Generation 7 Electronics Development

Posted by Traumflug

|

Re: Generation 7 Electronics Development December 13, 2015 12:21PM |

Registered: 13 years ago Posts: 7,616 |

It's off topic, but you should have a look at the .gsch2pcb file and also use xgsch2pcb.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development December 15, 2015 12:12AM |

Registered: 8 years ago Posts: 338 |

Thanks a lot for your reply.

Both recommended apps don't help at footprint creation.

Anyway - I read a lot about footprint creation and I think, I'm done with geda. If I got it right, it does not support pads on different layers for a single footprint, so no support for cardslots and the like ...

so eagle remains unbeaten

Both recommended apps don't help at footprint creation.

Anyway - I read a lot about footprint creation and I think, I'm done with geda. If I got it right, it does not support pads on different layers for a single footprint, so no support for cardslots and the like ...

so eagle remains unbeaten

|

Re: Generation 7 Electronics Development December 25, 2015 05:27PM |

Registered: 8 years ago Posts: 11 |

Quote

DeuxVis

The Gen7 I built works like a charm with Teacup, but I have some freezes during prints : printer stop moving, and doesn't reply to host software (printerface) until I reset it.

I suspect some electrical interference, but how to find if they happen on the usb cable or comes from the PSU ?

I just recently got my Prusa Mendel printer up and running, so I haven't gotten much beyond initial calibration. I have been experiencing freezes mid print using Teacup on a Gen 7 board similar to the conditions you mention. I have to reset on the board as well as the software becomes unresponsive.

"Simple" models like a 20x20mm test block will print, but anything with geometric complexity freezes mid print. Freezing seems to happen after sustained short, fast print moves. I've increased the move buffer with no success.

Do you know of a solution to this?

Thanks!

Edited 1 time(s). Last edit at 12/25/2015 05:29PM by aaron.r.

|

Re: Generation 7 Electronics Development December 26, 2015 05:57AM |

Registered: 13 years ago Posts: 7,616 |

If you have a repeatable test case (it stops always at the same position), it's most likely a firmware issue. The Teacup folks would love to see such a testcase, something reproducible is neccessary to allow fixing it.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development February 04, 2016 02:30PM |

Registered: 13 years ago Posts: 7,616 |

Nice!

I just received this from a Gen7 user:

I just received this from a Gen7 user:

Quote

First of all I want to congratulate you for the Gen7 Board-AVR 1.5. I have been using it since 2013 to now in my Prusa IT3 and I´m very happy with it, it´s 1000 times better than the fake chinese ramps I am using at my delta.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development February 04, 2016 05:20PM |

Registered: 13 years ago Posts: 7,616 |

Did something special happen today? Another PM, after months of silence:

Thank you very much.

Quote

My Gen7 buyed (The PCfrom you is still rocking hard with my PrintrBot v1!!

Thank you very much.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development February 28, 2016 01:05AM |

Registered: 8 years ago Posts: 1 |

|

Re: Generation 7 Electronics Development June 25, 2017 03:00PM |

Registered: 7 years ago Posts: 4 |

|

Re: Generation 7 Electronics Development June 25, 2017 03:56PM |

Registered: 13 years ago Posts: 7,616 |

I tried this already and v2.0 indeed got smaller (110x90, from 130x100), but further size reduction is hard because of all the components. These have to fit on top, even on a 2-sided board.

Also, the point of a Gen7 is to be DIY-able. There are plenty of less DIY-able boards out there and they're the right choice if one prefers buying industrial stuff.

Still, Gen7 boards are available, of course: [www.reprap-diy.com]

Also, the point of a Gen7 is to be DIY-able. There are plenty of less DIY-able boards out there and they're the right choice if one prefers buying industrial stuff.

Still, Gen7 boards are available, of course: [www.reprap-diy.com]

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development October 25, 2017 01:50PM |

Registered: 7 years ago Posts: 363 |

|

Re: Generation 7 Electronics Development October 25, 2017 02:24PM |

Registered: 13 years ago Posts: 7,616 |

NXP lists this part as active [www.nxp.com], so I'm not sure why they're out at stock on the major suppliers. MCUs in a DIL package going away would pretty much mean the end of DIY-able controllers :-/

That said, I have plenty of them, € 5.- a piece. Or € 22.- together with all other electronic components used on this board: [www.reprap-diy.com].

That said, I have plenty of them, € 5.- a piece. Or € 22.- together with all other electronic components used on this board: [www.reprap-diy.com].

