Optimum dimensions for a Delta - what size is yours?

Posted by DjDemonD

|

Optimum dimensions for a Delta - what size is yours? January 23, 2018 11:35AM |

Registered: 8 years ago Posts: 3,525 |

So Deckingman on duet forum was asking about the implications of making a 2.2m tall delta, you know - arm length, width, how these factors relate.

And so it begged the question - is there an optimum width to height ratio for a delta printer, which maximises printable volume?

I'm not a mathematician so if anyone knows how to determine if there is an optimum and what that optimum is please share your answer.

The way I'd propose to investigate this is to ask delta printer owners to post their printers height, width and printable bed area, and printable height. Perhaps arm length might be useful data to have. I will then plot these on a graph and see if an optimum emerges.

My Kossel XL 1m tall, 340mm Horizontal extrusions. Bed 330mm printable 280mm XY 450mm Z Arms 360mm.

Edited 4 time(s). Last edit at 01/23/2018 03:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

And so it begged the question - is there an optimum width to height ratio for a delta printer, which maximises printable volume?

I'm not a mathematician so if anyone knows how to determine if there is an optimum and what that optimum is please share your answer.

The way I'd propose to investigate this is to ask delta printer owners to post their printers height, width and printable bed area, and printable height. Perhaps arm length might be useful data to have. I will then plot these on a graph and see if an optimum emerges.

My Kossel XL 1m tall, 340mm Horizontal extrusions. Bed 330mm printable 280mm XY 450mm Z Arms 360mm.

Edited 4 time(s). Last edit at 01/23/2018 03:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: optimum dimenensions for a delta January 23, 2018 01:18PM |

Registered: 7 years ago Posts: 18 |

|

Re: optimum dimenensions for a delta January 23, 2018 03:12PM |

Registered: 8 years ago Posts: 3,525 |

Thanks.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 03:30AM |

Registered: 8 years ago Posts: 5,232 |

My gut feeling tells me, that the shortest possible arm length to achieve a certain radius, wins. Also effector weight is important. Both factors count when it comes to fast and accurate motion without ringing. Smalles possible distance between nozzle and effector also help to minimize tilt errors.

Just collecting a few datas from Delta builders will not help much. I have built my Kossel XL around the round aluminum bed ( 350mm) I could get cheap, then I sourced for readily cut carbon rods ( 350mm +2x Traxxas rod ends ) that match the bed size ( more or less ). Then I bought the longest available linear rails from Robotdigg (600mm). You see, my Kossel XL isn't setup following a golden ratio.

Just collecting a few datas from Delta builders will not help much. I have built my Kossel XL around the round aluminum bed ( 350mm) I could get cheap, then I sourced for readily cut carbon rods ( 350mm +2x Traxxas rod ends ) that match the bed size ( more or less ). Then I bought the longest available linear rails from Robotdigg (600mm). You see, my Kossel XL isn't setup following a golden ratio.

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 04:17AM |

Registered: 8 years ago Posts: 3,525 |

I can see your point, however what I'm trying to do is investigate if there is a golden ratio. The beauty of the delta design is that within reason they can be tall and thin or short and fat (or anywhere in between), plus the stationary bed, the scalability and the captivating motion. There must though, be an optimum. If someone asks the question, "I am going to build a delta 2.2m tall - how wide should I make it?" I find it odd that the best answers given were - depends on how big you want your bed. That's true but if you are going to maximise your build volume how wide should it be?

We know there are guidelines for arm length based on the 60 degrees at bed centre and 20 degrees at maximum distance away from that, these seem historic relating to traxxas type rod joints as it represents their range of motion, whereas with magball type systems the range of motion is greater. Add linear rails to magball arms and effector tilt is more or less eliminated, so I'd accept a wider range of arm length. Width of the bed plus 10% would be my best guide.

Plus it depends on how many data points I can get, if I got a few hundred then I'm pretty sure an optimum would emerge.

Edited 2 time(s). Last edit at 01/24/2018 05:11AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

We know there are guidelines for arm length based on the 60 degrees at bed centre and 20 degrees at maximum distance away from that, these seem historic relating to traxxas type rod joints as it represents their range of motion, whereas with magball type systems the range of motion is greater. Add linear rails to magball arms and effector tilt is more or less eliminated, so I'd accept a wider range of arm length. Width of the bed plus 10% would be my best guide.

Plus it depends on how many data points I can get, if I got a few hundred then I'm pretty sure an optimum would emerge.

