|

3d print PEEK March 24, 2015 06:29AM |

Registered: 9 years ago Posts: 1 |

Hello guys,

I found an article ( [www.3ders.org] )

where a german company claims they can print PEEK with a hot-end and also sell PEEK filaments .

Apparently they have 2 website, but this one is in english ( [indmatec.de] )

You could print custom implants or components for a reprap extruder.

What do you think of it?

I found an article ( [www.3ders.org] )

where a german company claims they can print PEEK with a hot-end and also sell PEEK filaments .

Apparently they have 2 website, but this one is in english ( [indmatec.de] )

You could print custom implants or components for a reprap extruder.

What do you think of it?

|

Re: 3d print PEEK July 01, 2015 02:59AM |

Registered: 9 years ago Posts: 52 |

Ehhh.... considering that most people have PEEK as a liner in their hot ends, this is probably going to start off very slow.

It would actually allow people to print custom implants and medical stuff, but if custom body modification is the only impetus, I think this is going to happen very slowly if at all.

That said, I'm working on a composite hot end that uses a borosilicate glass instead of the PTFE liner. I'm saving my nickels and dimes to buy the oxyacetylene torches I need to do the glass work.

It would actually allow people to print custom implants and medical stuff, but if custom body modification is the only impetus, I think this is going to happen very slowly if at all.

That said, I'm working on a composite hot end that uses a borosilicate glass instead of the PTFE liner. I'm saving my nickels and dimes to buy the oxyacetylene torches I need to do the glass work.

|

Re: 3d print PEEK September 15, 2015 04:16PM |

Registered: 8 years ago Posts: 9 |

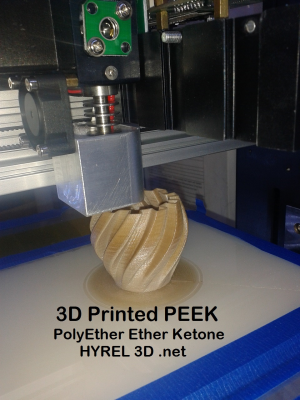

We printed this spiral vase in PEEK today on our Hyrel 3D System 30M with the MK1-350 print head, which prints at up to 400C and also prints with polycarbonate.

That's the MK1-350 above the vase.

That's the MK1-350 above the vase.

|

Re: 3d print PEEK September 16, 2015 01:22AM |

Registered: 9 years ago Posts: 344 |

|

Re: 3d print PEEK September 16, 2015 08:02AM |

Registered: 8 years ago Posts: 9 |

Quote

cristian

The most expensive plastic vase I have ever seen.

I have a short sample of PEEK filament, I am looking forward to trying it.

Does the extrusion work well? Did you notice any issues, such as delamination, filament break, slipping, ...?

Haha, agreed. Yet, we test each head, so... cost of doing business.

The extrusion works great. The PEEK bonds very well on a polycarbonate sheet - in fact, so well that it's a bit of work to remove it from the PC base. It's not sticking as well on plain glass, but we are still experimenting. We set the extruder temp to 390C for PEEK. The feed path is all stainless, brass 0.5mm nozzle.

|

Re: 3d print PEEK October 31, 2016 04:25PM |

Registered: 8 years ago Posts: 9 |

|

Re: 3d print PEEK December 24, 2016 11:35AM |

Registered: 9 years ago Posts: 344 |

|

Re: 3d print PEEK February 10, 2017 04:39AM |

Registered: 12 years ago Posts: 346 |

|

Re: 3d print PEEK November 02, 2018 09:52AM |

Registered: 8 years ago Posts: 9 |

Sorry, Philipp, I haven't checked in in a while.

We were using an 80C bed with a chamber at close to 55C as we could get it (but at least ~40C).

We now have a program to create a spiral pad of PEEK (better than a brim, with only one start and stop) and then G54 offset the Z by one layer thickness, then start the standard gcode. This removes the need to align and print from a second head for ABS.

And our new models have beds up to 120C (optionally 200C).

We were using an 80C bed with a chamber at close to 55C as we could get it (but at least ~40C).

We now have a program to create a spiral pad of PEEK (better than a brim, with only one start and stop) and then G54 offset the Z by one layer thickness, then start the standard gcode. This removes the need to align and print from a second head for ABS.

And our new models have beds up to 120C (optionally 200C).

|

Re: 3d print PEEK January 18, 2019 08:03AM |

Registered: 8 years ago Posts: 9 |

|

Re: 3d print PEEK February 19, 2019 09:59AM |

Registered: 5 years ago Posts: 10 |

i printed some peek and ultem parts with 400c v6 and enclosure (no active heating , only the bed)

what i found is , unless you have an active heated chamber its worthless to print in those filaments .

the parts might look nice and all , but the layer adhesion will be poor .

they wont function near their advertised tensile strength .

what i found is , unless you have an active heated chamber its worthless to print in those filaments .

the parts might look nice and all , but the layer adhesion will be poor .

they wont function near their advertised tensile strength .

Sorry, only registered users may post in this forum.