Delta printer ball joints, let's talk!

Posted by 3Dpassion

|

Delta printer ball joints, let's talk! November 04, 2019 04:15AM |

Registered: 5 years ago Posts: 11 |

Hello everyone, I am finally down to develop my own Delta machine, which is already completed in CAD and I am about to get that all machined on a factory, BUT, but.. I am a little lost on ball joint models and to be honest I have never used any of those and hoping someone with more hands on experience can shed some light on this topic.

What would be the best choice for ball joint regardless of price? Things to consider:

1) minimum possible weight

2) close to zero of backlash or play

3) minimum friction

4) rigidity (should not fall off easily as some magnetic joint can).

5) it will be a high speed machine (300-800mm/s), so rigidity is a factor again

Would love to hear any thoughts on this. This machine is planned for market possibly if I end up finishing up with success and I will open-source the drawings once finished.

What would be the best choice for ball joint regardless of price? Things to consider:

1) minimum possible weight

2) close to zero of backlash or play

3) minimum friction

4) rigidity (should not fall off easily as some magnetic joint can).

5) it will be a high speed machine (300-800mm/s), so rigidity is a factor again

Would love to hear any thoughts on this. This machine is planned for market possibly if I end up finishing up with success and I will open-source the drawings once finished.

|

Re: Delta printer ball joints, let's talk! November 04, 2019 06:49AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Delta printer ball joints, let's talk! November 04, 2019 07:02AM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Delta printer ball joints, let's talk! November 04, 2019 11:05PM |

Registered: 4 years ago Posts: 5 |

I am no expert, but I have been tinkering with joints for a while.

My first machine (2015) was a Geeeeeeeeetech G2 a mini delta that used brass/steel rose joints. They had play, and not a great range of motion. I used it to build a 400mm x 1000mm big guy.

On the big guy I tried magnets, but I never could get them to work. the machine would shake them apart. probably a bad design on my part, I've seen a lot of good magnets available now.

I tried printed parts such as Johann's originals.. Range of motion was good, but they were squeaky.

I modified Johann's to use bearings. Less squeak, but I never was happy with the design.

I tried a different heim/rose joint, better range of motion but worse play.

I've bought arms and balljoints from SeeMeCNC for the latest build. Mechanically it looks sound, I have to finish the wiring before I will know for sure.

My first machine (2015) was a Geeeeeeeeetech G2 a mini delta that used brass/steel rose joints. They had play, and not a great range of motion. I used it to build a 400mm x 1000mm big guy.

On the big guy I tried magnets, but I never could get them to work. the machine would shake them apart. probably a bad design on my part, I've seen a lot of good magnets available now.

I tried printed parts such as Johann's originals.. Range of motion was good, but they were squeaky.

I modified Johann's to use bearings. Less squeak, but I never was happy with the design.

I tried a different heim/rose joint, better range of motion but worse play.

I've bought arms and balljoints from SeeMeCNC for the latest build. Mechanically it looks sound, I have to finish the wiring before I will know for sure.

|

Re: Delta printer ball joints, let's talk! November 04, 2019 11:19PM |

Registered: 5 years ago Posts: 11 |

Sorry guys for the wrong section, I didn't see the dedicated delta section when I posted.

Thanks a lot for reply. Heard good stuff about SeeMeeCNC ones, but they are very heavy for my purpose also. Magnetic ones, I haven't tried, however it looks like there will be a lot of friction on most designs, which is also not optimal. I can design and machine my own joints as the last option (would rather buy tbh). Also was looking for all options online; composite joint would be the best on paper, but have not seen any tests for that yet, so that is unknown territory pretty much too. Ordering all metal parts for my new Delta today, super excited!

Thanks a lot for reply. Heard good stuff about SeeMeeCNC ones, but they are very heavy for my purpose also. Magnetic ones, I haven't tried, however it looks like there will be a lot of friction on most designs, which is also not optimal. I can design and machine my own joints as the last option (would rather buy tbh). Also was looking for all options online; composite joint would be the best on paper, but have not seen any tests for that yet, so that is unknown territory pretty much too. Ordering all metal parts for my new Delta today, super excited!

|

Re: Delta printer ball joints, let's talk! November 05, 2019 01:24PM |

Registered: 4 years ago Posts: 5 |

"they are very heavy for my purpose"

Ah, I think you saw the steel ones. They have plastic, this is what I bought from SeemeCNC:

[www.seemecnc.com]

Super light, far lighter than magnets.

