Underslung Delta Effector

Posted by aflactheastronaut

|

Re: Underslung Delta Effector July 22, 2018 08:01AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Barracuda72

but about what speeds are we talking?

150mm/s printspeed.. 5000-8000mm/s² accelrations? Magnetic system can easily handle that..

400mm/s print speed? 2G accelerations? Yes..maybe its too much for magnetic rods...but who print so fast on a daily base and not only to test the system limits?

I just ran a test print with 400mm for all speeds and 10000mm/sec^2 (1G) XYZ acceleration. I can't do an actual print at those speeds because my extruder won't extrude that fast, however there were no rod detachments and no missed steps.

At 20000mm/sec^2 acceleration the machine sounded much rougher and there were missed steps. I was getting a lot of motor stall warnings, so they might have been caused by insufficient motor torque rather than anything else. Again, no joint detachments. This was on a print with a lot of sharp corners.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Underslung Delta Effector July 22, 2018 08:23AM |

Registered: 10 years ago Posts: 732 |

First layer quality is not a feature of magnetic joints. It is a feature of calibration and z-probe ... which is something different. Yes, your smart effector is supposed to be used with magnetic arms. But one can design smart effector functionality for ball joints and the overall result would be better. It would support higher accelerations.Quote

Barracuda72

I dont want miss it anymore...so much comfort...perfect 1st layer..no matter if i triy a new nozzel..chage from normal hotend to volcano....airbrush nozzle..just hit print and the printer do the rest and give me a perfect layer. for that comfort im willing to have more weight because even now im far away from the limit, this system have.

Anyway if your primary goal is a perfect fist layer you should go for a cartesian printer. There are easier to calibrate precisely. If somebody would implement calibration for delta printers which takes into account individual tower tilt (towers which are not equidistant to each other), and carriages rotated on the towers and different diagonal rod length for the same tower then there will be no reason to prefer cartesians for the first layer quality. But as far as I know nobody is working on this.

It is not that one cannot use magnetic arms. It is that they are a suboptimal solution.

|

Re: Underslung Delta Effector July 22, 2018 09:46AM |

Registered: 6 years ago Posts: 85 |

|

Re: Underslung Delta Effector July 22, 2018 02:01PM |

Registered: 10 years ago Posts: 732 |

|

Re: Underslung Delta Effector July 22, 2018 02:58PM |

Registered: 10 years ago Posts: 14,672 |

Quote

hercek

Can RepRap FW auto detect towers which are not equidistant and compensate for it?

Or do all the towers need to be tilted in the same direction?

Yes and yes. The towers must be parallel to each other, but need not be equidistant.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Underslung Delta Effector July 22, 2018 03:07PM |

Registered: 10 years ago Posts: 732 |

Ok, thanks. So you correct tower positions and one common tilt for all the towers together (which is the same as one bed tilt) plus end-stops and possibly also diagonal rod length. That is still 9 parameters only. Is that correct?

It is a good result anyway. Good job. If you ever to get support for towers tilted in different directions (i.e. 13 parameters) then please make a big post somewhere here

It is a good result anyway. Good job. If you ever to get support for towers tilted in different directions (i.e. 13 parameters) then please make a big post somewhere here

|

Re: Underslung Delta Effector July 22, 2018 03:35PM |

Registered: 10 years ago Posts: 732 |

2G is about what I would expect with 400 g movable weight and 10N holding force for one rod. I would be interested whether you could get to 3G without disconnection. If you can crank up motor current more and would like to do the test then post the result please. Print quality would be terrible with this acceleration, movable weight and glass based belts but it is still interesting. IIRC you have linear rails so tower flex should not be an issue (it is a problem on traditional rostock with Ø 8 mm smooth rods).Quote

dc42

At 20000mm/sec^2 acceleration the machine sounded much rougher and there were missed steps. I was getting a lot of motor stall warnings, so they might have been caused by insufficient motor torque rather than anything else. Again, no joint detachments. This was on a print with a lot of sharp corners.

|

Re: Underslung Delta Effector July 22, 2018 05:47PM |

Registered: 6 years ago Posts: 85 |

I will try to test it tomorrow...I still got 1.8° motors on mine..so i guess it could be possible. David have 0.9° motors.

