Making PTFE cups for magnetic rods

Posted by gambrose

|

Making PTFE cups for magnetic rods March 06, 2018 08:51AM |

Registered: 6 years ago Posts: 15 |

I have recently got myself an Anycubic Linear Kossel which I have setup and got printing. One of the things I would like to do is upgrade it to use magnetic rods. One of the arms has already got a fair amount of play in the rod ends.

I want to build the arms with cylinder magnets in the rods and balls on the effector and carriages. So I need to make some sort of cup to locate the balls. I was wondering if I could use heated up metal balls pressed into PTFE sheet to create cup holders.

I saw o_lampe's post on using a heated ball to smooth printed rod ends I am wondering it I could use a headed steel ball to make a cup in a flat sheet using my Delta machine as "the press" to control the process.

My plan is to modify a brass nozzle by tapping a M4 thread down the centre and fitting a grub screw and metal ball. Then when installed in my printer I would heat in up and push it (slowly) into a small piece of PTFE sheet (I was thinking 2mm).

The idea that this would make a cup that I can then attach to the end of my homemade rods.

It’s my understanding I should be able to heat up the hotend enough to make the PTFE plastic enough to distort it. I was thinking I would just let the hot end cool down while still pressed in to the PTFE to avoid distortion.

I’m not sure if the PTFE would be glued to the ball if I allow it to cool on the ball. I have read that even though PTFE is very slippery It can act like a glue if heated enough. I’m hoping that I can avoid that by only heating the PTFE up enough to deform it and not melt it (above glass temperature but below meting point).

Once I work out the temp federate needed to make the cup I was thinking I would punch out 8mm diameter circles that I could locate on the centre of print head using a printed ring (8mm ID) that is still bonded to the print bed. That way when I drop the hot ball at the centre point the cup would be in the centre and I could fit the 8mm disk (now with cup) to the end of the rods.

I have been very impressed by the work of the RepRap community and though I should share my idea in the hope that I could get some feedback as to the workably of the idea.

I want to build the arms with cylinder magnets in the rods and balls on the effector and carriages. So I need to make some sort of cup to locate the balls. I was wondering if I could use heated up metal balls pressed into PTFE sheet to create cup holders.

I saw o_lampe's post on using a heated ball to smooth printed rod ends I am wondering it I could use a headed steel ball to make a cup in a flat sheet using my Delta machine as "the press" to control the process.

My plan is to modify a brass nozzle by tapping a M4 thread down the centre and fitting a grub screw and metal ball. Then when installed in my printer I would heat in up and push it (slowly) into a small piece of PTFE sheet (I was thinking 2mm).

The idea that this would make a cup that I can then attach to the end of my homemade rods.

It’s my understanding I should be able to heat up the hotend enough to make the PTFE plastic enough to distort it. I was thinking I would just let the hot end cool down while still pressed in to the PTFE to avoid distortion.

I’m not sure if the PTFE would be glued to the ball if I allow it to cool on the ball. I have read that even though PTFE is very slippery It can act like a glue if heated enough. I’m hoping that I can avoid that by only heating the PTFE up enough to deform it and not melt it (above glass temperature but below meting point).

Once I work out the temp federate needed to make the cup I was thinking I would punch out 8mm diameter circles that I could locate on the centre of print head using a printed ring (8mm ID) that is still bonded to the print bed. That way when I drop the hot ball at the centre point the cup would be in the centre and I could fit the 8mm disk (now with cup) to the end of the rods.

I have been very impressed by the work of the RepRap community and though I should share my idea in the hope that I could get some feedback as to the workably of the idea.

|

Re: Making PTFE cups for magnetic rods March 06, 2018 02:40PM |

Registered: 9 years ago Posts: 483 |

Your magnets wont generate enough force to hold the arms with a 2mm gap. It may work if you use a punch to cut a round hole in the PTFE first. Keeping the socket perfectly centered is probably the biggest issue you'll face. When I tried it with ABS a few years ago, I wasn't able to keep the sockets centered well enough to use them on my delta. The sockets themselves were a perfect match for the ball bearings.

I'm currently using PTFE sockets I made on the lathe. I can't detect any wear on them after a year.

