What about the use of UV glues and UV light

Posted by Robert T. Haas

|

What about the use of UV glues and UV light December 14, 2007 11:24AM |

i am designing a reprap that is very small and based on the original design and will be built almost comepletely out of .22 plexiglass which i will have CNC cut. i am going to have it setup so i can try all kinds of different print heads. i was thinking about these UV based glues that are often used by the dentest industry. [www.dymax.com]

i was thinking it would proably be a great idea to use this UV glue as a building material and the head can have a UV light on it that it will use to cure the super small droplets of UV glue.

has anyone every experiemented with this?

[i127.photobucket.com]

[i127.photobucket.com]

[i127.photobucket.com]

[i127.photobucket.com]

i was thinking it would proably be a great idea to use this UV glue as a building material and the head can have a UV light on it that it will use to cure the super small droplets of UV glue.

has anyone every experiemented with this?

[i127.photobucket.com]

[i127.photobucket.com]

[i127.photobucket.com]

[i127.photobucket.com]

|

Re: What about the use of UV glues and UV light December 14, 2007 03:17PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Robert,

... we use a DELO-UV-lamp and Glass-Bond-glue (sometimes other UV-cured glue-types and pastes too) for prefixing thin wires on aluminium or glueing glass-parts and mirrors on glass- or metall-plates.

It works very good and fast, the curing lasts 5 to 20 seconds until the glue is complete hardened ...

But it's very expensive - the UV-Lamp is nearly 3000 Euros with an estimated lifetime for the bulb of 2.000 hours or 2.000 cycles, then we have to buy a new bulb for 400 to 800 Euros (different wavelength- and energy-types)

So it's maybe easier and cheaper to try heat-curing - either with a diode-laser, or with a focussed IR-heater.

Viktor

... we use a DELO-UV-lamp and Glass-Bond-glue (sometimes other UV-cured glue-types and pastes too) for prefixing thin wires on aluminium or glueing glass-parts and mirrors on glass- or metall-plates.

It works very good and fast, the curing lasts 5 to 20 seconds until the glue is complete hardened ...

But it's very expensive - the UV-Lamp is nearly 3000 Euros with an estimated lifetime for the bulb of 2.000 hours or 2.000 cycles, then we have to buy a new bulb for 400 to 800 Euros (different wavelength- and energy-types)

So it's maybe easier and cheaper to try heat-curing - either with a diode-laser, or with a focussed IR-heater.

Viktor

|

Re: What about the use of UV glues and UV light December 15, 2007 03:57AM |

Admin Registered: 17 years ago Posts: 1,791 |

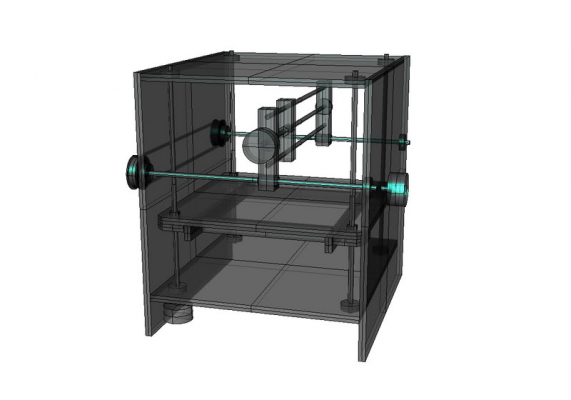

Interesting design.

A few questions:

How big is the machine?

Have you considered going with aluminum instead of plexiglass? Aluminum is much more stiff. You may be able to do light routing with your machine that way.

When you're moving back and forth in the y-axis, the x-axis subassembly rides on top of the two y-axis drive screws. Imagine a bunch of back-and-forth y-axis motion: the whole x-axis subassembly is going to sway back and forth (like a person standing in a bus that's hitting the brakes) when you switch direction. You may want to add two y-axis rails (smooth rods) slightly above or below the x-axis's top rail.

I would cut a very large square out of the top sheet. This way you can run feedstock and wires to the printhead. I would also move the x and y axes up in the machine to give you more room in the z.

The back side of it is open. What about putting in a sheet of material back there? That would make your machine much more stiff. You could even put a sheet on the front held on with thumbscrews.

How are you connecting the plexiglass sheets together? Fasteners? Adhesive?

A few questions:

How big is the machine?

Have you considered going with aluminum instead of plexiglass? Aluminum is much more stiff. You may be able to do light routing with your machine that way.

When you're moving back and forth in the y-axis, the x-axis subassembly rides on top of the two y-axis drive screws. Imagine a bunch of back-and-forth y-axis motion: the whole x-axis subassembly is going to sway back and forth (like a person standing in a bus that's hitting the brakes) when you switch direction. You may want to add two y-axis rails (smooth rods) slightly above or below the x-axis's top rail.

I would cut a very large square out of the top sheet. This way you can run feedstock and wires to the printhead. I would also move the x and y axes up in the machine to give you more room in the z.

The back side of it is open. What about putting in a sheet of material back there? That would make your machine much more stiff. You could even put a sheet on the front held on with thumbscrews.

