Rostock Max V2 - Help with new mainboard settings

Posted by RostockDude

|

Rostock Max V2 - Help with new mainboard settings September 10, 2020 01:47PM |

Registered: 3 years ago Posts: 9 |

Hello,

I have a Rostock Max v2 that have worked ok for many years. One day I decided to upgrade the original 8-bit mainboard to a 32-bit Bigtreetech SKR v1.4 Turbo.

All the main mechanics are still the same as the Rostock MAX v2 original.

I have tried to follow the guidance given in the Marlin firmware files (configuration.h) to use a generic delta profile from the Marlin 2.0.x library and modify it.

I have tried my best doing so and have successfully flashed the firmware onto the SKR 1.4 mainboard. I can connect to it with Pronterface and control the arms with the jog controls. However here is my problem.

The arms move really weirdly when I click the jog controls. If I try to move the effector on only X-axis 10 millimeters then the arms move in what could seem as a random movement, but it isn´t random but repeatable and predicatble. It´s just that it is moving in what seems like as if the effector was riding on the inside of a bowl. The further away from center it moves the more upwards the effector moves. And it also moves faster the further away from the center it moves.

I have tried reading a lot of similar threads on many forums and tried many differnet values in my Marlin configuration.h.

These are the values I have when typing M503 in the serial monitor:

I dont know if I have measured correctly when measuring the arms and effector offset, but all measurements are the original from the Rostock Max v2 was when it was delivered. I have contacted SeeMeCNC for help but they referred me to a newer configuration.h file from ther repetier frimware. I don´t know which values I should use. I can post the whole configuration.h file and maybe a little movie clip if that helps.

Anyone who can help me though this.. I would be very grateful for any help!

Thank you very much in advance!

I have a Rostock Max v2 that have worked ok for many years. One day I decided to upgrade the original 8-bit mainboard to a 32-bit Bigtreetech SKR v1.4 Turbo.

All the main mechanics are still the same as the Rostock MAX v2 original.

I have tried to follow the guidance given in the Marlin firmware files (configuration.h) to use a generic delta profile from the Marlin 2.0.x library and modify it.

I have tried my best doing so and have successfully flashed the firmware onto the SKR 1.4 mainboard. I can connect to it with Pronterface and control the arms with the jog controls. However here is my problem.

The arms move really weirdly when I click the jog controls. If I try to move the effector on only X-axis 10 millimeters then the arms move in what could seem as a random movement, but it isn´t random but repeatable and predicatble. It´s just that it is moving in what seems like as if the effector was riding on the inside of a bowl. The further away from center it moves the more upwards the effector moves. And it also moves faster the further away from the center it moves.

I have tried reading a lot of similar threads on many forums and tried many differnet values in my Marlin configuration.h.

These are the values I have when typing M503 in the serial monitor:

>>> M503 SENDING:M503 echo: G21 ; Units in mm (mm) echo: M149 C ; Units in Celsius echo:; Filament settings: Disabled echo: M200 S0 D1.75 echo:; Steps per unit: echo: M92 X80.00 Y80.00 Z80.00 E836.00 echo:; Maximum feedrates (units/s): echo: M203 X500.00 Y500.00 Z500.00 E25.00 echo:; Maximum Acceleration (units/s2): echo: M201 X9000.00 Y9000.00 Z9000.00 E10000.00 echo:; Acceleration (units/s2): P R T echo: M204 P3000.00 R3000.00 T3000.00 echo:; Advanced: B S T X Y Z E echo: M205 B20000.00 S0.00 T0.00 X10.00 Y10.00 Z10.00 E5.00 echo:; Endstop adjustment: echo: M666 X0.00 Y0.00 Z0.00 echo:; Delta settings: L R H S XYZ ABC echo: M665 L270.00 R135.20 H300.00 S200.00 X0.00 Y0.00 Z0.00 A0.00 B0.00 C0.00 echo:; Material heatup parameters: echo: M145 S0 H180 B70 F255 echo: M145 S1 H240 B100 F255 echo:; PID settings: echo: M301 P22.20 I1.08 D114.00 echo:; Stepper driver current: echo: M906 X800 Y800 Z800 echo: M906 T0 E800 echo:; Driver stepping mode: echo: M569 S1 X Y Z echo: M569 S1 T0 E

I dont know if I have measured correctly when measuring the arms and effector offset, but all measurements are the original from the Rostock Max v2 was when it was delivered. I have contacted SeeMeCNC for help but they referred me to a newer configuration.h file from ther repetier frimware. I don´t know which values I should use. I can post the whole configuration.h file and maybe a little movie clip if that helps.

