DemonDeltaTube - A delta inside an acrylic tube... Build

Posted by DjDemonD

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 29, 2018 05:02PM |

Registered: 8 years ago Posts: 3,525 |

Rods lengths I achieved:

No. 1 204.99mm

No. 2 205.26mm

No. 3 204.88mm

No. 4 204.83mm

No. 5 205.10mm

No. 6 205.14mm

So not perfect but if I pair up the most equal length rods, the firmware should be able to cope.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

No. 1 204.99mm

No. 2 205.26mm

No. 3 204.88mm

No. 4 204.83mm

No. 5 205.10mm

No. 6 205.14mm

So not perfect but if I pair up the most equal length rods, the firmware should be able to cope.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 29, 2018 05:29PM |

Registered: 8 years ago Posts: 3,525 |

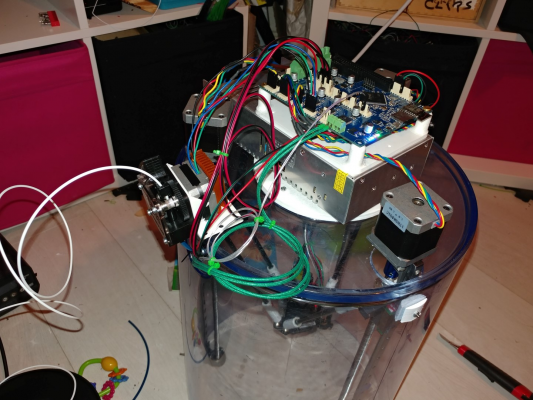

Its alive!

[youtu.be]

The rods don't foul the effector so very pleased with that. Now the real work of tuning and tweaking begins.

Looking forward to trying to print on varied surfaces with the open base. Might need to design a handle to lift the machine easily and some sort of cover for the psu and controller.

Edited 2 time(s). Last edit at 01/29/2018 09:58PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

[youtu.be]

The rods don't foul the effector so very pleased with that. Now the real work of tuning and tweaking begins.

Looking forward to trying to print on varied surfaces with the open base. Might need to design a handle to lift the machine easily and some sort of cover for the psu and controller.

Edited 2 time(s). Last edit at 01/29/2018 09:58PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 30, 2018 03:32AM |

Registered: 8 years ago Posts: 5,232 |

Congrats!

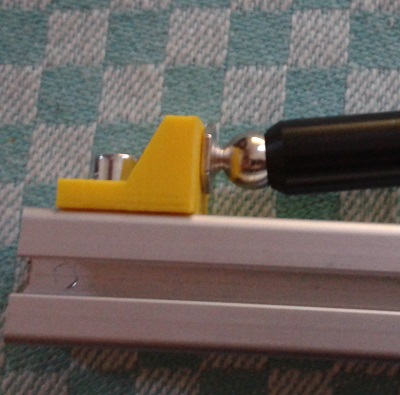

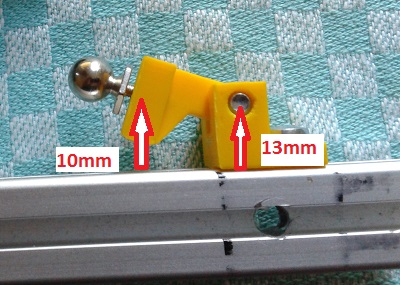

Did you try to adjust the length of the longest rods on the hot ballstud?

I didn't want to start a pi$$ing contest, but I felt I had to deliver something. Sorry, if I triggered a nerve or something.

So I made a toggle clamp rod-adjuster. It works fine with the T3P3 rods. We'll see how it goes with these printed rod-sleeves. They migth be a bit tougher to press them in.

Edited 1 time(s). Last edit at 01/30/2018 03:36AM by o_lampe.

Did you try to adjust the length of the longest rods on the hot ballstud?

Quote

Interested to see your version and to see how reliably it produces equal length rods.

I didn't want to start a pi$$ing contest, but I felt I had to deliver something. Sorry, if I triggered a nerve or something.

So I made a toggle clamp rod-adjuster. It works fine with the T3P3 rods. We'll see how it goes with these printed rod-sleeves. They migth be a bit tougher to press them in.

