Belt & Pully design - build question

Posted by Mils24

|

Belt & Pully design - build question September 09, 2017 05:48PM |

Registered: 9 years ago Posts: 54 |

Hello All,

Looking for some advice on delta build design.

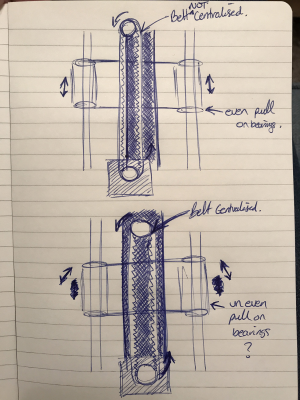

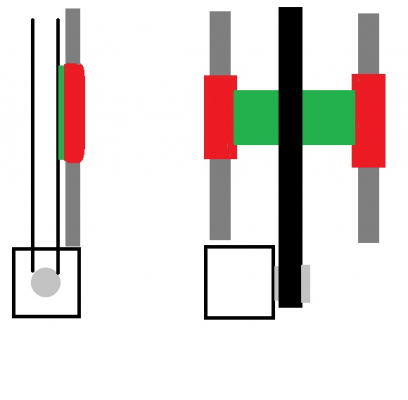

Does it matter if the belt is centralised on he vertical tower or if the top and bottom pulley is centralised on the tower?

Please see image for better explanation.

My original thoughts were that the belt should be centralised so that the sliding carriage would get an even pull on them. However it is causing some issues with my build finding space for belt tensioning and motor mounts at the bottom of each tower. If I could move the motors+pullys to be centralised then it would be a great help but Im scared it will cause uneven wear and force on the sliding bearings.

Thanks,

David

Looking for some advice on delta build design.

Does it matter if the belt is centralised on he vertical tower or if the top and bottom pulley is centralised on the tower?

Please see image for better explanation.

My original thoughts were that the belt should be centralised so that the sliding carriage would get an even pull on them. However it is causing some issues with my build finding space for belt tensioning and motor mounts at the bottom of each tower. If I could move the motors+pullys to be centralised then it would be a great help but Im scared it will cause uneven wear and force on the sliding bearings.

Thanks,

David

|

Re: Belt & Pully design - build question September 09, 2017 06:20PM |

Registered: 6 years ago Posts: 70 |

|

Re: Belt & Pully design - build question September 09, 2017 06:25PM |

Registered: 9 years ago Posts: 54 |

Hi, Number40fan, I really don't know what you mean?

Firstly, the motor is not centralised in both occasions. In the top image the motor is offset half the diameter of the pully and in the bottom image it is centralised.

Secondly, Im not intending to switch my motor mounts but how can rotating them 90deg help? how would that even work with GT2 belts? surly you would have to switch to string or something like that?

Thanks

Firstly, the motor is not centralised in both occasions. In the top image the motor is offset half the diameter of the pully and in the bottom image it is centralised.

Secondly, Im not intending to switch my motor mounts but how can rotating them 90deg help? how would that even work with GT2 belts? surly you would have to switch to string or something like that?

Thanks

|

Re: Belt & Pully design - build question September 10, 2017 12:15AM |

Registered: 6 years ago Posts: 70 |

I meant the smooth rod setup. Should have been more clear on that.

If you were looking down at the motors, rotating them 90° either clockwise or counter would put the flat of the belt against the carriage and you would be able to have them centered. Having a flat plate on the top of the delta would allow you to put the motors up there and in any position you wanted. Since you are using smooth rods, you could have the ribbed part of the belt against the carriage while running the belt down the track of the aluminum extrusion keeping the belt from sticking out and possible getting in the way of the diagonal arms.

If you were looking down at the motors, rotating them 90° either clockwise or counter would put the flat of the belt against the carriage and you would be able to have them centered. Having a flat plate on the top of the delta would allow you to put the motors up there and in any position you wanted. Since you are using smooth rods, you could have the ribbed part of the belt against the carriage while running the belt down the track of the aluminum extrusion keeping the belt from sticking out and possible getting in the way of the diagonal arms.

|

Re: Belt & Pully design - build question September 10, 2017 12:28AM |

Registered: 6 years ago Posts: 70 |

|

Re: Belt & Pully design - build question September 10, 2017 01:58AM |

Registered: 8 years ago Posts: 5,232 |

My question about the subject would be: Is it better to mount the belt in the center or off center?