I found a set of 360 mm arms (my delta is big) but there used to be a few people offering aftermarket cups that fit these balls.

Ah, I think you saw the steel ones. They have plastic, this is what I bought from SeemeCNC:

[www.seemecnc.com]

Super light, far lighter than magnets.

I found a set of 360 mm arms (my delta is big) but there used to be a few people offering aftermarket cups that fit these balls.

|

Re: Delta printer ball joints, let's talk! November 05, 2019 04:29PM |

Registered: 5 years ago Posts: 33 |

|

Re: Delta printer ball joints, let's talk! November 05, 2019 04:31PM |

Registered: 5 years ago Posts: 11 |

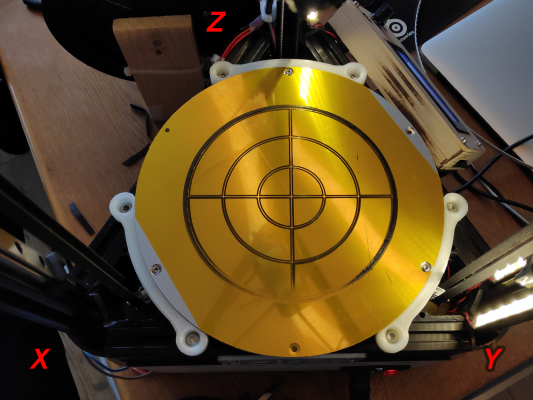

Yes, didn't see these. I only saw the steel ones. Interesting. I wonder how accurate these are. Gonna research this option for sure, thanks for the hint! My delta has hybrid circle-triangle bed shape with glass top and the circle is 270 and the triangle part has a max dimension of 310 and I plan to use 300mm arms for that. Ran simulation in my cad and seems to work nice. Ordered all sheet metal and base aluminum parts yesterday. Can't wait for them to be produced and arrive!

|

Re: Delta printer ball joints, let's talk! November 06, 2019 06:07AM |

Registered: 5 years ago Posts: 10 |

With regards to the plastic SMCNC joints, I can offer my experiences, as I owned a Rostock Max V3 for about 2 years until I made my own design delta. In my experience the backlash is very very minimal if anything at all. Friction was low as and they offer a good range of motion. Their main disadvantage that I have found is rigidity. The transition from the ball end to to where the screws go through is thin-ish, and thus, sensitive to flexing. I believe that is why they moved to a metal alternative.

Hope this helps

-Nxt

Hope this helps

-Nxt

|

Re: Delta printer ball joints, let's talk! November 07, 2019 11:03PM |

Registered: 5 years ago Posts: 11 |

I see. Yeah, I checked their geometry. While seems alright, it is definitely not high end and I am trying to find a super lightweight solution, hence need to stick to plastic alternatives, have been checking out IGUS options for that, but their customer support is pretty bad, but they are the only ones who is making this type of ball joints in plastic.

|

Re: Delta printer ball joints, let's talk! November 08, 2019 01:37AM |

Registered: 10 years ago Posts: 14,672 |

I started with Traxxas joints, which were OK except that nearly half of them had some play. So for anyone else using Traxxas I suggest buying twice as many as you need and selecting the best ones.

I then tried Igus joints. The problem was that they didn't have enough range of movement. The screw fittings next to the joint foul the housing. I made some tapered spacers to mitigate that, but they still didn't have enough range.

I switched to magnetic joints by Haydn Huntley (the ones with the machined Delrin ends) and they are brilliant. The combination of them and the Smart Effector have got my delta auto calibrating to a deviation of 25 microns. They are strong enough for the effector to lift a 1.5kg water bottle.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I then tried Igus joints. The problem was that they didn't have enough range of movement. The screw fittings next to the joint foul the housing. I made some tapered spacers to mitigate that, but they still didn't have enough range.

