Weird problem with idler pulley

Posted by Mj996

|

Weird problem with idler pulley March 27, 2021 02:05PM |

Registered: 4 years ago Posts: 23 |

I have changed my idler pulley multiple times but every time this happens after few days of printing !

[vimeo.com]

Lubrication doesn’t make any change as you can see there is a serious problem with idler pulley.

I’m using steel core GT2 6mm belts.

I’m wondering what can cause this issue and how can I solve it.

Any helps would be appreciated

[vimeo.com]

Lubrication doesn’t make any change as you can see there is a serious problem with idler pulley.

I’m using steel core GT2 6mm belts.

I’m wondering what can cause this issue and how can I solve it.

Any helps would be appreciated

|

Re: Weird problem with idler pulley March 27, 2021 04:16PM |

Registered: 4 years ago Posts: 285 |

Are you very, very sure that the belt and pulley are the same pitch (tooth spacing)? A 2.07mm pitch, 1/4" wide belt looks almost exactly the same as a 2mm pitch, 6mm wide belt. Also, wrapping a steel core belt around a pulley that is too small may be problematic.

Mismatched tooth pitch between pulley and belt will force the belt to jump a tooth (or at least try to), every few revolutions of the pulley as the mismatch accumulates.

Mismatched tooth pitch between pulley and belt will force the belt to jump a tooth (or at least try to), every few revolutions of the pulley as the mismatch accumulates.

|

Re: Weird problem with idler pulley March 27, 2021 04:40PM |

Registered: 4 years ago Posts: 23 |

Yes they match.However I double checked them and here are the datasheets:

My idler pulley datasheet:

Name: GT2 20 Teeh Timing Belt Pulley

Picth: 2mm

Teeth Number: 20

Belt width: 7mm

Bore: 3mm

Flange: Double flange

screw hole: 2xM3

Material: Aluminium Alloy

My belt datasheet:

Product Name: 2GT timing belt

Material: rubber

Color: black

Broadband: 6mm

Pitch: 2mm

I agree that the steel core belt on small pulley will make problems but will changing the belts really solve the problem?

My idler pulley datasheet:

Name: GT2 20 Teeh Timing Belt Pulley

Picth: 2mm

Teeth Number: 20

Belt width: 7mm

Bore: 3mm

Flange: Double flange

screw hole: 2xM3

Material: Aluminium Alloy

My belt datasheet:

Product Name: 2GT timing belt

Material: rubber

Color: black

Broadband: 6mm

Pitch: 2mm

I agree that the steel core belt on small pulley will make problems but will changing the belts really solve the problem?

|

Re: Weird problem with idler pulley March 28, 2021 12:23AM |

Registered: 4 years ago Posts: 285 |

Will changing the belts (or pulleys) solve the problem? Only you can say, since you've already changed the pulleys several times. I do know that my Anycubic delta printer came from the factory with mismatched pulleys and belts, and changing everything to real Gates products made an unbelievable improvement. Yes, that 0.07 mm difference in pitch means something. Whether or not that is your issue, only you can tell. But buying the cheapest possible parts from the interwebs practically guarantees that you won't get what you think you are paying for.

Even with new Gates pulleys, I chuck them in a lathe and verify that the bore is accurately machined (it almost never is), but I'm chasing sub-micron resolution on my printer at this point.

I would not use steel core belts on a printer. Gates doesn't make them in the smaller sizes for a reason. They are too rigid, and fatigue quickly when repetitively wrapped around a small pulley. Think about what happens to a paper clip if you bend it 10 or 20 times. It breaks from metal fatigue. Fiberglass or Kevlar doesn't do that. Steel cored belts do.

Even using a smooth idler on a toothed belt will display artifacts on the print, and a pulley with a 3 mm shaft is certainly not constrained enough to stay straight and true when subject to belt tension. Especially with a steel belt, and most especially when the pulley is cantilevered off the end of a long shaft without end support.

Keep in mind what you are trying to do: print an object using a robotically controlled hot-melt glue gun. If I walk into any machine shop and ask them to make me an aluminum cube 1 inch on a side accurate to 0.005 inch they'd say sure, give me $100 and come back tomorrow. If I asked for the same cube accurate to 0.001 inch, they'd say sure, give me $1000 and come back next week.

Your printer can only be as accurate as its wobbliest part. If something wobbles, drifts, wiggles, or stretches 0.1 inch with time, temperature or stress then the best you can print is within 0.1 inch. If you're lucky.

Just my thoughts. If I were in your shoes (and I've been there), I'd buy real Gates belts and pulleys from a real industrial supplier like McMaster-Carr, install them, and go from there. You get what you pay for. Sometimes. Trust but verify.

Edited 1 time(s). Last edit at 03/28/2021 12:39AM by rq3.

Even with new Gates pulleys, I chuck them in a lathe and verify that the bore is accurately machined (it almost never is), but I'm chasing sub-micron resolution on my printer at this point.

I would not use steel core belts on a printer. Gates doesn't make them in the smaller sizes for a reason. They are too rigid, and fatigue quickly when repetitively wrapped around a small pulley. Think about what happens to a paper clip if you bend it 10 or 20 times. It breaks from metal fatigue. Fiberglass or Kevlar doesn't do that. Steel cored belts do.