ahh about compensation...i guess we all have the same opinion that you have to build your printer as perfect as possible...Delta and Cartesian? In the end its a fdm printer..no way that we get it all to 100% too much variables in a print. But we can try to make the system as good we can

ahh about compensation...i guess we all have the same opinion that you have to build your printer as perfect as possible...Delta and Cartesian? In the end its a fdm printer..no way that we get it all to 100% too much variables in a print. But we can try to make the system as good we can

|

Re: Underslung Delta Effector July 30, 2018 11:29PM |

Registered: 8 years ago Posts: 916 |

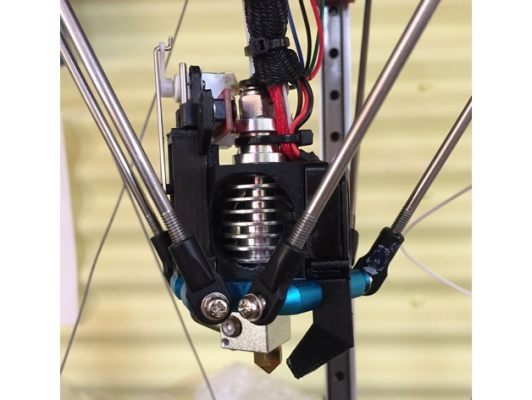

Here's mine:

[www.thingiverse.com]

I think it fits almost all your criteria, except for the cooling fan setup. Maybe it will give you some ideas.

Edited 2 time(s). Last edit at 07/30/2018 11:40PM by nebbian.

[www.thingiverse.com]

I think it fits almost all your criteria, except for the cooling fan setup. Maybe it will give you some ideas.

Edited 2 time(s). Last edit at 07/30/2018 11:40PM by nebbian.

|

Re: Underslung Delta Effector July 31, 2018 02:57PM |

Registered: 6 years ago Posts: 27 |

That's pretty cool! What kind of accuracy have you gotten with that movable z probe?

Also, I'd be worried about removing heatsink fans. One of my current problems is that my heatsink is too warm, so I'd rather not do that.

Ironically, since I started this thread, I've switched to a non-underslung (I'm sure there's another word for that) effector. I figure the E3D V6 is short enough and I can move my z stops, so I'll actually only lose about 20mm of build volume. I've found some really powerful fans on DigiKey that can fit in this effector (https://www.thingiverse.com/thing:1093345) and fan mount (https://www.thingiverse.com/thing:1973156). I did some research and apparently E3D's heatsink fan pushes about 3-4 cfm. The 40mm fan I found pushes 10, so I think I'll be fine. And I'll use the 30mm fan I already have plus the 30mm fan that comes with the V6 for bidirectional part cooling!

Thanks again for the input!

Alex

Also, I'd be worried about removing heatsink fans. One of my current problems is that my heatsink is too warm, so I'd rather not do that.

Ironically, since I started this thread, I've switched to a non-underslung (I'm sure there's another word for that) effector. I figure the E3D V6 is short enough and I can move my z stops, so I'll actually only lose about 20mm of build volume. I've found some really powerful fans on DigiKey that can fit in this effector (https://www.thingiverse.com/thing:1093345) and fan mount (https://www.thingiverse.com/thing:1973156). I did some research and apparently E3D's heatsink fan pushes about 3-4 cfm. The 40mm fan I found pushes 10, so I think I'll be fine. And I'll use the 30mm fan I already have plus the 30mm fan that comes with the V6 for bidirectional part cooling!

Thanks again for the input!

Alex

|

Re: Underslung Delta Effector August 01, 2018 12:08AM |

Registered: 8 years ago Posts: 916 |

You can't see it, but there's a 30mm heatsink fan on the far side.

I'm getting around +- 0.01mm repeatability on the Z probe. That's enough for me, and ensures that the nozzle is completely rigid with respect to the effector.

Regarding ball joints vs traxxas, I've found the traxxas to be well good enough for me. They are small, light, and I haven't seen any slop since I installed them (a couple of years ago). You do have to be careful putting them together though. There is more slop in the linear rails than the ball joints. Most people don't realise that you have to accurately space your ball joints on the carriage, as well as the effector (ie actually measure the distance between arm attachment points with calipers, and carefully shim/file both so that they match perfectly on each pair of diagonal arms). Another thing that many miss is that you must ensure that your carriage attachment points are exactly at 90 degrees to the rail -- the carriage has a bit of play with respect to the linear bearing, and you need to measure the relative height of the attachment points to get them perfect before tightening them down. Either of these slight misalignments will have drastically more effect on accuracy than using ball joints vs Traxxas. The only time I've had slop is when the ball joint attachment screws for either the effector or the carriage have backed out a bit. Loctite can help here.

No matter how good your measurements are, you will always have a small amount of effector tilt, so an underslung effector will minimise the distortion on printed parts. I've measured this, and is why I went to all the trouble of making many prototypes of underslung effectors before settling on this version. It's been in service for a year or two on both my delta printers, and I'm very happy with it.

