Generation 7 Spring Festival

Posted by Traumflug

|

Generation 7 Spring Festival April 14, 2012 08:28PM |

Registered: 13 years ago Posts: 7,616 |

Part One: Visolate 3

If you ever wondered why there is still no Gen7 v1.4, the story is as follows:

The last time I prepared for milling Gen7 boards - when Gen7 v1.3 came out - it took me no less than a month to get all the isolation tracks accurate to the tenth of a millimeter. With copper around drill holes sometimes only 0.2 or 0.3 mm wide, a tenth is a lot. Only after some 10 milled boards and endless hours with a generic G-code editor, a perfectionist like me was satisfied.

So I decided to do something about this: Say hello to Visolate, version 3.0.

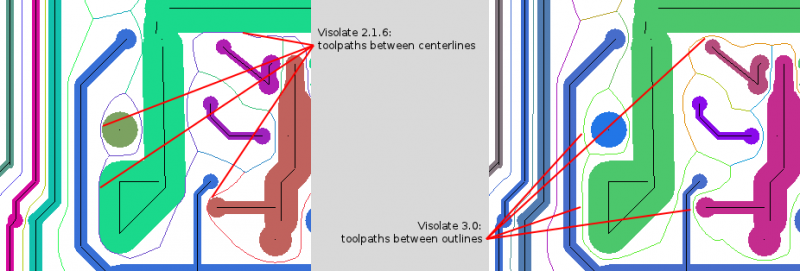

Most of the manual adjustmends required were due to Visolate not respecting the width of tracks. For Voronoi calculation, it used to use only the centerlines. A few weeks of nightly hacking ended this:

NEW in 3.0:

- Toolspaths now respect the thickness of elements. Earlier, only the centers of tracks/pads were taken for calculation, now the entire perimeters are.

- Path junctions are now kept accurately.

- Much faster path optimisation. So fast one of the progress bars went useless.

As always, a Wiki entry: [reprap.org] and a Github repository: [github.com] exists, of course.

If you ever wondered why there is still no Gen7 v1.4, the story is as follows:

The last time I prepared for milling Gen7 boards - when Gen7 v1.3 came out - it took me no less than a month to get all the isolation tracks accurate to the tenth of a millimeter. With copper around drill holes sometimes only 0.2 or 0.3 mm wide, a tenth is a lot. Only after some 10 milled boards and endless hours with a generic G-code editor, a perfectionist like me was satisfied.

So I decided to do something about this: Say hello to Visolate, version 3.0.

Most of the manual adjustmends required were due to Visolate not respecting the width of tracks. For Voronoi calculation, it used to use only the centerlines. A few weeks of nightly hacking ended this:

NEW in 3.0:

- Toolspaths now respect the thickness of elements. Earlier, only the centers of tracks/pads were taken for calculation, now the entire perimeters are.

- Path junctions are now kept accurately.

- Much faster path optimisation. So fast one of the progress bars went useless.

As always, a Wiki entry: [reprap.org] and a Github repository: [github.com] exists, of course.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival April 18, 2012 01:37AM |

Registered: 12 years ago Posts: 7 |

Hi vTruamflug

I am new to this forum but very keen to build a Reprap unit.

I come from an electronics /instrumentation background so please don't take anything below as any negative.

I like your board but there is a much simpler way to make cheap high resolution boards.

I have tried many methods over the years from tapes and UV sensitve boards to Dalo pens and transfer films with fair sucess.

However I needed to move to SMD for a couple of projects and discovered thi site below

[ultrakeet.com.au]

I bought some of their stuff and built a modified fuser as per the articles on their site and the results were spectacular.

I can now produce a double sided SMD board for my ATMEGA88A boards with almost no failures and it takes less than 30 minutes.

I print out the Eagle files using the transfer medium, put it and the blank board through the fuser and run it under water for a minute.

Then put the film on the image and run both through again and you now have a perfect fine pitch board ready to etch.

You can even do a silk screen layer in several colour choices and even a solder mask if needed using this method.

It's the closest I have ever seen to a commercial board.

You can buy this stuff in America as well as Australia so I expect someone in Europe will stock it.

I hope you try this as it will reduce your board revision time to hours instead of weeks (and I want to build a 1.4 version soon)

Hope this helps you and other Reprappers who want to build their own boards.

Following your exploits with great interest.

Regards

Denis

I am new to this forum but very keen to build a Reprap unit.