I switched to magnetic joints by Haydn Huntley (the ones with the machined Delrin ends) and they are brilliant. The combination of them and the Smart Effector have got my delta auto calibrating to a deviation of 25 microns. They are strong enough for the effector to lift a 1.5kg water bottle.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta printer ball joints, let's talk! November 08, 2019 06:09PM |

Registered: 10 years ago Posts: 732 |

I bought a lot of these:

[mpjet.com]

All of them were without play. They wear out eventually and need to replaced to keep them play free. I replaced mine after about 3 years. I do not print much. I may have printed about 30 kg of ABS in that time.

Edit: A different link.

Edit2: You will need a screw with conical head for it. Otherwise it will not have enough range.

Edited 2 time(s). Last edit at 11/08/2019 06:22PM by hercek.

[mpjet.com]

All of them were without play. They wear out eventually and need to replaced to keep them play free. I replaced mine after about 3 years. I do not print much. I may have printed about 30 kg of ABS in that time.

Edit: A different link.

Edit2: You will need a screw with conical head for it. Otherwise it will not have enough range.

Edited 2 time(s). Last edit at 11/08/2019 06:22PM by hercek.

|

Re: Delta printer ball joints, let's talk! November 15, 2019 06:09PM |

Registered: 5 years ago Posts: 11 |

Thank you for advice guys. I am a bit hesitant about magnetic only because of their weight. The assembly is quite heavy (well, relatively). And I will also be targeting 10000 Acceleration and very high speeds (600ish), which may become a problem with magnets.

As far as IGUS goes, do you think different orientation can solve angular limit issue? Say if I position them at ideal center angle instead of vertically. And how was the play by the way? I guess I can buy some to test them out then, but only if the play is acceptable. I don't want to sacrifice accuracy. Worst case scenario is to design and machine my own joints, but I'd really prefer to buy them off the market instead to save time.

As far as IGUS goes, do you think different orientation can solve angular limit issue? Say if I position them at ideal center angle instead of vertically. And how was the play by the way? I guess I can buy some to test them out then, but only if the play is acceptable. I don't want to sacrifice accuracy. Worst case scenario is to design and machine my own joints, but I'd really prefer to buy them off the market instead to save time.

|

Re: Delta printer ball joints, let's talk! November 16, 2019 02:23PM |

Registered: 10 years ago Posts: 732 |

Just the MP-Jet joints and use screws with conical head. Looks like you have access to a lathe when you consider making your own joints. If so then get simple M3 screws and make the head conical. You will want to make also M3 nuts with one side conical. That allows for easy mounting and enough range. The joints are super light and strong when compared to any magnetic joints.

|

Re: Delta printer ball joints, let's talk! December 03, 2019 10:11PM |

Registered: 5 years ago Posts: 11 |

|

Re: Delta printer ball joints, let's talk! December 05, 2019 02:02AM |

Registered: 9 years ago Posts: 483 |

|

Re: Delta printer ball joints, let's talk! December 05, 2019 05:06AM |

Registered: 10 years ago Posts: 732 |

Magnets give zero backslash only when they are strong enough or your accelerations are low enough. Ball joints give you zero backslash regardless of accelerations if you are willing to buy good ones and replace them over time. Choose your poison!

It depends on what accelerations you want to print with.

It depends on what accelerations you want to print with.

|

Re: Delta printer ball joints, let's talk! December 05, 2019 06:19AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

hercek

Magnets give zero backslash only when they are strong enough or your accelerations are low enough. Ball joints give you zero backslash regardless of accelerations if you are willing to buy good ones and replace them over time. Choose your poison!

It depends on what accelerations you want to print with.

I'm definitely moving away from magnets, ordered new ball joints and will mount them with round stock instead of bolts to make sure there is no play in the connections.

Magnets have given me a lot of headache the past month and even though I love the technique and think it's very elegant, ball joints just work and for example don't pop off when your hotend hits a little piece of plastic. Now of course, this shouldn't happen often, but sometimes slicing software makes a tiny mistake or freak error where it deposits plastic in the wrong place. Having an error killed my current heated bed surface as one magnet popped off and then the hotend dug into the kapton tape and scratched the aluminium heated bed.