Just my $0.02.

I'm getting around +- 0.01mm repeatability on the Z probe. That's enough for me, and ensures that the nozzle is completely rigid with respect to the effector.

Regarding ball joints vs traxxas, I've found the traxxas to be well good enough for me. They are small, light, and I haven't seen any slop since I installed them (a couple of years ago). You do have to be careful putting them together though. There is more slop in the linear rails than the ball joints. Most people don't realise that you have to accurately space your ball joints on the carriage, as well as the effector (ie actually measure the distance between arm attachment points with calipers, and carefully shim/file both so that they match perfectly on each pair of diagonal arms). Another thing that many miss is that you must ensure that your carriage attachment points are exactly at 90 degrees to the rail -- the carriage has a bit of play with respect to the linear bearing, and you need to measure the relative height of the attachment points to get them perfect before tightening them down. Either of these slight misalignments will have drastically more effect on accuracy than using ball joints vs Traxxas. The only time I've had slop is when the ball joint attachment screws for either the effector or the carriage have backed out a bit. Loctite can help here.

No matter how good your measurements are, you will always have a small amount of effector tilt, so an underslung effector will minimise the distortion on printed parts. I've measured this, and is why I went to all the trouble of making many prototypes of underslung effectors before settling on this version. It's been in service for a year or two on both my delta printers, and I'm very happy with it.

Just my $0.02.

|

Re: Underslung Delta Effector August 01, 2018 11:40AM |

Registered: 10 years ago Posts: 150 |

@nebbian

You express very well the accuracy requirements for a delta mechanic.

It is for these reasons that I propose Zatsit, a delta robot whose joints are replaced by hinges, which are all defined at once by a CNC, which engraves them in a special aluminium/polypropylene composite, with a typical accuracy of 1/50 mm.

This procedure ensures a very exact geometry, without any particular effort, which greatly simplifies things for a delta machine.

See

www.zatsit.fr

and particulary the videos at

www.zatsit.fr/test

Or, for the English speakers, my entry on Hackaday :

[hackaday.io]

You express very well the accuracy requirements for a delta mechanic.

It is for these reasons that I propose Zatsit, a delta robot whose joints are replaced by hinges, which are all defined at once by a CNC, which engraves them in a special aluminium/polypropylene composite, with a typical accuracy of 1/50 mm.

This procedure ensures a very exact geometry, without any particular effort, which greatly simplifies things for a delta machine.

See

www.zatsit.fr

and particulary the videos at

www.zatsit.fr/test

Or, for the English speakers, my entry on Hackaday :

[hackaday.io]

|

Re: Underslung Delta Effector August 27, 2018 04:15AM |

Registered: 6 years ago Posts: 50 |

This is so true...Quote

nebbian

Either of these slight misalignments will have drastically more effect on accuracy than using ball joints vs Traxxas.

Quote

nebbian

No matter how good your measurements are, you will always have a small amount of effector tilt, so an underslung effector will minimise the distortion on printed parts. I've measured this, and is why I went to all the trouble of making many prototypes of underslung effectors before settling on this version.

The underslung effector is definitely the better way to go, just much harder to get everything to fit

|

Re: Underslung Delta Effector May 14, 2019 04:12AM |

Registered: 7 years ago Posts: 56 |

The topic is old but there was a good discussion going on the first page about the pro/cons of Magballs on a delta. I'm leaning towards using ball joints after reading this but I can't find any of the two suggested in my country. Traxxas is easy to find but those are not good if I understood correctly. Any other suggestions?

|

Re: Underslung Delta Effector May 15, 2019 02:47AM |

Registered: 10 years ago Posts: 732 |

My recomendation is to build a cartesian printer.

The point is that you will find most information about printers using magnetic joints or 6 mm wide glass core belts (*) and those parts are not suitable for a quick printer. A quick printer needs also high acceleration to print quickly and most people here seem to use accelerations only around 0.5 G to get nice prints without ringing.

(*) Glass core belts are recommended since they last longer but their young's modulus is lower which leads to more ringing after corners. But 6 mm wide steel core belts are not ideal either. They are still too springy if you want to achieve acceleration above 1.6 G.

If you do not need quick printing then build a cartesian printer. You will save yourself a lot of calibration headaches and also a lot of money because you cannot build a good delta printer for cheap. And a quick delta printer will need a lot of non-standard parts and will get even more expensive and will require you to have more knowledge because the most common build plans do not apply.

I do not have experience with other joints than MP-Jet. No recommendation there.