Edited 1 time(s). Last edit at 01/30/2018 03:36AM by o_lampe.

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 30, 2018 05:10AM |

Registered: 8 years ago Posts: 3,525 |

That looks great, no not touched a nerve as such, I just didn't think an object that could fit diagonally on a "nominal" 200x200 bed would be that much of an ask to print. I have to remember having got very used to being able to reliably print across the whole bed every time (due to use of very accurate nozzle contact probes - Precision Piezo and Duet3D Smart Effector, and RRF) that not everyone is happily positioning parts anywhere that takes their fancy and hitting print. Although with this printer I will be leaning heavily on these compensations in order to just print on the table (or t-shirt or whatever).

I might try adjusting them on the heated stud, if they don't perform too well once the printer is in a state to be calibrated. My understanding is that if each rod pair is as equal as possible certainly RRF (or the least squares method) will compensate for the length difference as it sees it as a tower position error. But if the calibration is annoyingly off then adjusting them will be on the list of things to tweak.

I would say to those following on from this, the discrepancy might be caused by epoxy resin creeping down the side of the magnet and getting between the cup and ballstud. I certainly had to clean some off the two studs used on the jig even though I coated them in vaseline before each rod was made. One solution might be to glue the magnet in first, let the adhesive set forming a seal around the magnet, then go on to assemble the rods, there will be no path for adhesive to get past the magnet, or maybe I just used too much.

Edited 4 time(s). Last edit at 01/30/2018 05:53AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I might try adjusting them on the heated stud, if they don't perform too well once the printer is in a state to be calibrated. My understanding is that if each rod pair is as equal as possible certainly RRF (or the least squares method) will compensate for the length difference as it sees it as a tower position error. But if the calibration is annoyingly off then adjusting them will be on the list of things to tweak.

I would say to those following on from this, the discrepancy might be caused by epoxy resin creeping down the side of the magnet and getting between the cup and ballstud. I certainly had to clean some off the two studs used on the jig even though I coated them in vaseline before each rod was made. One solution might be to glue the magnet in first, let the adhesive set forming a seal around the magnet, then go on to assemble the rods, there will be no path for adhesive to get past the magnet, or maybe I just used too much.

Edited 4 time(s). Last edit at 01/30/2018 05:53AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 30, 2018 12:05PM |

Registered: 8 years ago Posts: 5,232 |

I'd think that excessive resin would disappear in the hollow carbon rod, which is the path of lowest resistance. Maybe it'd help to glue only one side at a time and hang them up, so the resin runs down the rod.

I was surprised about your printed rod -jig, since it must have taken some time and lots of filament.

BTW what did you mean with, you "have the right bearings to measure the length with calipers"?

Edited 1 time(s). Last edit at 01/30/2018 12:07PM by o_lampe.

I was surprised about your printed rod -jig, since it must have taken some time and lots of filament.

BTW what did you mean with, you "have the right bearings to measure the length with calipers"?

Edited 1 time(s). Last edit at 01/30/2018 12:07PM by o_lampe.

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 30, 2018 12:31PM |

Registered: 8 years ago Posts: 3,525 |

Quote

o_lampe

I'd think that excessive resin would disappear in the hollow carbon rod, which is the path of lowest resistance. Maybe it'd help to glue only one side at a time and hang them up, so the resin runs down the rod.

I was surprised about your printed rod -jig, since it must have taken some time and lots of filament.

BTW what did you mean with, you "have the right bearings to measure the length with calipers"?

My rods are solid, but if hollow then yes I expect it would be much less of a problem.

That rod jig printed on the XL 40% cubic infill in about 90 minutes.

When Haydn measures these he puts 3/8th inch high-grade ball bearings on each end and measures with calipers, as the end surface of the ball cups is potentially rough and isn't a mating surface, so measuring from those surfaces doesn't really tell you the effective length of each arm.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 31, 2018 03:28AM |

Registered: 8 years ago Posts: 5,232 |

Quote

When Haydn measures these he puts 3/8th inch high-grade ball bearings on each end and measures with calipers, as the end surface of the ball cups is potentially rough and isn't a mating surface, so measuring from those surfaces doesn't really tell you the effective length of each arm.