How are you connecting the plexiglass sheets together? Fasteners? Adhesive?

|

Re: What about the use of UV glues and UV light December 15, 2007 10:20PM |

|

Re: What about the use of UV glues and UV light December 17, 2007 02:20PM |

Registered: 17 years ago Posts: 304 |

Hello Robert!

I have done some research to achieve resin mixtures that would be UV cured. My goal was to make both the resins and the UV-lamps affordable, as well as fast curing.

There have been a couple of problems that have been encountered on the way.

Achieving cheap and fast curing mixes produced an effect that's called surface screening:

The top layer cures fast but the bottom layers don't get enough UV to cure through.

This is only a problem if you make thick layers (>0.2mm).

You can also use different catalyzer mixes that allow the UV to penetrate deeper, but this will cause the resin to cure much slower (the UV-range used is less energetic. Safer, yes, but needs longer cure times).

I have found that commercial acrylic or acydic air-drying varnishes (Only water-free! The glossy stuff is the best) can be used as a basis with the UV-active catalyzer Benzophenone to make a good starting point for UV-setting resins. UV-lamps for this catalyzer are of the germicidal kind (253nm) and cost around 50$ for a 25W lamp that will last between 4000 to 9000 hours. Stronger lamps will cure the resin faster of course.

I recommend building your Reprap as shielded as possible, so as to keep the UV radiation inside.

I have done some research to achieve resin mixtures that would be UV cured. My goal was to make both the resins and the UV-lamps affordable, as well as fast curing.

There have been a couple of problems that have been encountered on the way.

Achieving cheap and fast curing mixes produced an effect that's called surface screening:

The top layer cures fast but the bottom layers don't get enough UV to cure through.

This is only a problem if you make thick layers (>0.2mm).

You can also use different catalyzer mixes that allow the UV to penetrate deeper, but this will cause the resin to cure much slower (the UV-range used is less energetic. Safer, yes, but needs longer cure times).

I have found that commercial acrylic or acydic air-drying varnishes (Only water-free! The glossy stuff is the best) can be used as a basis with the UV-active catalyzer Benzophenone to make a good starting point for UV-setting resins. UV-lamps for this catalyzer are of the germicidal kind (253nm) and cost around 50$ for a 25W lamp that will last between 4000 to 9000 hours. Stronger lamps will cure the resin faster of course.

I recommend building your Reprap as shielded as possible, so as to keep the UV radiation inside.

|

Re: What about the use of UV glues and UV light December 18, 2007 06:08PM |

Registered: 16 years ago Posts: 246 |

|

Re: What about the use of UV glues and UV light December 19, 2007 07:39AM |

Admin Registered: 17 years ago Posts: 1,791 |

|

Re: What about the use of UV glues and UV light December 19, 2007 04:11PM |

Registered: 17 years ago Posts: 304 |

|

Re: What about the use of UV glues and UV light December 19, 2007 04:47PM |

Registered: 16 years ago Posts: 235 |

|

Re: What about the use of UV glues and UV light December 19, 2007 05:29PM |

Registered: 17 years ago Posts: 304 |

I'm not really sure but the fact is that it doesn't really need to block UVs as standard glass does that pretty well.

Nevertheless there are plastics, or better said additives that make a transparent plastic become UV filtering. You will just have to ask for it if you want to have that characteristic, but chances are that they will make you pay $$ for an otherwise quite cheap to achieve UV blocking plastic.

Nevertheless there are plastics, or better said additives that make a transparent plastic become UV filtering. You will just have to ask for it if you want to have that characteristic, but chances are that they will make you pay $$ for an otherwise quite cheap to achieve UV blocking plastic.

|

Re: What about the use of UV glues and UV light May 06, 2010 11:34PM |

I have a Auto Windshield Repair business, we repair small rock chips and small cracks by injecting a UV cured resin into in most cases a dime sized chip through a hole smaller than the tip of a bic point pen. I'm actually trying to learn more about the product we've been using and how to either make it myself or find someone like the people on this forum to make it for me. Currently I'm spending $85 for a liter of this stuff and wanting to cut my overhead a little and also re-sell it to others in my industry.

As far as I know (which isnt much) its some kind of polyurethane oligomer, photoinitiator, acrylate (meth) acrylate. I'm actually just reading off a few things i have printed off a well known and marketed glass repair resins MSDS. Ok now that i've proven how stupid i am, can someone please help me. If someone out there can make a product similar to ones used for windshield repair for me a little cheaper so i can market it or help me make it. I would be very interested I'm in Dallas Texas U.S. my email is gene.freerepair@yahoo.com

Options: Reply•Quote

As far as I know (which isnt much) its some kind of polyurethane oligomer, photoinitiator, acrylate (meth) acrylate. I'm actually just reading off a few things i have printed off a well known and marketed glass repair resins MSDS. Ok now that i've proven how stupid i am, can someone please help me. If someone out there can make a product similar to ones used for windshield repair for me a little cheaper so i can market it or help me make it. I would be very interested I'm in Dallas Texas U.S. my email is gene.freerepair@yahoo.com

Options: Reply•Quote

Sorry, only registered users may post in this forum.