When it's centered, even the smallest difference in friction can cause the carrier to wobble.

When it's a bit off center, the carrier is always preloaded. So small differences in friction won't change the movement. But wear is slightly bigger.

Too much offset and you get racking.

That's just my gut feeling talking and it's not scientificly evaluated...

When it's centered, even the smallest difference in friction can cause the carrier to wobble.

When it's a bit off center, the carrier is always preloaded. So small differences in friction won't change the movement. But wear is slightly bigger.

Too much offset and you get racking.

That's just my gut feeling talking and it's not scientificly evaluated...

|

Re: Belt & Pully design - build question September 10, 2017 07:45AM |

Registered: 9 years ago Posts: 54 |

o_lampe just so I understand you correctly when you say centred you mean my top picture? and when you say not centred you mean my bottom picture?

I think I probably have the wording of my picture wrong and it should state pulleys centred and pulley's not centred.

So just for clarification you would suggest having the pulleys centred and having the belts slightly off centre, correct?

Rotating the motors by 90deg as per number40fan's suggestion simply isn't an option unfortunately.

Thanks

Edited 1 time(s). Last edit at 09/10/2017 07:45AM by Mils24.

I think I probably have the wording of my picture wrong and it should state pulleys centred and pulley's not centred.

So just for clarification you would suggest having the pulleys centred and having the belts slightly off centre, correct?

Rotating the motors by 90deg as per number40fan's suggestion simply isn't an option unfortunately.

Thanks

Edited 1 time(s). Last edit at 09/10/2017 07:45AM by Mils24.

|

Re: Belt & Pully design - build question September 10, 2017 11:36AM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

My question about the subject would be: Is it better to mount the belt in the center or off center?

When it's centered, even the smallest difference in friction can cause the carrier to wobble.

When it's a bit off center, the carrier is always preloaded. So small differences in friction won't change the movement. But wear is slightly bigger.

Too much offset and you get racking.

That's just my gut feeling talking and it's not scientificly evaluated...

I could be wrong, but won't the preload change direction when the belt direction reverses, leading to backlash?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Belt & Pully design - build question September 10, 2017 12:12PM |

Registered: 9 years ago Posts: 54 |

So do I keep the side of the belt that is clamped to the sliding carriage centralised on the vertical tower or not guys?

As far as I can see the standard kossle style delta machines do not have the belt centralised so it must be ok?

Anyone out there built their own machines and know which way is preferred?

dc42, your delta does not have centralised belts. From your comment above do you have backlash?

Thanks

As far as I can see the standard kossle style delta machines do not have the belt centralised so it must be ok?

Anyone out there built their own machines and know which way is preferred?

dc42, your delta does not have centralised belts. From your comment above do you have backlash?

Thanks

|

Re: Belt & Pully design - build question September 10, 2017 02:34PM |

Registered: 10 years ago Posts: 14,672 |

My delta now uses linear rails, so there is negligible rotation of the carriages about their radial axes. But I still think it would be better to attach the belts centrally on the carriages.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Belt & Pully design - build question September 10, 2017 03:54PM |

Registered: 9 years ago Posts: 54 |

|

Re: Belt & Pully design - build question September 10, 2017 07:58PM |

Registered: 9 years ago Posts: 483 |

|

Re: Belt & Pully design - build question September 11, 2017 01:26AM |

Registered: 9 years ago Posts: 54 |

|

Re: Belt & Pully design - build question September 11, 2017 01:39AM |

Registered: 8 years ago Posts: 5,232 |

Quote

dc42

Quote

o_lampe

My question about the subject would be: Is it better to mount the belt in the center or off center?

When it's centered, even the smallest difference in friction can cause the carrier to wobble.

