Delta Printer building

Posted by Gaou

|

Delta Printer building April 11, 2021 09:23AM |

Registered: 9 years ago Posts: 294 |

hi guys,

been away from 3bprinting for a while i got the change of building a delta printer, thing that i always wanted. But i am new to this design so i would need guidance and advises.

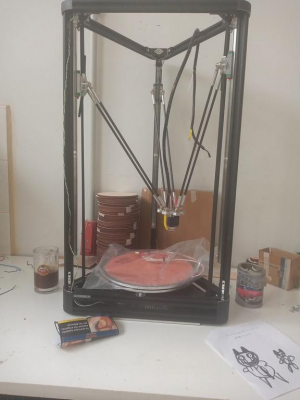

This is where i am at the moment .

.

The reason i choose to make a new effector was the easy of supplies... I already had the ball M4 screws and the fiber rods from robotdigg, so it would only need some tapping and magnets from local supplier.

What i didn't think is that the strong magnets wouldn't be very helpful on the parallel move of the effector. So i have to try some more on that .

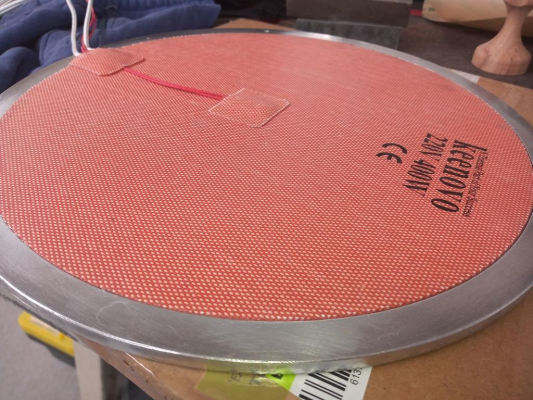

I am waiting for a 10" Keenovo mains power heater and i will order the e3d v6 hotend with titan extruder and some more things...

Also i would like to ask how critical is the proper placement of the rails and how do u measured them to be exactly at the center of the profile. Something else i noticed was a small gap on the some horizontal extrusions to the corner. We are talking something about .1mm to .2mm ( i didn't have something to measure it at that time)

This time i would like to use a thermocouple on my hotend but i dont know what kind of thermocouple and board do i have to choose to match my old 0.85 Duet. So if anyone knows please point it out.

Thanks in advance guys . Please Feel free to criticize ..

Delta Printer

Duet 0.8.5 firmware 1.19

been away from 3bprinting for a while i got the change of building a delta printer, thing that i always wanted. But i am new to this design so i would need guidance and advises.

This is where i am at the moment .

.

The reason i choose to make a new effector was the easy of supplies... I already had the ball M4 screws and the fiber rods from robotdigg, so it would only need some tapping and magnets from local supplier.

What i didn't think is that the strong magnets wouldn't be very helpful on the parallel move of the effector. So i have to try some more on that .

I am waiting for a 10" Keenovo mains power heater and i will order the e3d v6 hotend with titan extruder and some more things...

Also i would like to ask how critical is the proper placement of the rails and how do u measured them to be exactly at the center of the profile. Something else i noticed was a small gap on the some horizontal extrusions to the corner. We are talking something about .1mm to .2mm ( i didn't have something to measure it at that time)

This time i would like to use a thermocouple on my hotend but i dont know what kind of thermocouple and board do i have to choose to match my old 0.85 Duet. So if anyone knows please point it out.

Thanks in advance guys . Please Feel free to criticize ..

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building April 12, 2021 02:22AM |

Registered: 10 years ago Posts: 14,672 |

See [duet3d.dozuki.com] for how to connect a thermocouple to a Duet. However, unless you want to print at very high temperatures, I recommend using a PT100, PT1000 or thermistor instead.

Edited 1 time(s). Last edit at 04/12/2021 02:23AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/12/2021 02:23AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer building April 12, 2021 04:39AM |

Registered: 9 years ago Posts: 294 |

Quote

dc42

See [duet3d.dozuki.com] for how to connect a thermocouple to a Duet. However, unless you want to print at very high temperatures, I recommend using a PT100, PT1000 or thermistor instead.

The PT100 & PT1000 dont need a board ; do they plug as they are on my board?

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building April 13, 2021 02:24AM |

Registered: 10 years ago Posts: 14,672 |

PT100 needs a board, see [duet3d.dozuki.com]. PT1000 doesn't.

