DemonDeltaTube - A delta inside an acrylic tube... Build

Posted by DjDemonD

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 18, 2018 04:36AM |

Registered: 8 years ago Posts: 3,525 |

Not yet but getting the rails/screws running smoother is quite high on the list.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 18, 2018 09:50AM |

Registered: 8 years ago Posts: 3,525 |

So took the lower bearings off. Didn't look or sound any smoother, the screws were wobbling around a bit on longer Z moves, the motors were still wobbling around a little.

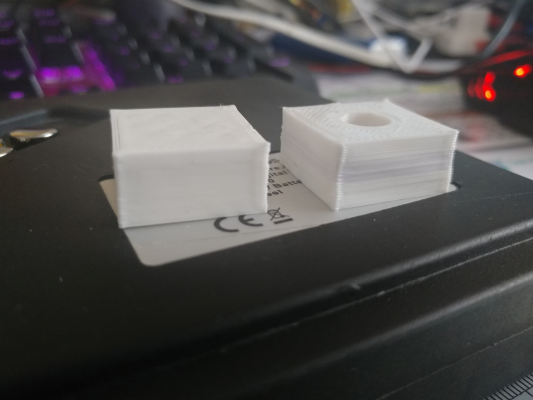

Printed this cube (right) without the lower bearings (but with a calibrated extruder). Apologies for grey bit in the middle thats where I was marking the filament to calibrate the extruder.

So I think next will be flex couplers at the top and put the lower bearings back, the axes moved pretty smoothly before they were installed.

Ps. The pt1000 for the bed works really well. I set the bed to 80 deg C and checked the top surface temp with a thermocouple probe 78 deg C measured. Seems drilling it into the side of the aluminium and adding some thermal compound gives an accurate temperature reading. I am going to add a 3rd one for the chamber temp. Being able to add up to 7 on duet is very useful.

Edited 3 time(s). Last edit at 02/18/2018 11:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Printed this cube (right) without the lower bearings (but with a calibrated extruder). Apologies for grey bit in the middle thats where I was marking the filament to calibrate the extruder.

So I think next will be flex couplers at the top and put the lower bearings back, the axes moved pretty smoothly before they were installed.

Ps. The pt1000 for the bed works really well. I set the bed to 80 deg C and checked the top surface temp with a thermocouple probe 78 deg C measured. Seems drilling it into the side of the aluminium and adding some thermal compound gives an accurate temperature reading. I am going to add a 3rd one for the chamber temp. Being able to add up to 7 on duet is very useful.

Edited 3 time(s). Last edit at 02/18/2018 11:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 19, 2018 05:01AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 19, 2018 05:32AM |

Registered: 8 years ago Posts: 3,525 |

No the bed sits on a printed ABS support with non-slip matt on top of it, which is bonded to what was the fish tank lid, the upside down fish tank sits quite snuggly into the lid. So I don't think its movement in the bed.

I need to take the three axes out and rebuild them. Initially using the preloaded flex couplers and ball bearings, keeping the lower bearings.

I am going to order some antibacklash nuts and slightly modify the carriages to hold them. I should have done this to begin with, as there is noticeable vertical play in the leadscrew nuts (which normally wouldn't be a problem with a heavy bed or heavy x-axis stacked on top of them).

Also, it might be worth trying to retain the leadscrew nuts to the carriages in such a way that they are unconstrained laterally, a bit like the i3 anti z-wobble mod where the Z-axis carriages sit on top of the leadscrew nuts but are not actually fixed to them. Would have to be very tight tolerances though to work here and also low friction. Acetal inserts for the carriages maybe?

What is hard to determine here is whether the issue is lateral movement in the screws, due to alignment or poor manufacture (they are not as far as I can see bent). Or whether its vertical play in the nuts. Or possibly both.

Whilst this has been fun, I am fairly sure getting decent prints out of a Chinese $200 delta kit machine, would be several of orders of magnitude easier than converting a fish tank into a delta. Also, there is a reason why almost all deltas are belt driven, leadscrews are a pain in the a$$.

Edited 4 time(s). Last edit at 02/19/2018 07:25AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I need to take the three axes out and rebuild them. Initially using the preloaded flex couplers and ball bearings, keeping the lower bearings.

I am going to order some antibacklash nuts and slightly modify the carriages to hold them. I should have done this to begin with, as there is noticeable vertical play in the leadscrew nuts (which normally wouldn't be a problem with a heavy bed or heavy x-axis stacked on top of them).