Even using a smooth idler on a toothed belt will display artifacts on the print, and a pulley with a 3 mm shaft is certainly not constrained enough to stay straight and true when subject to belt tension. Especially with a steel belt, and most especially when the pulley is cantilevered off the end of a long shaft without end support.

Keep in mind what you are trying to do: print an object using a robotically controlled hot-melt glue gun. If I walk into any machine shop and ask them to make me an aluminum cube 1 inch on a side accurate to 0.005 inch they'd say sure, give me $100 and come back tomorrow. If I asked for the same cube accurate to 0.001 inch, they'd say sure, give me $1000 and come back next week.

Your printer can only be as accurate as its wobbliest part. If something wobbles, drifts, wiggles, or stretches 0.1 inch with time, temperature or stress then the best you can print is within 0.1 inch. If you're lucky.

Just my thoughts. If I were in your shoes (and I've been there), I'd buy real Gates belts and pulleys from a real industrial supplier like McMaster-Carr, install them, and go from there. You get what you pay for. Sometimes. Trust but verify.

Edited 1 time(s). Last edit at 03/28/2021 12:39AM by rq3.

|

Re: Weird problem with idler pulley March 28, 2021 03:43AM |

Registered: 4 years ago Posts: 23 |

I got your point :"You get what you pay for" and those Gate's stuff are really high quality ones but Unfortunately I don't have access to high quality parts as I asked those suppliers and they told me that they don't have any shipping to my place.(Sad story)

I really have no choice here So I should choose the best between the alternatives or find another solution for idler.

So I have 2 options here :

First is to changing the belts to fiberglass core ones and the 3mm bore pulleys to 5mm bore.(of course with Choosing the best of what i have access to)

Second is changing the idler system.(i.e to something like blt3dp mechanism (idler Image below))

Are you using the same idler system as mine?(I mean the mechanism not the parts)

PS: I forgot to thank for your reply

I really have no choice here So I should choose the best between the alternatives or find another solution for idler.

So I have 2 options here :

First is to changing the belts to fiberglass core ones and the 3mm bore pulleys to 5mm bore.(of course with Choosing the best of what i have access to)

Second is changing the idler system.(i.e to something like blt3dp mechanism (idler Image below))

Are you using the same idler system as mine?(I mean the mechanism not the parts)

PS: I forgot to thank for your reply

|

Re: Weird problem with idler pulley March 28, 2021 03:45AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Weird problem with idler pulley March 28, 2021 03:53AM |

Registered: 4 years ago Posts: 23 |

Thanks for the reply MKSA

Actually I tried a couple of idler pulleys from different suppliers but this happened to all of them.

I agree that I should change the pulley size and belt type.

Do you think changing the pulleys to 5mm bore ones and switching to fiberglass core belts will solve it?

Actually I tried a couple of idler pulleys from different suppliers but this happened to all of them.

I agree that I should change the pulley size and belt type.

Do you think changing the pulleys to 5mm bore ones and switching to fiberglass core belts will solve it?

|

Re: Weird problem with idler pulley March 29, 2021 02:34AM |

Registered: 9 years ago Posts: 483 |

Is the bearing in the pulley riding on threads? If so, I'd be surprised if the bearings would last very long at all. I use pulleys with an 8mm bore, MF85ZZ bearings, and precision 5mm shoulder screws.

|

Re: Weird problem with idler pulley March 29, 2021 05:27AM |

Registered: 4 years ago Posts: 23 |

Thanks for your reply.Quote

etfrench

Is the bearing in the pulley riding on threads? If so, I'd be surprised if the bearings would last very long at all. I use pulleys with an 8mm bore, MF85ZZ bearings, and precision 5mm shoulder screws.

Yes, as you can see in the video The whole idler assembly is riding on a 3mm screw.

It seems that your idler system is just Nice.

Can you send some pics of your idler setup?

|

Re: Weird problem with idler pulley March 29, 2021 01:01PM |

Registered: 9 years ago Posts: 483 |

You won't see much in a picture, just the head of the shoulder screw and the pulley  Attached are images of the CAD model.

Attached are images of the CAD model.

The frame of the delta is Misumi 2550 extrusion. The pulley mount is attached to the narrow side with two locking bolts. The tension adjuster is just a threaded rod through the top plate (not shown) and uses a nut to adjust the tension. Once adjusted the locking bolts are tightened.

From your video, it looks like you have plenty of room to do something similar.

p.s. Using bearing shims also helps.

Edited 1 time(s). Last edit at 03/29/2021 01:07PM by etfrench.

Attached are images of the CAD model.

Attached are images of the CAD model.The frame of the delta is Misumi 2550 extrusion. The pulley mount is attached to the narrow side with two locking bolts. The tension adjuster is just a threaded rod through the top plate (not shown) and uses a nut to adjust the tension. Once adjusted the locking bolts are tightened.

From your video, it looks like you have plenty of room to do something similar.

p.s. Using bearing shims also helps.

