UV curable resins

Posted by spota

|

Re: UV curable resins June 12, 2008 02:08PM |

Registered: 15 years ago Posts: 3 |

|

Re: UV curable resins July 06, 2008 04:57PM |

Admin Registered: 16 years ago Posts: 13,884 |

|

Re: UV curable resins July 07, 2008 04:11AM |

Registered: 16 years ago Posts: 900 |

Umm slightly off topic guys (Sorry)

making resins cure with UV great....

What about other wavelengths....

Can they be made to cure with Infra Red (about the 808nm wavelength specificaly) ??

Is it possible to add an IR fluorescing agent to the resin to make the IR action/presence visible to humans without interfering with the set of the resin.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

making resins cure with UV great....

What about other wavelengths....

Can they be made to cure with Infra Red (about the 808nm wavelength specificaly) ??

Is it possible to add an IR fluorescing agent to the resin to make the IR action/presence visible to humans without interfering with the set of the resin.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: UV curable resins July 07, 2008 05:18AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Andy,

there are many 1K- and 2K-epoxies which are heat-cured.

Most other reactions are heat-sensitive too, so you can speedup the hardening process of most mixtures or achieve fast air-hardening when heated aditionally.

I salvaged an old toaster with two IR-glass-tubes instad of wire-heaters and want to try hardening paste, so i hope to dispend fluid pastes at room-temp and harden slice after slice ...

Maybe it's possible too to harden selectively with focussing IR in a small spot (IR-(laser-)diode or Halogen-bulb) - ist's much more fuzzy then curing with an UV-spot, but it should be possible to 'draw' hardened trays in a thin sheet of heat-activated resine too ...

Viktor

there are many 1K- and 2K-epoxies which are heat-cured.

Most other reactions are heat-sensitive too, so you can speedup the hardening process of most mixtures or achieve fast air-hardening when heated aditionally.

I salvaged an old toaster with two IR-glass-tubes instad of wire-heaters and want to try hardening paste, so i hope to dispend fluid pastes at room-temp and harden slice after slice ...

Maybe it's possible too to harden selectively with focussing IR in a small spot (IR-(laser-)diode or Halogen-bulb) - ist's much more fuzzy then curing with an UV-spot, but it should be possible to 'draw' hardened trays in a thin sheet of heat-activated resine too ...

Viktor

|

Re: UV curable resins July 07, 2008 06:37AM |

Registered: 16 years ago Posts: 900 |

The 808nm was because I was thinking specifically of salvaged laser diodes from cdrom drives.

There seem to be plenty of cost effective laser modules available to purchase too around the visible and near IR 780nm range.

Being Diode, Mount and collimating Lense for approx 30E. Very easy to drive too.

(The read only drives that were ubiquitous use IR laser Diodes).

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

There seem to be plenty of cost effective laser modules available to purchase too around the visible and near IR 780nm range.

Being Diode, Mount and collimating Lense for approx 30E. Very easy to drive too.

(The read only drives that were ubiquitous use IR laser Diodes).

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: UV curable resins July 17, 2008 04:38PM |

Registered: 15 years ago Posts: 35 |

[www.smooth-on.com]

[www.smooth-on.com]

/\plastics

Do they carry any resins that you can convert into a UV Curable format?

They are all Urethane based. 2 part cure types.

[www.smooth-on.com]

/\plastics

Do they carry any resins that you can convert into a UV Curable format?

They are all Urethane based. 2 part cure types.

|

Re: UV curable resins July 18, 2008 02:53AM |

Registered: 17 years ago Posts: 304 |

Not with the photoinitiators discussed here.

As far as I'm aware of, Urethane chemistry is based on 2 molecules that react together to form a polymer chain. As such, they don't need a catalyzer that could be triggered through UV.

Unless you modify one of the 2 constituent molecules to be triggered by UV, I don't see how this could be done.