That's cheating

In fact he should use the two ballstuds the rod will be attached to later, for real life measuring. ( I think the difference is academic anyway )

In fact he should use the two ballstuds the rod will be attached to later, for real life measuring. ( I think the difference is academic anyway )

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build January 31, 2018 03:45AM |

Registered: 8 years ago Posts: 3,525 |

Well yes that might make sense, but if you measure your ballstuds they actually vary in size a fact Haydn has apologised about. There was a thread on this on duet forum. So to test the theory I took my 360mm delrin rods to a local engineering firm and got them to measure them accurately using the ball bearing method.

I then measured the ball studs as best I could, but determining the exact position of the centre of rotation etc..was a bit beyond me.

I then matched rods and ballstuds to make the most equal sets possible with the 24 ball studs I had available stuck it all back into my XL machine and achieved no improvement in calibration deviation whatsoever. The effect of having magball joints and linear rails is 10x greater on improving a delta printer than having every rod exactly the same length to 0.01mm, especially if each rod pair are well matched.

Edited 3 time(s). Last edit at 01/31/2018 04:00AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I then measured the ball studs as best I could, but determining the exact position of the centre of rotation etc..was a bit beyond me.

I then matched rods and ballstuds to make the most equal sets possible with the 24 ball studs I had available stuck it all back into my XL machine and achieved no improvement in calibration deviation whatsoever. The effect of having magball joints and linear rails is 10x greater on improving a delta printer than having every rod exactly the same length to 0.01mm, especially if each rod pair are well matched.

Edited 3 time(s). Last edit at 01/31/2018 04:00AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 01, 2018 08:32AM |

Registered: 8 years ago Posts: 3,525 |

So effector installed and piezo z probe. Probe needs some dampening as leadscrews generate more mechanical noise than belts. But it's moving around, I haven't yet had time to check how much the effector is tilting as I move around the bed.

One thing I would say, when I've enclosed machines, they become much harder to access. But they're built by that point. When you begin your build in an enclosure expect difficult access from the start.

Also I'm only able to position the nozzle over a 150mm diameter without fouling the towers, so this method of cylinder build is not efficient with space 300mm cylinder =150mm bed! But this machine was never about being the easiest way to make a delta.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

One thing I would say, when I've enclosed machines, they become much harder to access. But they're built by that point. When you begin your build in an enclosure expect difficult access from the start.

Also I'm only able to position the nozzle over a 150mm diameter without fouling the towers, so this method of cylinder build is not efficient with space 300mm cylinder =150mm bed! But this machine was never about being the easiest way to make a delta.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 01, 2018 09:44AM |

Registered: 8 years ago Posts: 91 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 01, 2018 10:23AM |

Registered: 8 years ago Posts: 3,525 |

On this build as I have designed it, its the carriages and the bearings for the lower end of the leadscrews. Would be more usable space with belts. The effector could be is the carriages we're and rods spacing was lower, but using the 55mm rod spacing might enable me to swap my smart effector onto this machine, and this effector onto my Xl. I've made it as small as that rod spacing easily allows. Could shave 8-10mm off with a bit of clever magball angulation.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 02, 2018 11:07AM |

Registered: 6 years ago Posts: 35 |

Quote

o_lampe

I had good results with flexible couplers between leadscrew and stepper shaft. But I added a steel ball ( 4.5mm ) between them. Now the DOF in Z-direction is eliminated and it can only flex in X&Y.

Are you saying that by adding a ball bearing inside the coupler (with no gaps to either end), it would eliminate lateral stretch and compression? Compression would be eliminated but I'm not seeing how it would stop the stretching.

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 02, 2018 01:53PM |

Registered: 8 years ago Posts: 3,525 |

The rigid couplers are working on 2 of the towers, on one the motor is wobbling a little as it turns so something is slightly less well aligned. I'd quickly tweak it but nothing is easy to get at on this machine, especially the grubs screws on the couplers.

That being said it seems that flexible couplers are not required if the axis is precise and the leadscrews are straight. In my design there are no top bearings, so the rigid couplers are required to retain the leadscrews.

