My First Delta Printer build

Posted by ALLTHEGEARNOIDEA

|

My First Delta Printer build March 11, 2018 03:19PM |

Registered: 6 years ago Posts: 8 |

Hello Every this is my first post to the forum so apologies if I am not in the right place or asking silly questions.

Well I know pretty much nothing about 3D printing, but since I saw my first delta robot years ago I always wanted to build one. Unfortunately I have an aversion to belt drive systems since back in the 80s i was trapped for several days by a Sony Walkman after doing some routine repairs, lost a lot of hair and some skin. The memory still keeps me awake at night.

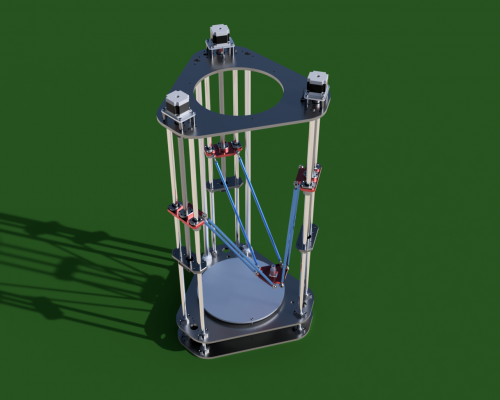

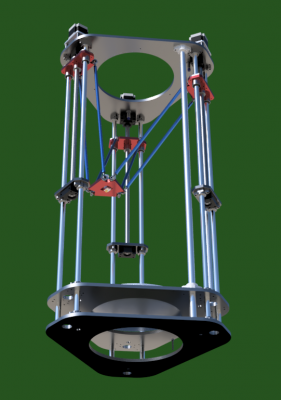

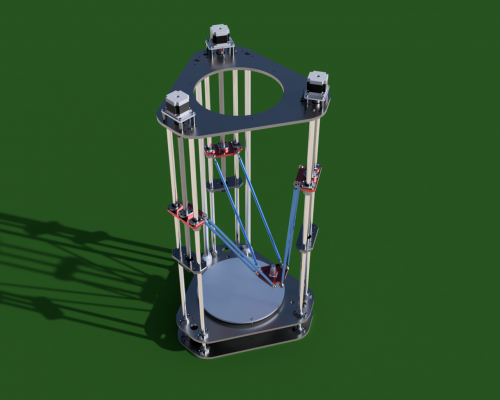

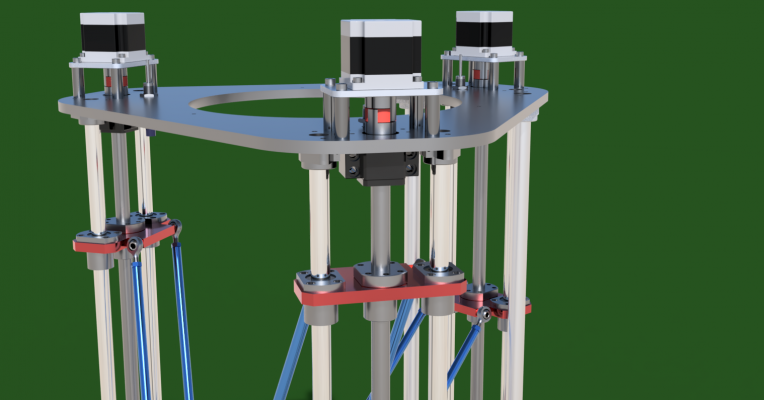

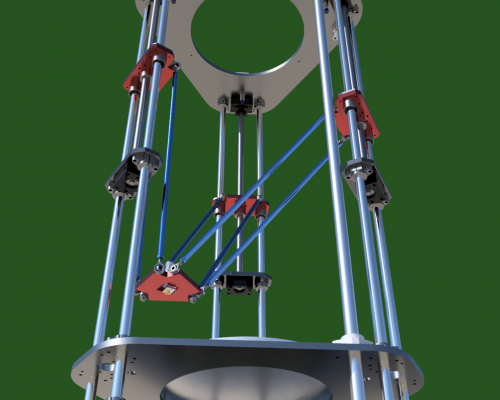

I have decided to try a ball screws design I am quite experienced with CNC equipment so I know about the advantage and disadvantages of screws. I am using conventional stepper motors in my prototype but if all goes to plan I will upgrade to servos as there becoming quite affordable and are much better for screw drive applications. The other reason I'm building a printer is that I just wanted a project and something to design and build as I am also learning fusion 360 at the moment.

So the main reason for posting is I have been a bit fearful by the math and complexity of the delta printer dimensions. I did have ago at downloading an excel spread sheet,that works out the dimensions but looks to be designed to work with something based of aluminum extrusions and it was not really clear to me what any of the parameter related too as there was no drawing to explain the parameters and geometry. Also just being a printer newbie it was a bit complicated off the bat. So basically I just wanted to rush off and design something. So I have attached some renders from fusion 360 and a link to down load the model for anyone that interested or just wants to ridicule my efforts, either is fine with me.