I come from an electronics /instrumentation background so please don't take anything below as any negative.

I like your board but there is a much simpler way to make cheap high resolution boards.

I have tried many methods over the years from tapes and UV sensitve boards to Dalo pens and transfer films with fair sucess.

However I needed to move to SMD for a couple of projects and discovered thi site below

[ultrakeet.com.au]

I bought some of their stuff and built a modified fuser as per the articles on their site and the results were spectacular.

I can now produce a double sided SMD board for my ATMEGA88A boards with almost no failures and it takes less than 30 minutes.

I print out the Eagle files using the transfer medium, put it and the blank board through the fuser and run it under water for a minute.

Then put the film on the image and run both through again and you now have a perfect fine pitch board ready to etch.

You can even do a silk screen layer in several colour choices and even a solder mask if needed using this method.

It's the closest I have ever seen to a commercial board.

You can buy this stuff in America as well as Australia so I expect someone in Europe will stock it.

I hope you try this as it will reduce your board revision time to hours instead of weeks (and I want to build a 1.4 version soon)

Hope this helps you and other Reprappers who want to build their own boards.

Following your exploits with great interest.

Regards

Denis

|

Re: Generation 7 Spring Festival April 18, 2012 08:56AM |

Registered: 13 years ago Posts: 7,616 |

Hello Blacksnake,

your link describes very detailed how the toner transfer method works and the Gen7 design supports this happily: [reprap.org]

There are two major reasons for isolation milling:

- It uses and produces no chemicals except tap water and soap for cleaning, so it's very environmental friendly.

- As you need to drill the holes as well, you have to fix the board on a milling machine anyways. So, isolation milling just adds the need for a mill bit (EUR 2.-) and some 20 minutes of time. Unless you want to drill several hundred holes by hand, of course.

Additional advantage of the latter: holes and tracks always fit nicely, no precision adjustment required.

your link describes very detailed how the toner transfer method works and the Gen7 design supports this happily: [reprap.org]

There are two major reasons for isolation milling:

- It uses and produces no chemicals except tap water and soap for cleaning, so it's very environmental friendly.

- As you need to drill the holes as well, you have to fix the board on a milling machine anyways. So, isolation milling just adds the need for a mill bit (EUR 2.-) and some 20 minutes of time. Unless you want to drill several hundred holes by hand, of course.

Additional advantage of the latter: holes and tracks always fit nicely, no precision adjustment required.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival April 23, 2012 10:59AM |

Registered: 13 years ago Posts: 7,616 |

Part Two: New Gen7 Arduino IDE Support package

Oh, it's monday already, I was held up a bit with searching for a muldiv algorithm: [forums.reprap.org]

Nevertheless, please find attached a new Gen7 Arduino IDE Support package. It's re-made almost from scratch and from the most recent Arduino IDE sources. This means, it works for Arduino 1.0 (and unfortunately not the IDE versions before). It supports all the new features coming with Arduino 1.0, like wide characters, wide strings, tones, Ethernet, and more.

This package should also remove the need for the IDE support package coming with some variants of Marlin. It should work for original Arduinos, as well as for Sanguinololus, Generation 3 Electronics and others. If it hadn't its roots in the Gen7 repository, I'd have named it RepRap Arduino IDE Support package.

Supported processors are about all ATtinys and ATmegas, including the ATmega644, ATmega644P and ATmega1284P. For these three are also binary bootloaders included, in 16 MHz and 20 MHz versions.

So far, the compiled package is distributed here only. It'll come as a package on Github with the Gen7 v1.4 release. Sources are on Github right now: [github.com] . Use the make.sh script there, if you want to do your own compilation.

Oh, it's monday already, I was held up a bit with searching for a muldiv algorithm: [forums.reprap.org]

Nevertheless, please find attached a new Gen7 Arduino IDE Support package. It's re-made almost from scratch and from the most recent Arduino IDE sources. This means, it works for Arduino 1.0 (and unfortunately not the IDE versions before). It supports all the new features coming with Arduino 1.0, like wide characters, wide strings, tones, Ethernet, and more.

This package should also remove the need for the IDE support package coming with some variants of Marlin. It should work for original Arduinos, as well as for Sanguinololus, Generation 3 Electronics and others. If it hadn't its roots in the Gen7 repository, I'd have named it RepRap Arduino IDE Support package.

Supported processors are about all ATtinys and ATmegas, including the ATmega644, ATmega644P and ATmega1284P. For these three are also binary bootloaders included, in 16 MHz and 20 MHz versions.