The point is that you will find most information about printers using magnetic joints or 6 mm wide glass core belts (*) and those parts are not suitable for a quick printer. A quick printer needs also high acceleration to print quickly and most people here seem to use accelerations only around 0.5 G to get nice prints without ringing.

(*) Glass core belts are recommended since they last longer but their young's modulus is lower which leads to more ringing after corners. But 6 mm wide steel core belts are not ideal either. They are still too springy if you want to achieve acceleration above 1.6 G.

If you do not need quick printing then build a cartesian printer. You will save yourself a lot of calibration headaches and also a lot of money because you cannot build a good delta printer for cheap. And a quick delta printer will need a lot of non-standard parts and will get even more expensive and will require you to have more knowledge because the most common build plans do not apply.

I do not have experience with other joints than MP-Jet. No recommendation there.

|

Re: Underslung Delta Effector May 15, 2019 02:04PM |

Registered: 10 years ago Posts: 14,672 |

Delta printers can be fast and easy to calibrate. I agree with @hercek that this does not come cheaply. You need accurate geometry, good electronics and firmware, and a nozzle-contact Z probe.

Where I disagree with @hercek is that you need non-standard parts. My Kossel variant (see [miscsolutions.wordpress.com] for the details) is built entirely from commercial parts. The delta geometry is accurate by design. Calibration is trivial, it is so quick (20 seconds) that I can run it every time I turn the printer on.

I haven't yet built a CoreXY printer, but from what I have read it appears that a good CoreXY costs even more than a good delta, although it is more flexible - for example, tool changing is easier to implement.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Where I disagree with @hercek is that you need non-standard parts. My Kossel variant (see [miscsolutions.wordpress.com] for the details) is built entirely from commercial parts. The delta geometry is accurate by design. Calibration is trivial, it is so quick (20 seconds) that I can run it every time I turn the printer on.

I haven't yet built a CoreXY printer, but from what I have read it appears that a good CoreXY costs even more than a good delta, although it is more flexible - for example, tool changing is easier to implement.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Underslung Delta Effector May 15, 2019 04:44PM |

Registered: 7 years ago Posts: 56 |

idkn if the corexy suggestions was in reply to me or because I bumped a old thread but I already got a scratch built core XY with 3030 frame, alu cnc machined parts, linear hiwin rails on all axis and 3x ballscrews + 3x linear rails for true bed leveling. No doubt corexy is fast and a great concept but this time I just want to chase my dream of having a delta and to learn about them. Always liked how they look when printing  It's more about the road to a good printer than actually printing..

It's more about the road to a good printer than actually printing..

Ordered a Anycubic Kossel that is arriving tomorrow and I'll assemble it with a Duet wifi board first thing without even trying stock electronics. Then I want to start improving the mechanics and eventually (after prolly replacing all parts) get a good printer. I got no budget for this project. For bed leveling I have a piezo discs and a unit from precisionpiezo that I used on another printer that will fit under the bed for now. I want it to be DIY so that's why I got the cheapest delta I could find as a base to learn from even if I know that in the end I'll replace most parts.

For now the main thing I'm not certain about is how to get the best kind of links. The magballs does sound like a good upgrade but when I read through this thread the two people arguing for ballcups pointed out a lot of cons I also had in mind about the magballs. Another thing is that I would hate to find a hotend that holds 2-300degrees C to drop off and cause a fire because something messed up in a print and the hotend came of. I've read enough stories about that and I do print quite a bit when I'm not in the same room as the printer so that's a big drawback to have to be worried about. Is there any thing that can be made DIY that will be better than what can be bought?

It's more about the road to a good printer than actually printing..

It's more about the road to a good printer than actually printing.. Ordered a Anycubic Kossel that is arriving tomorrow and I'll assemble it with a Duet wifi board first thing without even trying stock electronics. Then I want to start improving the mechanics and eventually (after prolly replacing all parts) get a good printer. I got no budget for this project. For bed leveling I have a piezo discs and a unit from precisionpiezo that I used on another printer that will fit under the bed for now. I want it to be DIY so that's why I got the cheapest delta I could find as a base to learn from even if I know that in the end I'll replace most parts.

For now the main thing I'm not certain about is how to get the best kind of links. The magballs does sound like a good upgrade but when I read through this thread the two people arguing for ballcups pointed out a lot of cons I also had in mind about the magballs. Another thing is that I would hate to find a hotend that holds 2-300degrees C to drop off and cause a fire because something messed up in a print and the hotend came of. I've read enough stories about that and I do print quite a bit when I'm not in the same room as the printer so that's a big drawback to have to be worried about. Is there any thing that can be made DIY that will be better than what can be bought?

|

Re: Underslung Delta Effector May 15, 2019 04:50PM |

Registered: 10 years ago Posts: 732 |

OK, that uses GT2 glass core belts and magnetic joints.