I'm currently using PTFE sockets I made on the lathe. I can't detect any wear on them after a year.

|

Re: Making PTFE cups for magnetic rods March 06, 2018 04:18PM |

Registered: 6 years ago Posts: 15 |

Thanks for the feedback etfrench.

I wouldn't have a 2mm gap to the magnet as the ball would be sunk into the PTFE by say 1.9mm so I would only have a 0.1mm gap to the magnet.

Do they need to be perfectly centered? I would expect I can get it within 0.5mm.

What issues would I see if I did not have the balls perfectly centered?

Quote

etfrench

Your magnets wont generate enough force to hold the arms with a 2mm gap.

I wouldn't have a 2mm gap to the magnet as the ball would be sunk into the PTFE by say 1.9mm so I would only have a 0.1mm gap to the magnet.

Quote

etfrench

Keeping the socket perfectly centered is probably the biggest issue you'll face.

Do they need to be perfectly centered? I would expect I can get it within 0.5mm.

What issues would I see if I did not have the balls perfectly centered?

|

Re: Making PTFE cups for magnetic rods March 07, 2018 02:16AM |

Registered: 8 years ago Posts: 5,232 |

Does your Delta create enough force to push the soft_but_not_fully_molten PTFE in shape?

I'd probably print a mould first, where I can place a punched_out piece of PTFE into.

But I don't think it's worth the trouble, since Delrin is very slippery too and a bit stiffer. It's the No1 choice for selflubricating gears, IMHO.

If IGUS filament wouldn't be so expensive, I'd try printing the cups and then use my smoothing method.

I'd probably print a mould first, where I can place a punched_out piece of PTFE into.

But I don't think it's worth the trouble, since Delrin is very slippery too and a bit stiffer. It's the No1 choice for selflubricating gears, IMHO.

If IGUS filament wouldn't be so expensive, I'd try printing the cups and then use my smoothing method.

|

Re: Making PTFE cups for magnetic rods March 07, 2018 03:46AM |

Registered: 9 years ago Posts: 483 |

|

Re: Making PTFE cups for magnetic rods March 07, 2018 04:26AM |

Registered: 6 years ago Posts: 15 |

|

Re: Making PTFE cups for magnetic rods March 07, 2018 04:56AM |

Registered: 6 years ago Posts: 15 |

Quote

o_lampe

Does your Delta create enough force to push the soft_but_not_fully_molten PTFE in shape?

Quite possibly not. I have ordered the bits now so I may try and see what happens.

Quote

o_lampe

I'd probably print a mould first, where I can place a punched_out piece of PTFE into.

I was planning on printing a mold on the print bed to hold the PTFE.

Or are you suggesting I print a cup and then line it with thin PTFE sheet?

Quote

o_lampe

But I don't think it's worth the trouble, since Delrin is very slippery too and a bit stiffer. It's the No1 choice for selflubricating gears, IMHO.

If IGUS filament wouldn't be so expensive, I'd try printing the cups and then use my smoothing method.

You may well be right about the trouble, although it is an order of magnitude more expensive to get a roll of filament than the small PTFE sheet.

Looking a Delrin it says "when overheated and may give off small amounts of formaldehyde gas".

Does anyone know if heating PTFE would detrimental to my health?

|

Re: Making PTFE cups for magnetic rods March 07, 2018 10:09AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Making PTFE cups for magnetic rods March 07, 2018 10:53AM |

Registered: 6 years ago Posts: 15 |

PTFE-tape, AKA plumbers tap is very cheep but it is non stick (it only sticks to itself) so how to you keep it in the rod end?

I would imagine it would be forced out sides or just fall out when you removed the ball.

I have found there is PTFE adhesive tape which is expensive. Probably not what you get down home depot.

You can get small amounts of PTFE adhesive tape on eBay but it all seems to be glass reinforced which I wouldn't of though would be ideal.

One of the reasons I though about starting with thicker PTFE and shaping it into a cup was then I mechanically restrain it at the edge of the disk.

I would imagine it would be forced out sides or just fall out when you removed the ball.

I have found there is PTFE adhesive tape which is expensive. Probably not what you get down home depot.