Edited 2 time(s). Last edit at 01/24/2018 05:11AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 09:11AM |

Registered: 8 years ago Posts: 301 |

Surely lots of data points only gives you the most common sizes or an average, it doesn't mean that its the optimal size.

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 09:39AM |

Registered: 8 years ago Posts: 3,525 |

I'd disagree, if I plot a 3D graph with width along x, height along y and print volume along z, there should emerge a cluster around the optimum.

As I said I will need a reasonably large number of data points for it to have any validity. And I accept that whilst certain sizes are popular, I suggest that might be because they are the optimum.

I'd prefer to do this mathematically but I'm not sure how I'd go about it.

Edited 1 time(s). Last edit at 01/24/2018 10:13AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

As I said I will need a reasonably large number of data points for it to have any validity. And I accept that whilst certain sizes are popular, I suggest that might be because they are the optimum.

I'd prefer to do this mathematically but I'm not sure how I'd go about it.

Edited 1 time(s). Last edit at 01/24/2018 10:13AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 09:51AM |

Registered: 10 years ago Posts: 732 |

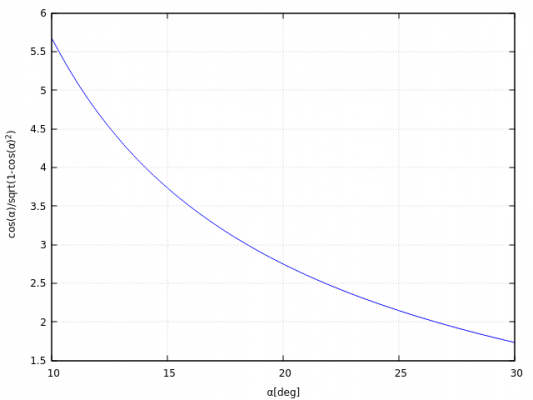

You do not want to allow diagonal rods going almost horizontal when printing. You want minimum angle between diagonal rod and the bed to be somewhere in the range of 10° - 20°. The reason is that the lower the angle the quicker the carriage must be able to move to keep constant hotend speed. Here is a chart showing how much quicker the carriage must be able to move (compared to the hotend) at given diagonal rod angle.

On the other side, the more horizontal you allow your diagonal rods to go the better numerical calibration results. The diagonal rod length error is well distinguishable from delta radius error only at low diagonal rod angles. There is an option of calibrating at bigger area than printing but that means wasting of horizontal space. Using too long diagonal rods (too big minimum angle to the hotbed) means wasting of vertical space.

And of course, if you want to print quickly (at high accelerations) then stretching of belts due to dynamic forces is bigger problem when printer is bigger (i.e. has longer belts).

On the other side, the more horizontal you allow your diagonal rods to go the better numerical calibration results. The diagonal rod length error is well distinguishable from delta radius error only at low diagonal rod angles. There is an option of calibrating at bigger area than printing but that means wasting of horizontal space. Using too long diagonal rods (too big minimum angle to the hotbed) means wasting of vertical space.

And of course, if you want to print quickly (at high accelerations) then stretching of belts due to dynamic forces is bigger problem when printer is bigger (i.e. has longer belts).

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 10:14AM |

Registered: 8 years ago Posts: 3,525 |

Thanks, that does make a lot of sense and explains neatly the considerations when choosing rod length. But that's rod length for any given height/width combination. I decided to collect rod length data in case it turns up anything interesting.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 10:30AM |

Registered: 10 years ago Posts: 732 |

You do not need to. The extreme case gives you result which is not useful.Quote

DjDemonD

I'd disagree, if I plot a 3D graph with width along x, height along y and print volume along z, there should emerge a cluster around the optimum.

I'd prefer to do this mathematically but I'm not how I'd go about it.

If you allow your diagonal rods to go horizontal and your diagonal rods cannot move behind carriage then you get the most volume when diagonalRodLength is somewhere just below 2/3*printerHeight. But such a printer would be extremely ugly with a terrible triangle bed. Moreover it is hard to print parts with big XY area because of warping. And it would require ball joints with huge freedom.

In other words, it does not make sense to maximize volume.

