Blacksmith Printer: A Polar Printer That Works

Posted by blacksmith_printer

|

Blacksmith Printer: A Polar Printer That Works June 06, 2013 12:30PM |

Registered: 10 years ago Posts: 6 |

Hello World!

I'm Blacksmith Printer.

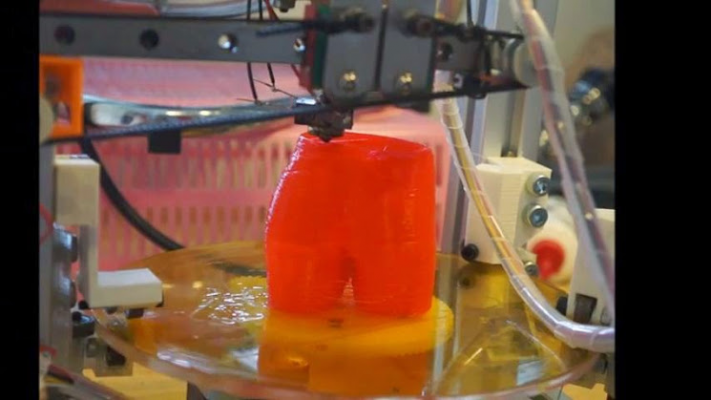

I was created to print in a polar fashion. My print platform purely rotates, and my arm deposits plastic on my platform.

For you, I print fast, I save your space, and I look good =)

Please see me perform on youtube by clicking this link.

Any comments please?

Edited 2 time(s). Last edit at 06/06/2013 12:33PM by blacksmith_printer.

I'm Blacksmith Printer.

I was created to print in a polar fashion. My print platform purely rotates, and my arm deposits plastic on my platform.

For you, I print fast, I save your space, and I look good =)

Please see me perform on youtube by clicking this link.

Any comments please?

Edited 2 time(s). Last edit at 06/06/2013 12:33PM by blacksmith_printer.

|

Re: Blacksmith Printer: A Polar Printer That Works June 07, 2013 07:13AM |

Registered: 11 years ago Posts: 248 |

|

Re: Blacksmith Printer: A Polar Printer That Works June 07, 2013 07:18AM |

Admin Registered: 16 years ago Posts: 13,886 |

... what's the max. possible moving speed in the middle? - and how slow have you to move on the outside?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Blacksmith Printer: A Polar Printer That Works June 07, 2013 07:56AM |

Registered: 10 years ago Posts: 6 |

VDX Wrote:

-------------------------------------------------------

> ... what's the max. possible moving speed in the

> middle? - and how slow have you to move on the

> outside?

Hi Viktor,

The max possible speed in the middle is limited by the hardware (motor esp.) My stepper motor is turning at feedrate 18000 with no problem.

Your question about the minimum speed to move on the outside nudged me to do a speed calibration. I will also calibrate the retraction to get rid of the 'stringiness' in the printed object. Will report back soon.

Cheers

Blacksmith

-------------------------------------------------------

> ... what's the max. possible moving speed in the

> middle? - and how slow have you to move on the

> outside?

Hi Viktor,

The max possible speed in the middle is limited by the hardware (motor esp.) My stepper motor is turning at feedrate 18000 with no problem.

Your question about the minimum speed to move on the outside nudged me to do a speed calibration. I will also calibrate the retraction to get rid of the 'stringiness' in the printed object. Will report back soon.

Cheers

Blacksmith

|

Re: Blacksmith Printer: A Polar Printer That Works June 07, 2013 08:38AM |

Admin Registered: 16 years ago Posts: 13,886 |

... what's your microstepping settings with the linear axes and the turntable?

It could even be interesting for this sort of printer to change the microstepping (on 'fullstep'-positions to avoid losses) depending on the radial position on the table.

In the middle area even half-stepping would besufficient, while the outer areas needs high angular resolution.

I have some 'beefy' steppers with 1000 fullsteps per rev and 1/10 microstepping and drivers with 1/256 microstepping for common bipolar stepper motors (51200 s/r with 1.8°-motors, 102400 s/r with 0.9° types) and have some development running for lathe-fabbing, where too the outer areas needs this resolutions when the radii exceeds 200mm ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

It could even be interesting for this sort of printer to change the microstepping (on 'fullstep'-positions to avoid losses) depending on the radial position on the table.

In the middle area even half-stepping would besufficient, while the outer areas needs high angular resolution.

I have some 'beefy' steppers with 1000 fullsteps per rev and 1/10 microstepping and drivers with 1/256 microstepping for common bipolar stepper motors (51200 s/r with 1.8°-motors, 102400 s/r with 0.9° types) and have some development running for lathe-fabbing, where too the outer areas needs this resolutions when the radii exceeds 200mm ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Blacksmith Printer: A Polar Printer That Works June 07, 2013 09:51AM |

Registered: 10 years ago Posts: 6 |

VDX Wrote:

-------------------------------------------------------

> ... what's your microstepping settings with the

> linear axes and the turntable?