As far as I'm aware of, Urethane chemistry is based on 2 molecules that react together to form a polymer chain. As such, they don't need a catalyzer that could be triggered through UV.

Unless you modify one of the 2 constituent molecules to be triggered by UV, I don't see how this could be done.

|

Re: UV curable resins July 18, 2008 04:18AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi all,

i found a promisimng material for UV-cured fabbing at room-temp, which reacts to PMMA or Plexiglass.

It's called "Acrifix 192" and is a light-/UV-cured 1K-glue for plexiglass.

Here are two sources with extremely different prices for the same size:

100g = 7,50 Euros: - [www.modulor.de]

100g = 49,95 USD: - [www.eglider.org]

And here the multilingual product-description: - [www.acrylglasprofi.de]

I'll try with some (manual) experiments in the next week ...

Viktor

Edited 2 time(s). Last edit at 07/18/2008 05:34PM by Viktor.

i found a promisimng material for UV-cured fabbing at room-temp, which reacts to PMMA or Plexiglass.

It's called "Acrifix 192" and is a light-/UV-cured 1K-glue for plexiglass.

Here are two sources with extremely different prices for the same size:

100g = 7,50 Euros: - [www.modulor.de]

100g = 49,95 USD: - [www.eglider.org]

And here the multilingual product-description: - [www.acrylglasprofi.de]

I'll try with some (manual) experiments in the next week ...

Viktor

Edited 2 time(s). Last edit at 07/18/2008 05:34PM by Viktor.

|

Re: UV curable resins July 18, 2008 06:17AM |

Registered: 17 years ago Posts: 304 |

Hey Viktor!

In the near future I will be able to give a formulation for Acrylic resin here that works on the same photoinitiators I sent you.

The difficulty now seems to be able to work with the same commercial resins, as their composition is not specified most of the times.

That's why for the Acrylic resin composition I will be using mostly the pure compounds, not commercial mixes.

I can get 1 Liter of pure MMA compound for around 18

In the near future I will be able to give a formulation for Acrylic resin here that works on the same photoinitiators I sent you.

The difficulty now seems to be able to work with the same commercial resins, as their composition is not specified most of the times.

That's why for the Acrylic resin composition I will be using mostly the pure compounds, not commercial mixes.

I can get 1 Liter of pure MMA compound for around 18

|

Re: UV curable resins July 18, 2008 06:29AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Fernando,

AFAIK the MMA-Polymerisation seems to be a very interesting way - high strength, translucent or coloured objects possible, extreme good surfaces, very good adhesion of the fluid to the underlaying layer, long storage-time and pot-life ...

I'll make some tests with the Acrifix and hope you manage the sources for our own 1K-UV-resin.

One backdraft is the toxicity and flammability of the Acrifix (see the datasheets) - is it system-inherent or can you mix a better compound?

Viktor

AFAIK the MMA-Polymerisation seems to be a very interesting way - high strength, translucent or coloured objects possible, extreme good surfaces, very good adhesion of the fluid to the underlaying layer, long storage-time and pot-life ...

I'll make some tests with the Acrifix and hope you manage the sources for our own 1K-UV-resin.

One backdraft is the toxicity and flammability of the Acrifix (see the datasheets) - is it system-inherent or can you mix a better compound?

Viktor

|

Re: UV curable resins July 18, 2008 07:00AM |

Registered: 17 years ago Posts: 304 |

Well flammability is really the problem here.

MMA is a volatile liquid with very low viscosity. So you need to work in safe conditions, no open flames and such. I could imagine a way of reducing volatility at the cost of increasing viscosity. Something along the lines of dissolving PMMA powder into MMA monomer could have the desired result.

Agree on your description of the advantages of Acrylic resins, they really are very attractive and a lot more controllable.

MMA is a volatile liquid with very low viscosity. So you need to work in safe conditions, no open flames and such. I could imagine a way of reducing volatility at the cost of increasing viscosity. Something along the lines of dissolving PMMA powder into MMA monomer could have the desired result.

