Kossel Delta xxl build project HELP

Posted by alex773

|

Re: Kossel Delta xxl build project HELP July 21, 2020 02:34PM |

Registered: 5 years ago Posts: 347 |

I start this print with 3.5 retraction Length under Filament Settings in PrusaSlicer and S3.5 in M207 in config.g

After 25 mm I send the M207 S4 F2300 Z0 to the printer and I changed the temperature to 190c. Maybe is just me but I don't see any difference.

I also checked that exposed section of the gear on the side of the Hemera and when it retracts it jumping back

Edited 3 time(s). Last edit at 07/21/2020 03:06PM by alex773.

After 25 mm I send the M207 S4 F2300 Z0 to the printer and I changed the temperature to 190c. Maybe is just me but I don't see any difference.

I also checked that exposed section of the gear on the side of the Hemera and when it retracts it jumping back

Edited 3 time(s). Last edit at 07/21/2020 03:06PM by alex773.

|

Re: Kossel Delta xxl build project HELP July 21, 2020 03:10PM |

Registered: 10 years ago Posts: 651 |

I don't really see much difference either. Could you post that gcode file?

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 03:16PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:20PM |

Registered: 10 years ago Posts: 651 |

Would you post the stl also, I'd like to slice it and see how it does the gcode for me.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:23PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:30PM |

Registered: 10 years ago Posts: 651 |

Yeah, something's going on at layer change or retract time. Here's a snip of gcode from yours.

It's moving to the next layer, retracting, then moving up by 0.7mm, moving to XY position, then going back down. Then unretracting.

Take a look at mine

Looks to be consistent each time. There's got to something somewhere in your slicer config.

Take a look at the Printer Settings Tab in the Custom G-Code section, in the Before and After layer change.

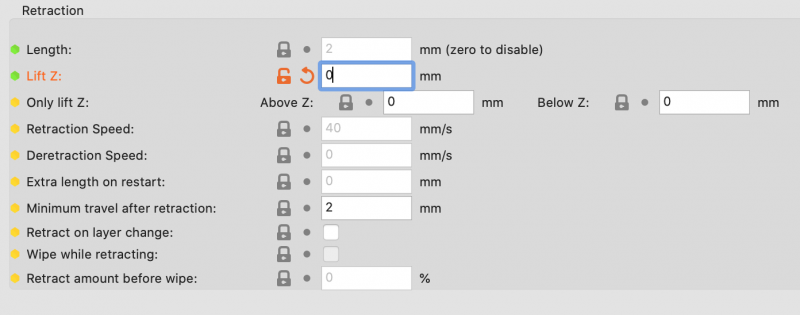

Edit: Looks like it might actually be on the Printer Settings tab, in the Extruder 1 section under Retraction Settings. Probably the Z lift there, take that out. If you need it, you can add it to your M207. I've never used it ever.

Edited 2 time(s). Last edit at 07/21/2020 04:38PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

G1 Z4.500 F5400.000 G10 ; retract G1 Z5.200 G1 X6.789 Y-44.591 G1 Z4.500 G11 ; unretract

It's moving to the next layer, retracting, then moving up by 0.7mm, moving to XY position, then going back down. Then unretracting.

Take a look at mine

G1 Z4.600 F5400.000 G10 ; retract G1 X7.551 Y-0.057 G11 ; unretract

Looks to be consistent each time. There's got to something somewhere in your slicer config.

Take a look at the Printer Settings Tab in the Custom G-Code section, in the Before and After layer change.

Edit: Looks like it might actually be on the Printer Settings tab, in the Extruder 1 section under Retraction Settings. Probably the Z lift there, take that out. If you need it, you can add it to your M207. I've never used it ever.

Edited 2 time(s). Last edit at 07/21/2020 04:38PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:38PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:39PM |

Registered: 10 years ago Posts: 651 |

Yeah, I did some playing around and looks like it might actually be on the Printer Settings tab, in the Extruder 1 section under Retraction Settings. Probably the Z lift there, take that out.

