Kossel xxxl

Posted by Thenewguy

|

Kossel xxxl October 23, 2017 06:56AM |

Registered: 6 years ago Posts: 20 |

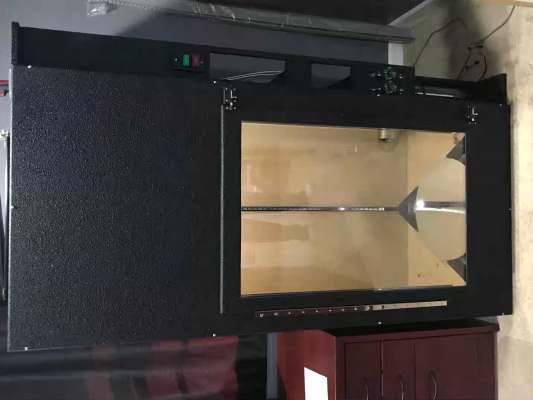

Building a large delta. Horizontal beam is 625, vertical is 1750, and arms are 505. I should print 17” x 3’. Some quick specs are heated chamber, hepa filtration, watercooled, smart effectors, Haydn ball arms, copper hotend and nozzle with titanium heartbreak, china bulldog extruder, Capricorn tubing, Nema 23 motors, duet wifi with Duex5, will have a bunch of thermistors watching the temps and going 24v. Prob won’t get the delta moving for another month.

Edited 5 time(s). Last edit at 10/23/2017 04:31PM by Thenewguy.

Edited 5 time(s). Last edit at 10/23/2017 04:31PM by Thenewguy.

|

Re: Kossel xxxl October 23, 2017 08:04AM |

Registered: 10 years ago Posts: 14,672 |

Looks good! I'm not sure that you need Nema23 motors for that size printer, but if you do use them, pick ones with a rated current of about 2.5 to 2.8A so that the Duet can drive them directly.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel xxxl October 23, 2017 10:12AM |

Registered: 6 years ago Posts: 20 |

Quote

dc42

Looks good! I'm not sure that you need Nema23 motors for that size printer, but if you do use them, pick ones with a rated current of about 2.5 to 2.8A so that the Duet can drive them directly.

I have these. [www.omc-stepperonline.com]

Stick around dc42 I will prob need your help when I get this delta moving.

|

Re: Kossel xxxl October 23, 2017 02:45PM |

Registered: 6 years ago Posts: 20 |

Sprayed with rino liner or bed liner.

Edited 1 time(s). Last edit at 10/23/2017 02:48PM by Thenewguy.

|

Re: Kossel xxxl October 24, 2017 09:52PM |

Registered: 6 years ago Posts: 20 |

The insulation I used in the picture is stone wool insulation batting. Does anyone have any idea for insulation inside the cabinet? I’m thinking about using the wool boards made by rolux but not sure if that’s a good idea with debris If any inside the cabinet from the wool. It could affect my first layer adhesion? The recirc fan will max out at 75cfm so nothing to crazy and I might even slow it down. I will have the hepa filter as well. Im also looking for a decent r value. The bubble insulation would look best but I want something that’s good resisting fires because I will be doing long prints and will be away from home. I could also use welders blanket. Looking for advise and suggestions.

|

Re: Kossel xxxl October 25, 2017 03:17AM |

Registered: 8 years ago Posts: 5,232 |

Not sure about the material for inside insulation, but it should be something alu-foil covered. The alu-surface reflects most of IR-rays and also the visible light which adds convenience while working "in" the cabinet.

I'd go for insulated wall paper that usually goes behind radiators, but that's not fire resistant.

Edited 1 time(s). Last edit at 10/25/2017 03:18AM by o_lampe.

I'd go for insulated wall paper that usually goes behind radiators, but that's not fire resistant.