Agree on your description of the advantages of Acrylic resins, they really are very attractive and a lot more controllable.

|

Re: UV curable resins July 18, 2008 08:28AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Fernando,

... i made a few quick tests with Acrifix and a normal Halogen-lightsource with glassfiber-lightfeeding (low UV, most visible light and IR).

After some seconds lighting the fluid tray got a gelatine-like 'skin', after nearly two minutes a thin filament is hardened, thicker filaments and droplets have fluid cores.

At home i'll test with my Eprom-erasing tube, so the curing will maybe go much faster with UV-light ...

Viktor

... i made a few quick tests with Acrifix and a normal Halogen-lightsource with glassfiber-lightfeeding (low UV, most visible light and IR).

After some seconds lighting the fluid tray got a gelatine-like 'skin', after nearly two minutes a thin filament is hardened, thicker filaments and droplets have fluid cores.

At home i'll test with my Eprom-erasing tube, so the curing will maybe go much faster with UV-light ...

Viktor

|

Re: UV curable resins July 18, 2008 10:02AM |

Registered: 17 years ago Posts: 304 |

Sounds good.

Seems like they are using some fancy photoinitiators if they work with near UV, henece the price of the product. It may be interesting to know what times you need to completely harden a 3-5mm film with the EPROM erasing UV. Imagine this would be like a 3 to 5 thick layers worth of resin and it's a good benchmark.

As a comparison, my mixes set within 7 minutes and completely hardened with 7 more minutes of high intensity UV.

Seems like they are using some fancy photoinitiators if they work with near UV, henece the price of the product. It may be interesting to know what times you need to completely harden a 3-5mm film with the EPROM erasing UV. Imagine this would be like a 3 to 5 thick layers worth of resin and it's a good benchmark.

As a comparison, my mixes set within 7 minutes and completely hardened with 7 more minutes of high intensity UV.

|

Re: UV curable resins July 18, 2008 11:07AM |

Registered: 15 years ago Posts: 35 |

[www.factor2.com]

Is any of that stuff of interest to you. I understand that it has to be an acrylic now. I have a dental equiptment and supply book around here somewhere. They sell photopolymerization resins. I'll post what they offer when I find it.

Is any of that stuff of interest to you. I understand that it has to be an acrylic now. I have a dental equiptment and supply book around here somewhere. They sell photopolymerization resins. I'll post what they offer when I find it.

|

Re: UV curable resins July 18, 2008 11:25AM |

Registered: 17 years ago Posts: 304 |

Yes dental UV-resins are extremely efficient acrylic polymers that activate in the near UV/blue wavelengths. The problem with these mixes is their very high prices.

The aim of what I did here was to device a cheap and standardized solution, for prices around 20$ a kg of resin with all the elements included.

The aim of what I did here was to device a cheap and standardized solution, for prices around 20$ a kg of resin with all the elements included.

|

Re: UV curable resins July 18, 2008 12:11PM |

Admin Registered: 17 years ago Posts: 1,915 |

Just out of curiosity, what is wrong with just ordinary methyl methacrylate, aside from the fact that it is a strong irritant and requires huge amounts of ventilation? It goes for about $1.25/lb in very large quantities last time I checked.

Edited 1 time(s). Last edit at 07/18/2008 12:12PM by Forrest Higgs.

Edited 1 time(s). Last edit at 07/18/2008 12:12PM by Forrest Higgs.

|

Re: UV curable resins July 18, 2008 12:54PM |

Registered: 17 years ago Posts: 304 |

There's nothing wrong with it at all, apart from it's volatility and flammability.

I think it's a very interesting candidate and I'm currently working on it.

It will work with similar photoinitiators as I mentioned in another thread and you could reduce it's volatility by adding polymethyl metacrylate powder to it, basically filing residue from PMMA cutters.

MMA would actually be one of the best candidates for formulating a ready to use mix that we could provide in the Reprap shop.

