and no more. the value of that fuse totally depends on the designed performance of the system.

sorry if this got long-winded and a little off-topic. ive tried the sprung-ball-cap design and right now I have magballs. im irritated by the tendency of the magballs to pop apart when Im fiddling with the effector (which should be considered an expected force) but without a lot of design calculations of the desired/expected performance of the entire system I have no way to design the optimal joint (other than what most people do: adjust things until they meet their needs)

|

Re: ball-cap rod-end concept pros and cons November 13, 2018 08:06PM |

Registered: 9 years ago Posts: 483 |

|

Re: ball-cap rod-end concept pros and cons November 14, 2018 01:04AM |

Registered: 9 years ago Posts: 280 |

agreed, the magnets would be best with some retention springs. except....why bother with magnets? I found the Trick Laser arms really trivial to pop off and they are as tight and smooth as the magnets. The only thing I would try to change is the springs. I dont like the way they load the rods; hard on the ball-cap-to-rod joint and the little plastic loops break off too easy. I would like to see the springs somehow located directly on the ball-cap, like a retention spring.

|

Re: ball-cap rod-end concept pros and cons December 03, 2018 01:34AM |

Registered: 6 years ago Posts: 50 |

All mag balls move under motion (or change of motion) when they are only using the magnetic force to hold the joint together and is further dependent on the amount of constraint the "cup" part of the join is providing (less cup = less constraint = more movement). The amount of movement on mag balls with a decent magnetic force is small but it is still there in all cases as the magnetic force is like an inverse rubber band (gets weaker the more you stretch it). Adding a spring to the setup will reduce this movement but not eliminate it as the spring can still stretch allowing the joint to move apart in the same way a magnetic force does, only the spring increases the amount of force applied when “stretched” vs the mag ball that applies less force as the joints surfaces move away from one another. You don’t need to be an engineer to easily see or understand why mag balls are not the best joint to be using on a delta printer, that’s not to say they can’t be your best option for your particular needs.

The only way to eliminate this movement is to fully constrain the joint and the only way to do this on a delta is with a rod end. A ball-end are a much more constrained joint than any mag joint but of course there is some big variances in the amount of constraint due to the different “ball & cup” design and they still don’t stack up to a rod end but they get 75% of the way there (as even the best ball-end design only technically provides a 75% constrained joint as you have to be able to add/remove the “ball” from the “cup”). Irrelevant of which ball and cup design you use (and excluding quality of product) they will all perform better than a mag ball as the direction of force during delta movements is pretty much always within the area of constraint of the ball-end joint which certainly is not the case in a mag ball no matter what brand/version/person you get it from.

Accuracy is much harder to achieve with a cup/ball design used both by mag-ends and ball-ends for several reasons. The more of the “cup” there is the more constrained the joint becomes, a mag-end only typically constrains about 20% of the ball at best, this enables the joint to be easily removed but allows the ball to move around in the cup area and also allows the ball to deflect away from the cup. A ball-end drastically reduces this movement by having the cup cover 50% or more of the ball and typically this means the ball is virtually fully constrained during 95% of the joint movements on a delta. Both the mag-end and ball-end require perfect alignment of the ball and cup components across multiple axis, where a rod end only requires a flat surface to mount against and a single axis of alignment (in other words alignment is much harder to stuff up and has less impact).

If we take DC42’s favorite mag balls he keeps spruiking by hayden, then you can see we are only constraining about 15% of the ball with the cup, and we now have to align the ball on the effector across 3 axis using a bolt hopefully centered on the ball through another slightly oversize hole in the effector. If we use a DC42 effector this is easier (we won’t get into the other problems with this effector design), but it still has play in the ball mounting holes and you can get 1mm out in the ball mounts from side to side, this is affecting the accuracy on every axis and is a complete pita to get accurate. Now you have to hope the mag ball and cup are perfect spheres as you won’t be able to tell looking at them and you won’t be able to see it by eye if it is moving around on a “cam” instead of a sphere and you don’t have the advantage of the joint/effector binding if they are not perfectly aligned (an easy test for rod ends as the joint can’t deflect when there is binding due to inaccuracies). Ball-ends do help and mostly act like rod ends here so have much of the same advantages but only while the force is well within the “cups” constraint.

There are also the other negative factors aside from movement in the mag joint;

- Mag joint wear faster, but you are unable to easily detect this wear due the magnets pulling the joint back together (some seem to think this is a good thing...)

- Effector crash that results in the hotend coming off while still heating and extruding plastic (so fun with Polycarb)

- Lower repeatability of prints (this is due to the movement in the joint)

- Mag joints are typically significantly more expensive than other joints, especially “decent” ones

The only upside to mag ends is the ability to quickly disconnect a joint but for most people they are not changing the effector/nozzle often enough (if at all) to take on the potential issues with mag balls or the additional cost. In the same breath most people probably wouldn't notice the difference in there printing (or care) between mag/ball/rod ends either as they have plenty of other lower quality items causing print degradation as well. The fact of the matter is, if mag balls joints were a “good idea” they would get used everywhere, but the simple fact of the matter is they are hardly used at all unlike ball-ends (aka ball joint) or probably the most commonly used joint that enables high articulation and 100% constraint at all angles is the rod end (aka heim/rose joint). Like I have said before, grab an effector on a mag ball setup and give it a wiggle (and it will wiggle around), then do the same on one with ball-ends and one with rod ends and see which one moves around (bad) and which one is rock solid (good). Spoiler alert, the rod ends will eat the mag balls in every scenario other than easy of removal when comparing similar quality products (be they top or bottom of the pricing pool), hence in the simplest joint test you can do to a delta (the effector wiggle test) will clearly show you the benefits of the high joint constraint in the rod end or ball joint over a mag ball setup.