When it's a bit off center, the carrier is always preloaded. So small differences in friction won't change the movement. But wear is slightly bigger.

Too much offset and you get racking.

That's just my gut feeling talking and it's not scientificly evaluated...

I could be wrong, but won't the preload change direction when the belt direction reverses, leading to backlash?

You are right, there is backlash. ( depending on the linear bearings ) but a centered belt would cause the same backlash, but in an unpredictable way.

|

Re: Belt & Pully design - build question September 11, 2017 04:05AM |

Registered: 9 years ago Posts: 483 |

Quote

Mils24

etfrench, is that pulleys centred (bottom image in OP) or belt centred (top image in OP)???

Thanks

Pulleys are centered. I use linear rails and the belts are GT2-2mm with 20 tooth pulleys. The arms are 60mm apart, so the ratio between the pitch radius of the pulleys and the arm distance is slightly more than 1:10.

|

Re: Belt & Pully design - build question September 11, 2017 08:07AM |

Registered: 9 years ago Posts: 54 |

Sorry to sound stupid but how did you work that out? And also what does that mean? Is 1:10 good?

My set up will be same belt and pulleys (GT2 2mm + 20 tooth) and my rods will be spaced 55mm apart.

There seems to be a real split on belt centered or belt offset. I'm starting to think does it really matter??

My set up will be same belt and pulleys (GT2 2mm + 20 tooth) and my rods will be spaced 55mm apart.

There seems to be a real split on belt centered or belt offset. I'm starting to think does it really matter??

|

Re: Belt & Pully design - build question September 11, 2017 10:15AM |

Registered: 10 years ago Posts: 732 |

If you want more opinions then here you go:

Edit: Yeah, if you are going to buy cheap Chinese linear bearing then buy about two times as much as you actually need. Then select ones which have the right fit (not too loose, not too tight). Throw the rest into a garbage bin ... or give it to your enemy if you feel fancy :-D

Edited 1 time(s). Last edit at 09/11/2017 10:25AM by hercek.

- Belt centered is slightly better (especially as for as bearing/rod wear goes).

- As for as predictability of backslash due to off center belt: It will also depend on how much off-center the belt mount is, the position of the head over the build platform, the current acceleration forces and friction between hotend and the part. I do not think it makes sense to consider higher predictability of off-center belt as a positive because the problem is much more complex. Better get longer linear bearings (or two bearings on each rod) to lower backslash in general if you are concerned about this.

- Space your rods as much far away as it is reasonable (55 mm sounds on the low side). The same is true for diagonal rods.

- Use at least Ø 12 mm rods. On my delta, 70 cm long, Ø 8 mm rods did bent visibly during printing. Will not be a big problem at low accelerations.

- Your glass core GT2 belts will be too springy. But it does not really matter if you intend to use accelerations below 5000 mm/s². Well for such low accelerations you can probably go for Ø 8 mm rods too.

Edit: Yeah, if you are going to buy cheap Chinese linear bearing then buy about two times as much as you actually need. Then select ones which have the right fit (not too loose, not too tight). Throw the rest into a garbage bin ... or give it to your enemy if you feel fancy :-D

Edited 1 time(s). Last edit at 09/11/2017 10:25AM by hercek.

|

Re: Belt & Pully design - build question September 11, 2017 01:10PM |

Registered: 9 years ago Posts: 54 |

Quote

hercek

If you want more opinions then here you go:

- Belt centered is slightly better (especially as for as bearing/rod wear goes).

- As for as predictability of backslash due to off center belt: It will also depend on how much off-center the belt mount is, the position of the head over the build platform, the current acceleration forces and friction between hotend and the part. I do not think it makes sense to consider higher predictability of off-center belt as a positive because the problem is much more complex. Better get longer linear bearings (or two bearings on each rod) to lower backslash in general if you are concerned about this.

- Space your rods as much far away as it is reasonable (55 mm sounds on the low side). The same is true for diagonal rods.

- Use at least Ø 12 mm rods. On my delta, 70 cm long, Ø 8 mm rods did bent visibly during printing. Will not be a big problem at low accelerations.