I think I'll need antibacklash nuts there is a noticeable amount of play in the carriages and unlike using leadscrews to lift a heavy bed, the rods and effector are unlikely to be heavy enough to counteract the backlash when changing direction.

Edited 1 time(s). Last edit at 02/02/2018 01:54PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

That being said it seems that flexible couplers are not required if the axis is precise and the leadscrews are straight. In my design there are no top bearings, so the rigid couplers are required to retain the leadscrews.

I think I'll need antibacklash nuts there is a noticeable amount of play in the carriages and unlike using leadscrews to lift a heavy bed, the rods and effector are unlikely to be heavy enough to counteract the backlash when changing direction.

Edited 1 time(s). Last edit at 02/02/2018 01:54PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 03, 2018 02:12AM |

Registered: 8 years ago Posts: 5,232 |

Quote

firefly555

Quote

o_lampe

I had good results with flexible couplers between leadscrew and stepper shaft. But I added a steel ball ( 4.5mm ) between them. Now the DOF in Z-direction is eliminated and it can only flex in X&Y.

Are you saying that by adding a ball bearing inside the coupler (with no gaps to either end), it would eliminate lateral stretch and compression? Compression would be eliminated but I'm not seeing how it would stop the stretching.

You can stretch the coupler while tightening the grubscrew. Then only streching forces greater than the "prestretch" will have an effect.

There are couplers with an "X" in the middle, they allow radial misalignment without lateral movement. If you have flexible filament for the "X", you could make them yourself

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 07, 2018 07:01AM |

Registered: 8 years ago Posts: 3,525 |

Okay, so some progress.

I fitted the new design effector and the rods. I was getting a lot of false triggers with the piezo sensor until I tightened down the four screws holding the upper and lower parts of the sensor assembly, and set a temporary 20mm/s2 acceleration during probing. I'm using a modest deafult max acceleration of X500 Y500 Z100 currently but these can be increased later.

Initially calibrating was proving challenging as I was starting off with very rough delta-parameters, and the probe was giving me trouble, but I set M558 P0 (no probe) and used the new manual levelling assistant, which is very easy, to get the initial values. Then switched the probe to iterate to a stable calibration. Now it's calibrating to 0.3mm deviation on my floor which is not very even. Expecting better with an aluminium bed which is in the post although being able to adapt to whatever the machine is placed on top of and then print on it will be one of the unique selling points of this design.

I've fitted the pt1000 (that's 1000 not 100) sensor to the hotend and one of our 50w heater cartridges which fits better than the "new e3d improved heater cartridge". Attached it to the E0 thermistor input and using RRF set

then autotuned, it overshoots by 2 degrees, but then this is the resolution achievable with pt1000 and no daughterboard using 8bit (10bit?) ADC with oversampling. Linear response, cartridge based and no thermistors/tables/B values to worry about. An offset can be added to adjust it to real nozzle temperature if desired.

So I need to wire up some fans and will begin with initially a titan extruder in Bowden setup (I have a length of Capricorn tubing which came with the e3d gold hotend kit) and I can start printing some stuff.

Edited 3 time(s). Last edit at 02/07/2018 07:33AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I fitted the new design effector and the rods. I was getting a lot of false triggers with the piezo sensor until I tightened down the four screws holding the upper and lower parts of the sensor assembly, and set a temporary 20mm/s2 acceleration during probing. I'm using a modest deafult max acceleration of X500 Y500 Z100 currently but these can be increased later.

Initially calibrating was proving challenging as I was starting off with very rough delta-parameters, and the probe was giving me trouble, but I set M558 P0 (no probe) and used the new manual levelling assistant, which is very easy, to get the initial values. Then switched the probe to iterate to a stable calibration. Now it's calibrating to 0.3mm deviation on my floor which is not very even. Expecting better with an aluminium bed which is in the post although being able to adapt to whatever the machine is placed on top of and then print on it will be one of the unique selling points of this design.

I've fitted the pt1000 (that's 1000 not 100) sensor to the hotend and one of our 50w heater cartridges which fits better than the "new e3d improved heater cartridge". Attached it to the E0 thermistor input and using RRF set

M305 P1 X501 R4700 ; heater 1 uses a PT1000 connected to thermistor channel 1 which has a 4.7K series resistor

then autotuned, it overshoots by 2 degrees, but then this is the resolution achievable with pt1000 and no daughterboard using 8bit (10bit?) ADC with oversampling. Linear response, cartridge based and no thermistors/tables/B values to worry about. An offset can be added to adjust it to real nozzle temperature if desired.