Can you post pictures of ringing with information about the used acceleration and speed?

Preferably something at printing movement speeds of at least 80 mm/s (preferably around 120 mm/s or higher) and accelerations of let's say 0.8 G and 1.6 G.

My point is not that you cannot print quickly at all. My point is that ringing will be bad with quick prints.

Can you post pictures of ringing with information about the used acceleration and speed?

Preferably something at printing movement speeds of at least 80 mm/s (preferably around 120 mm/s or higher) and accelerations of let's say 0.8 G and 1.6 G.

My point is not that you cannot print quickly at all. My point is that ringing will be bad with quick prints.

|

Re: Underslung Delta Effector May 15, 2019 05:03PM |

Registered: 7 years ago Posts: 56 |

For the corexy? I can try but how is that related to the delta joints? I don't have a assembled delta I just want to figure out what's the best joints/rods I can get for the delta and this was the best discussion I found about regular joints vs magballs.

This is a bit off track but what about using ballscrews instead of belts to avoid the belt issue on a delta?

This is a bit off track but what about using ballscrews instead of belts to avoid the belt issue on a delta?

|

Re: Underslung Delta Effector May 16, 2019 02:43AM |

Registered: 10 years ago Posts: 732 |

If you can find a thin (e.g. Ø 10 mm or smaller), long (at least 70 cm) screw with very high pitch (preferably around 5 mm or even higher) then it may be doable with ball screw or lead screw. The problem with screws is that to print quickly you need to spin them up quite a bit if they have small pitch and that kills your maximum acceleration. You will also hit maximum stepper motor RPM with small pitches (limits maximum speed). Such thin long high pitched screws may get expensive. If you do some research and find candidate screws in reasonable price range then we can check how much they kill your maximum acceleration compared to belts.

A cheap and quick candidate is a ~ Ø 1 mm steel cable as used on bicycles and some larter diameter custom drums (and almost for sure a gear slowing down stepper rotation by about 66%). Quality plastic gears can be bough easily. A custom drum would need to be machined. May be a 3d printed version of the drum can be built but its outer surfface must be metal or something tougher than ABS (e.g. delrin). Maybe a thin walled metal tube can be put on a printed ABS part.

Other option is much wider belts.

Maybe I'm wrong and somebody will post prints with negligible ringing at high speeds (>100 mm/s) and accelerations (>1G). But theoretical calculations with glass core belts indicate ringing will be quite severe at such speeds/accelerations. Also my 3d pritner with 6 mm steel core belts indicates the same and I use acceleration of only 0.9 G. Steel core belts are stiffer than glass core belts ... at least the GT2 glass core belts from Gates. But be aware that steel core belts break sooner than glass core ones.

Most people posting pretty printouts use accelerations around 0.5 G and speed only around 50 mm/s. That is not significantly better than a cartesian printer. If better at all. And cartesian printers are cheaper and much easier to calibrate.

A cheap and quick candidate is a ~ Ø 1 mm steel cable as used on bicycles and some larter diameter custom drums (and almost for sure a gear slowing down stepper rotation by about 66%). Quality plastic gears can be bough easily. A custom drum would need to be machined. May be a 3d printed version of the drum can be built but its outer surfface must be metal or something tougher than ABS (e.g. delrin). Maybe a thin walled metal tube can be put on a printed ABS part.

Other option is much wider belts.

Maybe I'm wrong and somebody will post prints with negligible ringing at high speeds (>100 mm/s) and accelerations (>1G). But theoretical calculations with glass core belts indicate ringing will be quite severe at such speeds/accelerations. Also my 3d pritner with 6 mm steel core belts indicates the same and I use acceleration of only 0.9 G. Steel core belts are stiffer than glass core belts ... at least the GT2 glass core belts from Gates. But be aware that steel core belts break sooner than glass core ones.