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 11:11AM |

Registered: 8 years ago Posts: 3,525 |

This is very illuminating. So basically the answer make it the shape you want is quite valid as the optimum shape would be ugly. Does this lend weight to the idea that delta printers are a lot about aesthetic? I am very guilty of this myself I own 2 and am building a third - and certainly not as its the cheapest or easiest way to get things printed.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Optimum dimensions for a Delta - what size is yours? January 24, 2018 12:05PM |

Registered: 10 years ago Posts: 732 |

I think a delta printer is for two kinds of users:

- those who like the funny way delta moves when it prints,

- users needing high printing speed (and high acceleration); in such a case:

- you do not want small diagonal rod angles with bed because of the chart I posted before

- you want short steel core belts (despite steel core lasting less than glass core)

- at least Ø 12 mm smooth rods (if you use the classical Rostock design)

- strong motors with microstepping not so much to achieve precision but only for quieter running (this is because static moment drops quickly with higher microstepping)

|

Re: Optimum dimensions for a Delta - what size is yours? January 25, 2018 03:09AM |

Registered: 8 years ago Posts: 5,232 |

Quote

DADIY

Surely lots of data points only gives you the most common sizes or an average, it doesn't mean that its the optimal size.

I agree. People should not only tell what sizes they picked, but also: WHY?

Was there a theory behind it or did they just copy what others described in their blogs/videos? Many choices are based on what bed heater can I get .

So you will see three hot spots in your data collection: 180mm, 220mm and 300mm bed size.

I also followed the 20° rule Hercek mentioned to pick the right rod length.

Edited 1 time(s). Last edit at 01/25/2018 03:12AM by o_lampe.

|

Re: Optimum dimensions for a Delta - what size is yours? January 25, 2018 03:18AM |

Registered: 8 years ago Posts: 3,525 |

If using a silicone heater and aluminium substrate there is more freedom I use a 240mm heater on a 6mm thick 330mm aluminium spreader and the edges are plenty hot enough.

What dimensions are your machines Olampe?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

What dimensions are your machines Olampe?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Optimum dimensions for a Delta - what size is yours? January 26, 2018 03:34AM |

Registered: 8 years ago Posts: 5,232 |

My data isn't relevant, since I build and rebuild my Deltas frequently. Most of the time I make compromises, like the rod length on my XL varied from 300mm, 330mm, to 360mm mag arms ( the only length I could get from T3P3 )

My most recent builds ( see compact carrier ) aren't finished yet and there's another unfinished Delta that won't fit in your data scheme: The coffeemug Delta

Edited 1 time(s). Last edit at 01/26/2018 03:37AM by o_lampe.

My most recent builds ( see compact carrier ) aren't finished yet and there's another unfinished Delta that won't fit in your data scheme: The coffeemug Delta

Edited 1 time(s). Last edit at 01/26/2018 03:37AM by o_lampe.

|

Re: Optimum dimensions for a Delta - what size is yours? January 27, 2018 01:29PM |

Registered: 8 years ago Posts: 3,525 |

That's cool I'm a fan of unusual deltas, just managed to get the leadscrew axes into the fishtank delta and it (sensorless) homes and moves around. So now it needs 6 magball rods and a custom effector. Thanks for the ballstud rod end smoother idea worked a treat, I used 150 deg C and a wipe with wd40.

Are you documenting the coffee mug print somewhere? Is it a dvd drive motor you're using? Very curious to know what sort of hotend you plan to use?

Edited 1 time(s). Last edit at 01/27/2018 01:33PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Are you documenting the coffee mug print somewhere? Is it a dvd drive motor you're using? Very curious to know what sort of hotend you plan to use?

Edited 1 time(s). Last edit at 01/27/2018 01:33PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Optimum dimensions for a Delta - what size is yours? January 28, 2018 02:40AM |

Registered: 8 years ago Posts: 5,232 |

[OT]

Thanks for your interest!

The coffee mug delta is just a side project, since I was looking for a "reasonable" use for the DVD steppers and smooth rods. I'm currently working on mini-Mag-rods that fit on Traxxas balls. The effector will be heatsink for the hotend, too. I think of making my own filament and nozzles. I ordered some geared DC motors and hope my theory is right and they will work without encoder. I'll start a thread about that, once I got the proof of concept.

[/OT]

Quote

Are you documenting the coffee mug print somewhere? Is it a dvd drive motor you're using? Very curious to know what sort of hotend you plan to use?

Thanks for your interest!

The coffee mug delta is just a side project, since I was looking for a "reasonable" use for the DVD steppers and smooth rods. I'm currently working on mini-Mag-rods that fit on Traxxas balls. The effector will be heatsink for the hotend, too. I think of making my own filament and nozzles. I ordered some geared DC motors and hope my theory is right and they will work without encoder. I'll start a thread about that, once I got the proof of concept.

[/OT]

Sorry, only registered users may post in this forum.