Want to build a kossel XL.

Posted by Vigilant

|

Want to build a kossel XL. November 09, 2017 09:18PM |

Registered: 7 years ago Posts: 51 |

A little bit of background. I've started with a Prusa I3, went to do my own Core XY and now planning to change it to a Delta, specifically a kossel xl.

For those who have build one , what would you have done better in hindsight after building it? Would you have change the way you build it given the chance?

For eg:-, For my core xy the number 1 on hindsight I realised is that corexy isn't really that hard. I got up and running with pretty good accuracy in the first try.

The hardest part was the cantilevered bed and all the issue that comes with leadscrew(z banding ). I think most CoreXY have this, it's just a matter of severity and whether it is only noticeable in closeup.

So while everyone is concentrating on the core xy mechanism, they failed to put in more priority in building a reliable Z print bed which I felt was harder than the coreXY mechanism itself.

Anyway,

I notice the way tevo little monster building it is a little different from the usual kossel build where you have a machined sheet metal holding the c beam extrusion ? Would that be a better way of building it? Or would robotdiggs aluminium corner suffice.

Edited 1 time(s). Last edit at 11/09/2017 09:35PM by Vigilant.

For those who have build one , what would you have done better in hindsight after building it? Would you have change the way you build it given the chance?

For eg:-, For my core xy the number 1 on hindsight I realised is that corexy isn't really that hard. I got up and running with pretty good accuracy in the first try.

The hardest part was the cantilevered bed and all the issue that comes with leadscrew(z banding ). I think most CoreXY have this, it's just a matter of severity and whether it is only noticeable in closeup.

So while everyone is concentrating on the core xy mechanism, they failed to put in more priority in building a reliable Z print bed which I felt was harder than the coreXY mechanism itself.

Anyway,

I notice the way tevo little monster building it is a little different from the usual kossel build where you have a machined sheet metal holding the c beam extrusion ? Would that be a better way of building it? Or would robotdiggs aluminium corner suffice.

Edited 1 time(s). Last edit at 11/09/2017 09:35PM by Vigilant.

|

Re: Want to build a kossel XL. November 10, 2017 02:07AM |

Registered: 8 years ago Posts: 5,232 |

I've built my Kossel XL upside-down with the small Robotdigg corners screwed to a solid MDF plate. That made a huge difference, but I'd chosen the wrong carbon rods. 6mm rods x 330mm long are not sufficient for fast prints with a heavy Diamond hotend.

So it only collected dust until I decided to give the smart effector with Haydn Huntleys magball rods a chance. To my surprise the rods are also 6mm dia.

I haven't got it running yet, but with a single extruder it'll do.

The Tevo monster approach is a bit weird. The C-beams stability are out off the question, but when the sheet metal plates aren't exactly flat, you're busted...

( I had a not_so flat round aluminum bed in my Kossel XL and despite RRF autocalibration it was a nightmare to print the 1st. layer.)

BTW: I've built a CoreXY too, but decided from the start to use linear rails and three ballscrews for the bed. No more wobbling or binding

So it only collected dust until I decided to give the smart effector with Haydn Huntleys magball rods a chance. To my surprise the rods are also 6mm dia.

I haven't got it running yet, but with a single extruder it'll do.

The Tevo monster approach is a bit weird. The C-beams stability are out off the question, but when the sheet metal plates aren't exactly flat, you're busted...

( I had a not_so flat round aluminum bed in my Kossel XL and despite RRF autocalibration it was a nightmare to print the 1st. layer.)

BTW: I've built a CoreXY too, but decided from the start to use linear rails and three ballscrews for the bed. No more wobbling or binding

|

Re: Want to build a kossel XL. November 10, 2017 03:42AM |

Registered: 10 years ago Posts: 14,672 |

I built a large Kossel two years ago, upgraded it several times, and finally rebuilt it earlier this year. It worked well from the start and got better with each upgrade. I described the journey at [miscsolutions.wordpress.com] and subsequent blog upgrades, and the rebuilt version at [miscsolutions.wordpress.com].

Some people prefer to put the electronics and motors at the top, and just the PSU and bed heater SSR under the bed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Some people prefer to put the electronics and motors at the top, and just the PSU and bed heater SSR under the bed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Want to build a kossel XL. November 10, 2017 11:27AM |

Registered: 6 years ago Posts: 70 |

|

Re: Want to build a kossel XL. November 11, 2017 04:07PM |

Registered: 8 years ago Posts: 3,525 |

I like the Tevo LM approach its a very simple frame and should be very sturdy. Get precision cut end plates made by laser cutting/waterjet which are thick enough and flat enough.

Then use linear rails, 0.9 degree steppers, Duet controller, Piezo probe/smart effector, magnetic rods, remote direct extruder.

Should be a pretty awesome delta. I've got one - and I love it. Mine is a Kossel style metal frame, as I made it before Tevo LM style frame was around but its stiff, calibrates to ludicrously low deviation 0.005mm or so and prints great.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Then use linear rails, 0.9 degree steppers, Duet controller, Piezo probe/smart effector, magnetic rods, remote direct extruder.