I think it's a very interesting candidate and I'm currently working on it.

It will work with similar photoinitiators as I mentioned in another thread and you could reduce it's volatility by adding polymethyl metacrylate powder to it, basically filing residue from PMMA cutters.

MMA would actually be one of the best candidates for formulating a ready to use mix that we could provide in the Reprap shop.

|

Re: UV curable resins July 18, 2008 03:20PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Fernando,

... i'm actually testing with my UV-tube (it's a Philips "TUV 4W, Ultraviolet").

I drop some bulbs and trays of Acrifix in maybe 0,5mm thick layers on a Plate and then on top of the old tray and cure for maybe 3 minutes.

The resine isn't hard after 3 minutes, but more like soft gelatine - the older layers stay elastic too.

I think the hardening is a passive process after the initiation, which will go for a longer time on - in the data-sheet i read something about 15 to 25 minutes curing with UV-light!

I'll try further ...

Viktor

... i'm actually testing with my UV-tube (it's a Philips "TUV 4W, Ultraviolet").

I drop some bulbs and trays of Acrifix in maybe 0,5mm thick layers on a Plate and then on top of the old tray and cure for maybe 3 minutes.

The resine isn't hard after 3 minutes, but more like soft gelatine - the older layers stay elastic too.

I think the hardening is a passive process after the initiation, which will go for a longer time on - in the data-sheet i read something about 15 to 25 minutes curing with UV-light!

I'll try further ...

Viktor

|

Re: UV curable resins July 18, 2008 04:09PM |

Admin Registered: 16 years ago Posts: 13,884 |

... either it's not enough power, or the wrong wavelength ...

It's the same when i cure 3minutes or more times the 3minutes - the Acrifix stays in the 'gelatine'-state and won't go into full hardening ...

In the basement of my parents i have a doublesided multitube-UV-source from ISEL which i used for PCB-making - i think this bigger tubes should be stronger too.

Earlier today i ordered a 100g-probe of 'Acrifix 192' on my own (the actual probes comes from my daywork and could be outdated), so in the next weeks i want to try with automated dispensing and curing the resin with my CNC-mill - maybe the 'gelatine'-body is enough stability for continuous fabbing and the complete hardening can be done after the fabbing ...

Viktor

It's the same when i cure 3minutes or more times the 3minutes - the Acrifix stays in the 'gelatine'-state and won't go into full hardening ...

In the basement of my parents i have a doublesided multitube-UV-source from ISEL which i used for PCB-making - i think this bigger tubes should be stronger too.

Earlier today i ordered a 100g-probe of 'Acrifix 192' on my own (the actual probes comes from my daywork and could be outdated), so in the next weeks i want to try with automated dispensing and curing the resin with my CNC-mill - maybe the 'gelatine'-body is enough stability for continuous fabbing and the complete hardening can be done after the fabbing ...

Viktor

|

Re: UV curable resins July 18, 2008 04:17PM |

Registered: 17 years ago Posts: 304 |

Interesting! That's actually slower than I was expecting. I suppose the concentration of photoinitiator is lower than what I use. On the other hand, you are using lamps that are 10% as powerful as the ones I use.

I'm pretty positive that if you were using 36 or 40W lamps as I am, this would all harden a lot faster.

I'm pretty positive that if you were using 36 or 40W lamps as I am, this would all harden a lot faster.

|

Re: UV curable resins July 18, 2008 04:20PM |

Registered: 17 years ago Posts: 304 |

I agree.

You need to know the curing wavelength of the acrylic mix.

You could be irradiating it all day long, if it doesn't match the correct wavelength for you photoinitiator, you won't get the desired results.

It's all about quantum mechanics: intensity is not enoug, you have to use the right energy quantums (read, wavelength).

Don't the specs of the product come with some info on that? They really should!

You need to know the curing wavelength of the acrylic mix.

You could be irradiating it all day long, if it doesn't match the correct wavelength for you photoinitiator, you won't get the desired results.

