Carbon rods: 6mm solid or hollow 10mm dia?

Posted by o_lampe

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? March 02, 2018 03:05PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? March 03, 2018 07:35AM |

Registered: 10 years ago Posts: 732 |

There are way too many kinds of PE (polyethylene). Young's modulus (E) can be as low as 1 GPa for the weaker types.

Spectra has more versions:

Spectra 900: E=66-73GPa; Spectra 1000: E=98-113GPa; Spectra 2000: E=113-124GPa

Kevlar has more versions too:

Kevlar 49: E=154 GPa; Kevlar 29: E=61 GPa, ...

Aramid seems to be some version of Kevlar.

Glass: 50 - 90 GPa

Steel: about 200 GPa.

There are big ranges of Young's modulus even for one material type. You must ask which exact material is used in the given fiber.

Check wikipedia article on Young's modulus: [en.wikipedia.org]

We can compensate for weaker Young's modulus with bigger cross-section.

Notice that you do not really care about weight (it does not really matter whether the cable has 0.5 g or 5 g) nor the tensile strength (it will be strong enough after you make it thick enough so that it is not stretchy). You care about how much it would stretch under a force (i.e. young's modulus). That also means that the cable will not be easy to bend. That means bigger pulleys or it must be a ribbon. It should be tightly weaved from many thin filaments so that it is easier to bend it and it is also better from the defects point of view.

E.g. Spectra would be great especially if we could buy some kind of ribbon from it. The ribbon would allow easy bending around pulley and it would have big enough cross-section to be still stiff (hard to stretch). If we are limited to cables with circular cross-section then steel is probably the best when we consider price, availability, and young's modulus.

Spectra has more versions:

Spectra 900: E=66-73GPa; Spectra 1000: E=98-113GPa; Spectra 2000: E=113-124GPa

Kevlar has more versions too:

Kevlar 49: E=154 GPa; Kevlar 29: E=61 GPa, ...

Aramid seems to be some version of Kevlar.

Glass: 50 - 90 GPa

Steel: about 200 GPa.

There are big ranges of Young's modulus even for one material type. You must ask which exact material is used in the given fiber.

Check wikipedia article on Young's modulus: [en.wikipedia.org]

We can compensate for weaker Young's modulus with bigger cross-section.

Notice that you do not really care about weight (it does not really matter whether the cable has 0.5 g or 5 g) nor the tensile strength (it will be strong enough after you make it thick enough so that it is not stretchy). You care about how much it would stretch under a force (i.e. young's modulus). That also means that the cable will not be easy to bend. That means bigger pulleys or it must be a ribbon. It should be tightly weaved from many thin filaments so that it is easier to bend it and it is also better from the defects point of view.

E.g. Spectra would be great especially if we could buy some kind of ribbon from it. The ribbon would allow easy bending around pulley and it would have big enough cross-section to be still stiff (hard to stretch). If we are limited to cables with circular cross-section then steel is probably the best when we consider price, availability, and young's modulus.

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? March 04, 2018 03:26AM |

Registered: 8 years ago Posts: 5,232 |

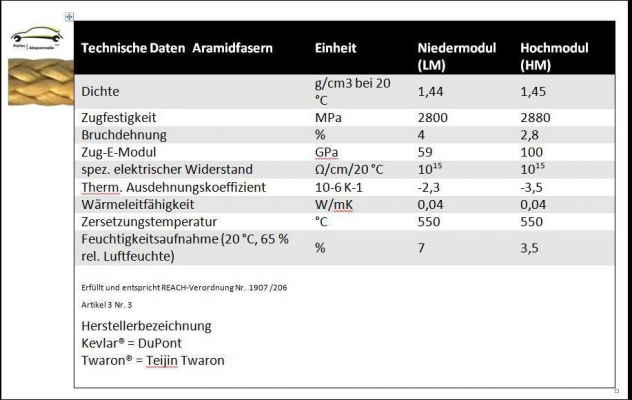

I thought of using grooved bearings for the idlers, which would work for circular cross-section too? I found a german manufacturer, who offers flat aramid rope too.

E-module is 59 or 100, which is in the same ballpark as glass, so steel it is...

Edited 1 time(s). Last edit at 03/04/2018 03:27AM by o_lampe.

E-module is 59 or 100, which is in the same ballpark as glass, so steel it is...