Also, it might be worth trying to retain the leadscrew nuts to the carriages in such a way that they are unconstrained laterally, a bit like the i3 anti z-wobble mod where the Z-axis carriages sit on top of the leadscrew nuts but are not actually fixed to them. Would have to be very tight tolerances though to work here and also low friction. Acetal inserts for the carriages maybe?

What is hard to determine here is whether the issue is lateral movement in the screws, due to alignment or poor manufacture (they are not as far as I can see bent). Or whether its vertical play in the nuts. Or possibly both.

Whilst this has been fun, I am fairly sure getting decent prints out of a Chinese $200 delta kit machine, would be several of orders of magnitude easier than converting a fish tank into a delta. Also, there is a reason why almost all deltas are belt driven, leadscrews are a pain in the a$$.

Edited 4 time(s). Last edit at 02/19/2018 07:25AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 19, 2018 08:42AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 19, 2018 08:56AM |

Registered: 8 years ago Posts: 3,525 |

Good point, I could envisage some sort of sprung device which allows lateral movement.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 21, 2018 08:21AM |

Registered: 8 years ago Posts: 3,525 |

Talking of which I am going to put the lower bearings back in, but also quite fancy printing some 608z bearings but making the central hole 8.5mm rather than 8. Then trying both to see whether slightly less contraint helps or not. (I'll print bushes rather than actual bearings).

Edited 1 time(s). Last edit at 02/21/2018 08:22AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 02/21/2018 08:22AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 22, 2018 02:23PM |

Registered: 8 years ago Posts: 3,525 |

So heres the latest cube:

What I've done is to fit flex couplers at each motor. I did not have any suitable ball bearings but found some small plastic fittings which are inside the couplers, the couplers are then stretched and tightened, to prevent any Z movement during reverses in motor direction (thanks to Olampe for this idea). Removed all three axes and reassembled them. Returned the lower bearings. Now nothing wobbles around as it moves.

So whilst by no means perfect, quite a big improvement on before. Now waiting on the anti-backlash nuts.

Use flex couplers, with leadscrews unless they are extremely precisely mounted, if anyone needs 3 rigid couplers (5mm ot 8mm) in fetching anodised blue, let me know.

It calibrates to 0.25mm deviation, which is a far cry from my XL which calibrates over the central 200mm of the bed to 0.004mm, but its made from a fish tank!

Maybe now to print something a little more useful as a test like a benchy.

Edited 5 time(s). Last edit at 02/23/2018 03:51PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

What I've done is to fit flex couplers at each motor. I did not have any suitable ball bearings but found some small plastic fittings which are inside the couplers, the couplers are then stretched and tightened, to prevent any Z movement during reverses in motor direction (thanks to Olampe for this idea). Removed all three axes and reassembled them. Returned the lower bearings. Now nothing wobbles around as it moves.

So whilst by no means perfect, quite a big improvement on before. Now waiting on the anti-backlash nuts.

Use flex couplers, with leadscrews unless they are extremely precisely mounted, if anyone needs 3 rigid couplers (5mm ot 8mm) in fetching anodised blue, let me know.

It calibrates to 0.25mm deviation, which is a far cry from my XL which calibrates over the central 200mm of the bed to 0.004mm, but its made from a fish tank!

Maybe now to print something a little more useful as a test like a benchy.

Edited 5 time(s). Last edit at 02/23/2018 03:51PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 23, 2018 10:27AM |

Registered: 6 years ago Posts: 35 |

I find the usual flex couplers quite annoying. Even with a straight leadscrew and a true spinning stepper, after connecting things up using a coupler, there is a slight wobble. The grub screws tend to push things off centre and depending on the alignment of the grub screws on the two ends of the coupler (some line up, some don't). Even with a bit of shimming, getting a dead centre isn't always guaranteed. I'm thinking of mounting another bearing very close to the coupler to shorten the wobbling section and see if the rest of the leadscrew would then turn true.

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 23, 2018 02:12PM |

Registered: 8 years ago Posts: 3,525 |

That's what I hoped I had achieved, but I didn't manage it. The rigid couplers made it worse. And I agree the grubscrews are the problem. However with the flex couplers as I have them configured now, its much smoother. With antibacklash nuts and modified carriages to accommodate them, I think its at least going to be in the same ballpark as belt driven deltas.