- Your glass core GT2 belts will be too springy. But it does not really matter if you intend to use accelerations below 5000 mm/s². Well for such low accelerations you can probably go for Ø 8 mm rods too.

Edit: Yeah, if you are going to buy cheap Chinese linear bearing then buy about two times as much as you actually need. Then select ones which have the right fit (not too loose, not too tight). Throw the rest into a garbage bin ... or give it to your enemy if you feel fancy :-D

Many thanks for your input hercek, few points to your comments below:

- Think I will settle on belt centred as this was my gut felling before I posted this - thanks to all for your inputs.

- I have designed to use x2 IGUS RJ4JP polymer bearings stacked on top of each other per vertical rod - x4 per tower. RJ4JP was chosen over LMU88 for noise.

- Distance between vertical rods is 60mm - also Im using 30x30 extrusion for extra rigidity (Its a bit of a tank) Distance between diagonal rods is 55mm

- I've gone for 8mm dia rods but don't intend to have them the full height of the towers. When the nozzle is touching the bed the vertical sliders are (very approx) about 2/3rds of the way down the towers due to the diagonal rods. Having the steel rods run right to the bottom is just a waste in my opinion and hopefully by making them no longer than necessary it will take some of the bowing out of them.

- As for the belts this is something I have not even considered, however I have bought them.

Are GT2 belts not considered pretty standard? what are the alternatives? Also without sounding too stupid what does 5000 mm/s² limit me too for actual printing speed and movement speed?

Are GT2 belts not considered pretty standard? what are the alternatives? Also without sounding too stupid what does 5000 mm/s² limit me too for actual printing speed and movement speed?Thanks

|

Re: Belt & Pully design - build question September 11, 2017 02:35PM |

Registered: 10 years ago Posts: 14,672 |

My 2p worth:

- I agree with attaching the belt centrally in the carriage if you have the choice.

- The spacing between diagonal rods is a compromise. Larger gives more stability; but it also increases the size of the effector (unless it needs to be large for other reasons), which reduces build space because the nozzle can't get as close to the towers. We chose 55mm for the Duet3D smart effector and I think this is a good compromise for a printer with a build diameter of 300mm. But it's too large for a Mini Kossel.

- Yes glass core GT2 belts are standard. The steel core ones wear out very quickly unless you use large diameter pulleys, which reduces resolution.

- Use 16 tooth pulleys, not 20 tooth. They give you better resolution, also the resolution is a more useful figure e.g. 10um per 1/16 microstep instead of 12.5um.

- For best results use 0.9deg motors and 24V power. But it's not essential, the print quality using 1.8deg motors is only slightly less.

- Use a nozzle-contact Z probe, such as our smart effector, or FSRs or piezos under the bed.

- Above all, design your printer so that the geometry is accurate. See [duet3d.com] for more.

HTH David

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- I agree with attaching the belt centrally in the carriage if you have the choice.

- The spacing between diagonal rods is a compromise. Larger gives more stability; but it also increases the size of the effector (unless it needs to be large for other reasons), which reduces build space because the nozzle can't get as close to the towers. We chose 55mm for the Duet3D smart effector and I think this is a good compromise for a printer with a build diameter of 300mm. But it's too large for a Mini Kossel.

- Yes glass core GT2 belts are standard. The steel core ones wear out very quickly unless you use large diameter pulleys, which reduces resolution.

- Use 16 tooth pulleys, not 20 tooth. They give you better resolution, also the resolution is a more useful figure e.g. 10um per 1/16 microstep instead of 12.5um.

- For best results use 0.9deg motors and 24V power. But it's not essential, the print quality using 1.8deg motors is only slightly less.

- Use a nozzle-contact Z probe, such as our smart effector, or FSRs or piezos under the bed.

- Above all, design your printer so that the geometry is accurate. See [duet3d.com] for more.

HTH David

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Belt & Pully design - build question September 11, 2017 02:53PM |

Registered: 9 years ago Posts: 54 |

Quote

dc42

My 2p worth:

- I agree with attaching the belt centrally in the carriage if you have the choice.