Edited 1 time(s). Last edit at 10/25/2017 03:18AM by o_lampe.

|

Re: Kossel xxxl October 25, 2017 06:41PM |

Registered: 6 years ago Posts: 70 |

|

Re: Kossel xxxl October 25, 2017 07:52PM |

Registered: 7 years ago Posts: 59 |

maybe the paneling they put behind and around stoves? might be cheap, should be fire resistant. the main issue with fire is the spool igniting, maybe make that in a fireproof box and the rest fairly fire resistant. if you can keep the spool igniting it is a factor of print size. if the spool ignites its a much larger fuel source. I am not sure how much you want to worry about it, but then having a system that removes later worry during long prints is awesome goal. I think a narrow metal tube will cutoff the oxygen and quench a burning strand of filament, needs testing but it seems resonable that a section of 3mm ID brass tube would stop fire advancing along filament. bent and polished it would be low friction, it would lead into a fireproof box for the filament.

Edited 1 time(s). Last edit at 10/25/2017 08:21PM by Milton.

Edited 1 time(s). Last edit at 10/25/2017 08:21PM by Milton.

|

Re: Kossel xxxl October 25, 2017 08:16PM |

Registered: 6 years ago Posts: 20 |

Added the front window. Used two 24”x36” glass panels. Trying to slow down the heat exchange from the enclosure to my room. Found silicone gaskets for doors and windows to make the seal.

|

Re: Kossel xxxl October 25, 2017 08:30PM |

Registered: 6 years ago Posts: 20 |

Quote

number40fan

Go with fire rated drywall. I'd maybe even look into a self releasing fire extinguisher.

Once I get the printer reliable on long prints I plan on doing that. I want a smoke alarm to be controled by arduino. Which will cut off 120v to the cabinet and will send a signal to a relay purging c02 from a small paintball tank into the enclosure. The main enclosure will already be sealed so once the oxygen burns up that will help. I priced out all the parts and it’s about $600 so I’m waiting for everything to turn out like it should.

|

Re: Kossel xxxl October 25, 2017 08:36PM |

Registered: 6 years ago Posts: 20 |

Quote

Milton

maybe the paneling they put behind and around stoves? might be cheap, should be fire resistant. the main issue with fire is the spool igniting, maybe make that in a fireproof box and the rest fairly fire resistant. if you can keep the spool igniting it is a factor of print size. if the spool ignites its a much larger fuel source. I am not sure how much you want to worry about it, but then having a system that removes later worry during long prints is awesome goal. I think a narrow metal tube will cutoff the oxygen and quench a burning strand of filament, needs testing but it seems resonable that a section of 3mm ID brass tube would stop fire advancing along filament. bent and polished it would be low friction, it would lead into a fireproof box for the filament.

The spool will be on top of the printer or to the left side halfway down. So it’s just the part I’m printing that I have to worry about. The concern I have is the ball arms coming loose and all hell breaks loose after that. I might go the ball cup route tricklaser makes but then I will need a lot of custom parts made. Time will tell.

Edited 1 time(s). Last edit at 10/25/2017 08:40PM by Thenewguy.