Just also want to say the sensorless homing is working perfectly as long as you remember to calibrate after homing. Otherwise there is enough inaccuracy to cause a head crash. This is worse now with the flexible couplers as they stretch when the carriages hit the motor brackets before the stall detection kicks in and stops the motors.

Edited 2 time(s). Last edit at 02/23/2018 03:56PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Just also want to say the sensorless homing is working perfectly as long as you remember to calibrate after homing. Otherwise there is enough inaccuracy to cause a head crash. This is worse now with the flexible couplers as they stretch when the carriages hit the motor brackets before the stall detection kicks in and stops the motors.

Edited 2 time(s). Last edit at 02/23/2018 03:56PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 23, 2018 06:28PM |

Registered: 6 years ago Posts: 207 |

@DJDemonD,

You need to get these, proper Oldham couplings.

Edited 2 time(s). Last edit at 02/23/2018 06:31PM by klcjr89.

You need to get these, proper Oldham couplings.

Edited 2 time(s). Last edit at 02/23/2018 06:31PM by klcjr89.

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 23, 2018 06:36PM |

Registered: 8 years ago Posts: 3,525 |

They look great, Olampe I think someone has already invented your anti wobble bearing

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 24, 2018 03:57AM |

Registered: 8 years ago Posts: 5,232 |

I mentioned those couplings earlier, but not knowing the name of them....Quote

Myself, on page two

There are couplers with an "X" in the middle, they allow radial misalignment without lateral movement. If you have flexible filament for the "X", you could make them yourself smiling smiley

You could print them in one piece with a TPU segment in the middle.

Edited 1 time(s). Last edit at 02/24/2018 04:00AM by o_lampe.

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 24, 2018 01:30PM |

Registered: 6 years ago Posts: 207 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 24, 2018 06:04PM |

Registered: 8 years ago Posts: 3,525 |

I've updated the thingiverse listing with most of the printed parts for anyone crazy enough to want to build one.

[www.thingiverse.com]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

[www.thingiverse.com]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 25, 2018 03:48AM |

Registered: 8 years ago Posts: 5,232 |

I just wanted to mention, the Oldham coupler won't do the trick. They only decouple the motor from the leadscrew, but not the leadscrew-nut from the rods

Even worth: by using them the screw can now wobble freely.

You'd have to design something similar for the anti-backlash nut.

Edited 1 time(s). Last edit at 02/25/2018 03:48AM by o_lampe.

Even worth: by using them the screw can now wobble freely.

You'd have to design something similar for the anti-backlash nut.

Edited 1 time(s). Last edit at 02/25/2018 03:48AM by o_lampe.

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 25, 2018 05:43AM |

Registered: 8 years ago Posts: 3,525 |

So printed a benchy too rough to show you but only had one fan. Then fitted the second fan and half printed another but the v6 predictably jammed printing pla in a chamber.

So will unjam and switch to abs. Might have to drill a hole to fit a vent fan to allow the inside to be cool when printing pla.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So will unjam and switch to abs. Might have to drill a hole to fit a vent fan to allow the inside to be cool when printing pla.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 25, 2018 02:25PM |