The hot end appears to reach all the bits of the bed is there anymore to this delta printer black magic?

Will it just be a matter of entering the dimensions of my printer into the controller software when its built. I keep reading bits of stuff about magic angles and 30 degrees. But its all being spoken by mystic delta shaman and they may even have gray beards.

So just looking for some general help and feedback from an Elmer or gray beard that know how it goes. Most of the parts are off the shelf linear bearings and screws and steppers etc. Other parts will be water jet cut from 10mm Aluminum or perhaps CNC routed. Its 1m high and the bed is 300mm diameter.

Thanks for any advice comments or feedback all gratefully received.

My best regard Chris

My Fusion share link [a360.co]

Silly question but how do I get my pictures to show up in the thread as some people dont like to download etc??

Edited 9 time(s). Last edit at 03/12/2018 04:34PM by ALLTHEGEARNOIDEA.

Attachments:

open | download - TriDelta_2018-Mar-10_05-52-32PM-000_CustomizedView13221024513.png (362.4 KB)

open | download - TriDelta_2018-Mar-10_06-01-59PM-000_CustomizedView10046391992.png (288.3 KB)

open | download - TriDelta_2018-Mar-10_06-04-11PM-000_CustomizedView10302604965.png (187.8 KB)

open | download - TriDelta_2018-Mar-10_06-21-39PM-000_CustomizedView4444358198.png (430.9 KB)

open | download - TriDelta_2018-Mar-10_05-52-32PM-000_CustomizedView13221024513.png (362.4 KB)

open | download - TriDelta_2018-Mar-10_06-01-59PM-000_CustomizedView10046391992.png (288.3 KB)

open | download - TriDelta_2018-Mar-10_06-04-11PM-000_CustomizedView10302604965.png (187.8 KB)

open | download - TriDelta_2018-Mar-10_06-21-39PM-000_CustomizedView4444358198.png (430.9 KB)

|

Re: My First Delta Printer build March 13, 2018 03:37AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: My First Delta Printer build March 13, 2018 05:51AM |

Registered: 10 years ago Posts: 14,672 |

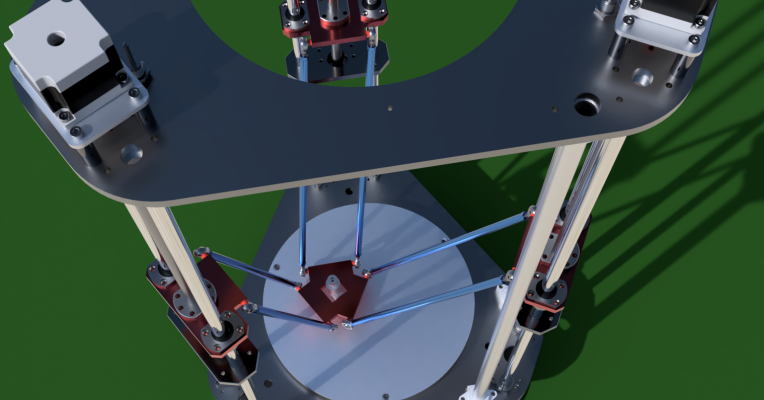

1. As @o_lampe says. When the nozzle is at the edge of the printable area opposite a tower, the angle of the rods to that tower should be no less than 20 degrees to the horizontal, preferably 25. In your last image it looks more like 40 degrees.

2. Choose the lead of the ballscrews carefully to get the steps/mm in the right range. The absolute lowest you should aim for is 80 microsteps/mm @ x16 microstepping; but if you are prepared to pay for good electronics and use 24V power then 200 microsteps/mm @ x16 microstepping will give you better print quality. You can select either 0.9 or 1.8deg motors to help get the steps/mm in the right range. When you think you have a good choice of ballscrews and motors, use the calculator at [reprapfirmware.org] to work out whether you can achieve your target speed. Belt-driven deltas can usually achieve high speeds, and you won't want to sacrifice that advantage because of your choice of ballscrews. 200mm/sec is a good figure to aim for.

3. As your motors will be at the top, IMO it makes sense to put the electronics at the top too because it simplifies the wiring. So consider using a SSR to switch the bed heater, with the PSU and SSR under the bed. That avoids running high power cables between top and bottom of the printer.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

2. Choose the lead of the ballscrews carefully to get the steps/mm in the right range. The absolute lowest you should aim for is 80 microsteps/mm @ x16 microstepping; but if you are prepared to pay for good electronics and use 24V power then 200 microsteps/mm @ x16 microstepping will give you better print quality. You can select either 0.9 or 1.8deg motors to help get the steps/mm in the right range. When you think you have a good choice of ballscrews and motors, use the calculator at [reprapfirmware.org] to work out whether you can achieve your target speed. Belt-driven deltas can usually achieve high speeds, and you won't want to sacrifice that advantage because of your choice of ballscrews. 200mm/sec is a good figure to aim for.

