Mid mounted pivoting extruders as a solution for a very short bowden

Posted by Milton

|

Mid mounted pivoting extruders as a solution for a very short bowden October 25, 2017 12:47AM |

Registered: 7 years ago Posts: 59 |

hello all, again, been a while. <3 the RepRap open source community

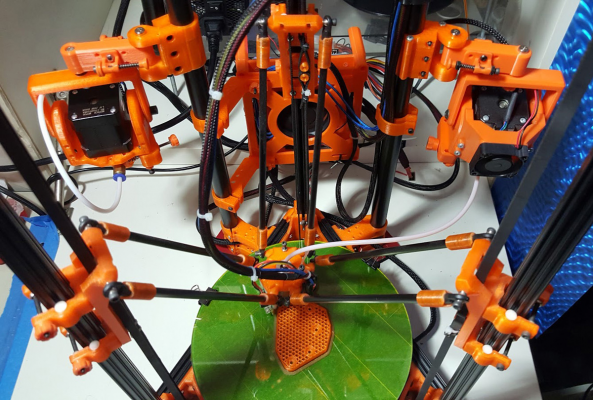

This is my solution for having good melt zone control with short bowdens on a Delta style printer.

YouTube demo of the system: Mid mounted pivoting extruder demo

This is all experimental, from the printed linear motion to the short bowden system. not bad quality for an entirely self made machine, this one is the second and was made by the first. Third is just about ready to commision using the first machines control board. The new "Unit3' set of parts with smooth axle pulleys and other nice refinements (wanted to call it the MK3 version but Prusa is totally owning the MK moniker ).

).

Anyway while its not ideal, it works at keeping the extruders weight totally seperate from the machines linear motion. The video explains my thinking, comments and observations and corrections are much appreciated.

Edited 1 time(s). Last edit at 10/25/2017 01:15AM by Milton.

This is my solution for having good melt zone control with short bowdens on a Delta style printer.

YouTube demo of the system: Mid mounted pivoting extruder demo

This is all experimental, from the printed linear motion to the short bowden system. not bad quality for an entirely self made machine, this one is the second and was made by the first. Third is just about ready to commision using the first machines control board. The new "Unit3' set of parts with smooth axle pulleys and other nice refinements (wanted to call it the MK3 version but Prusa is totally owning the MK moniker

).

).Anyway while its not ideal, it works at keeping the extruders weight totally seperate from the machines linear motion. The video explains my thinking, comments and observations and corrections are much appreciated.

Edited 1 time(s). Last edit at 10/25/2017 01:15AM by Milton.

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 25, 2017 03:10AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 25, 2017 04:30AM |

Registered: 7 years ago Posts: 59 |

Delrin brand Acetel, one of the densest low friction plastics and often used as a bushing in industrial setting. Works incredibly well. There is a certain amount of very consistent friction well below causing any stiction, they glide smoothly with zero lubrication. 2 adjustments of the preload screw in 10 months of use. I followed IGUS and others engineering recommendations for ratios of any cantilever and offset for polymer bushings from the point force is applied to move them, so they dont stick at all. They have constant positive preloaded contact and smooth moving ball joints so no issues of slop just of flex of the plastic after a certain amount of inertia is reached, but it's all super light so it can print fairly fast and accurate for literally everything but the extrusions and screws printed. The orange sleeves on the rods are printed adaptors, instead of the screws normally used. epoxied on and rods set in a jig with axles to make each exactly the same, the ends are accurately located.

i am not normally posting this late, its like a million degrees and sleep is impossible

i am not normally posting this late, its like a million degrees and sleep is impossible

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 25, 2017 05:54PM |

Registered: 8 years ago Posts: 3,525 |

I like the idea and related to the other thread and my smashed up microdelta I was thinking of trying a pivoting extruder when I rebuild it. I ought give this a go it's nicely executed.

One question how does the bowden tube look when the head is at z max? I presume the extruder is fixed? And you haven't opted for some sort of sliding system (in z) for the extruder?

Edited 3 time(s). Last edit at 10/25/2017 05:57PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

One question how does the bowden tube look when the head is at z max? I presume the extruder is fixed? And you haven't opted for some sort of sliding system (in z) for the extruder?

Edited 3 time(s). Last edit at 10/25/2017 05:57PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 25, 2017 06:14PM |

Registered: 7 years ago Posts: 59 |

the extruders tilt so they point upward for homing, it's a tight radius though at the endstops and I dont let it sit there too much, but sometimes it does sit at 220mm right at the top of build area after printing if I forget to drop it down to 160mm or so after removing the print. It seems to have no effect so far to have the PTFE at the tighter radius infrequently. I have tried to feed new filament in that position and it is more friction but it does feed so it's not horrible just not ideal, but it's not in the build area, the radius in the build area is good for low friction.

