Lean/Slant on Flsun Kossel - SOLVED (It was the belts!)

Posted by ormerod88

|

Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 15, 2017 06:08AM |

Registered: 8 years ago Posts: 7 |

Hey,

I thought I would share my experience here, as I found many discussions of leaning and only one of them had the solution on page 4 of 5.

I spent the last few weeks trying to find this problem. I completely rebuilt the printer, rolled back the firmware, tightened the pulleys, tightened everything, wiped the board completely, changed every firmware setting I could think of, and then did what I should have done initially and spent half an hour reading more forum posts. I was ready to give up and just alter the models to compensate the slant by 5 degrees!

I found this post of someone with a similar problem [forums.reprap.org]

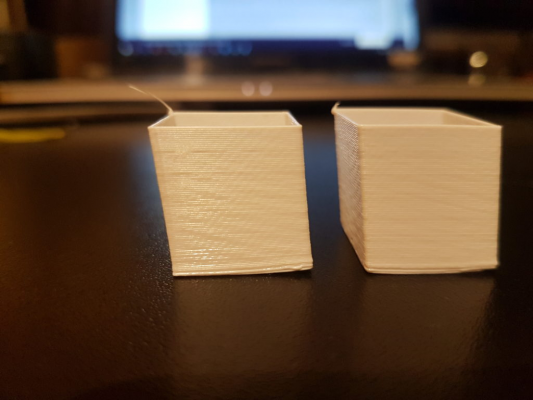

Here's a picture of my issue. The leaning is so constant and so I was convinced it was a firmware issue and not mechanical, but it turns out it was the steel core cables.

I don't know whether the problem is that the cores broke from over tightening the belts, or it the steel bent slightly. When I took them off they were a little warped along their length and had blackened from rubbing on the pulleys.

My solution was to go back to the standard black belts, maybe a pulley upgrade could also have worked.

Cheers.

I thought I would share my experience here, as I found many discussions of leaning and only one of them had the solution on page 4 of 5.

I spent the last few weeks trying to find this problem. I completely rebuilt the printer, rolled back the firmware, tightened the pulleys, tightened everything, wiped the board completely, changed every firmware setting I could think of, and then did what I should have done initially and spent half an hour reading more forum posts. I was ready to give up and just alter the models to compensate the slant by 5 degrees!

I found this post of someone with a similar problem [forums.reprap.org]

Here's a picture of my issue. The leaning is so constant and so I was convinced it was a firmware issue and not mechanical, but it turns out it was the steel core cables.

I don't know whether the problem is that the cores broke from over tightening the belts, or it the steel bent slightly. When I took them off they were a little warped along their length and had blackened from rubbing on the pulleys.

My solution was to go back to the standard black belts, maybe a pulley upgrade could also have worked.

Cheers.

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 15, 2017 09:59AM |

Registered: 8 years ago Posts: 3,525 |

Glad you solved it, I had this but it happened only for the first 50mm or so, after that the parts straightened up, it was the part of the belt in contact with the drive pulleys at the 0-50mm z range that was broken, and above that they weren't stretching.

I think we should consider 6 months for belts and then replace them as a routine service item, especially on deltas, they seem to take a battering.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I think we should consider 6 months for belts and then replace them as a routine service item, especially on deltas, they seem to take a battering.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 15, 2017 02:16PM |

Registered: 8 years ago Posts: 7 |

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 15, 2017 02:23PM |

Registered: 8 years ago Posts: 3,525 |

Im not sure I did, unless you found my delta build log where I documented it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 05:30AM |

Registered: 8 years ago Posts: 7 |

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 05:39AM |

Registered: 8 years ago Posts: 3,525 |

Happy to help, it caused a massive amount of frustration at the time as I tried everything.

I am quite keen to try making a leadscrew delta, mainly just for the hell of it, but also to see for myself if it is a realistic alternative to belts.

I've brought up the topic of belts, and improving quality/reliability of belts many times, but generally, most people are fairly dismissive of the idea, as if belts are just belts and cannot be improved, they are cheap and cheerful. This is true but many/most do not replace their belts routinely. The general opinion is that we are not using the belts anywhere near their capabilities, but then if this were the case, why do they stretch, partially fail and fail when used in 3d printers?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I am quite keen to try making a leadscrew delta, mainly just for the hell of it, but also to see for myself if it is a realistic alternative to belts.

I've brought up the topic of belts, and improving quality/reliability of belts many times, but generally, most people are fairly dismissive of the idea, as if belts are just belts and cannot be improved, they are cheap and cheerful. This is true but many/most do not replace their belts routinely. The general opinion is that we are not using the belts anywhere near their capabilities, but then if this were the case, why do they stretch, partially fail and fail when used in 3d printers?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 07:33AM |

Registered: 10 years ago Posts: 14,672 |

Quote

DjDemonD

I've brought up the topic of belts, and improving quality/reliability of belts many times, but generally, most people are fairly dismissive of the idea, as if belts are just belts and cannot be improved, they are cheap and cheerful. This is true but many/most do not replace their belts routinely. The general opinion is that we are not using the belts anywhere near their capabilities, but then if this were the case, why do they stretch, partially fail and fail when used in 3d printers?