Anyone who can help me though this.. I would be very grateful for any help!

Thank you very much in advance!

|

Re: Rostock Max V2 - Help with new mainboard settings September 10, 2020 09:09PM |

Registered: 5 years ago Posts: 83 |

|

Re: Rostock Max V2 - Help with new mainboard settings September 11, 2020 11:07AM |

Registered: 3 years ago Posts: 9 |

Thank you for your reply and assitance!

I read in a lot of places about a G33 auto-calibration process in Marlin. Itried sending the command G33 in the serial monitor promt but got a syntax error message back.

I dind´t dare to continue down that path until I knew what was wrong with the movement. Because if I try to move the effector up or down,,, the movement is so "skewed" that the effector runs out of the build area (mechanically reachable area) before I cn move the effector more than 10 cm up or down. I´m afraid of, if I send a G33 command successfully that it will forecefully jam itself into one of the towers almost immediately.

I tried using a caliper and measuring the radius manually by using the references from this image: mechanics.

That is how I came up with the values that I entered into configuration.h and what showed up in the M503 output.

If the radius is wrong, is it the setting that is called:

or

These are the values I have under the delta menu now:

I will try other values in these settings and try to see if it get better or worse.

I read in a lot of places about a G33 auto-calibration process in Marlin. Itried sending the command G33 in the serial monitor promt but got a syntax error message back.

I dind´t dare to continue down that path until I knew what was wrong with the movement. Because if I try to move the effector up or down,,, the movement is so "skewed" that the effector runs out of the build area (mechanically reachable area) before I cn move the effector more than 10 cm up or down. I´m afraid of, if I send a G33 command successfully that it will forecefully jam itself into one of the towers almost immediately.

I tried using a caliper and measuring the radius manually by using the references from this image: mechanics.

That is how I came up with the values that I entered into configuration.h and what showed up in the M503 output.

If the radius is wrong, is it the setting that is called:

#define DELTA_PRINTABLE_RADIUS 290.0

or

#define DELTA_RADIUS 200 // (mm) Get this value from G33 auto calibrate

These are the values I have under the delta menu now:

//=========================================================================== //============================== Delta Settings ============================= //=========================================================================== // Enable DELTA kinematics and most of the default configuration for Deltas #define DELTA #if ENABLED(DELTA) // Make delta curves from many straight lines (linear interpolation). // This is a trade-off between visible corners (not enough segments) // and processor overload (too many expensive sqrt calls). #define DELTA_SEGMENTS_PER_SECOND 200 // After homing move down to a height where XY movement is unconstrained //#define DELTA_HOME_TO_SAFE_ZONE // Delta calibration menu // uncomment to add three points calibration menu option. // See [minow.blogspot.com] #define DELTA_CALIBRATION_MENU // uncomment to add G33 Delta Auto-Calibration (Enable EEPROM_SETTINGS to store results) //#define DELTA_AUTO_CALIBRATION // NOTE NB all values for DELTA_* values MUST be floating point, so always have a decimal point in them #if ENABLED(DELTA_AUTO_CALIBRATION) // set the default number of probe points : n*n (1 -> 7) #define DELTA_CALIBRATION_DEFAULT_POINTS 4 #endif #if EITHER(DELTA_AUTO_CALIBRATION, DELTA_CALIBRATION_MENU) // Set the steprate for papertest probing #define PROBE_MANUALLY_STEP 0.05 // (mm) #endif // Print surface diameter/2 minus unreachable space (avoid collisions with vertical towers). #define DELTA_PRINTABLE_RADIUS 290.0 // (mm) // Center-to-center distance of the holes in the diagonal push rods. #define DELTA_DIAGONAL_ROD 270.0 // (mm) // Distance between bed and nozzle Z home position #define DELTA_HEIGHT 300.00 // (mm) Get this value from G33 auto calibrate #define DELTA_ENDSTOP_ADJ { 0.0, 0.0, 0.0 } // Get these values from G33 auto calibrate // Horizontal distance bridged by diagonal push rods when effector is centered. #define DELTA_RADIUS 200 // (mm) Get this value from G33 auto calibrate // Trim adjustments for individual towers // tower angle corrections for X and Y tower / rotate XYZ so Z tower angle = 0 // measured in degrees anticlockwise looking from above the printer #define DELTA_TOWER_ANGLE_TRIM { 0.0, 0.0, 0.0 } // Get these values from G33 auto calibrate // Delta radius and diagonal rod adjustments (mm) //#define DELTA_RADIUS_TRIM_TOWER { 0.0, 0.0, 0.0 } //#define DELTA_DIAGONAL_ROD_TRIM_TOWER { 0.0, 0.0, 0.0 } #endif