It's all about quantum mechanics: intensity is not enoug, you have to use the right energy quantums (read, wavelength).

Don't the specs of the product come with some info on that? They really should!

|

Re: UV curable resins July 18, 2008 05:29PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Fernando,

... now, after nearly an hour of testing it seems to be clear - small blobs of Acrifix (maybe 1mm diameter, 0,4 high) are complete hardened after 20 minutes UV-radiating with the 4W-tube from 30mm distance.

After short exposure, the resin is like gelatine, when covered with a new tray, it's shielded, so the reaction is slowed down - the multi-trays are like leather on the surface, but semifluid or like gelatine in the core.

So you need much more power for hardening in seconds or max a minute, what's needed for proper fabbing.

I have some UV-curable glass-glue from DELO, it's nearly the same behaviour with my small UV-tube, but in my previous job i cured the same glue with a 200-Watt-UV-source with two output-fibres in maybe 15 seconds for a blob of 0,3mm height. The source then was a Hg-lamp with UV-a,b and c.

For our needs we should focus on fast photo-initiators for the near-UV-band, so a cheap UV-tube could do the job ...

Viktor

... now, after nearly an hour of testing it seems to be clear - small blobs of Acrifix (maybe 1mm diameter, 0,4 high) are complete hardened after 20 minutes UV-radiating with the 4W-tube from 30mm distance.

After short exposure, the resin is like gelatine, when covered with a new tray, it's shielded, so the reaction is slowed down - the multi-trays are like leather on the surface, but semifluid or like gelatine in the core.

So you need much more power for hardening in seconds or max a minute, what's needed for proper fabbing.

I have some UV-curable glass-glue from DELO, it's nearly the same behaviour with my small UV-tube, but in my previous job i cured the same glue with a 200-Watt-UV-source with two output-fibres in maybe 15 seconds for a blob of 0,3mm height. The source then was a Hg-lamp with UV-a,b and c.

For our needs we should focus on fast photo-initiators for the near-UV-band, so a cheap UV-tube could do the job ...

Viktor

|

Re: UV curable resins July 18, 2008 08:22PM |

Registered: 15 years ago Posts: 35 |

I hope you all stray away from dangerous plastics and chemicals if at all possible.

The reprap machine looks like it could do what it does with wax.

I use a dental waxer from kerrlabs to sculpt in toxic mom wax. the heating tip has an adjustable temp via + and - buttons.

I'm thinking about several possible avenues for the perfect RP machine for me to go after.

Even more so now, with the Perfacto system seeming slightly impossible at cost effectiveness.

Gotta post another topic soon about the other two machines.

I'm just saying this because most of us would be doing this stuff in our houses near our computers.

So it should be some what safe.

"MEK" Methyl Ethyl Ketone is a solvent we sculptors try to avoid using- cause of the cancer and birth defect dangers associated with it.

[patft.uspto.gov]

Check that out. Abandoned as well.

The reprap machine looks like it could do what it does with wax.

I use a dental waxer from kerrlabs to sculpt in toxic mom wax. the heating tip has an adjustable temp via + and - buttons.

I'm thinking about several possible avenues for the perfect RP machine for me to go after.

Even more so now, with the Perfacto system seeming slightly impossible at cost effectiveness.

Gotta post another topic soon about the other two machines.

I'm just saying this because most of us would be doing this stuff in our houses near our computers.

So it should be some what safe.

"MEK" Methyl Ethyl Ketone is a solvent we sculptors try to avoid using- cause of the cancer and birth defect dangers associated with it.

[patft.uspto.gov]

Check that out. Abandoned as well.

|

Re: UV curable resins July 19, 2008 04:26AM |

Registered: 17 years ago Posts: 304 |

VDX Wrote:

-------------------------------------------------------

> Hi Fernando,

>

> ... now, after nearly an hour of testing it seems

> to be clear - small blobs of Acrifix (maybe 1mm

> diameter, 0,4 high) are complete hardened after 20

> minutes UV-radiating with the 4W-tube from 30mm

> distance.