So I need to wire up some fans and will begin with initially a titan extruder in Bowden setup (I have a length of Capricorn tubing which came with the e3d gold hotend kit) and I can start printing some stuff.

Edited 3 time(s). Last edit at 02/07/2018 07:33AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 07, 2018 10:45AM |

Registered: 8 years ago Posts: 3,525 |

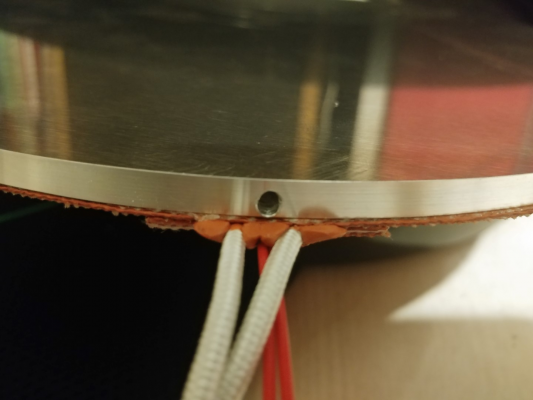

Just got my bed. It was from an eBay seller in Germany, nice to be able to get a circular piece and not have to take it to be machined:

[www.ebay.co.uk]

Which appears to be an aluminium/magnesium alloy. Very flat despite listing stating tolerance of 0.5mm.

So might have all the parts together now.

The other side is even more beautiful. Seems a shame to stick a silicone heater and a PEI surface to it. But printing onto it would ruin it anyway.

Edited 2 time(s). Last edit at 02/07/2018 10:49AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

[www.ebay.co.uk]

Which appears to be an aluminium/magnesium alloy. Very flat despite listing stating tolerance of 0.5mm.

So might have all the parts together now.

The other side is even more beautiful. Seems a shame to stick a silicone heater and a PEI surface to it. But printing onto it would ruin it anyway.

Edited 2 time(s). Last edit at 02/07/2018 10:49AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 07, 2018 03:45PM |

Registered: 8 years ago Posts: 49 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 07, 2018 04:27PM |

Registered: 8 years ago Posts: 3,525 |

No I've tried in the past you have to cover it in abs juice or hairspray or similar and it gets scratched up. It's a shame since it's so nice but I will probably use AndOrNot bed surface as its quite reliable and cheap.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 07, 2018 05:36PM |

Registered: 10 years ago Posts: 14,672 |

Is the PT1000 in a 3mm cartridge? Where did you get it?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 08, 2018 03:37AM |

Registered: 8 years ago Posts: 3,525 |

It's a sample from a supplier we are hoping to stock them soon.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 11, 2018 06:59PM |

Registered: 8 years ago Posts: 3,525 |

So a bit more progress.

Got my bed drilled a 3mm hole directly into the side of it - drill it straight yeah:

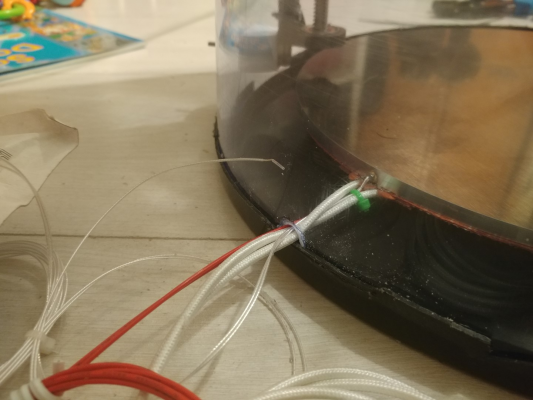

Then inserted the sample of the new Precision Piezo PT1000 sensor cartridge in there, coated it in thermal compound, secured it to the wires from the Keenovo 250w 24v silicone bed heater which is now bonded to the underside of the bed:

Then (rather roughly as it was difficult to cut) reduced the lid of the fishtank down in size so that it clears the mountings for the rails. I also cut some notches in it and the fishtank for the cables:

Then put it all roughly together:

Still a lot to do to neaten everything up. The bed will need heavy duty power connectors (Anderson Powerpole 15A I suspect I'll use), and something for the pt1000, so the bed can be disconnected when I am using the machine to print onto something else like floors/t-shirts/wood whatever.