You can get small amounts of PTFE adhesive tape on eBay but it all seems to be glass reinforced which I wouldn't of though would be ideal.

One of the reasons I though about starting with thicker PTFE and shaping it into a cup was then I mechanically restrain it at the edge of the disk.

|

Re: Making PTFE cups for magnetic rods March 07, 2018 11:32AM |

Registered: 8 years ago Posts: 22 |

|

Re: Making PTFE cups for magnetic rods March 07, 2018 03:17PM |

Registered: 6 years ago Posts: 1,007 |

Easy to do, you don't even need and shouldn't heat it.

Just press the steel ball with enough force. PTFE creeps under pressure. It is why it is not very good as is for bearings unless the load is very light.

Here e=1mm should be enough.

Done that in the past, for some bearings and valve gasket.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Just press the steel ball with enough force. PTFE creeps under pressure. It is why it is not very good as is for bearings unless the load is very light.

Here e=1mm should be enough.

Done that in the past, for some bearings and valve gasket.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Making PTFE cups for magnetic rods March 07, 2018 03:25PM |

Registered: 6 years ago Posts: 15 |

|

Re: Making PTFE cups for magnetic rods March 08, 2018 12:58AM |

Registered: 9 years ago Posts: 483 |

McMasters has conformable PTFE tape. A 5 yard role is enough to do 360 ends.

|

Re: Making PTFE cups for magnetic rods March 08, 2018 03:56AM |

Registered: 6 years ago Posts: 15 |

Good find etfrench. Nice selection and reasonable lengths.

I was thinking if you put a taper on the outside of the cup you could probably use a metal ring (like a key ring) slightly larger than the cup size to hold down the non adhesive PTFE tape. The stonking big magnet should hold the ring down and keep everything from moving.

I was thinking if you put a taper on the outside of the cup you could probably use a metal ring (like a key ring) slightly larger than the cup size to hold down the non adhesive PTFE tape. The stonking big magnet should hold the ring down and keep everything from moving.

|

Re: Making PTFE cups for magnetic rods March 09, 2018 03:27AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Making PTFE cups for magnetic rods March 09, 2018 04:55AM |

Registered: 6 years ago Posts: 15 |

Quote

o_lampe

Why not try to put the PTFE sheet between the raw printed cup and the heated ballstud to smooth the printed cup and bond it with the PTFE?

Would the PTFE bond to the PLA with heat? From what I have read I would not expect it to.

A lot of the printed designs I have seen the cup and the outer casing are one piece which ensures that that the magnet is in the centre. I plan to have the cup and casing as separate pieces.

Then assembling with the magnet and the ball in the cup I think the magnet should naturally centre the ball in the centre of the magnet field.

So if I press the ball into a 2mm sheet, heated or not I have a much larger diameter ring on the outside. Which is a larger surface for glue to hold the cup in the centre.

The glue would not stick to the PTFE but it would just be there to constrain the PFFE from moving around on top of the magnet then the joint is in use.

|

Re: Making PTFE cups for magnetic rods March 09, 2018 02:55PM |

Registered: 9 years ago Posts: 483 |

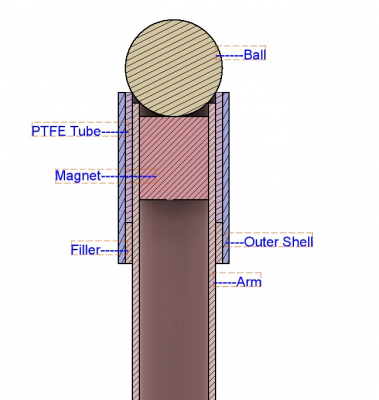

Here's a design that doesn't require any heating and uses standard size PTFE tubing:

The empty spaces between the ball and magnet could be filled with smaller sized PTFE tubing.

The empty spaces between the ball and magnet could be filled with smaller sized PTFE tubing.

|

Re: Making PTFE cups for magnetic rods March 10, 2018 02:57AM |

Registered: 8 years ago Posts: 5,232 |

Quite nice idea!

The outer shell and filler could be one printed part. The PTFE tube could be chamfered at the top to have bigger surface to the ball.