>

...

>

> So you need much more power for hardening in

> seconds or max a minute, what's needed for proper

> fabbing.

>

> I have some UV-curable glass-glue from DELO, it's

> nearly the same behaviour with my small UV-tube,

> but in my previous job i cured the same glue with

> a 200-Watt-UV-source with two output-fibres in

> maybe 15 seconds for a blob of 0,3mm height. The

> source then was a Hg-lamp with UV-a,b and c.

>

> For our needs we should focus on fast

> photo-initiators for the near-UV-band, so a cheap

> UV-tube could do the job ...

>

> Viktor

OK, so it seems that the UV source you are using is correct but not powerfull enough. If you check my other thread [forums.reprap.org] I have a section there that talks about 2 possible fluorescent tubes that you could try: One is a "blacklight" near UV, 40W tube that cost me 5

-------------------------------------------------------

> Hi Fernando,

>

> ... now, after nearly an hour of testing it seems

> to be clear - small blobs of Acrifix (maybe 1mm

> diameter, 0,4 high) are complete hardened after 20

> minutes UV-radiating with the 4W-tube from 30mm

> distance.

>

...

>

> So you need much more power for hardening in

> seconds or max a minute, what's needed for proper

> fabbing.

>

> I have some UV-curable glass-glue from DELO, it's

> nearly the same behaviour with my small UV-tube,

> but in my previous job i cured the same glue with

> a 200-Watt-UV-source with two output-fibres in

> maybe 15 seconds for a blob of 0,3mm height. The

> source then was a Hg-lamp with UV-a,b and c.

>

> For our needs we should focus on fast

> photo-initiators for the near-UV-band, so a cheap

> UV-tube could do the job ...

>

> Viktor

OK, so it seems that the UV source you are using is correct but not powerfull enough. If you check my other thread [forums.reprap.org] I have a section there that talks about 2 possible fluorescent tubes that you could try: One is a "blacklight" near UV, 40W tube that cost me 5

|

Re: UV curable resins July 20, 2008 07:56AM |

Registered: 15 years ago Posts: 35 |

[www.lincolndental.com]

This is the company I got my catalog from- I got it directly from a dentist. Tons of acrylic resins, too many to list.

I could laser scan these pages and post a link to the imagefiles here. Let me know.

This is the company I got my catalog from- I got it directly from a dentist. Tons of acrylic resins, too many to list.

I could laser scan these pages and post a link to the imagefiles here. Let me know.

|

Re: UV curable resins July 20, 2008 08:33AM |

Registered: 17 years ago Posts: 304 |

|

Re: UV curable resins July 21, 2008 05:25AM |

Admin Registered: 16 years ago Posts: 13,884 |

... update ...

After nearly an hour curing with the 4W-tube the multi-layered Acrifix/MMA was elastic like a thermoplast.

8 Hours in my basement didn't chnange the behaviour, so the hardening didn't progress furter.

The i deposited the chunk in my front-car-window in diffuse daylight for maybe 6 hours - it hardened completely to 'solid plexiglass' and is now strong but a liitle brittle, like solid PMMA.

Two more points:

1 - a 'bad' one: the resin shrinks while curing - the domes of single droplets shows sometimes a small cavity, so a continuous tray will shrink some percent in height, when cured.

2 - the 'good' one: the cured material didn'warp! - i removed the multilayered chunk from the bed when it was elastic and after complete hardening the bottom-surface stayed exactly plane, so i think with polymerising multilayered MMA you wouldn't have the warping problems as with other plastics, which shrinks after cooling down ...

Viktor

After nearly an hour curing with the 4W-tube the multi-layered Acrifix/MMA was elastic like a thermoplast.