|

Re: Kossel xxxl November 04, 2017 07:50PM |

Registered: 6 years ago Posts: 20 |

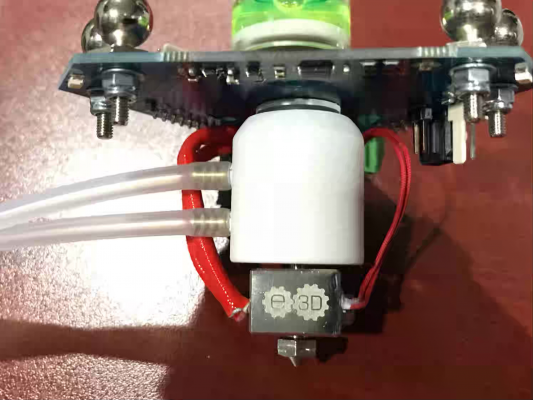

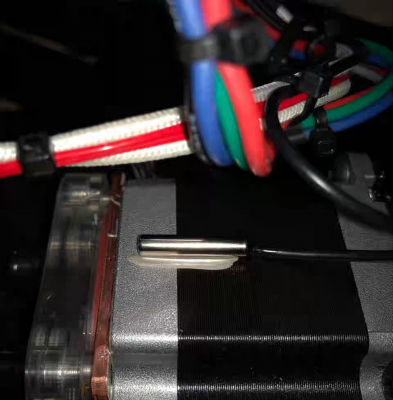

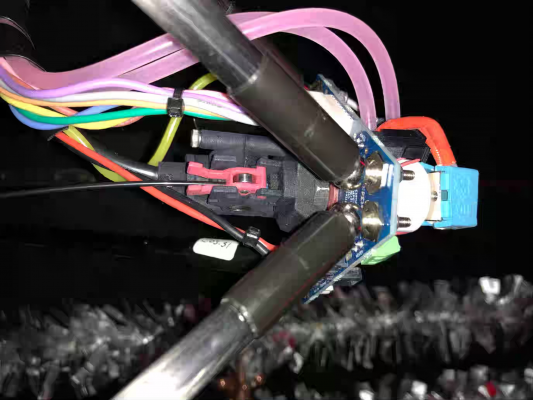

Watercooled, copper block+nozzle, titanium heat-break and pt100. Happy with how it turned out. Nimble extruder on the way and getting a mount printed from Shapeways. Still need to design a mount for the berd-air and the silicone tubing.

Edited 1 time(s). Last edit at 11/04/2017 08:03PM by Thenewguy.

|

Re: Kossel xxxl November 08, 2017 01:07AM |

Registered: 6 years ago Posts: 20 |

Total came out to 625.35 and all horizontals are within .10. 8020.net did a good job cutting these.

|

Re: Kossel xxxl November 13, 2017 09:19PM |

Registered: 6 years ago Posts: 20 |

3/4th 445mm round mic, keenovo 475watt 110v 440mm, 3/4 445mm carbon fiber blanket, and 445mm 22ga steel sheet.

Sandwich

Ground and hole is for thermal fuse.

Sandwich

Ground and hole is for thermal fuse.

|

Re: Kossel xxxl November 15, 2017 02:01AM |

Registered: 6 years ago Posts: 20 |

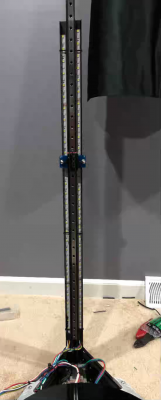

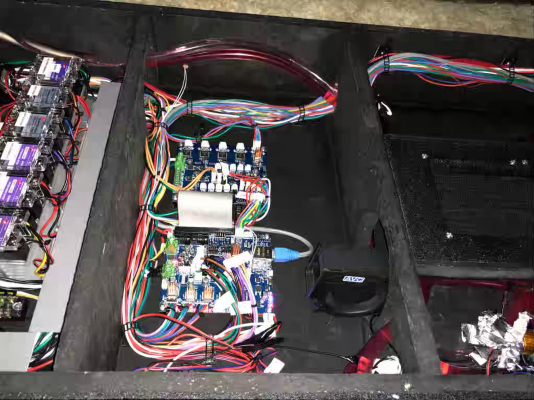

Not to happy with the black plastic covers. Might change it later on. Idk. 120v meter and rest are temp

The buttons are actually going to prob end up extra. The leds will light up when heating or cooling are in effect. Chamber, bed, hotend,etc. two flow meters one for the hotend and other is for motors.

Water cooling stepper motors.

Edited 1 time(s). Last edit at 11/15/2017 02:05AM by Thenewguy.

The buttons are actually going to prob end up extra. The leds will light up when heating or cooling are in effect. Chamber, bed, hotend,etc. two flow meters one for the hotend and other is for motors.

Water cooling stepper motors.

Edited 1 time(s). Last edit at 11/15/2017 02:05AM by Thenewguy.

