Buying a dusty second-hand Delta. What to do first?

Posted by Ohmarinus

|

Buying a dusty second-hand Delta. What to do first? June 18, 2019 03:13PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi all,

So I've managed to buy this Delta printer (does anyone know what model/brand this is?) for €100,- including shipping. It comes without a PSU but has a heated bed, linear slides (which by themselves are already pretty expensive) and everything else. I have an ATX PSU that I have converted to work with a heated bed printer so everything is going to look neat and clean. This printer is going to be put in my living room so I can print stuff while I'm working downstairs, and also have something to show to visitors.

It looks like it has collected a good amount of dust so I reckon I'll need to perform some cleanup. The stepper motors look unlike any I've had until now. Might be good, no clue. They look beefy. All the stepper motors that I have use a screw that goes into a hole on the backside, but with these stepper motors the bolts can be seen from the side when they're fully tightened. The belts look good, the pulleys look like they might be T2.5 though, which I'm less fond of, but they can be replaced of course if they really are T2.5.

I will put an inductive proximity sensor on the head so it can use ABL which it currently doesn't have yet. No worries, I'll make a circuit to protect the boards endstop connection from 12v.

Looks like it still needs a print-cooling fan

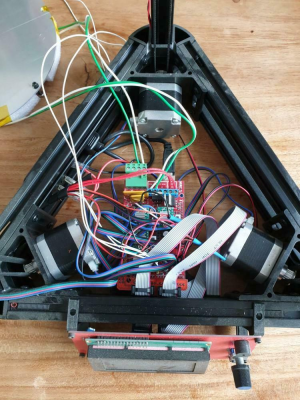

Messy wiring! Gonna put a fan on that for sure and redo all the cables, this just isn't right. Gonna make everything about as short as possible and tidy the place up!

Now, what are the first things to check on a second-hand Delta printer and what are the usual parts that get worn out? I am trying to prepare for this baby, it's been a long time dream of me to have such a printer so I'm pretty happy that I got a sweet deal on this one even though I'm not even sure what model this Delta is. It's obvious the printer needs some tweaking as the current owner just didn't care for it anymore, I think they put it together and never really bothered getting it to work in the first place. I'm not interested in precision (I've heard it's best in the center and worse around the edges), and I'm mainly in this Delta build for both the speed and just to have a non-cartesian printer. I now have a really good MendelMax 1.6 (with bowden setup) and a Prusa i3 MK2S (with custom upgrades) and have a CoreXY laser cutter selfbuilt/designed and a CoreXY pen plotter also selfbuilt and designed. So the basic stuff is doable for me. It's mostly that I'm just very new to Deltas and don't know much about the common issues and service regime for such machines.

Would be awesome to hear some tips from experienced Delta owners! Thanks in advance

Edited 2 time(s). Last edit at 06/18/2019 03:15PM by Ohmarinus.

http://www.marinusdebeer.nl/

So I've managed to buy this Delta printer (does anyone know what model/brand this is?) for €100,- including shipping. It comes without a PSU but has a heated bed, linear slides (which by themselves are already pretty expensive) and everything else. I have an ATX PSU that I have converted to work with a heated bed printer so everything is going to look neat and clean. This printer is going to be put in my living room so I can print stuff while I'm working downstairs, and also have something to show to visitors.

It looks like it has collected a good amount of dust so I reckon I'll need to perform some cleanup. The stepper motors look unlike any I've had until now. Might be good, no clue. They look beefy. All the stepper motors that I have use a screw that goes into a hole on the backside, but with these stepper motors the bolts can be seen from the side when they're fully tightened. The belts look good, the pulleys look like they might be T2.5 though, which I'm less fond of, but they can be replaced of course if they really are T2.5.

I will put an inductive proximity sensor on the head so it can use ABL which it currently doesn't have yet. No worries, I'll make a circuit to protect the boards endstop connection from 12v.

Looks like it still needs a print-cooling fan

Messy wiring! Gonna put a fan on that for sure and redo all the cables, this just isn't right. Gonna make everything about as short as possible and tidy the place up!

Now, what are the first things to check on a second-hand Delta printer and what are the usual parts that get worn out? I am trying to prepare for this baby, it's been a long time dream of me to have such a printer so I'm pretty happy that I got a sweet deal on this one even though I'm not even sure what model this Delta is. It's obvious the printer needs some tweaking as the current owner just didn't care for it anymore, I think they put it together and never really bothered getting it to work in the first place. I'm not interested in precision (I've heard it's best in the center and worse around the edges), and I'm mainly in this Delta build for both the speed and just to have a non-cartesian printer. I now have a really good MendelMax 1.6 (with bowden setup) and a Prusa i3 MK2S (with custom upgrades) and have a CoreXY laser cutter selfbuilt/designed and a CoreXY pen plotter also selfbuilt and designed. So the basic stuff is doable for me. It's mostly that I'm just very new to Deltas and don't know much about the common issues and service regime for such machines.