I will take a video of the autocalibration that shows the entire range of motion.

I will take a video of the autocalibration that shows the entire range of motion.

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 25, 2017 06:17PM |

Registered: 8 years ago Posts: 3,525 |

I will almost certainly try this if you want someone else to give it a whirl. Is it published anywhere?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 25, 2017 07:43PM |

Registered: 7 years ago Posts: 59 |

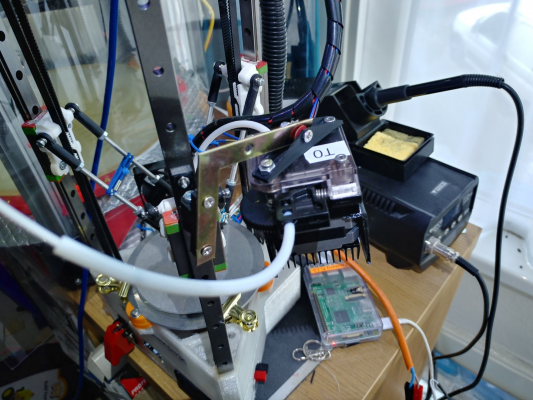

I am working on the explanatory and assembly instruction PDF now, but you dont need that. I will make a github post for it and link here unless you have a better suggestion. the round tubing is 19.95mm towel rods, literally the tubing you buy as replacements for tube and bracket designer bathroom fittings. its cheap for the variety of surface quality, I was able to match the extrusions on 2 machines with silver and black towel rods, its straight enough for simple framing. anything else will work.

I am making a base, the extruder towers will be completely removed from the frame, they induced a minor tilt. autocalibration went from .03-.05mm to .05-.07mm average results.

I need to make the explanatory doc, it's too much to post. I figure you can probably improve on this mechanical mechanism anyway, this is the 2nd prototype with a bunch of revisions some due to limitations of the route I went. The hanging C bracket and the extruder stepper center of geometry (close enough to its COM) at the tilt axis and pivot axis are the best parts and worth copying, the arm length now is good, but only for mini kossel build area you will need to experiment with the length of tubing and arm length to get the right movement of the mechanism for the build area. its specific to build area diameter and height for any printer the concept is applied to. Edit:yours will be very short, should be fairly awesome really. small build area means short tube and shorter swingarm than mine.

my swingarm base pivot point on the clamp to the extruder upright tube sucks, they squeak now, really horrible embarrassing design but it was one of the first and has not been revised. just barely good enough to test. something with bearings, an improved damping spring from my design, all would be good.

maybe I can make this a separate Fusion 360 project open to those that want to work on the concept? I will look into how to do that it would be easiest to just share the 3d files since major revision for build area is needed and it's some rough mechanical design that is still 'functionality testing/proof of concept'.

Edited 2 time(s). Last edit at 10/25/2017 07:45PM by Milton.

I am making a base, the extruder towers will be completely removed from the frame, they induced a minor tilt. autocalibration went from .03-.05mm to .05-.07mm average results.

I need to make the explanatory doc, it's too much to post. I figure you can probably improve on this mechanical mechanism anyway, this is the 2nd prototype with a bunch of revisions some due to limitations of the route I went. The hanging C bracket and the extruder stepper center of geometry (close enough to its COM) at the tilt axis and pivot axis are the best parts and worth copying, the arm length now is good, but only for mini kossel build area you will need to experiment with the length of tubing and arm length to get the right movement of the mechanism for the build area. its specific to build area diameter and height for any printer the concept is applied to. Edit:yours will be very short, should be fairly awesome really. small build area means short tube and shorter swingarm than mine.

my swingarm base pivot point on the clamp to the extruder upright tube sucks, they squeak now, really horrible embarrassing design but it was one of the first and has not been revised. just barely good enough to test. something with bearings, an improved damping spring from my design, all would be good.

maybe I can make this a separate Fusion 360 project open to those that want to work on the concept? I will look into how to do that it would be easiest to just share the 3d files since major revision for build area is needed and it's some rough mechanical design that is still 'functionality testing/proof of concept'.

Edited 2 time(s). Last edit at 10/25/2017 07:45PM by Milton.

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 26, 2017 03:11AM |

Registered: 8 years ago Posts: 5,232 |

Quote

my swingarm base pivot point on the clamp to the extruder upright tube sucks, they squeak now, really horrible embarrassing design but it was one of the first and has not been revised. just barely good enough to test. something with bearings, an improved damping spring from my design, all would be good.