So far, the compiled package is distributed here only. It'll come as a package on Github with the Gen7 v1.4 release. Sources are on Github right now: [github.com] . Use the make.sh script there, if you want to do your own compilation.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival April 25, 2012 09:01AM |

Registered: 13 years ago Posts: 7,616 |

You don't have to wait for the Gen7 v1.4 release. As making releases for all of the Gen7 stuff together has become a burden, I switched to making individual releases. Find the most recent Gen7 Arduino IDE Support package now on Github, it's version 2.0: [github.com]

Edited 2 time(s). Last edit at 04/25/2012 10:17AM by Traumflug.

Edited 2 time(s). Last edit at 04/25/2012 10:17AM by Traumflug.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival May 03, 2012 10:12AM |

Registered: 13 years ago Posts: 7,616 |

Part Three: Say Hello to the SevenSwitch

About every week or so a Gen6 user comes along and asks on how to connect a heated bed to his electronics. Or a Gen7 owner on how to connect a fan. And of course there are a lot more uses for controlable switches.

So I sat down and excerpted the circuitry for the heaters from the Gen7 design and put it on it's own PCB. Complete with it's own power connector, a few mounting holes and a signal connector.

Specifications:

- Sized 48 x 35 mm, so you can handle it without a magnifying glass.

- Switches up to 15 Ampére at 12 Volts, sufficient for a heated bed.

- Fast enough for 80 kHz PWM.

- As a matter of course: it's DIYable as much as possible.

As it shares symbols and footprints with Generation 7 Electronics, it's placed within this repository: [github.com]

Files needed for production are there, too: [github.com]

Last not least: a wiki page with extensive documentation: [reprap.org]

About every week or so a Gen6 user comes along and asks on how to connect a heated bed to his electronics. Or a Gen7 owner on how to connect a fan. And of course there are a lot more uses for controlable switches.

So I sat down and excerpted the circuitry for the heaters from the Gen7 design and put it on it's own PCB. Complete with it's own power connector, a few mounting holes and a signal connector.

Specifications:

- Sized 48 x 35 mm, so you can handle it without a magnifying glass.

- Switches up to 15 Ampére at 12 Volts, sufficient for a heated bed.

- Fast enough for 80 kHz PWM.

- As a matter of course: it's DIYable as much as possible.

As it shares symbols and footprints with Generation 7 Electronics, it's placed within this repository: [github.com]

Files needed for production are there, too: [github.com]

Last not least: a wiki page with extensive documentation: [reprap.org]

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival May 04, 2012 04:29AM |

Registered: 14 years ago Posts: 3,742 |

|

Re: Generation 7 Spring Festival May 04, 2012 10:07AM |

Admin Registered: 12 years ago Posts: 2,569 |

|

Re: Generation 7 Spring Festival May 10, 2012 09:12PM |

Registered: 12 years ago Posts: 77 |

|

Re: Generation 7 Spring Festival May 11, 2012 05:49AM |

Registered: 13 years ago Posts: 7,616 |

A Gen6 doesn't even have spare connectors? Sorry, I didn't look into that.

As I don't own a Gen6 I can offer you to solve this, if you send me yours. Including shipping time, this should take a week.

As I don't own a Gen6 I can offer you to solve this, if you send me yours. Including shipping time, this should take a week.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival May 11, 2012 12:28PM |

Registered: 12 years ago Posts: 77 |

Traumflug Wrote:

-------------------------------------------------------

> A Gen6 doesn't even have spare connectors? Sorry,

> I didn't look into that.

>

> As I don't own a Gen6 I can offer you to solve

> this, if you send me yours. Including shipping

> time, this should take a week.

I should first let you know that my knowledge of reprap electronics is limited to there basic operation and wiring that is shown in the various wiki's. With that clear the Gen6 does have some extra connectors but I'm not sure if they could be used to implement a SevenSwitch or not. They are not what I was hoping to find, though; a 2 pin header with ground and numbered pin.

Here is what is available:

6 pin icsp

4 pin i2c bus

RS485 bus

Is it possible to connect to any these with the SevenSwitch?

Thanks

-------------------------------------------------------

> A Gen6 doesn't even have spare connectors? Sorry,

> I didn't look into that.

>

> As I don't own a Gen6 I can offer you to solve

> this, if you send me yours. Including shipping

> time, this should take a week.