Edited 1 time(s). Last edit at 04/13/2021 02:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/13/2021 02:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer building April 13, 2021 02:55AM |

Admin Registered: 16 years ago Posts: 13,886 |

... or a 12Bit (16Bit/24Bit) ADC-input

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Delta Printer building April 13, 2021 11:39AM |

Registered: 9 years ago Posts: 294 |

Quote

dc42

See [duet3d.dozuki.com] guys. I ll order a PT1000. Thanks bith if u

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building May 09, 2021 05:09AM |

Registered: 9 years ago Posts: 294 |

Guys i have made some progress on my build, just to realize how many errors and mistakes i ve done...

I got myself some extruded plastic and now i am in the process of counting errors and finding a solutions. My biggest one turn out to be the rods length, that made my printing height short enough. The cheapest solution to this it to replace the vertical structure with taller ones to get at least 250mm more.

There is also another thing which is the weight of my moving parts . The steppers cant hold the moving parts still and they keep falling. This is not a problem as long as the printers is off, but when i doing a reset on the duet that few milliseconds that the steppers lose their holding torque they are getting some mm down. this is annoying trying to figure a way out cause i think it will disable the printing from continuing after a power shutdown.

I am also looking for a way to replace my ball with smaller thread ( M3) so i would be able to attach the duet smart effector. If you guys have any thoughts on any of these i would be very happy to hear..

Edited 1 time(s). Last edit at 05/09/2021 05:13AM by Gaou.

Delta Printer

Duet 0.8.5 firmware 1.19

I got myself some extruded plastic and now i am in the process of counting errors and finding a solutions. My biggest one turn out to be the rods length, that made my printing height short enough. The cheapest solution to this it to replace the vertical structure with taller ones to get at least 250mm more.

There is also another thing which is the weight of my moving parts . The steppers cant hold the moving parts still and they keep falling. This is not a problem as long as the printers is off, but when i doing a reset on the duet that few milliseconds that the steppers lose their holding torque they are getting some mm down. this is annoying trying to figure a way out cause i think it will disable the printing from continuing after a power shutdown.

I am also looking for a way to replace my ball with smaller thread ( M3) so i would be able to attach the duet smart effector. If you guys have any thoughts on any of these i would be very happy to hear..

Edited 1 time(s). Last edit at 05/09/2021 05:13AM by Gaou.

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building May 09, 2021 04:04PM |

Registered: 4 years ago Posts: 285 |

Some time ago one of the arms on my delta broke. I got tired of waiting for a replacement from China, so I made my own.

The balls are 1/2" diameter 440C stainless steel bearing balls. I got a box of stainless steel 3mmx0.5 flat head machine screws, 10 mm long. I threaded the screws into an aluminum hex standoff to protect the threads of the screws, and chucked it in a lathe. Then I plunged a 1/2" diameter round end mill into the screw head, making a pocket that exactly matched the balls. I abrasive blasted a tiny spot on each ball to help adhesion, and glued the screw head to the ball using JB-Weld epoxy.

The carbon fiber arms are 0.472 inches OD, and 0.390 inches ID. I used commonly available 3/8 inch diameter countersunk disc magnets as the "mate" for the balls. Each disc magnet has a 3/8 inch long by 3/8 inch diameter cylindrical magnet under it to increase the field strength. The magnet stacks were also gently abrasive blasted on the OD for adhesion, and glued into the ends of the carbon fiber tubes with standard industrial epoxy (Loctite EA9460) into which I mixed a small quantity of 4 mil diameter glass beads to keep the magnets centered in the tubes so as to prevent corrosion between the magnets and the carbon fiber.

You wouldn't think that a screw glued to a ball would be very strong, but I have had some pretty devastating effector crashes and have yet to have one fail. I tested a ball to destruction with a hammer, and the screw broke before the JB-Weld failed. JB-Weld is a steel filled high temperature epoxy, and nothing else will work.

Originally I had Teflon discs with adhesive backing in the magnet pockets, but tossed those long ago. About twice a year I pop the arms off the balls, clean everything, and fill the countersink in the magnet with Teflon loaded grease. I can see no apparent wear on either the magnets or the balls after many thousands of prints.

Edited 1 time(s). Last edit at 05/09/2021 04:56PM by rq3.

The balls are 1/2" diameter 440C stainless steel bearing balls. I got a box of stainless steel 3mmx0.5 flat head machine screws, 10 mm long. I threaded the screws into an aluminum hex standoff to protect the threads of the screws, and chucked it in a lathe. Then I plunged a 1/2" diameter round end mill into the screw head, making a pocket that exactly matched the balls. I abrasive blasted a tiny spot on each ball to help adhesion, and glued the screw head to the ball using JB-Weld epoxy.