One of the motors is not well aligned and moves about a little as the screw turns, so a bit of adjusting required there.

I tried a few bed probes onto the bed which is just mocked up supported on some wooden cubes I had lying around, I intend to make a bed support to go between the bed and the fishtank lid, but I am having great trouble with the piezo sensor, its so damn sensitive, the reverberation and vibration inside the cylinder is making it quite hard to use. I am using acceleration 5mm/s when probing but still getting some false triggers. More work to do might have to go on a mission to make it a lot less sensitive.

Still noticing some major "challenges" with this machine:

-everything is difficult to work on

-the printable area is very small. If I made a screw drive delta like this but on an open framed machine, I'd put the screws on the outside of the verticals so that they, and more importantly the lower bearing holders, don't foul the effector at any decent printable radius. Currently calibrating for 130mm diameter bed (from a 300mm diameter cylinder), of course I could have used belts like everyone else.

Edited 3 time(s). Last edit at 02/12/2018 05:21AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Got my bed drilled a 3mm hole directly into the side of it - drill it straight yeah:

Then inserted the sample of the new Precision Piezo PT1000 sensor cartridge in there, coated it in thermal compound, secured it to the wires from the Keenovo 250w 24v silicone bed heater which is now bonded to the underside of the bed:

Then (rather roughly as it was difficult to cut) reduced the lid of the fishtank down in size so that it clears the mountings for the rails. I also cut some notches in it and the fishtank for the cables:

Then put it all roughly together:

Still a lot to do to neaten everything up. The bed will need heavy duty power connectors (Anderson Powerpole 15A I suspect I'll use), and something for the pt1000, so the bed can be disconnected when I am using the machine to print onto something else like floors/t-shirts/wood whatever.

One of the motors is not well aligned and moves about a little as the screw turns, so a bit of adjusting required there.

I tried a few bed probes onto the bed which is just mocked up supported on some wooden cubes I had lying around, I intend to make a bed support to go between the bed and the fishtank lid, but I am having great trouble with the piezo sensor, its so damn sensitive, the reverberation and vibration inside the cylinder is making it quite hard to use. I am using acceleration 5mm/s when probing but still getting some false triggers. More work to do might have to go on a mission to make it a lot less sensitive.

Still noticing some major "challenges" with this machine:

-everything is difficult to work on

-the printable area is very small. If I made a screw drive delta like this but on an open framed machine, I'd put the screws on the outside of the verticals so that they, and more importantly the lower bearing holders, don't foul the effector at any decent printable radius. Currently calibrating for 130mm diameter bed (from a 300mm diameter cylinder), of course I could have used belts like everyone else.

Edited 3 time(s). Last edit at 02/12/2018 05:21AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 12, 2018 02:57AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 12, 2018 05:24AM |

Registered: 8 years ago Posts: 3,525 |

Thats actually a great idea. If I bond a piezo to the cylinder then wire it in parallel (but reversed polarity) to the one in the sensor it should flter the noise.

I don't know if it will work, but a fantastic idea thank you.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I don't know if it will work, but a fantastic idea thank you.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 12, 2018 03:48PM |

Registered: 8 years ago Posts: 3,525 |

Dear Olampe - you sir are a bloody genius

[forums.reprap.org]

Edited 1 time(s). Last edit at 02/12/2018 04:28PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

[forums.reprap.org]

Edited 1 time(s). Last edit at 02/12/2018 04:28PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 12, 2018 05:53PM |