Most people posting pretty printouts use accelerations around 0.5 G and speed only around 50 mm/s. That is not significantly better than a cartesian printer. If better at all. And cartesian printers are cheaper and much easier to calibrate.

|

Re: Underslung Delta Effector May 16, 2019 06:39PM |

Registered: 7 years ago Posts: 56 |

The idea with steel cable sounded pretty awesome. I have a lathe and a cnc mill so machining drums should be doable. This idea has to be checked out

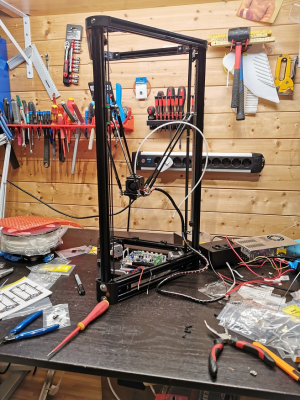

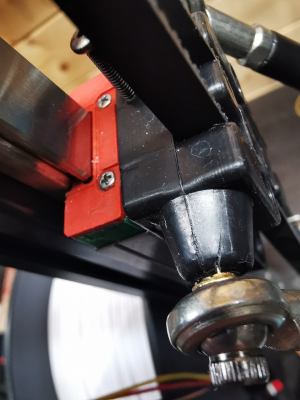

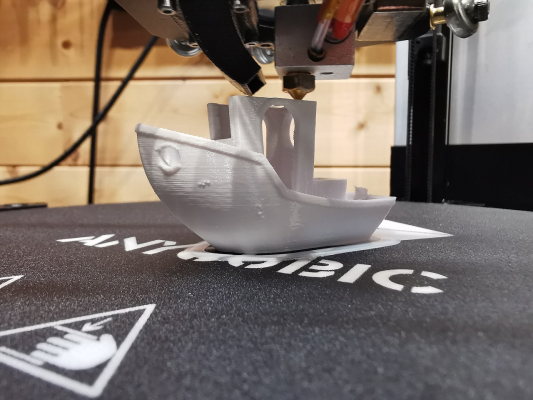

As I said cartesian is out of the question. I'm building a delta because I think they look cool while printing. The kossel arrived today so I spent the afternoon assembling it. Came with broken carrier and I trashed the controller and assembled it with a duet wifi. This is from the very first print or attempt. It worked pretty well for not having done a testcube or any tuning whatsoever.

That was a side step. I'm still looking for what kind of rods I should go for. Magballs or ball joints I can't decide

As I said cartesian is out of the question. I'm building a delta because I think they look cool while printing. The kossel arrived today so I spent the afternoon assembling it. Came with broken carrier and I trashed the controller and assembled it with a duet wifi. This is from the very first print or attempt. It worked pretty well for not having done a testcube or any tuning whatsoever.

That was a side step. I'm still looking for what kind of rods I should go for. Magballs or ball joints I can't decide

|

Re: Underslung Delta Effector May 17, 2019 07:51PM |

Registered: 10 years ago Posts: 732 |

OK; there is not any argument against "delta looking cool"!

If you want to play with the steel cable you can try this:

But belts and magnetic joints are OK when accelerations of 0.3 - 0.5 G and speeds about 50 mm/s are used. Which is what most people seem to be using. Of course, then there is a question why delta at all because for low speeds/accelerations it brings only much more expenses and headaches compared to a cartesian printer.

But when the reason is "I like how delta moves" then there is no possible objection against it. And I fully accept it

Mag joints will do for slow printing.

Edited 1 time(s). Last edit at 05/17/2019 07:53PM by hercek.

If you want to play with the steel cable you can try this:

- drum diameter 5 cm (big drum is important to have small number of turn of the cable on the drum; you need small number of turns to limit the errors from cable not going straightt up - horizontal cable position on the drum changes depending on carriage position; you also cannot bend a steel cable much

- steel cable diameter 1.5 mm

- drum length a bit above 8.5 mm (you need some kind of rims to make sure the cable cannot slip from the drum)

- you need gears slowing down steppers to drum connection by a factor of 4 (if you want to use standard Nema 17) - buy a precise plastic gears and spring load them to limit backslash

- low inductance steppers with at least 4 Mm torque; microstepping set to 4 only

- active carriage movement length 50 cm (put the bottom idler just behind the active length)

- cable must be tensioned to about 35 N

- maximum carriage weight: 65 g

- maximum platform weight together with the 6 arms and direct extruder mounted on the platform (to avoid bowden problems): 456 g

- maximum force at the arms will be 20 N (so if you want magnetic joints then they need to be good and light - you probably will not find such so that you still obey the previous weight limit)

- if the printer would use smooth rods then they must have diameter at least 16 mm (so that they do not bend too much under dynamic forces)

- maximum achievable acceleration: 6G

- maximum speed 300 mm/s

- dynamic error due to stepper not being precisely at the given microstep position: 24.5 µm

- positioning error due to drum length: 4.7 µm

- dynamic error due to cable elasticity: 96.6 µm

- dynamic error due to smooth rod bending: 40.3 µm

But belts and magnetic joints are OK when accelerations of 0.3 - 0.5 G and speeds about 50 mm/s are used. Which is what most people seem to be using. Of course, then there is a question why delta at all because for low speeds/accelerations it brings only much more expenses and headaches compared to a cartesian printer.