|

Re: Kossel xxxl December 11, 2017 10:08PM |

Registered: 6 years ago Posts: 20 |

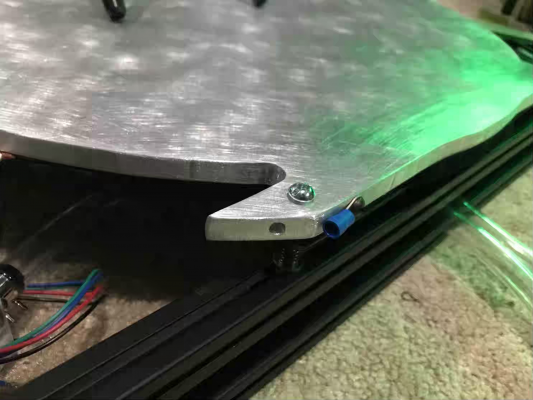

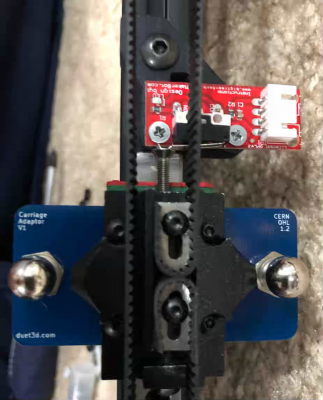

I had the endstop brackets and 4 of these 2020 rail alignment peices sls printed.

This is the best way to mount 9mm that I could come up with. I tried a few methods and even had toothed. This way had less belt wobble for me.

Edited 2 time(s). Last edit at 12/11/2017 10:15PM by Thenewguy.

This is the best way to mount 9mm that I could come up with. I tried a few methods and even had toothed. This way had less belt wobble for me.

Edited 2 time(s). Last edit at 12/11/2017 10:15PM by Thenewguy.

|

Re: Kossel xxxl December 12, 2017 02:48AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Kossel xxxl December 12, 2017 05:03AM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

No chance to use a longer screw so it's supported from both sides?

That's what I did in my build. See [miscsolutions.wordpress.com]. I used a flanged bearing to support the far end; so if the screw is bigger than M3 then some redesign would be needed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel xxxl December 12, 2017 01:03PM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Kossel xxxl December 13, 2017 12:23AM |

Registered: 7 years ago Posts: 51 |

Quote

Thenewguy

I had the endstop brackets and 4 of these 2020 rail alignment peices sls printed.

[attachment 100404 IMG_5427.jpg]

[attachment 100405 IMG_5426.jpg]

[attachment 100406 IMG_5425.jpg]

This is the best way to mount 9mm that I could come up with. I tried a few methods and even had toothed. This way had less belt wobble for me.

[attachment 100407 IMG_5423.jpg]

[attachment 100408 IMG_5424.jpg]

[attachment 100409 IMG_5429.jpg]

Better to support the screws at both sides

|

Re: Kossel xxxl December 13, 2017 02:10AM |

Registered: 7 years ago Posts: 51 |

|

Re: Kossel xxxl December 13, 2017 02:51AM |

Registered: 6 years ago Posts: 20 |

I did try dc method with the m3 screws and the toothed pulleys. Either the pully was bad or my screws were bending from the wider belts. This way really don’t flex believe it or not. If I could find longer screws that are smooth like these I’ll buy them. I got these on robotdig. Let me know.

As for the ikea enclosure I hope you are joking. I think your missing my whole point of everything being designed well and custom. This is my second heated enclosure. The last one I could of only hit 40c and wiring was a mess. A couple things are up in the air like enclosure heat up times but i hope the community will get some ideas about designs and heated chambers. I haven’t really seen anything like this build yet.

Edited 1 time(s). Last edit at 12/13/2017 02:57AM by Thenewguy.

As for the ikea enclosure I hope you are joking. I think your missing my whole point of everything being designed well and custom. This is my second heated enclosure. The last one I could of only hit 40c and wiring was a mess. A couple things are up in the air like enclosure heat up times but i hope the community will get some ideas about designs and heated chambers. I haven’t really seen anything like this build yet.

Edited 1 time(s). Last edit at 12/13/2017 02:57AM by Thenewguy.

|

Re: Kossel xxxl December 13, 2017 09:40PM |

Registered: 6 years ago Posts: 20 |

Insulated with carbon fiber welding blankets on the walls and installed brackets at the top and bottom for frame support on two sides. The bad news is the 2040 vertical frames flexes pretty easy. 4040 is probably needed. Also learned that I can’t use the full bed due to the chamber not being big enough.

Bottom

Top

Edited 1 time(s). Last edit at 12/13/2017 09:43PM by Thenewguy.

