Converting belt driven delta to leadscrew driven. Yes or no?

Posted by Alex_1234

|

Converting belt driven delta to leadscrew driven. Yes or no? May 14, 2018 06:33PM |

Registered: 6 years ago Posts: 27 |

I have had delta printer for a while now and I am wondering if converting it to a lead screw system is even possible and if it is would it increase print quality. The current problem I am having is I can push the effector and it will deflect about 2-3mm with little force and that is causing ghosting and exclusions on prints. Would lead screws solve this problem?

|

Re: Converting belt driven delta to leadscrew driven. Yes or no? May 15, 2018 04:15AM |

Registered: 10 years ago Posts: 732 |

|

Re: Converting belt driven delta to leadscrew driven. Yes or no? May 15, 2018 06:17AM |

Registered: 10 years ago Posts: 14,672 |

Are you sure that the reason you can move the effector is the elasticity of the belts, and not a loose joint, loose pulley or something else? Are the belts taut?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Converting belt driven delta to leadscrew driven. Yes or no? May 15, 2018 07:23AM |

Registered: 7 years ago Posts: 4 |

If the motors are powered, then it should need more than 'a little force' to move the carriages on the towers. So first check the carriages are not moving.

Then check for any slack in the belts, and the pulley mounts (as previously suggested).

Then check the screws holding the rod-ends (if your printer is like my Koseel XL) are not loose - they do not need to be forcefully tightened, but should not have any play.

Like that, the spider platform on my Kossel would still wobble with a light finger touch.

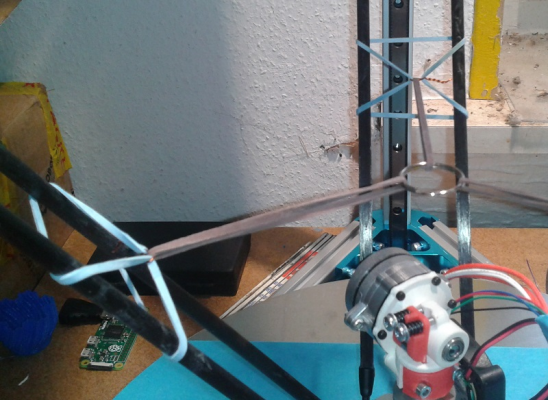

A friend with the same printer advised adding two tension springs between each pair of rods, one near the spider and one near the carriage. He used engineering wire springs with little (printed) clips to hold them to the carbon rods. I used rubber bands which are much cheaper, but perish after a while. I now have printed some PETG springs. With any of these, the spider platform is now very steady, and needs a lot of force to move it at all.

I hope this helps

John

Then check for any slack in the belts, and the pulley mounts (as previously suggested).

Then check the screws holding the rod-ends (if your printer is like my Koseel XL) are not loose - they do not need to be forcefully tightened, but should not have any play.

Like that, the spider platform on my Kossel would still wobble with a light finger touch.

A friend with the same printer advised adding two tension springs between each pair of rods, one near the spider and one near the carriage. He used engineering wire springs with little (printed) clips to hold them to the carbon rods. I used rubber bands which are much cheaper, but perish after a while. I now have printed some PETG springs. With any of these, the spider platform is now very steady, and needs a lot of force to move it at all.

I hope this helps

John

|

Re: Converting belt driven delta to leadscrew driven. Yes or no? May 15, 2018 10:27AM |

Registered: 8 years ago Posts: 5,232 |

What about the carriers? Are they rolling on V-wheels? If there is any play, replace them with linear rails. MGN12 are pretty popular.

I also had rubberbands installed. Helps alot against poor Traxxas rod end quality.

I also had rubberbands installed. Helps alot against poor Traxxas rod end quality.

|

Re: Converting belt driven delta to leadscrew driven. Yes or no? May 15, 2018 09:23PM |

Registered: 6 years ago Posts: 27 |

|

Re: Converting belt driven delta to leadscrew driven. Yes or no? June 21, 2018 05:45PM |

Registered: 8 years ago Posts: 3,525 |

[reprap.org]

I made a leadscrew delta and it works, theres a few things in that thread worth bearing in mind if you build one. Ignore the acrylic tube that was just a gimmick. If I had chance I'd rebuild it with a 2020 frame and have the screws on the outside of the towers, possibly the linear rails also, so that they take up less of the build volume with the carriages wrapping around the towers.

Speed wasn't an issue unless you're aiming for really fast delta printing, 400 steps/mm was no issue for a duet controller.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I made a leadscrew delta and it works, theres a few things in that thread worth bearing in mind if you build one. Ignore the acrylic tube that was just a gimmick. If I had chance I'd rebuild it with a 2020 frame and have the screws on the outside of the towers, possibly the linear rails also, so that they take up less of the build volume with the carriages wrapping around the towers.

Speed wasn't an issue unless you're aiming for really fast delta printing, 400 steps/mm was no issue for a duet controller.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.