Would be awesome to hear some tips from experienced Delta owners! Thanks in advance

Edited 2 time(s). Last edit at 06/18/2019 03:15PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Buying a dusty second-hand Delta. What to do first? June 19, 2019 03:42PM |

Registered: 10 years ago Posts: 732 |

Looks like some Kossel version with RAMPS electronics. Diagonal arms seem too long. Belts too long as well. It will have serious ringing with high accelerations (1 G or more).

Make sure there is no play in it and that the frame is sturdy. Calibrate it numerically e.g. using these: It will work well enough after callibration at about 120 mm/s (definitely if you get rid of the LCD and set segments per second to about 80).

Or get duet electronics for it and ask dc4. You will get numerical calibration directly in the firmware. It makes things easier.

Make sure there is no play in it and that the frame is sturdy. Calibrate it numerically e.g. using these: It will work well enough after callibration at about 120 mm/s (definitely if you get rid of the LCD and set segments per second to about 80).

Or get duet electronics for it and ask dc4. You will get numerical calibration directly in the firmware. It makes things easier.

|

Re: Buying a dusty second-hand Delta. What to do first? June 19, 2019 04:05PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

hercek

Looks like some Kossel version with RAMPS electronics. Diagonal arms seem too long. Belts too long as well. It will have serious ringing with high accelerations (1 G or more).

Make sure there is no play in it and that the frame is sturdy. Calibrate it numerically e.g. using these: It will work well enough after callibration at about 120 mm/s (definitely if you get rid of the LCD and set segments per second to about 80).

Or get duet electronics for it and ask dc4. You will get numerical calibration directly in the firmware. It makes things easier.

Thanks a lot for your comment. I will try to get it working as-is first to check out the physical properties of the machine. I compared the Kossel with other machines and indeed also thought it was a Kossel. It has Ramps 1.4 and linear slides.

I've seen a lot of Kossels work perfectly fine with Ramps 1.4 and the Duet3D is definitely out of my budget for now

(it will cost me more than the printer itself, the low price point was for me the reason to buy it because I have too many spare parts laying around at home and I want to put it to use). Is there some kind of fixed length that the diagonal arms need to have? I might be able to shorten them. And are those belts really too long? Do you think it's a good idea to shorten the diagonal arms and after that also shorten the vertical extrusions (therefor shortening the belts as well)?

(it will cost me more than the printer itself, the low price point was for me the reason to buy it because I have too many spare parts laying around at home and I want to put it to use). Is there some kind of fixed length that the diagonal arms need to have? I might be able to shorten them. And are those belts really too long? Do you think it's a good idea to shorten the diagonal arms and after that also shorten the vertical extrusions (therefor shortening the belts as well)?About the firmware, is it correct that understand from your reaction that the RepetierFW is better to use on a Delta than Marlin?

I have been checking out this topic, it seems it's all over the place hahaha:

[reprap.org]

After looking around for 32-bit controllers I think the SKR V1.3 Smoothieboard (from Aliexpress) also looks interesting. I do not like the TFT touchscreen idea though. It's a cheap solution to upgrade to 32-bit. The Duet is not in my budget sadly. Combined with TMC2208 or TMC2130 drivers I'll be able to make it livingroom suitable. I'll have to check which I like more, UART vs SPI and what the Amps are.

Edited 4 time(s). Last edit at 06/19/2019 04:39PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Buying a dusty second-hand Delta. What to do first? June 19, 2019 05:17PM |

Registered: 10 years ago Posts: 732 |

Rule of thumb is that a diagonal rod should have angle of 20° or slightly more when the hotend is most far away from a tower. Don't bother with it. It is not a big deal. Consequences of longer arms are:Quote

Ohmarinus

Is there some kind of fixed length that the diagonal arms need to have?

- numerical calibration will be slightly less stable (it will have harder time to converge to the proper result)

- waste of printing height

- even badly calibrated printer will put the first layer better

Yes, if you want to print with high accelerations. If you want to print with 4000 mm/s² as most delta printer users do then don't bother with it. First make some prints with the printer as it is. Later, if you will mind the ringing at the accelerations you want to use then start to think about what to do with the belts.Quote

Ohmarinus

And are those belts really too long?

I use Repetier for ... posslibly last 3 years???Quote

Ohmarinus

About the firmware, is it correct that understand from your reaction that the RepetierFW is better to use on a Delta than Marlin?