Edited 1 time(s). Last edit at 03/04/2018 03:27AM by o_lampe.

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? March 04, 2018 04:39AM |

Registered: 6 years ago Posts: 1,007 |

Quote

o_lampe

I thought of using grooved bearings for the idlers, which would work for circular cross-section too? I found a german manufacturer, who offers flat aramid rope too.

[attachment 103042 aramid-data.JPG]

E-module is 59 or 100, which is in the same ballpark as glass, so steel it is...

They are woven and will stretch. One has to use // strands.

I looked at that in the past. The other issue is to attach it to the belt. It must be strong, light, not deform the belt.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? March 04, 2018 11:06AM |

Registered: 8 years ago Posts: 5,232 |

Maybe it's woven, but maybe that's just the protection cover?

They say, it stretches less than 1.5%. Is it worth trying?

They say, it stretches less than 1.5%. Is it worth trying?

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? March 04, 2018 01:43PM |

Registered: 10 years ago Posts: 732 |

If it is only protective layer and the inner core is straight and tightly packed then it may work. But the inner fibers will not be packed tightly enough ... probably.

The other option which may work is if the strands are only twisted.

You need to test it first regardless how the string is made.

Take about 2 m of the string and hang about 5 kg on it. This is so that the string stretches to its working state. Mark how long it is. Maybe clamp something on the string and mark its position on the wall. Add another 10 kg and check whether you can see any visible stretching (it should not stretch more than 0.2 mm after another 10 kg is added. If it stretches more than 0.5 mm after the additional 10 kg is added then do not bother.

I would use about Ø 1.5 mm steel cable on at least Ø 3 cm pulley. You can find them in any bicycle shop. Cheap and easy to get. Other thing which may work is some kid of ribbon from some plastics (Spectra, Kevlar). But the ribbon must have significant portion of filaments which are straight. It cannot be woven diagonally (like common shoe laces (without straight core) are woven).

I'm afraid that too thick strings with circular cross-section would deform around pulley in a way which is not predictable - not consistently the same as the strings moves around pulley when the printer is printing. In other words: the length of the string around the pulley can be different when the carriage moved a lot in one direction contrary to the case when it moved many times only about 1-2 cm around the same place. If the filaments are not tightly packed then they will settle differently and it will probably lead to error. I do not really know. This just my worry about thick string with circular cross-section.

The problem is that we want error around 0.01 mm (when it is finally on the printer) so that this makes sense.

The other option which may work is if the strands are only twisted.

You need to test it first regardless how the string is made.

Take about 2 m of the string and hang about 5 kg on it. This is so that the string stretches to its working state. Mark how long it is. Maybe clamp something on the string and mark its position on the wall. Add another 10 kg and check whether you can see any visible stretching (it should not stretch more than 0.2 mm after another 10 kg is added. If it stretches more than 0.5 mm after the additional 10 kg is added then do not bother.

I would use about Ø 1.5 mm steel cable on at least Ø 3 cm pulley. You can find them in any bicycle shop. Cheap and easy to get. Other thing which may work is some kid of ribbon from some plastics (Spectra, Kevlar). But the ribbon must have significant portion of filaments which are straight. It cannot be woven diagonally (like common shoe laces (without straight core) are woven).

I'm afraid that too thick strings with circular cross-section would deform around pulley in a way which is not predictable - not consistently the same as the strings moves around pulley when the printer is printing. In other words: the length of the string around the pulley can be different when the carriage moved a lot in one direction contrary to the case when it moved many times only about 1-2 cm around the same place. If the filaments are not tightly packed then they will settle differently and it will probably lead to error. I do not really know. This just my worry about thick string with circular cross-section.

The problem is that we want error around 0.01 mm (when it is finally on the printer) so that this makes sense.

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? September 16, 2019 06:13PM |

Registered: 9 years ago Posts: 12 |

|

Re: Carbon rods: 6mm solid or hollow 10mm dia? September 16, 2019 06:20PM |

Registered: 8 years ago Posts: 3,525 |

Hi Haydn,

Thanks, truthfully I haven't even switched on a 3d printer for over a year. Am considering doing so soon though.

Hope you are well.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Thanks, truthfully I haven't even switched on a 3d printer for over a year. Am considering doing so soon though.

Hope you are well.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.