Bottom

Top

Edited 1 time(s). Last edit at 12/13/2017 09:43PM by Thenewguy.

|

Re: Kossel xxxl December 13, 2017 09:49PM |

Registered: 6 years ago Posts: 20 |

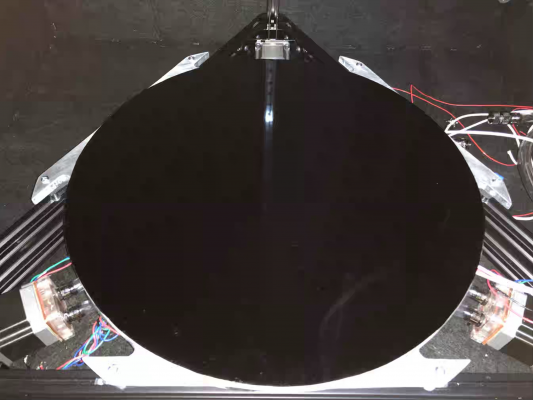

Printbite bed surface installed.

Zoomed in with the iPhone X and used a flashlight for extra lighting. You can see all the holes in the material. I think I read they expand and contract with heat gripping the print.

Zoomed in with the iPhone X and used a flashlight for extra lighting. You can see all the holes in the material. I think I read they expand and contract with heat gripping the print.

|

Re: Kossel xxxl December 20, 2017 09:50PM |

Registered: 6 years ago Posts: 20 |

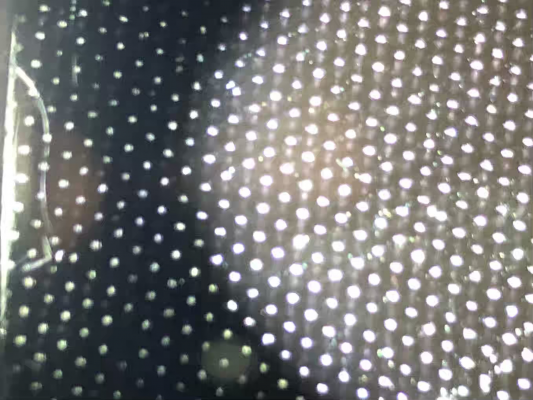

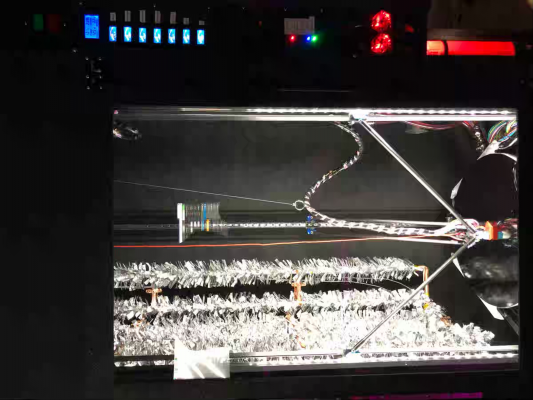

24v RGBW leds on aluminum strips. I mounted them directly on two of the front 2040 to help move the heat away from the leds better. The leds can handle 120c on the chip and if the chamber hits 85c I won’t have much room to play with. If they don’t last long I can always put them through the water loop but I would rather not to keep the heat in the chamber. They will be on the duet 5 pwm so I can give them less power. Using the colors for different modes of the print. I also put temp probes on the led bar and on the motor to get a better idea of temps. I might even be able to have to duet control the brightness of the leds to the chamber temps automatically. I think I can get it to do that when I play with everything later. Also all the wires in the chamber are silicone which can go up to around 200c.

Edited 3 time(s). Last edit at 12/22/2017 01:38PM by Thenewguy.

Edited 3 time(s). Last edit at 12/22/2017 01:38PM by Thenewguy.