>

> It could even be interesting for this sort of

> printer to change the microstepping (on

> 'fullstep'-positions to avoid losses) depending on

> the radial position on the table.

>

> In the middle area even half-stepping would

> besufficient, while the outer areas needs high

> angular resolution.

>

You have a great idea here. I read your post http://forums.reprap.org/read.php?160,63490. It seems difficult to implement unless using a microstepping system/controller.

Any suggestion how to easily control the step options (microstep, half-step, fullstep), and if existing firmwares support it? Perhaps a GCode command to control stepping options would be very useful.

I'm using Marlin V1 at the moment.

> I have some 'beefy' steppers with 1000 fullsteps

> per rev and 1/10 microstepping and drivers with

> 1/256 microstepping for common bipolar stepper

> motors (51200 s/r with 1.8°-motors, 102400 s/r

> with 0.9° types) and have some development

> running for lathe-fabbing, where too the outer

> areas needs this resolutions when the radii

> exceeds 200mm ...

Any link for a peek of your development?

-------------------------------------------------------

> ... what's your microstepping settings with the

> linear axes and the turntable?

>

> It could even be interesting for this sort of

> printer to change the microstepping (on

> 'fullstep'-positions to avoid losses) depending on

> the radial position on the table.

>

> In the middle area even half-stepping would

> besufficient, while the outer areas needs high

> angular resolution.

>

You have a great idea here. I read your post http://forums.reprap.org/read.php?160,63490. It seems difficult to implement unless using a microstepping system/controller.

Any suggestion how to easily control the step options (microstep, half-step, fullstep), and if existing firmwares support it? Perhaps a GCode command to control stepping options would be very useful.

I'm using Marlin V1 at the moment.

> I have some 'beefy' steppers with 1000 fullsteps

> per rev and 1/10 microstepping and drivers with

> 1/256 microstepping for common bipolar stepper

> motors (51200 s/r with 1.8°-motors, 102400 s/r

> with 0.9° types) and have some development

> running for lathe-fabbing, where too the outer

> areas needs this resolutions when the radii

> exceeds 200mm ...

Any link for a peek of your development?

|

Re: Blacksmith Printer: A Polar Printer That Works June 07, 2013 10:37AM |

Admin Registered: 16 years ago Posts: 13,886 |

... for switching the microstepping resolution 'on the fly' you have to connect the resolution selector pins to your controller instead of setting them per jumper.

Changing the resolution without position errors is only doable when the driver/motor is on a 'fullstep'-position - most drivers I'm using flags this with a signal on a pin, so you can define your 'resolution zones' with a 2-step hysteresis area and, when entering the inner area and leaving to one side, you can switch the resolution when sensing the next fullstep-signal.

For the 'lathe-fabbing' development - some bits'n'bytes are spread over the forums ( [dev.forums.reprap.org] ), other was really old development before internet and blogging, so no infos, links or images remained -- but I'm reactivating some aspects of this again for 'laser-assisted fabbing', so will bring some related infos in the next monts, when working again in this field ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Changing the resolution without position errors is only doable when the driver/motor is on a 'fullstep'-position - most drivers I'm using flags this with a signal on a pin, so you can define your 'resolution zones' with a 2-step hysteresis area and, when entering the inner area and leaving to one side, you can switch the resolution when sensing the next fullstep-signal.

For the 'lathe-fabbing' development - some bits'n'bytes are spread over the forums ( [dev.forums.reprap.org] ), other was really old development before internet and blogging, so no infos, links or images remained -- but I'm reactivating some aspects of this again for 'laser-assisted fabbing', so will bring some related infos in the next monts, when working again in this field ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Blacksmith Printer: A Polar Printer That Works June 08, 2013 10:50PM |

Registered: 10 years ago Posts: 6 |

|

Re: Blacksmith Printer: A Polar Printer That Works June 17, 2013 07:06AM |

Registered: 10 years ago Posts: 6 |

Panelolu has arrived at my mailbox today!

Am going to upgrade Blacksmith to a standalone 3D printer with microSD.

Am going to upgrade Blacksmith to a standalone 3D printer with microSD.

|

Re: Blacksmith Printer: A Polar Printer That Works June 21, 2013 03:00AM |

Registered: 14 years ago Posts: 43 |

This is amazing.

I'm working on a very similar printer [reprap.org]. What kind of software are you using? Did you modify Marlin to do the Cartesian to polar conversion on the fly? Or did you create a slicer that produces g-code with polar coordinates? Whatever you did, can you put the code up somewhere? I'd love to collaborate with you on this.