The carbon fiber arms are 0.472 inches OD, and 0.390 inches ID. I used commonly available 3/8 inch diameter countersunk disc magnets as the "mate" for the balls. Each disc magnet has a 3/8 inch long by 3/8 inch diameter cylindrical magnet under it to increase the field strength. The magnet stacks were also gently abrasive blasted on the OD for adhesion, and glued into the ends of the carbon fiber tubes with standard industrial epoxy (Loctite EA9460) into which I mixed a small quantity of 4 mil diameter glass beads to keep the magnets centered in the tubes so as to prevent corrosion between the magnets and the carbon fiber.

You wouldn't think that a screw glued to a ball would be very strong, but I have had some pretty devastating effector crashes and have yet to have one fail. I tested a ball to destruction with a hammer, and the screw broke before the JB-Weld failed. JB-Weld is a steel filled high temperature epoxy, and nothing else will work.

Originally I had Teflon discs with adhesive backing in the magnet pockets, but tossed those long ago. About twice a year I pop the arms off the balls, clean everything, and fill the countersink in the magnet with Teflon loaded grease. I can see no apparent wear on either the magnets or the balls after many thousands of prints.

Edited 1 time(s). Last edit at 05/09/2021 04:56PM by rq3.

|

Re: Delta Printer building May 11, 2021 03:41PM |

Registered: 9 years ago Posts: 294 |

Quote

rq3

About twice a year I pop the arms off the balls, clean everything, and fill the countersink in the magnet with Teflon loaded grease.

so you are saying you are metal on metal, like mine ? you ve done great work with the rods for sure. i dont have the tools or the mechanical knowledge and experience to do what you did.

i got myself a print today and it seems that i have a problem with stepping or the duet calibration as i got the X and Y 35mm (what they should be) but the Z come out 43mm (instead of 35mm..)....

So first things firsts i got to solve this first....

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building May 11, 2021 10:24PM |

Registered: 4 years ago Posts: 285 |

Quote

Gaou

Quote

rq3

About twice a year I pop the arms off the balls, clean everything, and fill the countersink in the magnet with Teflon loaded grease.

so you are saying you are metal on metal, like mine ? you ve done great work with the rods for sure. i dont have the tools or the mechanical knowledge and experience to do what you did.

i got myself a print today and it seems that i have a problem with stepping or the duet calibration as i got the X and Y 35mm (what they should be) but the Z come out 43mm (instead of 35mm..)....

So first things firsts i got to solve this first....

Well, they're metal on grease on metal. There's a difference

|

Re: Delta Printer building May 16, 2021 02:49AM |

Registered: 9 years ago Posts: 294 |

Guys i need some help. My nozzle is higher on the edges of the bed than it is on the center. Is it an effector thing or is it something else on delta printers that i am not aware of ? is it possible wrong settings on the configuration file causing this ?

i do have an ir differential probe but since the tilt is big i dont know how helpfull would be to install.

Delta Printer

Duet 0.8.5 firmware 1.19

i do have an ir differential probe but since the tilt is big i dont know how helpfull would be to install.

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building May 16, 2021 07:12AM |

Registered: 4 years ago Posts: 285 |

|

Re: Delta Printer building May 16, 2021 02:30PM |

Registered: 12 years ago Posts: 1,450 |

I think what you may want is this [escher3d.com]

I think there may be some other similar programs as well but this is the one I have used. Each of them look for errors in many parameters such as Delta arm length, Delta radius etc...

Mike

I think there may be some other similar programs as well but this is the one I have used. Each of them look for errors in many parameters such as Delta arm length, Delta radius etc...

Mike

|

Re: Delta Printer building May 19, 2021 11:43AM |

Registered: 9 years ago Posts: 294 |

thanks guys both of you ..!

i can take a perfect square as long as it is smalll ( 30mm) . from that point my nozlle is far away of the bed so there must be something wrong...! one thing i ve notice is that my carriage rod distance is smaller than my efector's one . i also understood that the more the length between the rods the less tilt i am getting on the effector.

i have seen this from David but i thought it needed an ir probe or a smart effector ( which by the way i have laying around) . i just realize that i can do this with some simple fillers...! thanks a lot guys...!