3. As your motors will be at the top, IMO it makes sense to put the electronics at the top too because it simplifies the wiring. So consider using a SSR to switch the bed heater, with the PSU and SSR under the bed. That avoids running high power cables between top and bottom of the printer.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My First Delta Printer build March 13, 2018 09:44AM |

Registered: 6 years ago Posts: 8 |

Quote

o_lampe

I'm not a Delta guru or shaman, but to me your rods look too long. You'll loose a lot of print height that way.

My way of calculating the rod length is based on the 20° rule:

Rod length = bed diameter / cos(20)

Then add some mm for safety margin.

Many thanks for the reply. I keep reading about the this 20 percent angle rule but was not sure where it came from and its never really explained. Regarding the length of the rods is there a problem in having them longer, apart from the reduction in build height. I assume that the possible deflection will increase with rod length and that would be a negative. I can make the rods any length I need as I was planning on making them from 10mm Aluminium tube this will be tapped at the ends for the rose joints.

I guess I’m more worried that there is some critical dimension that if I get it wrong than my printer won’t work at all. Many of the discussion here are really quite complex and detailed for a new boy like me and so I appreciate the advice.

Great Advice and I thank you very much.

Best Regards Chris

|

Re: My First Delta Printer build March 13, 2018 10:01AM |

Registered: 6 years ago Posts: 8 |

Quote

dc42

1. As @o_lampe says. When the nozzle is at the edge of the printable area opposite a tower, the angle of the rods to that tower should be no less than 20 degrees to the horizontal, preferably 25. In your last image it looks more like 40 degrees.

2. Choose the lead of the ballscrews carefully to get the steps/mm in the right range. The absolute lowest you should aim for is 80 microsteps/mm @ x16 microstepping; but if you are prepared to pay for good electronics and use 24V power then 200 microsteps/mm @ x16 microstepping will give you better print quality. You can select either 0.9 or 1.8deg motors to help get the steps/mm in the right range. When you think you have a good choice of ballscrews and motors, use the calculator at [reprapfirmware.org] to work out whether you can achieve your target speed. Belt-driven deltas can usually achieve high speeds, and you won't want to sacrifice that advantage because of your choice of ballscrews. 200mm/sec is a good figure to aim for.

3. As your motors will be at the top, IMO it makes sense to put the electronics at the top too because it simplifies the wiring. So consider using a SSR to switch the bed heater, with the PSU and SSR under the bed. That avoids running high power cables between top and bottom of the printer.

1) Many thanks for that I will have a look at reducing the rod length as Im machining them myself

2) You have made some very good points about the ball screws. I had not really considered the pitch, I have the ball screws left over from another project so was hoping to find a use for them. I had not really considered my target speed would just be delighted to see it work but you are correct. Again I have the stepper motors left over from another project so I will check these when I get home. I was joking about the belts, but I really just like the screw motion over belts. My plan is to fairly quickly replace the stepper will full servo arrangement and was hoping to push the screw acceleration really hard. We have been using some servos at work that take a pulse input and direction and look easy to use with a built in driver.

3) I have already bought the bed heater. It is 230V at 500W and probably a bit over specification for what I need. Yes I will be using a solid state relay for the bed switching. Not sure where I will distribute the various electronics at the moment. I have two 20mm Tubes at the back of the printer going from the bed to the top for wiring. Probably put the heater and main switch mode power supply at the bottom and the control board at the top adjacent to the stepper motors and proximity limit switches.

Do you think given the tcost of the machine its justified to add multiple extruders dows this cause any additional complication. I was thinking of two extruders plus a bed leveling switch.

Many Thanks Regards chris

Edited 1 time(s). Last edit at 03/13/2018 10:02AM by ALLTHEGEARNOIDEA.

|

Re: My First Delta Printer build March 13, 2018 11:22AM |

Registered: 10 years ago Posts: 14,672 |

Dual nozzles on deltas are tricky because of the need to keep the nozzles at exactly the same height. Single nozzle using a switching or mixing hot end is more practical, but comes with its own issues. As it's your first printer, I suggest you built it single extrusion to start with, but design the effector size to be able to accommodate a switching/mixing hot end if you wish.

See [duet3d.dozuki.com] for a list of mechanical aspects that you need to get right to close tolerances when building a delta printer. One way of getting some of these right and doing bed probing is to use the Smart Effector, [duet3d.dozuki.com].