I switched from Marlin to Repetier since Repetier was quicker for small printers (i.e. printers with all dimensions smaller than 65535 microsteps). Maybe Marlin is better now but I did not try it for many years. Maybe Repetier is still quicker even now.

I do not have enough experience with 32 bit boards to give any reasonable opinion except:

- 32 bit boards are quicker and you will not need to be so careful about configuration which does not waste MCU cycles.

- Some 32 bit board support numerical calibration directly in the firmware (at least duet + reprap fw).

|

Re: Buying a dusty second-hand Delta. What to do first? June 20, 2019 04:36AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

hercek

Rule of thumb is that a diagonal rod should have angle of 20° or slightly more when the hotend is most far away from a tower. Don't bother with it. It is not a big deal. Consequences of longer arms are:Quote

Ohmarinus

Is there some kind of fixed length that the diagonal arms need to have?

- numerical calibration will be slightly less stable (it will have harder time to converge to the proper result)

- waste of printing height

- even badly calibrated printer will put the first layer better

Yes, if you want to print with high accelerations. If you want to print with 4000 mm/s² as most delta printer users do then don't bother with it. First make some prints with the printer as it is. Later, if you will mind the ringing at the accelerations you want to use then start to think about what to do with the belts.Quote

Ohmarinus

And are those belts really too long?

I use Repetier for ... posslibly last 3 years???Quote

Ohmarinus

About the firmware, is it correct that understand from your reaction that the RepetierFW is better to use on a Delta than Marlin?

I switched from Marlin to Repetier since Repetier was quicker for small printers (i.e. printers with all dimensions smaller than 65535 microsteps). Maybe Marlin is better now but I did not try it for many years. Maybe Repetier is still quicker even now.

I do not have enough experience with 32 bit boards to give any reasonable opinion except:

- 32 bit boards are quicker and you will not need to be so careful about configuration which does not waste MCU cycles.

- Some 32 bit board support numerical calibration directly in the firmware (at least duet + reprap fw).

Ahhh now it becomes more clear, thanks. I thought I got ripped of with a fantasy machine that could never work when you spoke about the length of the diagonal rods. I have just received the machine and honestly I do not think they ever got it to work.. I inspected the extruder and it is clear that the hobbed pulley has completely eaten the filament they tried to print with. So I'll fix the extrusion system first. Then I'll tension the belts. The previous owner clearly had zero clue what they were doing. Luckily it's not a lot of work for me to get this up and running. I'm expecting the hotend to be clogged and I don't know what nozzle size they have. The owner has not responded anymore to my questions after shipping the product. I have found out through some reverse googling that the previous owner had sent me this printer from his private account, but that the printer was actually a demo model for a webshop that the guy owns. He didn't want to sell this machine through his store as not to lose face value. They sell 3D-printer parts but they clearly have no clue about how those printers actually work. The machine parts all look pretty good and well designed but there is literally not a single part installed as it should be. This is where my luck comes in. None of the bolts are overtightened to everything is basically as new. The heated bed is aluminium (hurray inductive proximity sensor!) with countersunk holes (another hurray) and most of the machine parts are either aluminium or injection molded parts which all seem to be pretty well made judging by the mold lines.

This afternoon I'll strip all the electronics and I'll lay it all out on my workbench starting fresh with preparing the frame being triangually square ^_^ and I'll check it the diagonal rods can be shortened. If not, maybe I'll have to get a new set, which would be a shame because the individual parts look pretty well made.

I'll update some this afternoon as I now have to go and work two jobs. Thanks for your time so far. I will first get it to run with the supplied Ramps and decide if I'm content with how it's running. If I notice any slowdowns I'll consider getting a 32-bit board off of Aliexpress with TMC2208 or 2130 driver since I have gotten those on my other printer and they seem to run incredibly well.

http://www.marinusdebeer.nl/

|

Re: Buying a dusty second-hand Delta. What to do first? June 20, 2019 04:46AM |

Registered: 10 years ago Posts: 732 |

|

Re: Buying a dusty second-hand Delta. What to do first? June 20, 2019 08:03AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Ohmarinus

The Duet is not in my budget sadly. Combined with TMC2208 or TMC2130 drivers I'll be able to make it livingroom suitable. I'll have to check which I like more, UART vs SPI and what the Amps are.

Don't forget that the Duets include the Trinamic drivers, but for other 32-bit boards they will cost you extra. A Duet Maestro may not cost you much more than a cheap 32-bit board plus 4 or 5 good drivers; and unlike the other solutions it will give you a built-in web interface, resume-after-power fail option, configuration via the web interface (no need to rebuild the firmware to make changes), built-in least-squares auito calibration, etc.