I should first let you know that my knowledge of reprap electronics is limited to there basic operation and wiring that is shown in the various wiki's. With that clear the Gen6 does have some extra connectors but I'm not sure if they could be used to implement a SevenSwitch or not. They are not what I was hoping to find, though; a 2 pin header with ground and numbered pin.

Here is what is available:

6 pin icsp

4 pin i2c bus

RS485 bus

Is it possible to connect to any these with the SevenSwitch?

Thanks

|

Re: Generation 7 Spring Festival May 12, 2012 08:09AM |

Registered: 13 years ago Posts: 7,616 |

About all pins of an ATmega can be configured for multiple uses, so the answer is yes. For a list of PWM-able pins, see the bottom of each config.h template in the Teacup sources. Can't find the time to work this out in detail, though.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival May 14, 2012 08:29PM |

Registered: 13 years ago Posts: 7,616 |

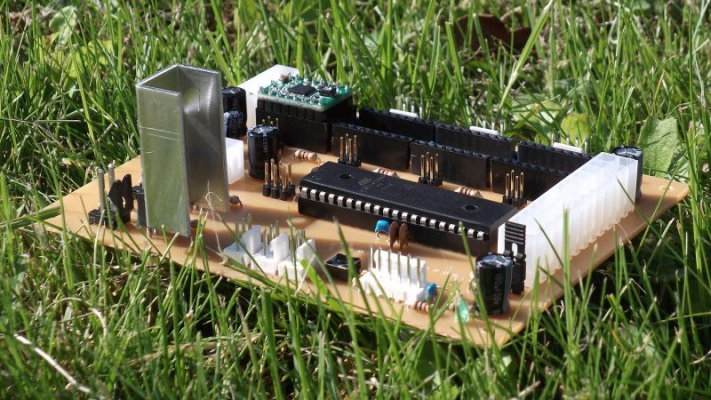

Part Four: Finally! Generation 7 Electronics v1.4!

After a looong journey, v1.4 is finally released. With quite a number of new features, the biggest of these is support for the Gen7 Extension Board. Starting today, one can get a simple and affordable Gen7 basic board to get the machine running and add on features later. Features, like SD card support, multiple extruders, display, whatever the ATmega world has to offer.

Of course there is a more detailed description: [reprap.org]

... and a Github repository: [github.com]

... and there are release documents: [github.com]

So, get your etching box ready or mail me for a list of available PCBs and kits: mah@jump-ing.de

This was the last part of the Generation 7 Spring Festival. I hope you enjoyed it as much as me.

After a looong journey, v1.4 is finally released. With quite a number of new features, the biggest of these is support for the Gen7 Extension Board. Starting today, one can get a simple and affordable Gen7 basic board to get the machine running and add on features later. Features, like SD card support, multiple extruders, display, whatever the ATmega world has to offer.

Of course there is a more detailed description: [reprap.org]

... and a Github repository: [github.com]

... and there are release documents: [github.com]

So, get your etching box ready or mail me for a list of available PCBs and kits: mah@jump-ing.de

This was the last part of the Generation 7 Spring Festival. I hope you enjoyed it as much as me.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival May 14, 2012 08:46PM |

Registered: 13 years ago Posts: 7,616 |

|

Re: Generation 7 Spring Festival May 19, 2012 04:52PM |

Registered: 12 years ago Posts: 56 |

I totally missed this topic while I was building my own bed driver. :-)

Q: Why use the IRFZ44N MOSFET? There are MOSFETs with a lower RDSon than 17.5 mOhm. At 10 amps, you need to dissipate 1.75 watts, which is still a lot without active cooling. (My current circuit has a 3 mOhm MOSFET which heats up to 120 degrees Celcius until it reaches the target temperature and then cools down to 40 degrees)

Q2: When using a 10 ohm resistor between the Arduino and the MOSFET, aren't you pulling 500 mA from the output pin? As far as I know, 40 mA was the maximum an Arduino (ATmega 12-something) can deliver to its output pins, which is not enough to quickly drive a FET into its saturation.

This is why I added a transistor to drive the FET with 12 volts and higher currents while the Arduino only has to push the transistor (@ 12 mA). The downside is that I effectively inverted the signal.