But when the reason is "I like how delta moves" then there is no possible objection against it. And I fully accept it

Mag joints will do for slow printing.

Edited 1 time(s). Last edit at 05/17/2019 07:53PM by hercek.

|

Re: Underslung Delta Effector May 18, 2019 06:40AM |

Registered: 7 years ago Posts: 56 |

Hehe no  I like to build and experiment and the last 3 printers i built was cartesian/corexy so I just want to try something new and I enjoy how deltas look during printing.

I like to build and experiment and the last 3 printers i built was cartesian/corexy so I just want to try something new and I enjoy how deltas look during printing.

Thanks for the detailed explanation and math. I will need to experiment and learn some more about delta's before I start on something like this tho. I see that there is a a lot of small pitfalls here that I wouldn't have thought about.

It doesn't hurt to get rods that is suited for increased speed in the first place. I see that you say mag joints will do for slow printing but I don't like having to upgrade items two times when end goal is having something good. Since I got the printer two days ago I've upgraded it with duet wifi and converted it to 24V. Today it's getting piezo underbed sensors for better homing and I've ordered 17HM19-2004S1 0.9degree steppers. This is all hardware I hope that I don't have to replace later on in the project. There's like 1mm slop in the effector now so next step is getting joints. What I know is that these metal ones supplied with the printer is crap so I would like to avvoid getting the same ***** when i do a upgrade.

I like to build and experiment and the last 3 printers i built was cartesian/corexy so I just want to try something new and I enjoy how deltas look during printing.

I like to build and experiment and the last 3 printers i built was cartesian/corexy so I just want to try something new and I enjoy how deltas look during printing. Thanks for the detailed explanation and math. I will need to experiment and learn some more about delta's before I start on something like this tho. I see that there is a a lot of small pitfalls here that I wouldn't have thought about.

It doesn't hurt to get rods that is suited for increased speed in the first place. I see that you say mag joints will do for slow printing but I don't like having to upgrade items two times when end goal is having something good. Since I got the printer two days ago I've upgraded it with duet wifi and converted it to 24V. Today it's getting piezo underbed sensors for better homing and I've ordered 17HM19-2004S1 0.9degree steppers. This is all hardware I hope that I don't have to replace later on in the project. There's like 1mm slop in the effector now so next step is getting joints. What I know is that these metal ones supplied with the printer is crap so I would like to avvoid getting the same ***** when i do a upgrade.

|

Re: Underslung Delta Effector May 18, 2019 09:24AM |

Registered: 10 years ago Posts: 14,672 |

Good magnetic joints work for high speed printing too. My delta using Haydn's mag joints + Duet3D Smart Effector + E3Dv6 hot end will lift more than 1.5kg without disconnecting. The mass of the effector and hot end is about 400g. So I could push it to more than 4G without it disconnecting.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Underslung Delta Effector May 18, 2019 03:24PM |

Registered: 12 years ago Posts: 1,450 |

Quote

hercek

.............

[*] dynamic error due to stepper not being precisely at the given microstep position: 24.5 µm

[*] positioning error due to drum length: 4.7 µm

...........

Viewing those two points, surely there would be a better compromise than a 5cm drum? Also, does the error calculation assume that no mitigating measures are taken to optimise the geometry?

Is 1.5mm cable a reasonable choice as even 0.81mm will work comfortably at 100N?

Mike

Edited 1 time(s). Last edit at 05/18/2019 03:25PM by leadinglights.

|

Re: Underslung Delta Effector May 18, 2019 04:16PM |

Registered: 10 years ago Posts: 732 |

If you get some time, then print right angle corners at 2 G and about 120 mm/s to show us what kind of ringing will be there. If you think your joints can hold 4 G then try even 4 G and at least 120 mm/s. You may need low layer height so that your extruder can keep up at high speeds and the test part must have huge circumference so that slicer does not slow down the walls because of minimum layer time if infill is zero % (maybe some kind of an outline of a comb shape). But you surely already know that.Quote

dc42

Good magnetic joints work for high speed printing too. My delta using Haydn's mag joints + Duet3D Smart Effector + E3Dv6 hot end will lift more than 1.5kg without disconnecting. The mass of the effector and hot end is about 400g. So I could push it to more than 4G without it disconnecting.