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development October 25, 2017 02:30PM |

Registered: 7 years ago Posts: 363 |

|

Re: Generation 7 Electronics Development October 25, 2017 02:52PM |

Admin Registered: 16 years ago Posts: 13,884 |

Quote

Traumflug

... MCUs in a DIL package going away would pretty much mean the end of DIY-able controllers :-/

... yes, this would make it hard for the typical craftsmen ... but populating and soldering SMD is doable in DIY-scale too, if using a stereo-microscope (got two for 30€ and 60€ from ebay), fine soldering iron tips and 0,3mm thick solder wire

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Generation 7 Electronics Development October 25, 2017 02:56PM |

Registered: 13 years ago Posts: 7,616 |

Quote

obelisk79

Will there be any updates to the design due to this?

Good question. Swapping the DIL chip for a SMT (0.65 mm pin pitch) one is easily doable, but what's the point of a Gen7, then? Wherever I look I see requests for more and more complex controllers (Bluetooth, WiFi, 6, 8, 10 steppers, web server, ...), next to never wishes for simple, rock-solid, DIY-able ones.

Folks thinking that Generation 7 Electronics should enter the SMT era: NOW is the ideal time to speak up!

For example, being forced into SMT anyways also means there's no longer a reason to stick to a Cortex-M0, Cortex-M4 are just as easy to handle. And these have been demonstrated to generate step rates 100 times higher than a RAMPS: 1'598'000 steps per second.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development October 25, 2017 03:03PM |

Registered: 13 years ago Posts: 7,616 |

Quote

VDX

populating and soldering SMD is doable in DIY-scale too, if using a stereo-microscope

Microscope. Ha ha.

Over time I got a number of comments expressing fear about this MCP2200 chip on the copper side of the Gen7, which is SMT. 1,27 mm pin pitch and fairly easily handleable with bare fingers, still people don't trust it. And these SOIC chips are rare, too.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development October 25, 2017 03:35PM |

Registered: 7 years ago Posts: 363 |

I wouldn't mind seeing a SMT M4 solution, I've hand soldered fine pitch TQFP components before using a tip-drag technique. However it wasn't easy and I don't know if it would be considered very DIY.

More expensive, but what about building something around the Teensy 3.5 or Teensy 3.2, those are more plug-and-play type DIY-able options.

They already have

usb

sdcard

and 5V tolerant signal pins.

Or this very inexpensive Nucleo dev board, which also has 5v tolerant signal pins and costs less.

[www.st.com]

Edited 2 time(s). Last edit at 10/25/2017 03:38PM by obelisk79.

More expensive, but what about building something around the Teensy 3.5 or Teensy 3.2, those are more plug-and-play type DIY-able options.

They already have

usb

sdcard

and 5V tolerant signal pins.

Or this very inexpensive Nucleo dev board, which also has 5v tolerant signal pins and costs less.

[www.st.com]

Edited 2 time(s). Last edit at 10/25/2017 03:38PM by obelisk79.

|

Re: Generation 7 Electronics Development October 25, 2017 05:52PM |

Registered: 9 years ago Posts: 204 |

|

Re: Generation 7 Electronics Development October 25, 2017 06:05PM |

Registered: 7 years ago Posts: 363 |

|

Re: Generation 7 Electronics Development October 25, 2017 06:16PM |

Admin Registered: 16 years ago Posts: 13,884 |

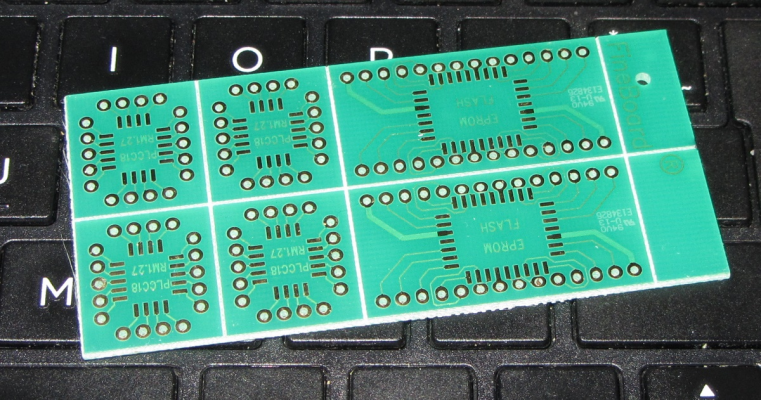

... hmmm ... is there enough interest to start a series of "SMD_to_DIL"-adapters for specific chips?