I will try other values in these settings and try to see if it get better or worse.

|

Re: Rostock Max V2 - Help with new mainboard settings September 11, 2020 11:53AM |

Registered: 5 years ago Posts: 83 |

I dig up the Repetier config for Max v2. It doesn't seem apples to apples but I think DELTA_RADIUS could be derived from this section of the Repetier config:

[github.com]

#define DELTA_DIAGONAL_ROD 291.06 // ball cup arms

#define DELTA_MAX_RADIUS 145.0

#define PRINTER_RADIUS 200.0

#define Z_MAX_LENGTH 350

#define END_EFFECTOR_HORIZONTAL_OFFSET 30.22

#define CARRIAGE_HORIZONTAL_OFFSET 26.5 // molded cheapskates

After selecting delta printer type on the config page (https://www.repetier.com/firmware/v100/index.php) it seems like DELTA_RADIUS = PRINTER_RADIUS - END_EFFECTOR_HORIZONTAL_OFFSET. So you could try setting DELTA_RADIUS to 169.78 and see how that changes things.

[github.com]

#define DELTA_DIAGONAL_ROD 291.06 // ball cup arms

#define DELTA_MAX_RADIUS 145.0

#define PRINTER_RADIUS 200.0

#define Z_MAX_LENGTH 350

#define END_EFFECTOR_HORIZONTAL_OFFSET 30.22

#define CARRIAGE_HORIZONTAL_OFFSET 26.5 // molded cheapskates

After selecting delta printer type on the config page (https://www.repetier.com/firmware/v100/index.php) it seems like DELTA_RADIUS = PRINTER_RADIUS - END_EFFECTOR_HORIZONTAL_OFFSET. So you could try setting DELTA_RADIUS to 169.78 and see how that changes things.

|

Re: Rostock Max V2 - Help with new mainboard settings September 12, 2020 06:59AM |

Registered: 3 years ago Posts: 9 |

Thank you kindly for your assistance!

I will try this a soon as possible and report back. I also have recently learned that it is possible to temporarily change the radius with M665 R [X] where X in my case would be 169.78 in this trial. This might help someone in a similar situation as me. This would possibly speed up the trial and error part of this since I don´t have to rebuild the whole firmware and reflash the mainboard everytime to just change one value. This might have been self evident for more experienced users, but I´m learning as I go here.