It's now well known (thanks to you and others) that steel-cored belts fail when they are run over small diameter pulleys; but do you have any evidence that good glass-cored belts are not reliable in 3D printers?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 07:37AM |

Registered: 8 years ago Posts: 7 |

Yes I also read through one of your belt discussions. The print quality suffered changing back to the old rubber belts, so I'm going to look into an upgrade. Maybe back to steel core with larger pulleys, though I take your point about lower resolution with larger pulleys. I'm not sure if I'm ready to get so experimental as to consider leadscrews (I only have one printer so im risk averse) but I will be following your progress closely!

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 08:26AM |

Registered: 8 years ago Posts: 3,525 |

Hi David, evidence no. So I could leave it there, but do you or anyone else know of any evidence relating to suitability of various belts to 3d printing. I can see the logic behind using GT2, but not the evidence.

I think there would be a lot of interest in someone doing some independent research into various belts available. Things like elasticity, longevity, flexibility, dimensional accuracy of tooth spacing etc.. .

I suppose the issue is that most of us are using no name belts - origin unknown, as these values are known for branded belts like Gates and the like.

Edited 1 time(s). Last edit at 11/16/2017 10:34AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I think there would be a lot of interest in someone doing some independent research into various belts available. Things like elasticity, longevity, flexibility, dimensional accuracy of tooth spacing etc.. .

I suppose the issue is that most of us are using no name belts - origin unknown, as these values are known for branded belts like Gates and the like.

Edited 1 time(s). Last edit at 11/16/2017 10:34AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 11:55AM |

Registered: 10 years ago Posts: 732 |

You can find out how elastic your belts are yourself. You can just measure it. Or you can compute an approximate value. Cut a small piece of the belt and pull out the core. There are two main options: steel or glass. If your belt is GT2 then it probably uses glass (but can use steel too). If your belt is T2.5 then it probably uses steel (but can use glass too). There are other options like kevlar or carbon but they are not common.

Measure the diameter of the core and compute how much they will stretch: [en.wikipedia.org]

My T2.5 steel core belts have core cross section area of about 0.28 mm².

The belt stretches about 0.02 mm per 1 meter per 1 newton. This was measured.

The belt should stretch about 0.018 mm per 1 meter per 1 newton. Computed as 1/(0.28e-6*200e9); SteelYoungModulus = 200e9 Pa.

Maybe somebody can post his stretch measurements for his glass core belt. I would assume the value to be at least 2 times worse.

I use small diameter pulley and also a small idler. So far I needed to replace one belt once. One steel strand failed at the place where stepper pulley is most of the time while printing. The un-evenness of belt back was a good indication of a broken core strand. There was a small depression on the smooth side of the belt. So I can confirm steel core belts fail from time to time but it is not that bad.

Measure the diameter of the core and compute how much they will stretch: [en.wikipedia.org]

My T2.5 steel core belts have core cross section area of about 0.28 mm².

The belt stretches about 0.02 mm per 1 meter per 1 newton. This was measured.

The belt should stretch about 0.018 mm per 1 meter per 1 newton. Computed as 1/(0.28e-6*200e9); SteelYoungModulus = 200e9 Pa.

Maybe somebody can post his stretch measurements for his glass core belt. I would assume the value to be at least 2 times worse.

I use small diameter pulley and also a small idler. So far I needed to replace one belt once. One steel strand failed at the place where stepper pulley is most of the time while printing. The un-evenness of belt back was a good indication of a broken core strand. There was a small depression on the smooth side of the belt. So I can confirm steel core belts fail from time to time but it is not that bad.

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 02:47PM |

Registered: 6 years ago Posts: 35 |

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 03:00PM |

Registered: 8 years ago Posts: 3,525 |

Not a bad idea.

If anyone comes up with a source of kevlar reinforced gt2 6mm belt - let us know.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

If anyone comes up with a source of kevlar reinforced gt2 6mm belt - let us know.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Lean/Slant on Flsun Kossel - SOLVED (It was the belts!) November 16, 2017 04:21PM |

Registered: 10 years ago Posts: 732 |

Young's modulus of Kevlar is about 70 - 112 GPa. It is easier to stretch than a good steel (200 GPa).

In my opinion, trying to glue some reinforcement on the back (smooth) side of the belt will not work. It will quickly delaminate. The reason is that the belt already contains reinforcements inside (the steel/glass core). The core and the glued on reinforcements will be at different diameters when the belt is turning around pulley/idler. This will lead to internal stress and delamination. Just my opinion.

Here are the materials I read about being used in belts: polyester (8GPa), carbon (50-60 GPa), glass (50-90GPa), kevlar (70-112GPa), steel (200GPa). Really, steel seems to be the only option from the cheap stuff.

I did not hear about somebody using more expensive fibers in belts like eg. silicon carbide (380-415 GPa) or even carbon nanotube / graphene (~1000 GPa).

In my opinion, trying to glue some reinforcement on the back (smooth) side of the belt will not work. It will quickly delaminate. The reason is that the belt already contains reinforcements inside (the steel/glass core). The core and the glued on reinforcements will be at different diameters when the belt is turning around pulley/idler. This will lead to internal stress and delamination. Just my opinion.

Here are the materials I read about being used in belts: polyester (8GPa), carbon (50-60 GPa), glass (50-90GPa), kevlar (70-112GPa), steel (200GPa). Really, steel seems to be the only option from the cheap stuff.

I did not hear about somebody using more expensive fibers in belts like eg. silicon carbide (380-415 GPa) or even carbon nanotube / graphene (~1000 GPa).

Sorry, only registered users may post in this forum.