Edited 1 time(s). Last edit at 07/21/2020 04:40PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

Edited 1 time(s). Last edit at 07/21/2020 04:40PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:44PM |

Registered: 10 years ago Posts: 651 |

Also in your start gcode, you can replace that G0 Z0.200 F1800 with G0 Z[first_layer_height] F1800

Prusa can do some variables, then it will go to whatever the first later height that you set in the gui.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

Prusa can do some variables, then it will go to whatever the first later height that you set in the gui.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:49PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:51PM |

Registered: 10 years ago Posts: 651 |

I would. Though it shouldn't affect your issue. It's only to say if the travel is this short, don't retract.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:55PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP July 21, 2020 04:57PM |

Registered: 10 years ago Posts: 651 |

That works, though you can actually type in [first_layer_height] and Slicer will put in whatever the first layer height you set in the gui. Is useful if you change the first layer height, you don't have to remember to change the start gcode.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 05:23PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP July 21, 2020 06:13PM |

Registered: 10 years ago Posts: 651 |

Looks a lot better. I believe we're looking at a cooling issue with the remaining stringeys and the bridge quality there. I've never actually printed a bridge yet on my printer, mine might come out the same. I'll print this file and let you know how it goes.

You may actually slow down the bridge speed, so the fan has time to cool it mid air.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

You may actually slow down the bridge speed, so the fan has time to cool it mid air.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP July 21, 2020 07:36PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP November 10, 2020 08:59PM |

Registered: 5 years ago Posts: 347 |

I changed my rods with the new ones from Filastruder.

After 2 months I noticed the magballs on my effector and carriage adapters were getting this black powder . I lube them with synthetic grease. The same reason why I changed them in the first place. I don't know why it is doing the same thing. I checked every screw and nut on this printer. Please advice . I'm using exclusive Prusa Slicer and I start like it.

After 2 months I noticed the magballs on my effector and carriage adapters were getting this black powder . I lube them with synthetic grease. The same reason why I changed them in the first place. I don't know why it is doing the same thing. I checked every screw and nut on this printer. Please advice . I'm using exclusive Prusa Slicer and I start like it.

|

Re: Kossel Delta xxl build project HELP November 10, 2020 09:03PM |

Registered: 10 years ago Posts: 651 |

Me too, I think it’s just not good design. Delrin on chrome steel, I dunno about long term wear at this point. I wonder if rod ends with steel balls in bronze cups would be better. I can’t say I have a real solution.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

Quote

alex773

I changed my rods with the new ones from Filastruder.

After 2 months I noticed the magballs on my effector and carriage adapters were getting this black powder . I lube them with synthetic grease. The same reason why I changed them in the first place. I don't know why it is doing the same thing. I checked every screw and nut on this printer. Please advice . I'm using exclusive Prusa Slicer and I start like it.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP November 10, 2020 10:44PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP November 10, 2020 10:49PM |

Registered: 10 years ago Posts: 651 |

There’s this thing.

https://713maker.com/rostock/duet-smart-effector-adaptor

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

https://713maker.com/rostock/duet-smart-effector-adaptor

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP November 10, 2020 11:01PM |

Registered: 10 years ago Posts: 651 |

I’m thinking about doing this. But with better rod ends. I’d want to take time to model it up so I can make sure I can still hit the full build plate.

https://www.thingiverse.com/thing:3603550

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

https://www.thingiverse.com/thing:3603550

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP November 11, 2020 01:18AM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP November 11, 2020 09:17AM |

Registered: 4 years ago Posts: 48 |

Quote

alex773

I changed my rods with the new ones from Filastruder.

After 2 months I noticed the magballs on my effector and carriage adapters were getting this black powder . I lube them with synthetic grease. The same reason why I changed them in the first place. I don't know why it is doing the same thing. I checked every screw and nut on this printer. Please advice . I'm using exclusive Prusa Slicer and I start like it.

The black powder may just be "polishing dust". Check and see if the rod leaves a black stain on a clean light coloured rag that you sprayed with WD40 and wiped the rods with. It won't be much black but will be an obvious streak. Also if you have belt drives on your printer you will find black powder below the pulleys.

|

Re: Kossel Delta xxl build project HELP November 11, 2020 09:50AM |

Registered: 10 years ago Posts: 651 |

Unfortunately I get it on the effector side. Upon inspection, it’s definitely the delrin rod ends wearing down.