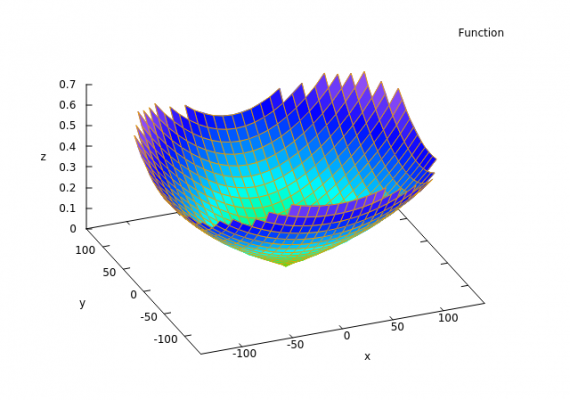

To illustrate the problem I´m having is that my effektor has a movment pattern similar to this image that I found in a post by the user hercek in this thread Link on this forum.

Thank you thehankinator! I really appreciate your help!

Edited 1 time(s). Last edit at 09/12/2020 07:02AM by RostockDude.

I will try this a soon as possible and report back. I also have recently learned that it is possible to temporarily change the radius with M665 R [X] where X in my case would be 169.78 in this trial. This might help someone in a similar situation as me. This would possibly speed up the trial and error part of this since I don´t have to rebuild the whole firmware and reflash the mainboard everytime to just change one value. This might have been self evident for more experienced users, but I´m learning as I go here.

To illustrate the problem I´m having is that my effektor has a movment pattern similar to this image that I found in a post by the user hercek in this thread Link on this forum.

Thank you thehankinator! I really appreciate your help!

Edited 1 time(s). Last edit at 09/12/2020 07:02AM by RostockDude.

|

Re: Rostock Max V2 - Help with new mainboard settings September 12, 2020 07:57AM |

Registered: 3 years ago Posts: 9 |

Hell oagain,

I Itried the Radius value of 169.78 and it still was kind of weird. I also tried very high values and low values to see if the problem got better or worse. I still couldn´t understand if the value was too high or too low. I even tried values as low as 130 and as high as 200. I´m starting to suspect that there might be something else that is off aswell.

I found one error that I corrected.. Maybe kind of obvious for experienced people. On a delta one of the XYZ motors needs to be inverted. I tried different combinations and finally got the printer to move all motors in the same direction when manually moving the effector in the Z-axis. This completely changed everything. The radius error still persists though. I cannot run the G33 command yet because I can´t home the any of the axis yet. It absolutely flies off i warp speed up and crashes violently into the endstops. Still, there is small progress. If I get homing working I imagine I can start trying to use the G33 delta calibration program. I will try to change the homing speed. This was the default value:

Is there any command to change it without rebuilding the whole firmware? Vscode and platformio is giving me a hard time not working so well unfortunately (not loading platformio correctly, and redownloading and reinstalling extensions everytime I restart)

I tried finding the speed setting for "homing" in the config file. It seems to want to home in a absolutely insane speed. It makes the motors scream in pain during the travel. So now I´m trying to find that value.

Not easy this...

Edited 1 time(s). Last edit at 09/12/2020 08:02AM by RostockDude.

I Itried the Radius value of 169.78 and it still was kind of weird. I also tried very high values and low values to see if the problem got better or worse. I still couldn´t understand if the value was too high or too low. I even tried values as low as 130 and as high as 200. I´m starting to suspect that there might be something else that is off aswell.

I found one error that I corrected.. Maybe kind of obvious for experienced people. On a delta one of the XYZ motors needs to be inverted. I tried different combinations and finally got the printer to move all motors in the same direction when manually moving the effector in the Z-axis. This completely changed everything. The radius error still persists though. I cannot run the G33 command yet because I can´t home the any of the axis yet. It absolutely flies off i warp speed up and crashes violently into the endstops. Still, there is small progress. If I get homing working I imagine I can start trying to use the G33 delta calibration program. I will try to change the homing speed. This was the default value:

// Delta only homes to Z #define HOMING_FEEDRATE_Z (200*60)

Is there any command to change it without rebuilding the whole firmware? Vscode and platformio is giving me a hard time not working so well unfortunately (not loading platformio correctly, and redownloading and reinstalling extensions everytime I restart)

I tried finding the speed setting for "homing" in the config file. It seems to want to home in a absolutely insane speed. It makes the motors scream in pain during the travel. So now I´m trying to find that value.