Now that your mention it... there is enough "meat" around the screws to add small flanged bearings.

My swinging extruder work without dampening. Do you see any overshoot when you try without dampers?

BTW: I like the cylindric shape of the Delrin gliders, they provide way more guidance than the v-rollers. Just wondering if the friction/stiction could be even lower with an hourglass shape instead off plain cylindric?

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 26, 2017 03:20PM |

Registered: 7 years ago Posts: 59 |

Quote

o_lampe

Now that your mention it... there is enough "meat" around the screws to add small flanged bearings.

My swinging extruder work without dampening. Do you see any overshoot when you try without dampers?

BTW: I like the cylindric shape of the Delrin gliders, they provide way more guidance than the v-rollers. Just wondering if the friction/stiction could be even lower with an hourglass shape instead off plain cylindric?

yes bearings like that would be much better, flanged is a good suggestion, will look into that.

yes, without damping the extruder follows the 140mm/s travel moves and the swingarm slams into the clamp to the vertical main support, shakes rattles and rolls the entire structure. the damping i have now is rough prototype with on hand parts. works but its hard to service and adjust, modeled revisions to get what i needed but now it needs analysis and refinement so its minimal mass easy to assemble and smoother motion.

No, I dont think any other geometry than round is going to have any real benefits. It would also be hard to source a specific oval shape of extruded dense Delrin versus standard industrial use 1/4" rod. The Delrin rod is incredibly cheap. I am still using the first set of bushings cut, not even rotated to new surface yet, for over a year now. The functional lifespan of a 1 foot rod of Delrin as bushing supply for one delta printer might be several generations of users, not resale actual family generations, like 100 years seriously. Edit: OK that is stretching it, I dont think the plastics shelf life is that long

lets just say it's very durable for the task it has in this system, the forces involved dont even scratch its surface it looks brand new where it's running on the aluminum.

lets just say it's very durable for the task it has in this system, the forces involved dont even scratch its surface it looks brand new where it's running on the aluminum.Edited 1 time(s). Last edit at 10/26/2017 03:30PM by Milton.

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 28, 2017 03:59AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 28, 2017 10:07AM |

Registered: 8 years ago Posts: 3,525 |

Hi Milton, are you willing to share the stl's for your pivoting extruder? I would love to give it a try, and modify it to work with e3d titan extruders.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 29, 2017 11:03AM |

Registered: 8 years ago Posts: 3,525 |

I decided to replicate the general idea but with what I had lying around.

[youtu.be]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

[youtu.be]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 29, 2017 02:03PM |

Registered: 7 years ago Posts: 59 |

NICE! that is how mine started, with threaded rod as tower and simple zip tie existing extruder to it. it then pivoted on its own and gave me the inception of the idea that it pivot and follow the effector.

I am trying to figure out hosting, I dont use thingiverse anymore since makerbot claims my even visiting makes all my designs their marketing material. scumbags are greedy and it sucks.

I am trying to figure out hosting, I dont use thingiverse anymore since makerbot claims my even visiting makes all my designs their marketing material. scumbags are greedy and it sucks.

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 29, 2017 03:16PM |

Registered: 7 years ago Posts: 59 |

I tried to export my Fusion 360 files, sort of failed. I tried to share a file, tested the function by downloading it. Autodesk uses an email link to download to datamine emails from anyone trying to collaborate, and then the file they send is a '.f3z' and fusion 360 doesn't even recognize it!??!?!?!?! F360 wants an '.f3d' and just ignores the file won't even see it browsing files to open and ignores it using drag and drop.

I am a bit frustrated with Autodesk, will try again later. trying to save my design to my computer, it tells me local saving functionality is disabled for distributed designs. so somehow they have control of my design work not me, pretty sketchy. Here is the link I made, they will want your email, and I can't even open the file they send. pretty useless :p

[a360.co]

use at own risk I am not sure if Autodesk is 'friendly' or not they seem very intent on making things harder just to mine emails.

I am a bit frustrated with Autodesk, will try again later. trying to save my design to my computer, it tells me local saving functionality is disabled for distributed designs. so somehow they have control of my design work not me, pretty sketchy. Here is the link I made, they will want your email, and I can't even open the file they send. pretty useless :p

[a360.co]

use at own risk I am not sure if Autodesk is 'friendly' or not they seem very intent on making things harder just to mine emails.

|

Re: Mid mounted pivoting extruders as a solution for a very short bowden October 30, 2017 02:56AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.