|

Re: Kossel xxxl February 12, 2018 03:28AM |

Registered: 6 years ago Posts: 20 |

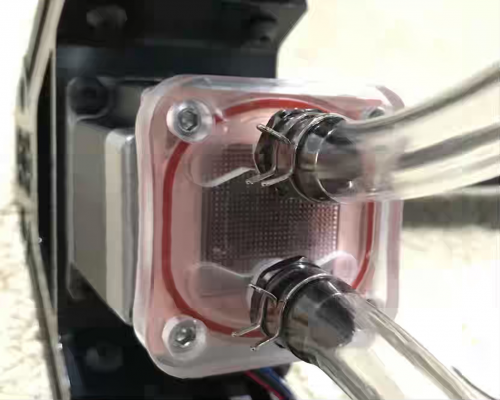

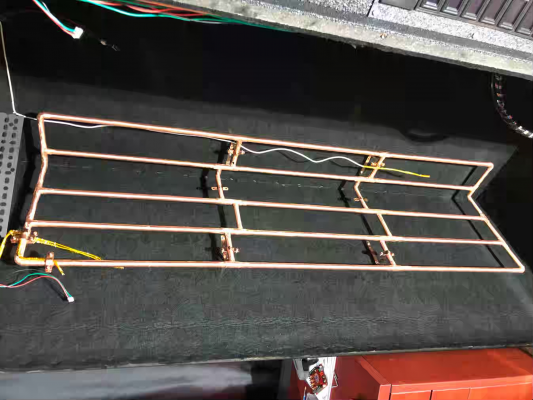

This is the radiator inside the chamber. Using 1/2 inch copper tubing welded with silicone bronze at the joints. I first used nichrome and kapton tape as the heating element but kept on tripping the gcfi so I bought two 120v 500watt Keenovo heater strips. So I’m running two thermistors on the radiator one at each end wired in parallel. I have two thermal fuses in the middle of the radiator for safety. I used about 5 large rolls of Aluminium foil that I used to wrap the copper. It took forever to make these and wrap!

The good news is that it works extremely well at exchanging the heat for a fanless design. With the chamber door open and inside temps at 22c. I set the heater to use 750watts and the radiator maxed out at 75c. When I bump the power up to 950watts and the door closed the radiator gets to 85c in about 8mins. With all my heaters on and the printer running I’m hitting about 1750watts heating this bad boy up.

Edited 1 time(s). Last edit at 02/12/2018 03:44AM by Thenewguy.

The good news is that it works extremely well at exchanging the heat for a fanless design. With the chamber door open and inside temps at 22c. I set the heater to use 750watts and the radiator maxed out at 75c. When I bump the power up to 950watts and the door closed the radiator gets to 85c in about 8mins. With all my heaters on and the printer running I’m hitting about 1750watts heating this bad boy up.

Edited 1 time(s). Last edit at 02/12/2018 03:44AM by Thenewguy.

|

Re: Kossel xxxl February 12, 2018 03:54AM |

Registered: 6 years ago Posts: 20 |

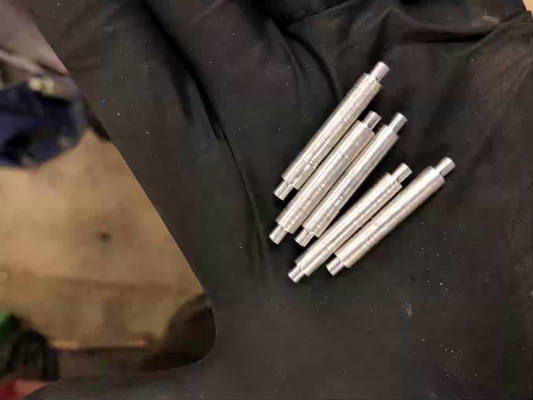

The way I had the top pullies just didn’t really work out. So I took these to the lathe down to 5mm for the bearings.

|

Re: Kossel xxxl February 12, 2018 04:05AM |

Registered: 6 years ago Posts: 20 |

The bed leveling works great as well as the PrintBite. With chamber temps to about 65c I get zero warping with abs. I can now just push a button and walk away without first layer worries and stuff like that. The RGBW leds in the chamber are pretty cool. I change the colors while heating up, probing, printing, cooling down ect.

Third one I made in abs. Still could use adjustments.

[attachment 102419 IMG_5692.jpg

Edited 2 time(s). Last edit at 02/12/2018 04:12AM by Thenewguy.

Third one I made in abs. Still could use adjustments.

[attachment 102419 IMG_5692.jpg

Edited 2 time(s). Last edit at 02/12/2018 04:12AM by Thenewguy.

|

Re: Kossel xxxl February 13, 2018 03:00AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Kossel xxxl February 15, 2018 09:33PM |

Registered: 6 years ago Posts: 20 |

Sorry, only registered users may post in this forum.