I'm working on a very similar printer [reprap.org]. What kind of software are you using? Did you modify Marlin to do the Cartesian to polar conversion on the fly? Or did you create a slicer that produces g-code with polar coordinates? Whatever you did, can you put the code up somewhere? I'd love to collaborate with you on this.

|

Re: Blacksmith Printer: A Polar Printer That Works July 08, 2013 03:06PM |

|

Re: Blacksmith Printer: A Polar Printer That Works September 03, 2013 03:40PM |

Registered: 10 years ago Posts: 219 |

It´s a nice concept but I do not see any advantage over a conventional cartesian bot. X and Z is still conventional only Y is a roundtable component which makes things unnesessary complicated. Don´t get me wrong: I have all the respect for somone who manages to get such a design working, but so far there is no convincing advantage to me that balances the complicated kinetics. Maybe there is an application out there that benefits from this design, but that remains unknown to me.

|

Re: Blacksmith Printer: A Polar Printer That Works January 12, 2014 11:34AM |

Registered: 10 years ago Posts: 1 |

I see a big advantage to this one, In a machine shop, with a lathe and a milling machine you can do anything, This configuration is not for everything, but certain form factors should work better in a polar config. like this, anything round, cuplike, column forms, human figures, i can see the potential resolution of these forms could be much higher, and faster, your not fitting a roung peg into a square hole, conversly, linear and geometric parts and models would be better on the traditional setup

|

Re: Blacksmith Printer: A Polar Printer That Works January 15, 2014 09:44PM |

Registered: 10 years ago Posts: 77 |

I am curious to know if this polar machine could be run usefully either with the whole machine inclined or with it tipped completely on it's side.

Before flaming me as a crack-pot, think about the potential here... if the turntable is continually rotating, it may enable the printing of complex models with huge overhangs without the need for support. Obviously adhesion to the build bed would be more critical and it may not suit every model, but if it proved a useful technique it might be worth trying. Think of what optimized G-code for a polar bot with an inclined or vertical turntable might be able to achieve.

Has anyone tried a polar bot tipped over? If not, I might need to try it.

Neil

Before flaming me as a crack-pot, think about the potential here... if the turntable is continually rotating, it may enable the printing of complex models with huge overhangs without the need for support. Obviously adhesion to the build bed would be more critical and it may not suit every model, but if it proved a useful technique it might be worth trying. Think of what optimized G-code for a polar bot with an inclined or vertical turntable might be able to achieve.

Has anyone tried a polar bot tipped over? If not, I might need to try it.

Neil

|

Re: Blacksmith Printer: A Polar Printer That Works June 12, 2014 03:26PM |

Registered: 9 years ago Posts: 135 |

The problem with printing on a sideways polar platform is that the platform isn't rotating at a constant speed or direction. It speeds up stops and reverses all the time unless you're printing a simple cylindrical shape.

I've thought in the past about a "polar" printer that uses a cylinder on its side as the "bed", for printing round objects that need to have a solid core. Like an additive lathe, where the print head moves in the x(along the centerline of the core) and Z direction while the core being printed on turns to simulate the Y axis. It may be a novel process to print things like gears or bearings directly onto the shaft they would use in assembly. You could get some very large prints from a "core" as small as a single strand of filament. (as long as it goes through the center of gravity and can hold the load of the finished print, that is.)

Of course, my idea would require a whole new slicing program, rather than just new firmware, and I'm nowhere near experienced enough with code to go there.

I've thought in the past about a "polar" printer that uses a cylinder on its side as the "bed", for printing round objects that need to have a solid core. Like an additive lathe, where the print head moves in the x(along the centerline of the core) and Z direction while the core being printed on turns to simulate the Y axis. It may be a novel process to print things like gears or bearings directly onto the shaft they would use in assembly. You could get some very large prints from a "core" as small as a single strand of filament. (as long as it goes through the center of gravity and can hold the load of the finished print, that is.)

Of course, my idea would require a whole new slicing program, rather than just new firmware, and I'm nowhere near experienced enough with code to go there.

|

Re: Blacksmith Printer: A Polar Printer That Works August 15, 2014 08:44AM |

Registered: 9 years ago Posts: 6 |

|

Re: Blacksmith Printer: A Polar Printer That Works August 18, 2014 10:01AM |

Registered: 9 years ago Posts: 6 |

|

Re: Blacksmith Printer: A Polar Printer That Works August 18, 2014 11:31AM |

Registered: 9 years ago Posts: 135 |

It's worth noting that the Blacksmith team seems to have done just that, though they've gone and made a Indiegogo campaign for their printer ( [igg.me] I wish them the best of luck). It doesn't look much like a RepRap anymore, with a built-in laser and camera, for both 3D scanning and remotely monitoring in-progress prints. IMO, the $1,400 price is a bit much for the average RepRapper, so there's not a whole lot to get excited over just yet.

Sorry, only registered users may post in this forum.