Q: Why use the IRFZ44N MOSFET? There are MOSFETs with a lower RDSon than 17.5 mOhm. At 10 amps, you need to dissipate 1.75 watts, which is still a lot without active cooling. (My current circuit has a 3 mOhm MOSFET which heats up to 120 degrees Celcius until it reaches the target temperature and then cools down to 40 degrees)

Q2: When using a 10 ohm resistor between the Arduino and the MOSFET, aren't you pulling 500 mA from the output pin? As far as I know, 40 mA was the maximum an Arduino (ATmega 12-something) can deliver to its output pins, which is not enough to quickly drive a FET into its saturation.

This is why I added a transistor to drive the FET with 12 volts and higher currents while the Arduino only has to push the transistor (@ 12 mA). The downside is that I effectively inverted the signal.

|

Re: Generation 7 Spring Festival May 20, 2012 05:24AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Q: Why use the IRFZ44N MOSFET?

This one is proven to be sufficient and it's cheap (50 Euro cents). Before the IRFZ44N there was a TIP120 and I read exactly the same, with a recommendation towards the current choice.

Quote

Q2: When using a 10 ohm resistor between the Arduino and the MOSFET, aren't you pulling 500 mA from the output pin?

If the ATmega can deliver that, yes. RAMPS electronics also uses an 10 ohms resistor and Sanguinololu even no resistor at all. Obviously, ATmegas survive that.

Quote

This is why I added a transistor to drive the FET with 12 volts and higher currents while the Arduino only has to push the transistor (@ 12 mA). The downside is that I effectively inverted the signal.

Well, does this extra effort help? I mean help, not like in satisfying some theory formulas, but like in measured temperature on the heatsink? For testing, you can configure Teacup Firmware with a temperature measurement device of type TT_NONE, allowing you to set PWM directly. I'd be very interested in your measurement results.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival June 03, 2012 10:20AM |

Registered: 12 years ago Posts: 56 |

Traumflug Wrote:

-------------------------------------------------------

>> Q2: When using a 10 ohm resistor between the

>> Arduino and the MOSFET, aren't you pulling 500 mA

>> from the output pin?

>

> If the ATmega can deliver that, yes. RAMPS

> electronics also uses an 10 ohms resistor and

> Sanguinololu even no resistor at all. Obviously,

> ATmegas survive that.

After talking to some people using Arduinos it seems that they probably survive this 'abuse' because the current will flow for a short time until the MOSFET is saturated. Still, according to the official 'guide lines' and stories from people, it might wear out the transistors for that particular pin...

I opted to go the safe route and since the added logic costs 50 cents, I don't really mind either way.

> Well, does this extra effort help? I mean help,

> not like in satisfying some theory formulas, but

> like in measured temperature on the heatsink? For

> testing, you can configure Teacup Firmware with a

> temperature measurement device of type TT_NONE,

> allowing you to set PWM directly. I'd be very

> interested in your measurement results.

I tried lowering the resistor value to 50 ohms to see what would happen and of course the temperatures on the heatsink improved drastically: I smoked the 3rd MOSFET after heating it up to 250+ degrees, with the heatsink attached. The 50 ohms test heated a new MOSFET (same type) up to 55+ degrees in a couple of minutes, at which point I shut down the machine as the bed was at 45 degrees Celcius.

Then I build the driver with the 12V control logic and it seems to still get hot if I do not use PWM as it peaks at 90 degrees Celcius (with the bed turned on continuously). However, when connected to the Gen7, it heats up to 45 to 50 initially but stabilizes at 40 when the target temperature is reached.

The problem I see is that I still had a larger resistor connected than you did, so perhaps it would be just as cool as the new driver board.

I just modified the firmware to run the extruder normally and the bed using inverted PWM (as in: pwm = 255 - heater_tick value) to test if this solves my issues. If it does, I'll make a 'decent' PCB to hold all the components and probably add a another transistor to invert my inverter and a bypass to run it straight from the Arduino so I can actually measure the difference.

-------------------------------------------------------

>> Q2: When using a 10 ohm resistor between the

>> Arduino and the MOSFET, aren't you pulling 500 mA

>> from the output pin?

>

> If the ATmega can deliver that, yes. RAMPS

> electronics also uses an 10 ohms resistor and

> Sanguinololu even no resistor at all. Obviously,

> ATmegas survive that.

After talking to some people using Arduinos it seems that they probably survive this 'abuse' because the current will flow for a short time until the MOSFET is saturated. Still, according to the official 'guide lines' and stories from people, it might wear out the transistors for that particular pin...

I opted to go the safe route and since the added logic costs 50 cents, I don't really mind either way.