Edited 1 time(s). Last edit at 06/20/2019 08:04AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Buying a dusty second-hand Delta. What to do first? June 21, 2019 12:44PM |

Registered: 7 years ago Posts: 619 |

Quote

hercek

Rule of thumb is that a diagonal rod should have angle of 20° or slightly more when the hotend is most far away from a tower. Don't bother with it. It is not a big deal. Consequences of longer arms are:Quote

Ohmarinus

Is there some kind of fixed length that the diagonal arms need to have?

- numerical calibration will be slightly less stable (it will have harder time to converge to the proper result)

- waste of printing height

- even badly calibrated printer will put the first layer better

Yes, if you want to print with high accelerations. If you want to print with 4000 mm/s² as most delta printer users do then don't bother with it. First make some prints with the printer as it is. Later, if you will mind the ringing at the accelerations you want to use then start to think about what to do with the belts.Quote

Ohmarinus

And are those belts really too long?

I use Repetier for ... posslibly last 3 years???Quote

Ohmarinus

About the firmware, is it correct that understand from your reaction that the RepetierFW is better to use on a Delta than Marlin?

I switched from Marlin to Repetier since Repetier was quicker for small printers (i.e. printers with all dimensions smaller than 65535 microsteps). Maybe Marlin is better now but I did not try it for many years. Maybe Repetier is still quicker even now.

I do not have enough experience with 32 bit boards to give any reasonable opinion except:

- 32 bit boards are quicker and you will not need to be so careful about configuration which does not waste MCU cycles.

- Some 32 bit board support numerical calibration directly in the firmware (at least duet + reprap fw).

20 degrees angle from the tower or the top?

I collect Delta rules of thumb because these things are so hard to calibrate.

I discovered that the end effector radius from the nozzle to the rod connection points have to be a certain percentage of the rod length or Delta has serious speed/positioning issues. I don't have my notes in front of me so I don't remember what that is. I discovered this when I did my custom design of a "micro" Kossel with a 70x70x90 mm build volume for a portable table top figure printer.

thanks,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Buying a dusty second-hand Delta. What to do first? June 21, 2019 07:46PM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, I have ordered an SKR v1.3 as a tryout board anyway. Let's see where this will bring us. I'll hope to start working on it asap but it's now going to be a summer-death trap in my country for the next week so it might take a while.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: Buying a dusty second-hand Delta. What to do first? June 23, 2019 01:52PM |

Registered: 10 years ago Posts: 732 |

@ldc60:

20° between diagonal rod and the heat bed when the effector is furthest from the corresponding tower.

Only these rules come to my mind when deciding effector (platform) radius:

20° between diagonal rod and the heat bed when the effector is furthest from the corresponding tower.

Only these rules come to my mind when deciding effector (platform) radius:

- The bigger it is the more horizontal space is wasted.

- Bigger platform allows bigger diagonal rod separation which minimizes bad consequences of the errors in diagonal rod length and ball joint positions. Put diagonal rods corresponding to one tower as far away as your platform allows.

- It is good when planes containing diagonal rods of one tower contain the hotend tip because the intersection point of these 3 planes defines the point around which hotend rotates when there is play in ball joints. That position minimizes the errors. But notice that the position of the point of the rotation relative to the effector changes with XY position. Therefore you cannot place it perfectly.

|

Re: Buying a dusty second-hand Delta. What to do first? June 24, 2019 12:51PM |

Registered: 7 years ago Posts: 619 |

"It is good when planes containing diagonal rods of one tower contain the hotend tip because the intersection point of these 3 planes defines the point around which hotend rotates when there is play in ball joints. That position minimizes the errors. But notice that the position of the point of the rotation relative to the effector changes with XY position. Therefore you cannot place it perfectly."Quote

hercek

@ldc60:

20° between diagonal rod and the heat bed when the effector is furthest from the corresponding tower.

Only these rules come to my mind when deciding effector (platform) radius:

- The bigger it is the more horizontal space is wasted.

- Bigger platform allows bigger diagonal rod separation which minimizes bad consequences of the errors in diagonal rod length and ball joint positions. Put diagonal rods corresponding to one tower as far away as your platform allows.

- It is good when planes containing diagonal rods of one tower contain the hotend tip because the intersection point of these 3 planes defines the point around which hotend rotates when there is play in ball joints. That position minimizes the errors. But notice that the position of the point of the rotation relative to the effector changes with XY position. Therefore you cannot place it perfectly.

Not sure what you are describing here. Can you elaborate?