Not easy this...

Edited 1 time(s). Last edit at 09/12/2020 08:02AM by RostockDude.

|

Re: Rostock Max V2 - Help with new mainboard settings September 12, 2020 08:54AM |

Registered: 3 years ago Posts: 9 |

I tried changing the homing rate to a really low value to see whats going on. I set it to:

I can see that all endstop triggers are working using M119 command and holding the endstop switch down. This worked for X, Y and Z, illustrating only x_max below.

The problem is that the motors keep moving up one at least one axis and the motor starts skipping. So something isn´t registering the face that the endstop is triggered. So I haven´t been able to use G33 yet. Still trying to fix homing errors now.

#define HOMING_FEEDRATE_Z (10*60)

I can see that all endstop triggers are working using M119 command and holding the endstop switch down. This worked for X, Y and Z, illustrating only x_max below.

SENT: M119 READ: Reporting endstop status READ: x_max: TRIGGERED READ: y_max: open READ: z_max: open

The problem is that the motors keep moving up one at least one axis and the motor starts skipping. So something isn´t registering the face that the endstop is triggered. So I haven´t been able to use G33 yet. Still trying to fix homing errors now.

|

Re: Rostock Max V2 - Help with new mainboard settings September 12, 2020 09:27AM |

Registered: 5 years ago Posts: 83 |

Hmm that sounds like you may have the motors and endstops mixed up. I would verify your cabling that the motor on the X tower is wired to the X port on your controller. Same for Y and Z. Might as well do the same for your endstops - X tower, zmax, etc. If they are mixed up the controller could think the wrong motor has hit the an endstop and keep going.

|

Re: Rostock Max V2 - Help with new mainboard settings September 12, 2020 09:58AM |

Registered: 3 years ago Posts: 9 |

|

Re: Rostock Max V2 - Help with new mainboard settings September 12, 2020 03:06PM |

Registered: 3 years ago Posts: 9 |

Thank you kindly dear thehankinator!

I´ve gotten my old printer to work again with a new 32-bit mainboard. This makes me immensly happy!

Just a little support and helping attitude gave me the extra energy to keep pushing.

It all works fine now! I just have to calibrate everything in finner detail now!

All the best!

I´ve gotten my old printer to work again with a new 32-bit mainboard. This makes me immensly happy!

Just a little support and helping attitude gave me the extra energy to keep pushing.

It all works fine now! I just have to calibrate everything in finner detail now!

All the best!

|

Re: Rostock Max V2 - Help with new mainboard settings September 12, 2020 03:10PM |

Registered: 5 years ago Posts: 83 |

|

Re: Rostock Max V2 - Help with new mainboard settings October 10, 2020 06:03AM |

Registered: 3 years ago Posts: 1 |

Quote

RostockDude

Thank you kindly dear thehankinator!

I´ve gotten my old printer to work again with a new 32-bit mainboard. This makes me immensly happy!

Just a little support and helping attitude gave me the extra energy to keep pushing.

It all works fine now! I just have to calibrate everything in finner detail now!

All the best!

hii!

can you share the Configuration.h and Configuration_adv.h?

I'm having problems in configurating my Rostock Max V2 with mks gen l.

Thank you!

|

Re: Rostock Max V2 - Help with new mainboard settings January 28, 2023 09:47AM |

Registered: 3 years ago Posts: 9 |

Hello,

Sorry for the long absence. I have attached my custom config files here. Since it was a couple of years since I had the printer working, I cant guarantee that the settings are correct.

But hopefully it will help someone.

I am in the process of updating to the newest Marlin, and a lot of settings have changed. These files worked with MARLIN 2.0.x Configurations-release-2.0.6.

Sorry for the long absence. I have attached my custom config files here. Since it was a couple of years since I had the printer working, I cant guarantee that the settings are correct.

But hopefully it will help someone.

I am in the process of updating to the newest Marlin, and a lot of settings have changed. These files worked with MARLIN 2.0.x Configurations-release-2.0.6.

Sorry, only registered users may post in this forum.