Still waiting on the ball joint rods I ordered but can surely say that it will be much more reliable, even though it's less practical.

http://www.marinusdebeer.nl/

|

Re: Delta printer ball joints, let's talk! December 05, 2019 02:25PM |

Registered: 10 years ago Posts: 732 |

Hitting a piece of plastics is common when one prints bigger parts with ABS either without a heat chamber or with low temperature heat chamber. Not sure how much ball joints help here. They will not disconnect but motors can skip some steps and that may lead to more head crashes to the printed part possibly also the bed or towers. But hitting towers or bed is rare. Most of the time the layers get shifted at the height when head collided with bent plastic part (which de-laminated from bed). The print is kaput but otherwise no big deal.

|

Re: Delta printer ball joints, let's talk! December 06, 2019 05:48AM |

Registered: 6 years ago Posts: 10 |

I've had the same problems with magnetic joints. I thought it was just me. I've 'fixed' the problem using long springs to attach each pair of rods to the effector. The extra holding force helps.

But with fast printing the plastic deposition is sometimes uneven which leads to bumps. Those get evened out with time. But with magnetic joints the effector comes loose and the print is kaput.

I've ordered these fisheye rods: [www.aliexpress.com] for my Anycubic Kossel Mini. Are those joints any better than the usual plastic Traxxas joints? The stock joints had a lot of play after ~1 year of printing.

But with fast printing the plastic deposition is sometimes uneven which leads to bumps. Those get evened out with time. But with magnetic joints the effector comes loose and the print is kaput.

I've ordered these fisheye rods: [www.aliexpress.com] for my Anycubic Kossel Mini. Are those joints any better than the usual plastic Traxxas joints? The stock joints had a lot of play after ~1 year of printing.

|

Re: Delta printer ball joints, let's talk! December 06, 2019 07:32AM |

Registered: 10 years ago Posts: 732 |

Ach, the metal ball joints (steel ball and brass sleeve) will last for ever. And will not have any play if you bought a good quality ones. The problem is that they do not have the weight advantage over magnetic joints.

I do not have experience with the ones you linked to. But metal ball joints are very reliable and long lasting generally.

Edited 1 time(s). Last edit at 12/06/2019 08:46AM by hercek.

I do not have experience with the ones you linked to. But metal ball joints are very reliable and long lasting generally.

Edited 1 time(s). Last edit at 12/06/2019 08:46AM by hercek.

|

Re: Delta printer ball joints, let's talk! December 06, 2019 10:51AM |

Registered: 6 years ago Posts: 10 |

|

Re: Delta printer ball joints, let's talk! December 07, 2019 02:33AM |

Registered: 5 years ago Posts: 11 |

Hi Guys. A little update from me:

Purchased standard plastic ball joints (https://www.amazon.com/gp/product/B07Q2XLP42/) in M3 size. They are tiny, but also pretty strong. I only wish they made injection plastic part out of PTFE and not ABS, would help a lot. I may consider manufacturing those with PTFE if community will show any demand. And yeah, they are super light, and so far I feel zero backlash in actual joint (there is indeed a huge play in the screw, no way I will connect it like that ). When it comes to weight, pone joint maybe not such a big deal, but we have to remember that there is 6 joint. So any weight difference x6. And for the Machine that I am designing it will be crucial. I purchased all frame two days ago to be machined, super excited to get my hands on it when it arrives. Came out super expensive, but not more expensive than market printer of this size would cost me... which is near $1500 anyways. So I am happy.

). When it comes to weight, pone joint maybe not such a big deal, but we have to remember that there is 6 joint. So any weight difference x6. And for the Machine that I am designing it will be crucial. I purchased all frame two days ago to be machined, super excited to get my hands on it when it arrives. Came out super expensive, but not more expensive than market printer of this size would cost me... which is near $1500 anyways. So I am happy.

I have seen these metal ones and considered them too, but they are heavy for my application. If there is a little chance to reduce weight, I do that They definitely have longevity advantage. I wonder what it will take me to injection mold them of POM or PTFE, gonna check that out. IGUS also sells some models, but they are not available on public market, and hard to get hands on, so I went for more available options.