- The spacing between diagonal rods is a compromise. Larger gives more stability; but it also increases the size of the effector (unless it needs to be large for other reasons), which reduces build space because the nozzle can't get as close to the towers. We chose 55mm for the Duet3D smart effector and I think this is a good compromise for a printer with a build diameter of 300mm. But it's too large for a Mini Kossel.

- Yes glass core GT2 belts are standard. The steel core ones wear out very quickly unless you use large diameter pulleys, which reduces resolution.

- Use 16 tooth pulleys, not 20 tooth. They give you better resolution, also the resolution is a more useful figure e.g. 10um per 1/16 microstep instead of 12.5um.

- For best results use 0.9deg motors and 24V power. But it's not essential, the print quality using 1.8deg motors is only slightly less.

- Use a nozzle-contact Z probe, such as our smart effector, or FSRs or piezos under the bed.

- Above all, design your printer so that the geometry is accurate. See [duet3d.com] for more.

HTH David

Hello David,

Many thanks for your input, please see comments below:

- My aim is and has always been 300mm dia print bed. I think It may be 280 though.

- I have a BLTouch bed probe however I am also adding a spring loaded bed as per Ultimaker style therefor I am not even sure if I will go to the hassle of adding in the BLTouch. (Maybe a future update)

- I have 0.9deg motors already purchased (17HM19-1684S x4)

Thanks

|

Re: Belt & Pully design - build question September 12, 2017 01:01AM |

Registered: 9 years ago Posts: 483 |

Quote

Mils24

Sorry to sound stupid but how did you work that out? And also what does that mean? Is 1:10 good?

My set up will be same belt and pulleys (GT2 2mm + 20 tooth) and my rods will be spaced 55mm apart.

There seems to be a real split on belt centered or belt offset. I'm starting to think does it really matter??

The pitch radius of a 20 tooth GT2-2mm pulley is 6.3662 and the arm width is 60mm, so it's actually a bit more than 1:10. It's useful information if you want to do stress analysis. I designed my printer before I had access to stress analysis software. The primary reason for choosing 20 tooth pulleys is you can get them with a bore of 8mm which makes it easy to use 8mmX5mm bearings in the idler pulley. You can't do this with a 16 tooth pulley.

The pitch radius of a 16 tooth GT2-2mm pulley is 5.093.

I also used .9 degree steppers so the lose of resolution compared to a 1.8 degree stepper with 16 tooth pulleys is

Edited 1 time(s). Last edit at 09/12/2017 01:05AM by etfrench.

|

Re: Belt & Pully design - build question September 12, 2017 04:56AM |

Registered: 10 years ago Posts: 732 |

Making smooth rods shorter will compensate for the small diameter so that is a good approach when you already have Ø 8 mm rods.

As for as glass core belts: As dc42 have written, they are the standard. They will last longer which is the main reason to use them. Also GT2 profile is a bit better as for as precise matching of belts to pulleys. Using steal core belts with small diameter pulleys is against the manufacturer specifications. Anyway I do it on my machine. So far one belt (of the 3) failed after printing about 20 kg of filament. Maybe that one belt was faulty from production or I'm just lucky with the other two belts. The glass core belts are about 2-3 times more stretchier than steel core belts. That is their only problem. The consequences will be "ringing" after sharp corners of your prints if you will print with high accelerations. Using Ø 8 mm rods instead of Ø 12 or 16 mm rods will increase "ringing" too.

Is the acceleration limit somewhere around 5000 mm/s² a problem for you? It depends on the shape of your prints and how much you care about print time. If you are going to print big parts with small number of (small) holes then it does not matter because the head will mostly move in long straight lines. Acceleration does not matter much there. Only the maximum print speed does. If your models are going to have a lot of holes resulting in a lot of lines being very short then low acceleration will considerably increase your print time. Lets say your model has about half of the lines long only about 1.3 mm and then there is a sharp direction change. E.g. a lot of short infill lines between model walls ... or using fine hexagonal infill or whatever. Then using maximum print speed of 120 mm/s and acceleration of 5000 mm/s² (instead of 10000 mm/s²) will lead to longer print time by about 25%. Just a very rough estimate to give you an idea.