Edited 1 time(s). Last edit at 03/29/2021 01:07PM by etfrench.

|

Re: Weird problem with idler pulley March 30, 2021 01:35AM |

Registered: 4 years ago Posts: 23 |

Thanks for the pics etfrench.Quote

etfrench

You won't see much in a picture, just the head of the shoulder screw and the pulleyAttached are images of the CAD model.

The frame of the delta is Misumi 2550 extrusion. The pulley mount is attached to the narrow side with two locking bolts. The tension adjuster is just a threaded rod through the top plate (not shown) and uses a nut to adjust the tension. Once adjusted the locking bolts are tightened.

From your video, it looks like you have plenty of room to do something similar.

p.s. Using bearing shims also helps.

There’s sth I don’t understand about your pulley.how does it spin?I mean as much as I see the pulley is locked to the soulder bolt and the bolt is tightened into the mount.So how is it possible for the pulley to spin?

|

Re: Weird problem with idler pulley March 30, 2021 02:21AM |

Registered: 9 years ago Posts: 483 |

|

Re: Weird problem with idler pulley March 31, 2021 02:34AM |

Registered: 4 years ago Posts: 23 |

Ok I got it.Quote

etfrench

The pulley has an 8mm bore. The shoulder bolt is 5mm. The two MF85ZZ bearings have flanges. The head of the shoulder bolt doesn't need a bearing shim, the threaded end does.

I think those kind of shoulder bolts are rare cause I couldn't find any.(and it seems that if you are not from US you can't shop from Misum unless you have a registered company).

So back in the first place I should design something.

|

Re: Weird problem with idler pulley March 31, 2021 03:38AM |

Registered: 4 years ago Posts: 23 |

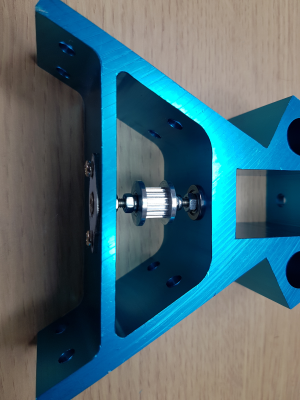

I designed an idler assembly which contains a 8mm bore timing pulley driving on 8mm D-shaft which sandwiches between two 8mm ID flange bearings.(Please look at the attached image below)Quote

etfrench

The pulley has an 8mm bore. The shoulder bolt is 5mm. The two MF85ZZ bearings have flanges. The head of the shoulder bolt doesn't need a bearing shim, the threaded end does.

I would be happy to hear your idea about this design.

PS: The image is just an illustration of how this assembly works.Actually one of the sides of the mount is open and after putting all the components inside the mount we place a rectangular metal sheet on the open side of the mount and screw it to the mount to close hole and fix the shaft and bearing.

Any advice would be appreciated

Edited 2 time(s). Last edit at 03/31/2021 04:38AM by Mj996.

|

Re: Weird problem with idler pulley March 31, 2021 01:08PM |

Registered: 9 years ago Posts: 483 |

|

Re: Weird problem with idler pulley March 31, 2021 02:37PM |

Registered: 4 years ago Posts: 23 |

Sure that’s the tricky part.Quote

etfrench

It should work fine. The only difficult part is ensuring the holes for the shaft are perfectly aligned.

Don’t you think that with this kind of assembly we add a friction factor between shaft and bearings that needs more torque to turn and cause imprecision ?

I use 6kg steppers by the way.

|

Re: Weird problem with idler pulley March 31, 2021 03:40PM |

Registered: 9 years ago Posts: 483 |

|

Re: Weird problem with idler pulley April 01, 2021 01:22AM |

Registered: 4 years ago Posts: 23 |

How about a seperate 3d-printed mount for this assembly that place on top of the frame?Quote

etfrench

No, it will just cause the bearings to wear faster. The most accurate method of making the holes is to use a boring bar on a lathe or a boring head on a mill. If neither of these is available, then using a new drill and a reamer should work.

|

Re: Weird problem with idler pulley April 01, 2021 02:37AM |

Registered: 9 years ago Posts: 483 |

|

Re: Weird problem with idler pulley April 01, 2021 04:48AM |

Registered: 10 years ago Posts: 14,672 |

I too use idler pulleys mounted on M3 screws. However, in my case the entire screw is free to rotate, with bearings at either end. This has been working well for several years.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Weird problem with idler pulley April 01, 2021 06:05AM |

Registered: 4 years ago Posts: 23 |

|

Re: Weird problem with idler pulley April 01, 2021 06:09AM |

Registered: 4 years ago Posts: 23 |

Thanks for the reply DC42Quote

dc42

I too use idler pulleys mounted on M3 screws. However, in my case the entire screw is free to rotate, with bearings at either end. This has been working well for several years.

Do you mean that the screw turns with idler pulley?

How is it possible for the screw to turn while its tightened to bearings with nuts?

|

Re: Weird problem with idler pulley April 01, 2021 03:59PM |

Registered: 10 years ago Posts: 14,672 |

Yes, the screw turns with the pulley. See section Upper Triangle at [miscsolutions.wordpress.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.