If you want to use 6mm carbon rods, but 10mm magnets, the hole assembly would be different. The filler would have to reach up halfway to the magnet...

Edited 2 time(s). Last edit at 03/10/2018 03:04AM by o_lampe.

The outer shell and filler could be one printed part. The PTFE tube could be chamfered at the top to have bigger surface to the ball.

If you want to use 6mm carbon rods, but 10mm magnets, the hole assembly would be different. The filler would have to reach up halfway to the magnet...

Edited 2 time(s). Last edit at 03/10/2018 03:04AM by o_lampe.

|

Re: Making PTFE cups for magnetic rods March 11, 2018 06:26PM |

Registered: 6 years ago Posts: 15 |

The using tube idea is a good one. It seems you can get quite a range of tube diameters and thicknesses. Although wonder if creep would be an issue if you made the contact surface too small?

I got some parts though ans did some experimenting today but failed to make much of an impression on my PTFE.

I soldered a ball bearing to a M6 bolt and loaded it into the printers hot end.

Then heated it up to 150°C and decreased Z 0.1mm about every 10 secs. Only managed to create a 4mm diameter cup in the PTFE.

I tried increasing the temp to 220°C (when the ball was touching the PTFE as this is above the melting point of the solder holding the bearing on) did not make any difference.

I have some more bits on order to try the brute force method MKSA suggested.

MKSA, what did you mean by "Here e=1mm should be enough"?

I got some parts though ans did some experimenting today but failed to make much of an impression on my PTFE.

I soldered a ball bearing to a M6 bolt and loaded it into the printers hot end.

Then heated it up to 150°C and decreased Z 0.1mm about every 10 secs. Only managed to create a 4mm diameter cup in the PTFE.

I tried increasing the temp to 220°C (when the ball was touching the PTFE as this is above the melting point of the solder holding the bearing on) did not make any difference.

I have some more bits on order to try the brute force method MKSA suggested.

MKSA, what did you mean by "Here e=1mm should be enough"?

|

Re: Making PTFE cups for magnetic rods March 12, 2018 08:43AM |

Registered: 8 years ago Posts: 5,232 |

I made a mini rod from 4mm magnets and 4.5mm steelball in a 6mm carbon rod. The PTFE part was so tiny ( it only fills the gap between magnet and bearing)

I had to chamfer it with a cutter knife. It runs really smooth, but I think the steel ball is V2A steel. It is not particularly magnetic.

I had to chamfer it with a cutter knife. It runs really smooth, but I think the steel ball is V2A steel. It is not particularly magnetic.

|

Re: Making PTFE cups for magnetic rods March 12, 2018 09:25AM |

Registered: 6 years ago Posts: 15 |

|

Re: Making PTFE cups for magnetic rods March 15, 2018 05:00AM |

Registered: 6 years ago Posts: 1,007 |

Quote

gambrose

...

MKSA, what did you mean by "Here e=1mm should be enough"?

I meant in fact less or equal to 1mm. No need for ticker.

Now, you have really to press hard, in a vise, ball better be hardened steel (from a ball bearing).

Note earlier on, may be not in this thread, I suggested a thin sheet of PTFE, the kind with one side with glue cut with a punch. Now, this is Ok unless the diam is too much and it may wrinkle.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Making PTFE cups for magnetic rods March 24, 2018 02:56PM |

Registered: 6 years ago Posts: 6 |

Here is my solution:

Magnetic Ball Joints for the Anycubic Kossel Delta 3D Printer

Exactly on the Anycubic Kossel linear.

I just printed the sleeves in PLA. The distance between the ball and the magnet should be 0.1mm (according to the model :-).

I do lubricate them with silicone grease.

Edited 2 time(s). Last edit at 03/24/2018 03:07PM by ruevs.

Magnetic Ball Joints for the Anycubic Kossel Delta 3D Printer

Exactly on the Anycubic Kossel linear.

I just printed the sleeves in PLA. The distance between the ball and the magnet should be 0.1mm (according to the model :-).

I do lubricate them with silicone grease.

Edited 2 time(s). Last edit at 03/24/2018 03:07PM by ruevs.

Sorry, only registered users may post in this forum.