Edited 1 time(s). Last edit at 03/13/2018 11:24AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

See [duet3d.dozuki.com] for a list of mechanical aspects that you need to get right to close tolerances when building a delta printer. One way of getting some of these right and doing bed probing is to use the Smart Effector, [duet3d.dozuki.com].

Edited 1 time(s). Last edit at 03/13/2018 11:24AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My First Delta Printer build March 13, 2018 04:11PM |

Registered: 6 years ago Posts: 8 |

Quote

dc42

Dual nozzles on deltas are tricky because of the need to keep the nozzles at exactly the same height. Single nozzle using a switching or mixing hot end is more practical, but comes with its own issues. As it's your first printer, I suggest you built it single extrusion to start with, but design the effector size to be able to accommodate a switching/mixing hot end if you wish.

See [duet3d.dozuki.com] for a list of mechanical aspects that you need to get right to close tolerances when building a delta printer. One way of getting some of these right and doing bed probing is to use the Smart Effector, [duet3d.dozuki.com].

That’s brilliant advice I would never have thought of the problem with dual extruders. I have already bought some type of bed sensing switch I think it’s called a 3D Touch. I didn’t really research this but i saw a lot of people using them.

Thanks again for the advice that really helpful.

Regards Chris

|

Re: My First Delta Printer build March 13, 2018 07:12PM |

Registered: 10 years ago Posts: 14,672 |

For delta printers, it's important to get the Z probe as close to the nozzle as possible, or (preferably) to use the nozzle itself as the probe.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My First Delta Printer build March 14, 2018 12:03AM |

Registered: 7 years ago Posts: 51 |

|

Re: My First Delta Printer build March 14, 2018 03:15AM |

Registered: 6 years ago Posts: 8 |

Quote

dc42

For delta printers, it's important to get the Z probe as close to the nozzle as possible, or (preferably) to use the nozzle itself as the probe.

Ok I will do that. Not detailed the end effector yet and that is probably going to be my next job. Many thanks for the advice.

Regards Chris

|

Re: My First Delta Printer build March 14, 2018 03:27AM |

Registered: 6 years ago Posts: 8 |

Quote

Vigilant

You should worry more on frame rigidity , repeatabilty, reliability and accuracy of your config values . Delta maths are handled by firmware not you, so you shouldn't worry about it.

Thanks. Ok by the maths I thought there was some black art math in just working out the the length of the diagonal rods and the actual positioning of the towers etc or my printer would not work at all. From the other comment it looks like it will work provided the hot end can reach all areas of the bed etc. I have a good feeling following the simple joint modelling in fusion 360. Not sure how rigid the frame will be. The beds 10mm plate and the columns from Top to bottom are 6 x 16mm x 1m ground steel bars. There’s also a couple of 20mm tubes that wiring will run in. I’m guessing that there are side forces will be imparted to the frame when accelerating the end effector and possibly resonance effects. I guess we just give it a try and learn from the outcome.

Many thanks.

Regards Chris

Edited 2 time(s). Last edit at 03/14/2018 03:29AM by ALLTHEGEARNOIDEA.

|

Re: My First Delta Printer build March 22, 2018 05:13PM |

Registered: 8 years ago Posts: 3,525 |

I've built a machine very similar to the one you show but using a cylinder as a frame. Definitely think about the steps/mm, mine runs 400 which does work fine, although I have not experimented yet with high speeds as I haven't had time. Perhaps using ballscrews offers a better chance of the screws being straight. As using smooth rods, especially long ones, will result in possible lateral wobble. I chose linear rails to stiffen the system, whether the wobble in my leadscrews will wear these out I am unsure.

Having the rods at 20 degrees minimum angle to the effector (and having a 60 degree angle with the effector dead centre) are great rules of thumb, but a very precise and mechanically stiff machine with joints between the arms and effector/carriage with sufficient range of movement, can operate with a lower angle than this. That being said changing diagonal rod length can fix this, and extending your rods is not particularly difficult. Having slightly longer rods is no real problem, but too short can limit your XY printing area.

Edited 2 time(s). Last edit at 03/22/2018 05:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Having the rods at 20 degrees minimum angle to the effector (and having a 60 degree angle with the effector dead centre) are great rules of thumb, but a very precise and mechanically stiff machine with joints between the arms and effector/carriage with sufficient range of movement, can operate with a lower angle than this. That being said changing diagonal rod length can fix this, and extending your rods is not particularly difficult. Having slightly longer rods is no real problem, but too short can limit your XY printing area.

Edited 2 time(s). Last edit at 03/22/2018 05:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: My First Delta Printer build June 11, 2018 12:58PM |

Registered: 6 years ago Posts: 8 |

Ok starting to make some progress now the aluminium platforms that I had water jet cut have arrived. I have included links here to my YouTube build diary.

Regards Chris

[youtu.be]

YouTube link

Regards Chris

[youtu.be]

YouTube link

Sorry, only registered users may post in this forum.