I have some for standard SMD-chips, but it's easy enough to design and order some ten or more for any other type too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I have some for standard SMD-chips, but it's easy enough to design and order some ten or more for any other type too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Generation 7 Electronics Development October 25, 2017 06:24PM |

Registered: 13 years ago Posts: 7,616 |

Quote

Shank man

I’m kicking myself for not buying a extra MCU when they were available

Quote

obelisk79

That is an interesting adapter.

So you two prefer to buy a $6 adapter plus a $4 chip over a $5 genuine chip?

One reason against designing a new(er) board is the observation that quite a number of people try very hard and often at additional expenses to avoid buying from the original designer. Just saying.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development October 25, 2017 06:40PM |

Registered: 7 years ago Posts: 363 |

I'm not trying to avoid buying from you. I rather appreciate the sheer simplicity in your design on the Gen 7 board.

You asked if people would be willing to do SMD. I would, but it might discourage others, so offered other options in my response.

NXP had apparently tried to discontinue the LPC1114FN28 earlier this year, but someone else had contacted them and they decided to renew production.

Edited 1 time(s). Last edit at 10/25/2017 06:42PM by obelisk79.

You asked if people would be willing to do SMD. I would, but it might discourage others, so offered other options in my response.

NXP had apparently tried to discontinue the LPC1114FN28 earlier this year, but someone else had contacted them and they decided to renew production.

Edited 1 time(s). Last edit at 10/25/2017 06:42PM by obelisk79.

|

Re: Generation 7 Electronics Development October 25, 2017 06:41PM |

Registered: 9 years ago Posts: 204 |

|

Re: Generation 7 Electronics Development October 25, 2017 06:44PM |

Registered: 7 years ago Posts: 363 |

|

Re: Generation 7 Electronics Development October 25, 2017 07:10PM |

Registered: 13 years ago Posts: 7,616 |

Quote

obelisk79

NXP had apparently tried to discontinue the LPC1114FN28 earlier this year, but someone else had contacted them and they decided to renew production.

That's good news! Another advantage of these genuine DIL chips over an adapter is that they're 5V-tolerant out of the box.

Quote

Shank man

It's just not a simple process of buying things from Germany and getting them delivered to the US of A in a reasonable amount of time.

The process is as simple as sending address and funds, like in every shop. Shipping to the US typically takes three days plus the time inside the US (which can apparently be another 7 days). Actually I shipped more Gen7 kits to the US than to inside Germany so far :-)

Quote

Shank man

I can remove the suggestion if you like.

Thanks for the offering, but thanks, not necessary. My wellbeing doesn't depend on these Gen7 sales.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Generation 7 Electronics Development October 25, 2017 07:20PM |

Registered: 7 years ago Posts: 363 |

Quote

Traumflug

The process is as simple as sending address and funds, like in every shop. Shipping to the US typically takes three days plus the time inside the US (which can apparently be another 7 days). Actually I shipped more Gen7 kits to the US than to inside Germany so far :-)

I believe that!

|

Re: Generation 7 Electronics Development October 26, 2017 04:36PM |

Admin Registered: 16 years ago Posts: 13,884 |

Quote

VDX

... hmmm ... is there enough interest to start a series of "SMD_to_DIL"-adapters for specific chips?

I have some for standard SMD-chips, but it's easy enough to design and order some ten or more for any other type too ...

... quoting myself - but I've found one of the "SMD_to_DIL-adapter"-PCB's:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Generation 7 Electronics Development October 26, 2017 04:39PM |

Registered: 10 years ago Posts: 14,672 |

I've found soldering LFQP chips easy enough using solder paste and a hotplate. In fact it was from instructions for building an earlier generation of RepRap electronics, by Adrian Bowyer himself AFAIR, that I first learned of this method. But I appreciate that soldering a through-hole IC is even easier.

A hybrid solution would be to produce a daughter board carrying an ARM 4 chip such as the ATSAM4S8B or 8C along with the critical components such as the crystal and decoupling capacitors, that can be plugged in to socket strips on a 2 layer PCB or even perfboard. Buying such a daughter board from Traumflug would be little different from buying one of those DIL packaged processors that are becoming scarce. The purists could still buy those components separately and solder them on a hotplate.