As for as glass core belts: As dc42 have written, they are the standard. They will last longer which is the main reason to use them. Also GT2 profile is a bit better as for as precise matching of belts to pulleys. Using steal core belts with small diameter pulleys is against the manufacturer specifications. Anyway I do it on my machine. So far one belt (of the 3) failed after printing about 20 kg of filament. Maybe that one belt was faulty from production or I'm just lucky with the other two belts. The glass core belts are about 2-3 times more stretchier than steel core belts. That is their only problem. The consequences will be "ringing" after sharp corners of your prints if you will print with high accelerations. Using Ø 8 mm rods instead of Ø 12 or 16 mm rods will increase "ringing" too.

Is the acceleration limit somewhere around 5000 mm/s² a problem for you? It depends on the shape of your prints and how much you care about print time. If you are going to print big parts with small number of (small) holes then it does not matter because the head will mostly move in long straight lines. Acceleration does not matter much there. Only the maximum print speed does. If your models are going to have a lot of holes resulting in a lot of lines being very short then low acceleration will considerably increase your print time. Lets say your model has about half of the lines long only about 1.3 mm and then there is a sharp direction change. E.g. a lot of short infill lines between model walls ... or using fine hexagonal infill or whatever. Then using maximum print speed of 120 mm/s and acceleration of 5000 mm/s² (instead of 10000 mm/s²) will lead to longer print time by about 25%. Just a very rough estimate to give you an idea.

|

Re: Belt & Pully design - build question September 12, 2017 08:07AM |

Registered: 9 years ago Posts: 54 |

|

Re: Belt & Pully design - build question September 12, 2017 08:51AM |

Registered: 10 years ago Posts: 732 |

Well, I typically use speed of 120 mm/s and accelerations 9000 mm/s², non-printing speed 250 mm/s.

Why would one build delta if not for speed? Cartesians can print at low speed just fine and they are much easier to calibrate and do not need as powerful electronics.

Well there are some other reasons to use a delta printer as well. E.g. when one wants to print very tall objects or just likes the funny way delta moves. But otherwise deltas have only disadvantages. They are harder to build precisely. And did I mention that they are a real pain to calibrate if you do not happen to have dc42's firmware or are not skilled enough to use my calibration notebook? And still the numerical calibration methods are not good enough. If you were unlucky and built your delta with skewed towers then you are screwed. You can just dump it and star over ... or wait till somebody implements calibration which will compensate for this. It is possible but nobody cared enough to implement it yet.

Why would one build delta if not for speed? Cartesians can print at low speed just fine and they are much easier to calibrate and do not need as powerful electronics.

Well there are some other reasons to use a delta printer as well. E.g. when one wants to print very tall objects or just likes the funny way delta moves. But otherwise deltas have only disadvantages. They are harder to build precisely. And did I mention that they are a real pain to calibrate if you do not happen to have dc42's firmware or are not skilled enough to use my calibration notebook? And still the numerical calibration methods are not good enough. If you were unlucky and built your delta with skewed towers then you are screwed. You can just dump it and star over ... or wait till somebody implements calibration which will compensate for this. It is possible but nobody cared enough to implement it yet.

|

Re: Belt & Pully design - build question September 12, 2017 09:18AM |

Registered: 9 years ago Posts: 1,159 |

Quote

hercek

Well, I typically use speed of 120 mm/s and accelerations 9000 mm/s², non-printing speed 250 mm/s.

Why would one build delta if not for speed? Cartesians can print at low speed just fine and they are much easier to calibrate and do not need as powerful electronics.