Thanks,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Buying a dusty second-hand Delta. What to do first? June 24, 2019 04:31PM |

Registered: 10 years ago Posts: 732 |

|

Re: Buying a dusty second-hand Delta. What to do first? November 14, 2019 06:42PM |

Admin Registered: 11 years ago Posts: 3,096 |

Ohwell, other than having the machine dying on me just now with a weird error (bed maxtemp failsafe on booting while the machine is cold), I got it to work pretty well.

Just a teaser:

[www.youtube.com]

I made a mistake with the probe-Z offset, that's why the first layer was garbage and the piece came off near the end of the print. But hey, a great maiden print! Especially for a Delta.

Especially for a Delta.

http://www.marinusdebeer.nl/

Just a teaser:

[www.youtube.com]

I made a mistake with the probe-Z offset, that's why the first layer was garbage and the piece came off near the end of the print. But hey, a great maiden print!

Especially for a Delta.

Especially for a Delta.http://www.marinusdebeer.nl/

|

Re: Buying a dusty second-hand Delta. What to do first? November 16, 2019 09:21AM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, the second run of the printer has been a great success!

[www.youtube.com]

After adjusting the Z-height for the first layer, it is now perfect. In the video it was now a little too close. I have printer towers of 100mm that came out as 100,06mm ('perfect' imo).

Right now I'm printing a bear model for a girl I love and I must say this printer prints the best out of any printer I've ever had. I'm pretty sure this has to do with it being the 5th machine I'm building in my life (Air 2 > MendelMax 1.5 > Homemade Laser CoreXY > Pen Plotter CoreXY > Delta). The machine isn't perfect yet, I still have to fix the frame here and there, but even with these temporary fasteners, the machine is probably performing even better than the Ultimaker 2's we have at work. All push-fit parts I've printed today click together in one try and I can print without a brim!

For the bear I'm printing now I found back an old spool of black PLA filament which had become super brittle because it's been laying in the open air for four or five years in a humid room. So I put it in the oven for a couple of hours at around 60~70ºC and now it's printing like the best new black PLA filament I've ever had. This is really encouraging me to try and use the other filament spools I still have laying around so I'll dump those in the oven as well today and let them bake together.

I will try to do a write-up on the machine and how I have turned the shittiest Kossel known to man into the best printer I've ever owned if anyone is interested in the build process.

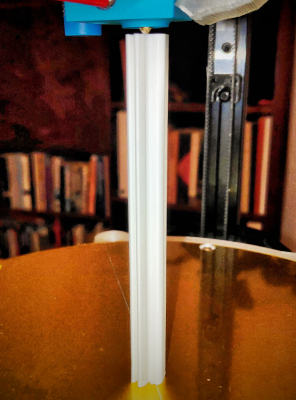

Here, a tower that I've printer as a test in vase mode, 100mm high, layers look perfect and are super strong, especially for a vase mode object.

This is the machine right now, the only thing I'm going to add is LED lights to illuminate the build platform and probably try to find a Dell DA-2 adapter to make the machine completely quiet.

http://www.marinusdebeer.nl/

[www.youtube.com]

After adjusting the Z-height for the first layer, it is now perfect. In the video it was now a little too close. I have printer towers of 100mm that came out as 100,06mm ('perfect' imo).

Right now I'm printing a bear model for a girl I love and I must say this printer prints the best out of any printer I've ever had. I'm pretty sure this has to do with it being the 5th machine I'm building in my life (Air 2 > MendelMax 1.5 > Homemade Laser CoreXY > Pen Plotter CoreXY > Delta). The machine isn't perfect yet, I still have to fix the frame here and there, but even with these temporary fasteners, the machine is probably performing even better than the Ultimaker 2's we have at work. All push-fit parts I've printed today click together in one try and I can print without a brim!

For the bear I'm printing now I found back an old spool of black PLA filament which had become super brittle because it's been laying in the open air for four or five years in a humid room. So I put it in the oven for a couple of hours at around 60~70ºC and now it's printing like the best new black PLA filament I've ever had. This is really encouraging me to try and use the other filament spools I still have laying around so I'll dump those in the oven as well today and let them bake together.

I will try to do a write-up on the machine and how I have turned the shittiest Kossel known to man into the best printer I've ever owned if anyone is interested in the build process.

Here, a tower that I've printer as a test in vase mode, 100mm high, layers look perfect and are super strong, especially for a vase mode object.

This is the machine right now, the only thing I'm going to add is LED lights to illuminate the build platform and probably try to find a Dell DA-2 adapter to make the machine completely quiet.

http://www.marinusdebeer.nl/

Sorry, only registered users may post in this forum.