Delta Printer

Duet 0.8.5 firmware 1.19

i can take a perfect square as long as it is smalll ( 30mm) . from that point my nozlle is far away of the bed so there must be something wrong...! one thing i ve notice is that my carriage rod distance is smaller than my efector's one . i also understood that the more the length between the rods the less tilt i am getting on the effector.

i have seen this from David but i thought it needed an ir probe or a smart effector ( which by the way i have laying around) . i just realize that i can do this with some simple fillers...! thanks a lot guys...!

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building May 20, 2021 04:12PM |

Registered: 5 years ago Posts: 26 |

Quote

Gaou

Guys i need some help. My nozzle is higher on the edges of the bed than it is on the center. Is it an effector thing or is it something else on delta printers that i am not aware of ? is it possible wrong settings on the configuration file causing this ?

i do have an ir differential probe but since the tilt is big i dont know how helpfull would be to install.

The problem you describe is relatively easy to fix.

The bowl or arch as the nozzle is moved across the center of the bed is a factor of the length of the carriage rods. As long as you are certain that the rod radius is entered correctly, then it is only a matter of adjusting the rod length in the firmware/eeprom to flatten the travel.

My method of bed level and calibration is to level the bed with 3 points, one near each of the 3 towers. I then check the nozzle height at the center of the bed. If it is high then shorten the rod length until the center position gives the same clearance as at the outer 3 points. If it is low then lengthen the rod length the same way.

I never use the auto bed leveling, and once everything is calibrated for flat travel the only routine checks needed are the 3 point level checks. My printer has a 280 mm dia bed and the travel is flat all the way across. I use a 0.2mm first layer.

Edited 1 time(s). Last edit at 05/20/2021 04:15PM by wildone.

|

Re: Delta Printer building May 22, 2021 07:51AM |

Registered: 9 years ago Posts: 294 |

Quote

wildone

The problem you describe is relatively easy to fix.....

thnaks a lot for the tip mate. i disassemble the rods the rails and the effector for changing them to smart effector with haydn rods.

i ll keep ur infos for the next without smart effector build . you ve made it sound pretty easy .

Quote

wildone

I use a 0.2mm first layer.

thats pretty impressive

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building May 31, 2021 03:40PM |

Registered: 2 years ago Posts: 1 |

|

Re: Delta Printer building September 12, 2021 06:01AM |

Registered: 9 years ago Posts: 294 |

Guys i have done some prints and the printer looks quite promising . I still have some minor problems though . The one is the stringing which i believe is caused by the length of the ptde tube, and the most annoying one is that i am getting everything mirrored ? i suspect it is my configuration and not the slic3r that i am using but i dont know how to overcome this.

Delta Printer

Duet 0.8.5 firmware 1.19

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building September 12, 2021 05:07PM |

Registered: 5 years ago Posts: 33 |

I'm probably not going to tell you anything you don't know about reducing stringing but:

As you indicated, bowden tube as short as is reasonable.

I find capricorn tubing helps.

Increase retraction. Of course going too far will risk jams.

Make sure your pla(?) is dry.

Try different filament.

If you try (for instance): G1 x-50 y0 z20

does it go to your left when facing the printer?

As you indicated, bowden tube as short as is reasonable.

I find capricorn tubing helps.

Increase retraction. Of course going too far will risk jams.

Make sure your pla(?) is dry.

Try different filament.

If you try (for instance): G1 x-50 y0 z20

does it go to your left when facing the printer?

|

Re: Delta Printer building September 13, 2021 02:51AM |

Registered: 10 years ago Posts: 14,672 |

I find that the retraction needed is a little under 1% of the Bowden tube length plus 1 or 2mm.

Reducing hot end temperature is very effective at reducing PLA stringing, if you can still get good prints at lower temperature.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Reducing hot end temperature is very effective at reducing PLA stringing, if you can still get good prints at lower temperature.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer building September 14, 2021 04:39AM |

Registered: 9 years ago Posts: 294 |

Quote

jcs

If you try (for instance): G1 x-50 y0 z20

does it go to your left when facing the printer?

yes it does. any more thoughts ?

the stringing was probably there because of a bad heater calibration. fix that and shortened my tube a little and it seems way better now...

thanks guys.

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building September 16, 2021 05:25PM |

Registered: 5 years ago Posts: 33 |

|

Re: Delta Printer building September 17, 2021 05:08AM |

Registered: 10 years ago Posts: 14,672 |

@Gaou please check that you have set up your delta printer like this:

X tower on the left

Y tower on the right

Z tower at the back

Then if you command +X movement in Duet Web Control, the effector should move towards the right. If you command +Y movement then it should move towards the back. The only reason this would be different is if you have used the M579 command in config.g to deliberately invert invert X or Y, by using a negative scale factor.