Should be a pretty awesome delta. I've got one - and I love it. Mine is a Kossel style metal frame, as I made it before Tevo LM style frame was around but its stiff, calibrates to ludicrously low deviation 0.005mm or so and prints great.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Want to build a kossel XL. November 12, 2017 04:33AM |

Registered: 7 years ago Posts: 51 |

Quote

o_lampe

I've built my Kossel XL upside-down with the small Robotdigg corners screwed to a solid MDF plate. That made a huge difference, but I'd chosen the wrong carbon rods. 6mm rods x 330mm long are not sufficient for fast prints with a heavy Diamond hotend.

So it only collected dust until I decided to give the smart effector with Haydn Huntleys magball rods a chance. To my surprise the rods are also 6mm dia.

I haven't got it running yet, but with a single extruder it'll do.

The Tevo monster approach is a bit weird. The C-beams stability are out off the question, but when the sheet metal plates aren't exactly flat, you're busted...

( I had a not_so flat round aluminum bed in my Kossel XL and despite RRF autocalibration it was a nightmare to print the 1st. layer.)

BTW: I've built a CoreXY too, but decided from the start to use linear rails and three ballscrews for the bed. No more wobbling or binding

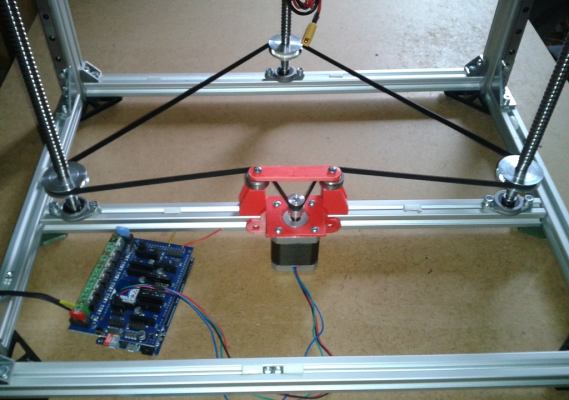

[attachment 99507 ballscrews_x3.jpg]

Do you have a picture of how it looks like, the robotdigg corners screwed to the MDF plate?

I was contemplating whether to redo my whole core xy to a bigger frame and improve the Z axis stage or rebuild to another printer. I guess part of me wanted something new.

Edited 1 time(s). Last edit at 11/12/2017 04:39AM by Vigilant.

|

Re: Want to build a kossel XL. November 12, 2017 05:09AM |

Registered: 7 years ago Posts: 51 |

Quote

DjDemonD

I like the Tevo LM approach its a very simple frame and should be very sturdy. Get precision cut end plates made by laser cutting/waterjet which are thick enough and flat enough.

Then use linear rails, 0.9 degree steppers, Duet controller, Piezo probe/smart effector, magnetic rods, remote direct extruder.

Should be a pretty awesome delta. I've got one - and I love it. Mine is a Kossel style metal frame, as I made it before Tevo LM style frame was around but its stiff, calibrates to ludicrously low deviation 0.005mm or so and prints great.

I do agree that the approach is simpler and can be very stiff but custom machining/laser cut without the volume will most likely be more expensive than just buying the corners from robotdigg i guess.

|

Re: Want to build a kossel XL. November 12, 2017 05:18AM |

Registered: 8 years ago Posts: 3,525 |

Yes that is the limiting factor but then I'm not sure you can build a really good large delta without spending a good chunk of money. Someone mentioned that the actual tevo LM frame endplates aren't that good? Shame.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Want to build a kossel XL. November 12, 2017 05:19AM |

Registered: 7 years ago Posts: 51 |

Quote

dc42

I built a large Kossel two years ago, upgraded it several times, and finally rebuilt it earlier this year. It worked well from the start and got better with each upgrade. I described the journey at [miscsolutions.wordpress.com] and subsequent blog upgrades, and the rebuilt version at [miscsolutions.wordpress.com].

Some people prefer to put the electronics and motors at the top, and just the PSU and bed heater SSR under the bed.

Wouldn't steppers at the top make it top heavy ? and vibrate more.

|

Re: Want to build a kossel XL. November 12, 2017 05:21AM |

Registered: 7 years ago Posts: 51 |

|

Re: Want to build a kossel XL. November 12, 2017 05:32AM |

Registered: 8 years ago Posts: 3,525 |

Quote

Vigilant

Quote

dc42

I built a large Kossel two years ago, upgraded it several times, and finally rebuilt it earlier this year. It worked well from the start and got better with each upgrade. I described the journey at [miscsolutions.wordpress.com] and subsequent blog upgrades, and the rebuilt version at [miscsolutions.wordpress.com].

Some people prefer to put the electronics and motors at the top, and just the PSU and bed heater SSR under the bed.

Wouldn't steppers at the top make it top heavy ? and vibrate more.

These scale of frames 1m + etc are very heavy, I could stand on my kossel Xl with no concern the frame would bend. A few motors and PSUs up top isn't going to make a difference.

Edited 1 time(s). Last edit at 11/12/2017 05:33AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.