The only way to eliminate this movement is to fully constrain the joint and the only way to do this on a delta is with a rod end. A ball-end are a much more constrained joint than any mag joint but of course there is some big variances in the amount of constraint due to the different “ball & cup” design and they still don’t stack up to a rod end but they get 75% of the way there (as even the best ball-end design only technically provides a 75% constrained joint as you have to be able to add/remove the “ball” from the “cup”). Irrelevant of which ball and cup design you use (and excluding quality of product) they will all perform better than a mag ball as the direction of force during delta movements is pretty much always within the area of constraint of the ball-end joint which certainly is not the case in a mag ball no matter what brand/version/person you get it from.

Accuracy is much harder to achieve with a cup/ball design used both by mag-ends and ball-ends for several reasons. The more of the “cup” there is the more constrained the joint becomes, a mag-end only typically constrains about 20% of the ball at best, this enables the joint to be easily removed but allows the ball to move around in the cup area and also allows the ball to deflect away from the cup. A ball-end drastically reduces this movement by having the cup cover 50% or more of the ball and typically this means the ball is virtually fully constrained during 95% of the joint movements on a delta. Both the mag-end and ball-end require perfect alignment of the ball and cup components across multiple axis, where a rod end only requires a flat surface to mount against and a single axis of alignment (in other words alignment is much harder to stuff up and has less impact).

If we take DC42’s favorite mag balls he keeps spruiking by hayden, then you can see we are only constraining about 15% of the ball with the cup, and we now have to align the ball on the effector across 3 axis using a bolt hopefully centered on the ball through another slightly oversize hole in the effector. If we use a DC42 effector this is easier (we won’t get into the other problems with this effector design), but it still has play in the ball mounting holes and you can get 1mm out in the ball mounts from side to side, this is affecting the accuracy on every axis and is a complete pita to get accurate. Now you have to hope the mag ball and cup are perfect spheres as you won’t be able to tell looking at them and you won’t be able to see it by eye if it is moving around on a “cam” instead of a sphere and you don’t have the advantage of the joint/effector binding if they are not perfectly aligned (an easy test for rod ends as the joint can’t deflect when there is binding due to inaccuracies). Ball-ends do help and mostly act like rod ends here so have much of the same advantages but only while the force is well within the “cups” constraint.

There are also the other negative factors aside from movement in the mag joint;

- Mag joint wear faster, but you are unable to easily detect this wear due the magnets pulling the joint back together (some seem to think this is a good thing...)

- Effector crash that results in the hotend coming off while still heating and extruding plastic (so fun with Polycarb)

- Lower repeatability of prints (this is due to the movement in the joint)

- Mag joints are typically significantly more expensive than other joints, especially “decent” ones

The only upside to mag ends is the ability to quickly disconnect a joint but for most people they are not changing the effector/nozzle often enough (if at all) to take on the potential issues with mag balls or the additional cost. In the same breath most people probably wouldn't notice the difference in there printing (or care) between mag/ball/rod ends either as they have plenty of other lower quality items causing print degradation as well. The fact of the matter is, if mag balls joints were a “good idea” they would get used everywhere, but the simple fact of the matter is they are hardly used at all unlike ball-ends (aka ball joint) or probably the most commonly used joint that enables high articulation and 100% constraint at all angles is the rod end (aka heim/rose joint). Like I have said before, grab an effector on a mag ball setup and give it a wiggle (and it will wiggle around), then do the same on one with ball-ends and one with rod ends and see which one moves around (bad) and which one is rock solid (good). Spoiler alert, the rod ends will eat the mag balls in every scenario other than easy of removal when comparing similar quality products (be they top or bottom of the pricing pool), hence in the simplest joint test you can do to a delta (the effector wiggle test) will clearly show you the benefits of the high joint constraint in the rod end or ball joint over a mag ball setup.

|

Re: ball-cap rod-end concept pros and cons December 03, 2018 01:04PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Redemptioner

Like I have said before, grab an effector on a mag ball setup and give it a wiggle (and it will wiggle around)

My effector has zero wiggle. Yes, ZERO.

Quote

Redemptioner

If we take DC42’s favorite mag balls he keeps spruiking by hayden, then you can see we are only constraining about 15% of the ball with the cup, and we now have to align the ball on the effector across 3 axis using a bolt hopefully centered on the ball through another slightly oversize hole in the effector. If we use a DC42 effector this is easier (we won’t get into the other problems with this effector design), but it still has play in the ball mounting holes and you can get 1mm out in the ball mounts from side to side..

I'm sorry, but IMHO that's utter rubbish! The holes in the effector are slightly undersize (2.9mm), not oversize. The ball studs are a close fit in them with nothing like 1mm side to side play before tightening, maybe 0.1mm. And what exactly do you mean by "only constraining about 15% of the ball with the cup"? Is that by surface area, angle, or what? Any way I measure it, it's far more than 15%. The ball ends are more than adequately constrained, bearing in mind that the forces applied during printing are predominantly longitudinal.

You have obviously never used Haydn Huntley's magnetic joints. Please stop assuming that your experience with inferior magnetic joints applies to all magnetic joints.

Quote

Redemptioner

If we use a DC42 effector this is easier (we won’t get into the other problems with this effector design)...

Suggestions for improving our products are always welcome, provided they are based on actual experience and not theorising.

Edited 1 time(s). Last edit at 12/03/2018 01:10PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.