If the movement directions are both correct, check that you haven't enabled the option in your slicer to mirror the print.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

X tower on the left

Y tower on the right

Z tower at the back

Then if you command +X movement in Duet Web Control, the effector should move towards the right. If you command +Y movement then it should move towards the back. The only reason this would be different is if you have used the M579 command in config.g to deliberately invert invert X or Y, by using a negative scale factor.

If the movement directions are both correct, check that you haven't enabled the option in your slicer to mirror the print.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer building September 20, 2021 03:06AM |

Registered: 9 years ago Posts: 294 |

Quote

dc42

@Gaou please check that you have set up your delta printer like this:

X tower on the left

Y tower on the right

Z tower at the back

i got X on the left Z on the right and Y tower on the back..

Is this what is causing the mirrorring ? if so can i remap the drives through firmware ?

edit: i remmaped the drives but it wasnt a good idea as there is no option of remmaping the endstops....

Edited 1 time(s). Last edit at 09/20/2021 05:05AM by Gaou.

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building September 20, 2021 03:15AM |

Registered: 10 years ago Posts: 14,672 |

Yes you can remap the drives using the M584 command. You will also need to change the M574 commands that assign the endstop inputs.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer building September 20, 2021 01:23PM |

Registered: 9 years ago Posts: 294 |

|

Re: Delta Printer building September 22, 2021 02:42AM |

Registered: 10 years ago Posts: 14,672 |

You are right, you will need to swap the endstop connections over.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer building November 21, 2021 10:39AM |

Registered: 9 years ago Posts: 294 |

Here i am again...! this time with my second delta build where i am getting noise and vibration.

I double checked all the fittings and they are tight. playing around with speeds accel. steps/mm the noise are not quite the same. the only change between the two deltas are the stepper step angle (0.9 first 1.8 this one with the noise) and the linear rails brand.

i have posted a video so if anyone has the time please take a look and share any thoughts.

edit: probably it is the noname cheap linear rails that i bought from robotdigg

Edited 1 time(s). Last edit at 11/21/2021 01:44PM by Gaou.

Delta Printer

Duet 0.8.5 firmware 1.19

I double checked all the fittings and they are tight. playing around with speeds accel. steps/mm the noise are not quite the same. the only change between the two deltas are the stepper step angle (0.9 first 1.8 this one with the noise) and the linear rails brand.

i have posted a video so if anyone has the time please take a look and share any thoughts.

edit: probably it is the noname cheap linear rails that i bought from robotdigg

Edited 1 time(s). Last edit at 11/21/2021 01:44PM by Gaou.

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: Delta Printer building November 22, 2021 09:28AM |

Registered: 10 years ago Posts: 14,672 |

It sounds to me like a combination of low frequency noise, possibly caused by running the stepper drivers with no or very low microstepping, and a higher frequency rattle.

If you move the three towers individually using G1 H2 moves, do they all make the same noise?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If you move the three towers individually using G1 H2 moves, do they all make the same noise?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer building November 22, 2021 01:06PM |

Registered: 9 years ago Posts: 294 |

david thanks for ur reply.

Yes they do . i have replaced the four screws that keeps the carriage with shorter ones but it didn't help either. It seems that my fear of the cheap rails comes true. the rails have some play and when i proper tighten the screws the noise is there and louder . If i unscrew the three cup screws and leave one then there is no noise at all.

This is my second delta and apart from the rails and steppers there were no other changes . the config was just a copy paste. I have three hiwin rails and i ll install them . The problem is that ur effector's carriage dont fit a mgn15 so i ll have to cut and print some new carriages.

lesson learned about not so cheap chinese rails....

Delta Printer

Duet 0.8.5 firmware 1.19

Quote

dc42

do they all make the same noise?

Yes they do . i have replaced the four screws that keeps the carriage with shorter ones but it didn't help either. It seems that my fear of the cheap rails comes true. the rails have some play and when i proper tighten the screws the noise is there and louder . If i unscrew the three cup screws and leave one then there is no noise at all.

This is my second delta and apart from the rails and steppers there were no other changes . the config was just a copy paste. I have three hiwin rails and i ll install them . The problem is that ur effector's carriage dont fit a mgn15 so i ll have to cut and print some new carriages.

lesson learned about not so cheap chinese rails....

Delta Printer

Duet 0.8.5 firmware 1.19

Sorry, only registered users may post in this forum.