> Well, does this extra effort help? I mean help,

> not like in satisfying some theory formulas, but

> like in measured temperature on the heatsink? For

> testing, you can configure Teacup Firmware with a

> temperature measurement device of type TT_NONE,

> allowing you to set PWM directly. I'd be very

> interested in your measurement results.

I tried lowering the resistor value to 50 ohms to see what would happen and of course the temperatures on the heatsink improved drastically: I smoked the 3rd MOSFET after heating it up to 250+ degrees, with the heatsink attached. The 50 ohms test heated a new MOSFET (same type) up to 55+ degrees in a couple of minutes, at which point I shut down the machine as the bed was at 45 degrees Celcius.

Then I build the driver with the 12V control logic and it seems to still get hot if I do not use PWM as it peaks at 90 degrees Celcius (with the bed turned on continuously). However, when connected to the Gen7, it heats up to 45 to 50 initially but stabilizes at 40 when the target temperature is reached.

The problem I see is that I still had a larger resistor connected than you did, so perhaps it would be just as cool as the new driver board.

I just modified the firmware to run the extruder normally and the bed using inverted PWM (as in: pwm = 255 - heater_tick value) to test if this solves my issues. If it does, I'll make a 'decent' PCB to hold all the components and probably add a another transistor to invert my inverter and a bypass to run it straight from the Arduino so I can actually measure the difference.

|

Re: Generation 7 Spring Festival June 03, 2012 04:31PM |

Registered: 13 years ago Posts: 7,616 |

Thanks for the research, Cyberwizzard. Here are my findings: [reprap.org]

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival June 07, 2012 04:02AM |

Registered: 11 years ago Posts: 1 |

Hi.

I've been reading forum a lot and I think it's time for me to help.

Traumflug have you tried STP40NF03L ? I haven't found anything about it on the forum.

It's 10 cents more expensive but it's TTL MOSFET. Problem with IRFZ44N is that it doesn't reach it's RDSon with Vgs of 5V. By comparing datasheets (yeah, that's theoretical) we can clearly see much better RDSon @ Vgs=5v and Vds=10V of STP40NF03L.

I'm using IRFZ44N for extruder heater (4ohms, standard PWM frequency of Marlin - I don't remember it right now) and STP40NF03L for heated bed (1ohm, 1Hz). Switching from IRF to STP on heated bed resulted in getting 40°C lower temperature of transistor (80° compared to 120°, without any radiator) during initial heating (~11A for 7 minutes - thats Al bed). As STP is TTL transistor the difference should be greater with greater frequency - but now I don't have any way of comparing results - desoldering transistor from Sanguinololu is really painful.

I've been reading forum a lot and I think it's time for me to help.

Traumflug have you tried STP40NF03L ? I haven't found anything about it on the forum.

It's 10 cents more expensive but it's TTL MOSFET. Problem with IRFZ44N is that it doesn't reach it's RDSon with Vgs of 5V. By comparing datasheets (yeah, that's theoretical) we can clearly see much better RDSon @ Vgs=5v and Vds=10V of STP40NF03L.

I'm using IRFZ44N for extruder heater (4ohms, standard PWM frequency of Marlin - I don't remember it right now) and STP40NF03L for heated bed (1ohm, 1Hz). Switching from IRF to STP on heated bed resulted in getting 40°C lower temperature of transistor (80° compared to 120°, without any radiator) during initial heating (~11A for 7 minutes - thats Al bed). As STP is TTL transistor the difference should be greater with greater frequency - but now I don't have any way of comparing results - desoldering transistor from Sanguinololu is really painful.

|

Re: Generation 7 Spring Festival June 07, 2012 05:57AM |

Registered: 13 years ago Posts: 7,616 |

Thanks for the data point, kelow. Well, swapping MOSFETs is about the only option to test them.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival August 12, 2012 09:29AM |

|

Re: Generation 7 Spring Festival August 12, 2012 02:44PM |

Registered: 13 years ago Posts: 7,616 |

It was almost done. Then, a guy with a touch display came around the corner and demanded two analog pins. Looks like the extension board header has to be reviewed again.

If you want to try yourself, here's something very similar: [github.com]

Also, Kliment's SD card adapter has good chances to work.

If you want to try yourself, here's something very similar: [github.com]

Also, Kliment's SD card adapter has good chances to work.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Spring Festival August 12, 2012 03:46PM |

Registered: 12 years ago Posts: 290 |

Sorry, only registered users may post in this forum.