Well there are some other reasons to use a delta printer as well. E.g. when one wants to print very tall objects or just likes the funny way delta moves. But otherwise deltas have only disadvantages. They are harder to build precisely. And did I mention that they are a real pain to calibrate if you do not happen to have dc42's firmware or are not skilled enough to use my calibration notebook? And still the numerical calibration methods are not good enough. If you were unlucky and built your delta with skewed towers then you are screwed. You can just dump it and star over ... or wait till somebody implements calibration which will compensate for this. It is possible but nobody cared enough to implement it yet.

Actually DC42's FW will now compensate for skewed towers

|

Re: Belt & Pully design - build question September 12, 2017 09:28AM |

Registered: 10 years ago Posts: 732 |

Does it compensate for wrong tower positions only or also for skewed towers (towers which are not equidistant to each other)?

If it does the later too then that is great! Se could dismiss the calibration disadvantage of deltas as irrelevant. Deltas would need just more powerful/expensive hardware. Not a big deal.

If it does the later too then that is great! Se could dismiss the calibration disadvantage of deltas as irrelevant. Deltas would need just more powerful/expensive hardware. Not a big deal.

|

Re: Belt & Pully design - build question September 12, 2017 09:55AM |

Registered: 9 years ago Posts: 1,159 |

Quote

hercek

Does it compensate for wrong tower positions only or also for skewed towers (towers which are not equidistant to each other)?

If it does the later too then that is great! Se could dismiss the calibration disadvantage of deltas as irrelevant. Deltas would need just more powerful/expensive hardware. Not a big deal.

not sure about the equidistant but does do rotational and tilt

4-factor: Similar to traditional manual delta calibration, but much faster. Adjusts the endstop switch position corrections (M666 XYZ parameters) and the delta radius (M665 R parameter).

6-factor: as 4-factor but also adjusts the X and Y tower position corrections.

7-factor: as 6-factor but also adjusts the diagonal rod length (M665 L parameter).

8-factor: as 6-factor but also adjusts the X and Y tilt angles (M666 A and B parameters).

9-factor: as 8-factor but also adjusts the diagonal rod length (M665 L parameter).

Lifted from the Duet documentation I always use the 8Factor calibration on mine takes about 30 secs to do 16 points on a 360mm diam bed

|

Re: Belt & Pully design - build question September 12, 2017 10:12AM |

Registered: 10 years ago Posts: 732 |

Based on your reply it does not do full compensation for tilted towers. One needs at least 4 (or 6 depending how we interpret the problem) additional factors. But DC42's 8-factor calibration adds only 2 factors when compared to 6-factor. It probably assumes all towers are equidistant and tilted the same way. Two additional parameters should be enough for this subset of the problem.

Looks like delta calibration has still same way to go :-)

IIRC the full linear robot (delta is a subset of linear robots) needs 64 factors ... or something like that ... I probably do not remember it well.

Looks like delta calibration has still same way to go :-)

IIRC the full linear robot (delta is a subset of linear robots) needs 64 factors ... or something like that ... I probably do not remember it well.

|

Re: Belt & Pully design - build question September 12, 2017 11:58AM |

Registered: 10 years ago Posts: 14,672 |

My calibration algorithm assumes that the towers are parallel, so if they are skewed in the sense of not being parallel then it will not compensate for that.

It does now compensate for bed tilt i.e. bed not perpendicular to towers. Or to put it another way, towers tilted but still parallel. In practice, a tilted bed causes much the same type of height errors as a tower in slightly the wrong place, so calibrating the compensation for both requires a good number of probe points as far from the centre as possible.

IMO the best approach is to build a delta in such as way as to minimise the likelihood of geometrical errors. That's why I use metal vertices, linear rails and Haydn's rods, and also why we developed the PCB effector and carriage adapters.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

It does now compensate for bed tilt i.e. bed not perpendicular to towers. Or to put it another way, towers tilted but still parallel. In practice, a tilted bed causes much the same type of height errors as a tower in slightly the wrong place, so calibrating the compensation for both requires a good number of probe points as far from the centre as possible.

IMO the best approach is to build a delta in such as way as to minimise the likelihood of geometrical errors. That's why I use metal vertices, linear rails and Haydn's rods, and also why we developed the PCB effector and carriage adapters.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.