Also as to losing print volume due to the fans. I wouldn’t use that fan setup. It’s just a ridiculous setup.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

Also as to losing print volume due to the fans. I wouldn’t use that fan setup. It’s just a ridiculous setup.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP November 11, 2020 02:17PM |

Registered: 5 years ago Posts: 347 |

The black powder may just be "polishing dust". Check and see if the rod leaves a black stain on a clean light coloured rag that you sprayed with WD40 and wiped the rods with. It won't be much black but will be an obvious streak. Also if you have belt drives on your printer you will find black powder below the pulleys.[/quote]

doug_scott Thank you for your input. I checked everything and what I noticed is that the magnet from the arm it ate the chrome off the balls . This is happening on the effector side on one single rod end. On the older set it was happening on 3 ends.

After blt3dp show me the 713maker Smart Effector adaptor I start thinking about replace the Haydn arms with the SeeMeCNC 350mm arms . The question is how I can fit the CeeMeCNC arms on my carriages , and if this setup is going to be better than the one I have. To replace the arms every 6 months because of this is going to be a very expensive printer to maintain.

Edited 2 time(s). Last edit at 11/11/2020 02:26PM by alex773.

doug_scott Thank you for your input. I checked everything and what I noticed is that the magnet from the arm it ate the chrome off the balls . This is happening on the effector side on one single rod end. On the older set it was happening on 3 ends.

After blt3dp show me the 713maker Smart Effector adaptor I start thinking about replace the Haydn arms with the SeeMeCNC 350mm arms . The question is how I can fit the CeeMeCNC arms on my carriages , and if this setup is going to be better than the one I have. To replace the arms every 6 months because of this is going to be a very expensive printer to maintain.

Edited 2 time(s). Last edit at 11/11/2020 02:26PM by alex773.

|

Re: Kossel Delta xxl build project HELP November 11, 2020 02:23PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP November 11, 2020 02:26PM |

Registered: 10 years ago Posts: 651 |

Yeah, it’s the delrin wearing down. I’ve cleaned all the rod ends using a q-tip and alcohol until the q-tip comes out clean. Made sure to lube them using the recommended line and it still happens. It eventually gets to the point where the magnet runs the ball. I’m looking at solutions also. I’d like to use a rod end that has a bronze insert. That should provide much better longevity. Though my concern is the angle of rotation. I hope not to limit the printable area. I’ll have to model it up.

Interesting about the fans.

Edited 1 time(s). Last edit at 11/11/2020 02:27PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

Interesting about the fans.

Edited 1 time(s). Last edit at 11/11/2020 02:27PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP November 11, 2020 04:45PM |

Registered: 5 years ago Posts: 347 |

|

Re: Kossel Delta xxl build project HELP November 11, 2020 07:48PM |

Registered: 10 years ago Posts: 651 |

They’re definitely of interest. I like the idea of the replacement parts being cheap. Maybe just stock some extra in the event they do get work down.

I’m also thinking about these.

https://www.yeahracing.com/aluminum-reversed-thread-m3-rod-ends-5pcs-black-ya-0572bk-00077947?search=YA-0572BK&description=true

I like that the body is aluminum so they’re light, the ball is steel, and there’s a brass/bronze sleeve. Plus they are already assembled. I might order a pack to see if there’s any play in them.

I was also looking at these, though I dunno if I like the ball directly touching the magnet, I think I’d prefer the brass to touch the magnet.

https://www.aliexpress.com/i/32898256074.html

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

I’m also thinking about these.

https://www.yeahracing.com/aluminum-reversed-thread-m3-rod-ends-5pcs-black-ya-0572bk-00077947?search=YA-0572BK&description=true

I like that the body is aluminum so they’re light, the ball is steel, and there’s a brass/bronze sleeve. Plus they are already assembled. I might order a pack to see if there’s any play in them.

I was also looking at these, though I dunno if I like the ball directly touching the magnet, I think I’d prefer the brass to touch the magnet.

https://www.aliexpress.com/i/32898256074.html

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Kossel Delta xxl build project HELP November 11, 2020 10:42PM |

Registered: 5 years ago Posts: 347 |

Sorry, only registered users may post in this forum.