Registered: 8 years ago Posts: 3,525 |

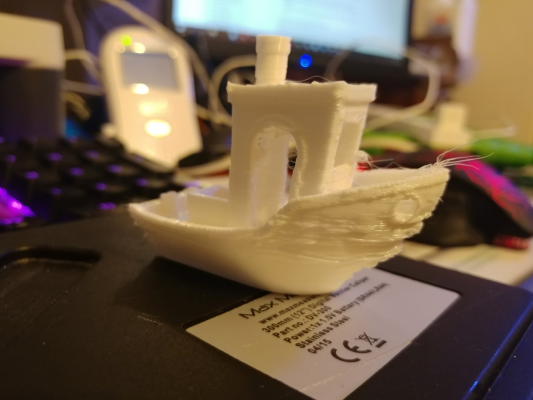

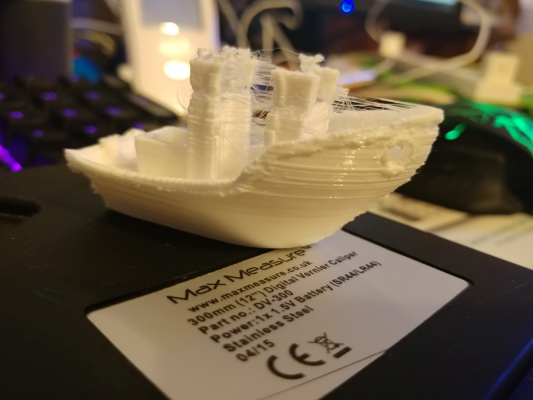

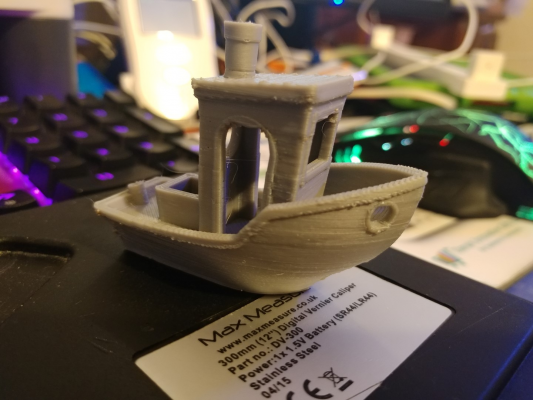

Okay, so why not show my awful benchies?

Here the first in PLA, with woefully inadequate cooling:

The second, same PLA but with twin fans, nozzle jammed:

The third in ABS (my preferred material by far):

Now its not perfect, fans could be ducted to provide better cooling, especially as the machine is an always enclosed machine by it's nature. I currently have not done any pressure advance tuning, to make the seams neater. But I think its okay for its 5th print, and given that its not a precise delta frame but a used fishtank.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Here the first in PLA, with woefully inadequate cooling:

The second, same PLA but with twin fans, nozzle jammed:

The third in ABS (my preferred material by far):

Now its not perfect, fans could be ducted to provide better cooling, especially as the machine is an always enclosed machine by it's nature. I currently have not done any pressure advance tuning, to make the seams neater. But I think its okay for its 5th print, and given that its not a precise delta frame but a used fishtank.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 25, 2018 03:24PM |

Registered: 7 years ago Posts: 18 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build February 25, 2018 04:30PM |

Registered: 8 years ago Posts: 3,525 |

Yes that might help. It is warm in there so even with two Precision Piezo 30mm blowers (other fans are available), the air being blown is still 45 deg C. Thanks though for the encouragement. I wouldn't recommend this build, as whilst it looks cool, and has been fun, it is all of the hassles of an enclosed machine (from the start) without being able to just take the side panels off, or lift the machine out. As a way of building a delta either better/more accurate (it isn't), or easier (it isn't) it fails on both counts. An opaque cylinder of some sort would be even more difficult to work with, and transparent ones are either pricey or are fishtanks, which aren't cylindrical. It has been a good exercise in problem solving, design and using ingenuity.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 02, 2018 11:50AM |

Registered: 8 years ago Posts: 3,525 |

Now seeing small cracks all over the acrylic so I think it's reacting negatively to the heat cycling going from 13 degrees (it's cold right now) to 50 degrees that it reaches at abs temps. It's not showing any signs of structurally being weak but i get the feeling it might fall apart at some point.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 02, 2018 01:57PM |

Registered: 7 years ago Posts: 18 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 02, 2018 02:08PM |

Registered: 8 years ago Posts: 3,525 |

Good advice moving to warmer climes. Might give that a whirl. Convincing the wife I can bring all my printers, tricky!

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 02, 2018 03:26PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 02, 2018 03:47PM |

Registered: 6 years ago Posts: 1,007 |

You can sell it here:

[www.obxstore.com]

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

[www.obxstore.com]

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 02, 2018 03:48PM |

Registered: 8 years ago Posts: 3,525 |

It's not a bad idea. 3d printer in a bottle.

Edited 1 time(s). Last edit at 03/02/2018 03:54PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 03/02/2018 03:54PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 02, 2018 10:37PM |

Registered: 7 years ago Posts: 18 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 03, 2018 12:36AM |

Registered: 8 years ago Posts: 3,525 |

I know, but we seem to have reached the point of making a few joke's. If it does fall apart I might build a slightly more conventional frame and see how it performs.

Edited 1 time(s). Last edit at 03/03/2018 12:36AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 03/03/2018 12:36AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 03, 2018 03:02AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: DemonDeltaTube - A delta inside an acrylic tube... Build March 03, 2018 03:05AM |

Registered: 8 years ago Posts: 3,525 |

I'm in the UK, so... But I know the things you mean. No I meant like made from something truly exotic like aluminium extrusions... I'll keep the leadscrews though but I'll rejig the carriages so the screws are on the outside and then the lower bearings don't take up so much of the print volume.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.