Edited 3 time(s). Last edit at 10/26/2017 04:52PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

A hybrid solution would be to produce a daughter board carrying an ARM 4 chip such as the ATSAM4S8B or 8C along with the critical components such as the crystal and decoupling capacitors, that can be plugged in to socket strips on a 2 layer PCB or even perfboard. Buying such a daughter board from Traumflug would be little different from buying one of those DIL packaged processors that are becoming scarce. The purists could still buy those components separately and solder them on a hotplate.

Edited 3 time(s). Last edit at 10/26/2017 04:52PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Generation 7 Electronics Development October 26, 2017 06:26PM |

Admin Registered: 16 years ago Posts: 13,884 |

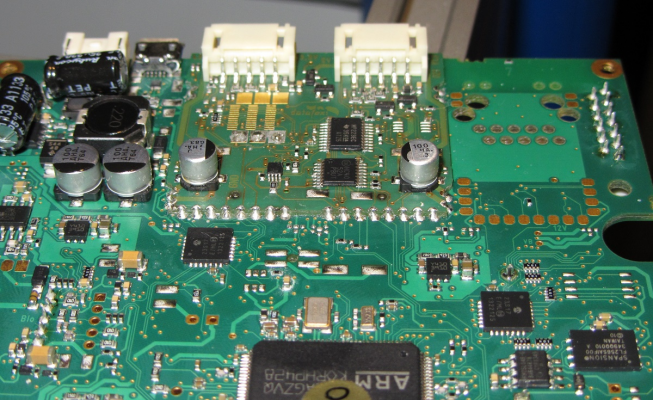

... there are some other common "stackig" methodes too - this is one of my actual projects:

This modules can be of any type and either "single-" or "double-sized", like in the image ... or any other size or configuration ...

Some years ago I've assembled/stacked micro-sensors and complex assemblies with pitch sizes of 60 to 100 microns and soldered or brazed wires with 10 microns or even thinner on them - this image shows a small section of one of this "micro-sensors" with 10µ and 1µ wires across a gap:

[reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

This modules can be of any type and either "single-" or "double-sized", like in the image ... or any other size or configuration ...

Some years ago I've assembled/stacked micro-sensors and complex assemblies with pitch sizes of 60 to 100 microns and soldered or brazed wires with 10 microns or even thinner on them - this image shows a small section of one of this "micro-sensors" with 10µ and 1µ wires across a gap:

[reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Generation 7 Electronics Development October 27, 2017 05:48PM |

Registered: 9 years ago Posts: 204 |

Quote

Traumflug

Quote

Shank man

I’m kicking myself for not buying a extra MCU when they were available

Quote

obelisk79

That is an interesting adapter.

So you two prefer to buy a $6 adapter plus a $4 chip over a $5 genuine chip?

One reason against designing a new(er) board is the observation that quite a number of people try very hard and often at additional expenses to avoid buying from the original designer. Just saying.

I admit to be taken aback by this remark. My suggestion of using the TSSOP28 to DIP28 adapter was not to deprive anyone of a revenue stream or to save a few dollars but only to perpetuate the life of the controller by using a LPC1114FDH2/102 instead of the obsolete LPC1114FN2/102 MCU. The latter has been discontinued regardless of that letter posted by NXP. If its still in production why isn’t anybody stocking it? Because there is no demand for them that’s why. Whether or not using the adapter chip is a feasible solution, I don’t know, that’s why I put it out there.

Also who in world builds a controller like this to save money? No one, that’s who. I have over $250.00 wrapped up in the 2 I built. Copper clad boards, etching solution, soldering iron & solder suckers, those little drill bits that break just taking them out of the package all add to the cost. Not to mention buying 2 ATX power supplies when I already had a couple of MeanWells. There was no money saved. I can afford any controller out there but this is the one I wanted so I did what it took to get them. If you have an issue with people buying the parts from places other than yourself, why do you post a detailed parts list and assembly instructions? Why don’t you lock down the design and sell assembled boards? I would have gladly bought a couple pre-assembled ones. I’m certainly not adverse from buying parts from you but

your site isn’t very commerce friendly. I just want to put in my address and credit card information and

be done with it. Anyway I’m satisfied with the controllers I have and feel they were well worth the effort to build and the expense it took to get them.

Respectfully

Ray

|

Re: Generation 7 Electronics Development October 27, 2017 06:08PM |

Registered: 13 years ago Posts: 7,616 |

Quote

Shank man

[...]

Hello number three :-)

Edited 1 time(s). Last edit at 10/27/2017 06:08PM by Traumflug.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

Sorry, only registered users may post in this forum.