Edited 1 time(s). Last edit at 05/18/2019 04:35PM by hercek.

|

Re: Underslung Delta Effector May 18, 2019 04:33PM |

Registered: 10 years ago Posts: 732 |

You can go with smaller drum but there is a limit at the minimum drum diameter of at least abut 2.5 - 3 cm. That is because you cannot bend Ø 1.5 mm steel cable too much. It would break too soon. And to achieve enough torque from the best Nema 17 motors one can buy you need to use low microstepping. Than forces you to use gears to get higher precision. And when you are already forced to use gears then it does not make sense to strive for too small drums. Smaller drums mean higher wear on the cable due to its bending and smaller drums mean higher positioning error due to drum length.Quote

leadinglights

Viewing those two points, surely there would be a better compromise than a 5cm drum?

Specify better what do you mean.Quote

leadinglights

Also, does the error calculation assume that no mitigating measures are taken to optimise the geometry?

It is not about how much force a cable can withstand before it breaks. From this point of view even simple narrow glass core belts are overkill.Quote

leadinglights

Is 1.5mm cable a reasonable choice as even 0.81mm will work comfortably at 100N?

It is about young's modulus of the cables. It is about how many percent a 1 m long cable elongates when you load it with 1 N of additional force. It is important because cable elasticity is one of the main components of the dynamic hotend position error. Notice that the biggest error of 96.6 µm is there because even Ø 1.5 mm steel cable is still too easy to stretch. Ø 0.81 mm cables will be even easier to stretch and lead to bigger dynamic errors.

Dynamic errors are what causes ringing at the print corners at high speeds / accelerations.

|

Re: Underslung Delta Effector May 18, 2019 07:19PM |

Registered: 7 years ago Posts: 56 |

Quote

dc42

Good magnetic joints work for high speed printing too. My delta using Haydn's mag joints + Duet3D Smart Effector + E3Dv6 hot end will lift more than 1.5kg without disconnecting. The mass of the effector and hot end is about 400g. So I could push it to more than 4G without it disconnecting.

I'll try magnetic joints I guess

Btw would it be possible to use that stall detection the other way around on the duet for detecting if an arm pops off? Would be nice to halt the printer and hotend temp if arms came off.

Btw would it be possible to use that stall detection the other way around on the duet for detecting if an arm pops off? Would be nice to halt the printer and hotend temp if arms came off.

|

Re: Underslung Delta Effector May 20, 2019 02:06PM |

Registered: 10 years ago Posts: 732 |

|

Re: Underslung Delta Effector May 20, 2019 11:04PM |

Registered: 6 years ago Posts: 50 |

Quote

dc42

Good magnetic joints work for high speed printing too. My delta using Haydn's mag joints + Duet3D Smart Effector + E3Dv6 hot end will lift more than 1.5kg without disconnecting. The mass of the effector and hot end is about 400g. So I could push it to more than 4G without it disconnecting.

I don't know why you think the static load is relevant for mag joints, as soon as you move the load it increases its force pulling on the joint which would be fine to use on a solid joint like a rod end (same sized and priced rod end would be good for several hundreds if not thousands of kilograms) but the joint isn't solid, its a magnet, so any force applied to the arm moves the magnet joint, the more force the more the joint will move (be it out of alignment and/or away from the joint). As we have discussed before, a magnetic joint has a very low percentage of constraint for the joint and even lower stiffness due to a magnetic force being used to hold/constrain the joint rather than a mechanical constraint. So the mag ball joint might not disconnect at higher speeds & acceleration, it will certainly show artefacts from the movement of the mag ball joints as you increase speeds above 100mm/s. Now some of the artefacts I see will be coming from the "smart" effector flexing as it is just pcb material, but when the mag ball joints are connected to a solid aluminium effector it shows pretty much the same surface artefacts, with rod ends there are none (admittedly never run rod ends on the smart effector). Using a 10Nm magnet with a 0.1mm gap between the 2 magnets you will start to yield/increase the gap with 0.5Nm of force, the joint will stay together but it is no longer at the correct alignment or length (shearing force is even less and in this particular case the force is mechanically amplified/aided by the "cup" design of the joint). I am pretty sure you are going to reach this force almost immediately on any delta movement which is one of the reasons why a magnetic joint is considered to be a very low constrained joint and is also why it is pretty much never used.

If you are aiming for high speed, high accuracy and good wall finish/tolerances then rod ends are the best option, if you are looking for something to make it easier to change nozzles/hotends then the mag balls are the way to go (if you are using the mosquito hotend then most of the reason for having mag balls goes away as it is easier to change nozzles in the mosquito hotend than it is to change mag ball effector), if you want something in between then go for ball ends.

Edited 1 time(s). Last edit at 05/20/2019 11:08PM by Redemptioner.

Sorry, only registered users may post in this forum.