Registered: 8 years ago Posts: 3,525 |

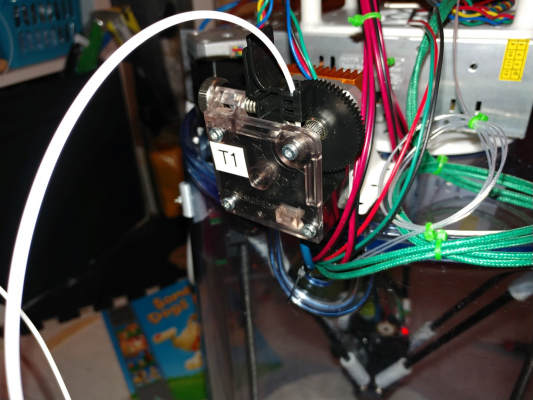

Decided to go with Titan Bowden for now. As I have a titan extruder and Capricorn Tubing. Extruder bracket is bonded to a printed block and then to the cylinder. One good thing about acrylic is you can stick stuff to it.

Gave it a quick test, and filament came out of the nozzle.

Umbilical cable is now quite stiff, and magnets are disconnecting a bit. But I am going to make new rods, and will try to get the N52 magnets (not N50).

Edited 2 time(s). Last edit at 02/13/2018 03:33AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Gave it a quick test, and filament came out of the nozzle.

Umbilical cable is now quite stiff, and magnets are disconnecting a bit. But I am going to make new rods, and will try to get the N52 magnets (not N50).

Edited 2 time(s). Last edit at 02/13/2018 03:33AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 13, 2018 02:42AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 13, 2018 03:29AM |

Registered: 8 years ago Posts: 3,525 |

Yes I think that's the answer get the magnet as close to the ball stud as possible without it touching.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 15, 2018 05:47PM |

Registered: 8 years ago Posts: 3,525 |

So wired up the bed, and placed connectors for the bed heater and pt1000 sensor. Only had one pair of Anderson powerpole connectors so used some tamiya rc car crimp connectors. Now the bed can be disconnected if using the machine open at the base. They are meant to be good for 10amps and its a 250w bed at 24v so might need replacing at some point. They are rated for 15A which is plenty.

Haven't got time to heat it up and try it. Also designed a bed support to fit this bed into the fishtank lid which is printing now on the XL.

Edited 1 time(s). Last edit at 02/16/2018 06:20PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Haven't got time to heat it up and try it. Also designed a bed support to fit this bed into the fishtank lid which is printing now on the XL.

Edited 1 time(s). Last edit at 02/16/2018 06:20PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 17, 2018 04:38PM |

Registered: 8 years ago Posts: 3,525 |

Well, first print, and whilst there is a long list of things to tune and tweak, it appears to be viable:

See it printing here: [youtu.be]

Layer registration is better than I expected with the screws and not using antibacklash nuts.

List of things to sort out:

-wobbly motors, alignment of some motors to leadscrews not perfect. So either use flex-couplers with the ball bearings inside and pre-stretched technique or work on aligning everything better.

-Noisy generally, some dampening and the like required in places, put the machine on soft feet.

-Extruder to calibrate properly, just using default steps/mm for titan in the video above.

-Temperature inside the cylinder. This is by far the most airtight (not completely as there are holes) enclosed machine I've used. Printing PLA with the slightly oversized bed the chamber air temp is 39 deg C. So my PLA mag arms will need to become ABS/PETG. At ABS temps they will likely soften/deform.

-A handle for the top (which can incorporate a spool holder) to make lifting the machine off the base easier.

Edited 1 time(s). Last edit at 02/17/2018 05:26PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

See it printing here: [youtu.be]

Layer registration is better than I expected with the screws and not using antibacklash nuts.

List of things to sort out:

-wobbly motors, alignment of some motors to leadscrews not perfect. So either use flex-couplers with the ball bearings inside and pre-stretched technique or work on aligning everything better.

-Noisy generally, some dampening and the like required in places, put the machine on soft feet.

-Extruder to calibrate properly, just using default steps/mm for titan in the video above.

-Temperature inside the cylinder. This is by far the most airtight (not completely as there are holes) enclosed machine I've used. Printing PLA with the slightly oversized bed the chamber air temp is 39 deg C. So my PLA mag arms will need to become ABS/PETG. At ABS temps they will likely soften/deform.

-A handle for the top (which can incorporate a spool holder) to make lifting the machine off the base easier.

Edited 1 time(s). Last edit at 02/17/2018 05:26PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 18, 2018 03:38AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.

):

):