They definitely have longevity advantage. I wonder what it will take me to injection mold them of POM or PTFE, gonna check that out. IGUS also sells some models, but they are not available on public market, and hard to get hands on, so I went for more available options.

And yeah, we all print at different settings, so what works for one, may not work for other. I too got excited about magnetic joints, until I realized that they are significantly heavier than any other solution.

Also, what you have to consider is not only effector side joint, but also rail carriage side too. That carriage will need to move significantly faster than your effector, so you want that as light as possible too. That all of course if you want to print fast. But why else to have delta? ))

))

Purchased standard plastic ball joints (https://www.amazon.com/gp/product/B07Q2XLP42/) in M3 size. They are tiny, but also pretty strong. I only wish they made injection plastic part out of PTFE and not ABS, would help a lot. I may consider manufacturing those with PTFE if community will show any demand. And yeah, they are super light, and so far I feel zero backlash in actual joint (there is indeed a huge play in the screw, no way I will connect it like that

). When it comes to weight, pone joint maybe not such a big deal, but we have to remember that there is 6 joint. So any weight difference x6. And for the Machine that I am designing it will be crucial. I purchased all frame two days ago to be machined, super excited to get my hands on it when it arrives. Came out super expensive, but not more expensive than market printer of this size would cost me... which is near $1500 anyways. So I am happy.

). When it comes to weight, pone joint maybe not such a big deal, but we have to remember that there is 6 joint. So any weight difference x6. And for the Machine that I am designing it will be crucial. I purchased all frame two days ago to be machined, super excited to get my hands on it when it arrives. Came out super expensive, but not more expensive than market printer of this size would cost me... which is near $1500 anyways. So I am happy. I have seen these metal ones and considered them too, but they are heavy for my application. If there is a little chance to reduce weight, I do that

They definitely have longevity advantage. I wonder what it will take me to injection mold them of POM or PTFE, gonna check that out. IGUS also sells some models, but they are not available on public market, and hard to get hands on, so I went for more available options.

They definitely have longevity advantage. I wonder what it will take me to injection mold them of POM or PTFE, gonna check that out. IGUS also sells some models, but they are not available on public market, and hard to get hands on, so I went for more available options. And yeah, we all print at different settings, so what works for one, may not work for other. I too got excited about magnetic joints, until I realized that they are significantly heavier than any other solution.

Also, what you have to consider is not only effector side joint, but also rail carriage side too. That carriage will need to move significantly faster than your effector, so you want that as light as possible too. That all of course if you want to print fast. But why else to have delta?

))

))

|

Re: Delta printer ball joints, let's talk! December 07, 2019 02:15PM |

Registered: 9 years ago Posts: 483 |

Quote

hercek

Magnets give zero backslash only when they are strong enough or your accelerations are low enough. Ball joints give you zero backslash regardless of accelerations if you are willing to buy good ones and replace them over time. Choose your poison!

It depends on what accelerations you want to print with.

The springs can provide more than enough strength.

|

Re: Delta printer ball joints, let's talk! December 09, 2019 05:04AM |

Registered: 6 years ago Posts: 10 |

Thanks for your update.Quote

I wonder what it will take me to injection mold them of POM or PTFE

I thought about 3d printing the plastic cage. Don't laugh

I have some POM at home. This stuff is difficult to print and dangerous, but sippery. The inner ball needs to be pressed into the cage anyways, so inaccuracies might be evened out.

I have some POM at home. This stuff is difficult to print and dangerous, but sippery. The inner ball needs to be pressed into the cage anyways, so inaccuracies might be evened out.What do you guys think?

|

Re: Delta printer ball joints, let's talk! December 10, 2019 04:12AM |

Registered: 5 years ago Posts: 11 |

3D Printing the cage isn't worth it imo. Will be crazy inaccurate. As a side note, I received those plastic joints on Friday and I am not sure what's the bad feedback is about, they are actually extremely solid and there is definitely zero backlash in them, super light too. With that said, M3 screw obviously will not secure that joint correctly, it needs a proper install, probably with M2 screw and a spacer instead to make it all tight.

|

Re: Delta printer ball joints, let's talk! December 10, 2019 06:21AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

3Dpassion

3D Printing the cage isn't worth it imo. Will be crazy inaccurate. As a side note, I received those plastic joints on Friday and I am not sure what's the bad feedback is about, they are actually extremely solid and there is definitely zero backlash in them, super light too. With that said, M3 screw obviously will not secure that joint correctly, it needs a proper install, probably with M2 screw and a spacer instead to make it all tight.