8 Hours in my basement didn't chnange the behaviour, so the hardening didn't progress furter.

The i deposited the chunk in my front-car-window in diffuse daylight for maybe 6 hours - it hardened completely to 'solid plexiglass' and is now strong but a liitle brittle, like solid PMMA.

Two more points:

1 - a 'bad' one: the resin shrinks while curing - the domes of single droplets shows sometimes a small cavity, so a continuous tray will shrink some percent in height, when cured.

2 - the 'good' one: the cured material didn'warp! - i removed the multilayered chunk from the bed when it was elastic and after complete hardening the bottom-surface stayed exactly plane, so i think with polymerising multilayered MMA you wouldn't have the warping problems as with other plastics, which shrinks after cooling down ...

Viktor

|

Re: UV curable resins July 23, 2008 03:06PM |

Registered: 17 years ago Posts: 304 |

@Viktor: Okay, so you will have to play around with the light source. Probably, a near UV would give the best results? Maybe blue light?

Shrinkage is bad, indeed. Maybe a drop is to thick though to make a test. try this: put one thin layer, harden it, and repeat with a couple more layers and see if you get weird deformations due to shrinkage.

Shrinkage is bad, indeed. Maybe a drop is to thick though to make a test. try this: put one thin layer, harden it, and repeat with a couple more layers and see if you get weird deformations due to shrinkage.

|

Re: UV curable resins February 13, 2009 04:10PM |

Admin Registered: 16 years ago Posts: 13,884 |

... an update:

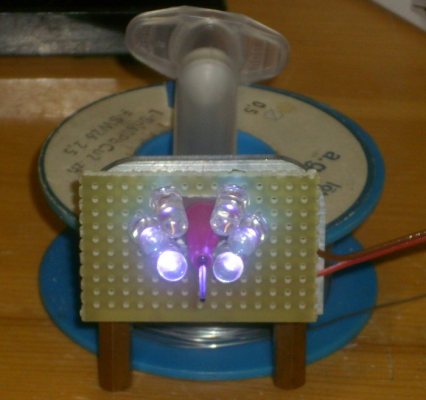

Ordered some standard UV-LED's with peak at 400nm and built a module with 6 of them:

First tests with UV-curable fluid PMMA (Acrifix 192) weren't so bad - the intensity isn't enough for hardening a thin thread completelly in 20 seconds, but it works as UV-initiator, so the pre-cured area hardened without fürther activating to a supporting gel after some minutes and to a complete solid after an hour.

So with slow dispensing and maybe some minutes curing-time between layers it sould be self-supporting for continued fabbing and will harden to solid PMMA with time.

Actually i'm strucked down by a flu but want to embed the dispenser in my CAM and perform some fabbing tests this month ...

Viktor

Ordered some standard UV-LED's with peak at 400nm and built a module with 6 of them:

First tests with UV-curable fluid PMMA (Acrifix 192) weren't so bad - the intensity isn't enough for hardening a thin thread completelly in 20 seconds, but it works as UV-initiator, so the pre-cured area hardened without fürther activating to a supporting gel after some minutes and to a complete solid after an hour.

So with slow dispensing and maybe some minutes curing-time between layers it sould be self-supporting for continued fabbing and will harden to solid PMMA with time.

Actually i'm strucked down by a flu but want to embed the dispenser in my CAM and perform some fabbing tests this month ...

Viktor

|

Re: UV curable resins February 13, 2009 05:25PM |

Admin Registered: 17 years ago Posts: 7,879 |

Nice work Viktor, get well soon.

I need to make a transparent object, so I was thinking of extruding from a 3mm PMMA rod as it is a thermoplastic which melts at 140C. By combining that with your technique perhaps we could bulk out the object quickly with FFF and add fine detail with the UV-cure.

[www.hydraraptor.blogspot.com]

I need to make a transparent object, so I was thinking of extruding from a 3mm PMMA rod as it is a thermoplastic which melts at 140C. By combining that with your technique perhaps we could bulk out the object quickly with FFF and add fine detail with the UV-cure.

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.