Exactly, I never quite understood why these joints are delivered with M3 bolts in the first place. As a company you make wonderfully designed ball joints and then you shoot yourself in the foot by selling it with a totally unsuitable set of bolts. I think you can get away with wrapping a bit of PTFE foil around the M3 bolt to make it so that the balljoint sits tight around the bolt though.

Today or tomorrow I'll probably receive my replacement as well for my current magnetic system and my cat is moving into a new home so I'll have to hobby some to take my mind off of it anyway. When I have the parts I'll try out some methods of fastening and post them here.

http://www.marinusdebeer.nl/

|

Re: Delta printer ball joints, let's talk! December 11, 2019 05:07PM |

Registered: 5 years ago Posts: 11 |

Once I finish my delta, I am definitely going to make and throw some of the good joints to amazon, probably aluminum version. I will machine the special metal part instead of M3 screw with press fit in there and a special top that will prevent it from interfering with the ball, along with special stiffest CF tubes. I am already testing wrapped CF vs Extruded for stiffness. The reason why they are selling it so horribly with M3 screws, is because that is a market part from RC car hobby, and has zero to do with 3D Printers. Nobody actually designed a proper 3D printing joint yet.

Edited 1 time(s). Last edit at 12/11/2019 05:09PM by 3Dpassion.

Edited 1 time(s). Last edit at 12/11/2019 05:09PM by 3Dpassion.

|

Re: Delta printer ball joints, let's talk! December 18, 2019 04:40PM |

Admin Registered: 11 years ago Posts: 3,096 |

Suddenly I had the idea of a hybrid balljoint/magnet joint system. Has this been done before?

The magnets will only be on the effector and the rods are fixes to the axes by ball joints for example.

http://www.marinusdebeer.nl/

The magnets will only be on the effector and the rods are fixes to the axes by ball joints for example.

http://www.marinusdebeer.nl/

|

Re: Delta printer ball joints, let's talk! December 24, 2019 06:43AM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, I have converted the machine to use ball joints and fixed the joints by adding a piece of thin plastic straw around the M3 bolts that fix the joints to the carts and effector.

Works great!

The only issue I'm having is that the test cube I'm printing is 0.1mm too big in one direction and 0.1mm too small in the other. (X to Y tower dimension is a little too big and to and from the Z-tower the dimension is about 0.08mm too small).

How would one go about solving this? The arms are exactly equally lengths and the deviation with G33 was 0.008

I don't understand how to correctly use G29. Should you 'activate' G29 before each print by adding a special command in the start script of each gcode file? And what's the best guide I should read to learn how to correctly use G29 on a Delta? I believe doing manual calibration should give better results than G33 and a piezo or FSR.

Moving footage:

[youtu.be]

Slow motion:

[youtu.be]

Edited 5 time(s). Last edit at 12/24/2019 09:48AM by Ohmarinus.

http://www.marinusdebeer.nl/

Works great!

The only issue I'm having is that the test cube I'm printing is 0.1mm too big in one direction and 0.1mm too small in the other. (X to Y tower dimension is a little too big and to and from the Z-tower the dimension is about 0.08mm too small).

How would one go about solving this? The arms are exactly equally lengths and the deviation with G33 was 0.008

I don't understand how to correctly use G29. Should you 'activate' G29 before each print by adding a special command in the start script of each gcode file? And what's the best guide I should read to learn how to correctly use G29 on a Delta? I believe doing manual calibration should give better results than G33 and a piezo or FSR.

Moving footage:

[youtu.be]

Slow motion:

[youtu.be]

Edited 5 time(s). Last edit at 12/24/2019 09:48AM by Ohmarinus.

http://www.marinusdebeer.nl/

Sorry, only registered users may post in this forum.