Tri-Polar Bot Concept -- Meet Wally

Posted by see3d

|

Re: Tri-Polar Bot Concept -- Meet Wally July 29, 2013 01:36AM |

Registered: 10 years ago Posts: 18 |

Of course you're right. KISS principle is best way to go to get this working and off the ground. But on a later 2 extruder model, how about 2 side mounted spools on the side triangles, it could possibly fit within the same overal footprint as the working arms already hang over the sides.

|

Re: Tri-Polar Bot Concept -- Meet Wally July 29, 2013 02:05AM |

Registered: 10 years ago Posts: 979 |

Bam! Too easy. Too easy.

I have to really thank you. It did not even occur to me to use the bolted connection I already have for the spool holder. This will only cost me 2 608 bearings, a little plastic, and the price difference on a slightly longer bolt. I estimate that the total cost to include this will be 75 cents. I actually will be saving money because the sit on the ground solution uses 4 bearings which is $1 right there.

Thanks again. This is why open source development is amazing. Keep the ideas coming. I am finalizing my plans for the beta run but there is always the next version.

Edited 2 time(s). Last edit at 07/29/2013 02:07AM by nicholas.seward.

I have to really thank you. It did not even occur to me to use the bolted connection I already have for the spool holder. This will only cost me 2 608 bearings, a little plastic, and the price difference on a slightly longer bolt. I estimate that the total cost to include this will be 75 cents. I actually will be saving money because the sit on the ground solution uses 4 bearings which is $1 right there.

Thanks again. This is why open source development is amazing. Keep the ideas coming. I am finalizing my plans for the beta run but there is always the next version.

Edited 2 time(s). Last edit at 07/29/2013 02:07AM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally July 29, 2013 02:22AM |

Registered: 10 years ago Posts: 18 |

With the spool on the side would the extruder work better mounted directly behind the nearest arm motor, possibly with the same fixings straight thro the board? Non-symetrical for one extruder, but allows updrade to two.

Do you have a size for largest component as I want to make sure I'll have suitable capacity to print the parts and make one if I'm not lucky to get on the beta program.

Do you have a size for largest component as I want to make sure I'll have suitable capacity to print the parts and make one if I'm not lucky to get on the beta program.

|

Re: Tri-Polar Bot Concept -- Meet Wally July 29, 2013 02:26AM |

Registered: 10 years ago Posts: 979 |

Everyone that has filled in the form so far is going to get at least a Wally or a Simpson. (If you don't know what I am talking about and want in on the beta program go to ConceptFORGE.)

I will look into filament drive placement alternatives. I literally have 6 hours until I mill out the first test Wally and Simpson's wooden pieces. I don't have to get it perfect but it wouldn't hurt.

The biggest dimension on any part is 175mm. This will fit diagonally on a 120mmx140mm bed. :-)

Edited 1 time(s). Last edit at 07/29/2013 02:28AM by nicholas.seward.

I will look into filament drive placement alternatives. I literally have 6 hours until I mill out the first test Wally and Simpson's wooden pieces. I don't have to get it perfect but it wouldn't hurt.

The biggest dimension on any part is 175mm. This will fit diagonally on a 120mmx140mm bed. :-)

Edited 1 time(s). Last edit at 07/29/2013 02:28AM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 02, 2013 11:12AM |

Registered: 12 years ago Posts: 37 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 02, 2013 01:24PM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 06:46PM |

Registered: 10 years ago Posts: 979 |

I know that you guys a waiting for evidence of a physical Wally. That is coming. I am printing like a mad man. (I have had a few printer setbacks. I have considered buying a few commercial prints but the lead time is less than helpful. I should have Wally and Maggie up and running by the time they would get here.)

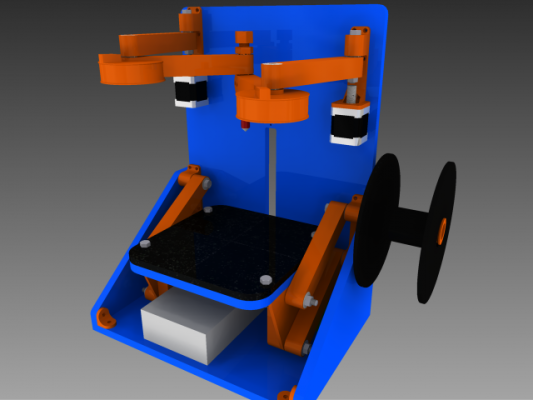

In the meantime, here is my new arrangement of the xy-arms. I hated the break in symmetry of the previous arm mounts. I know that with this new design the arms are now asymmetric but I think the arrangement looks cool and purposeful. If you guys have any feedback to offer, I am going to start printing the large pulleys and forearms tomorrow.

Also, you can see the 180 degree stops for the arms. I am going to play with using no end stops just like I did with the original Simpson. (It worked great in case you were wondering.) The procedure for a print will be...

1) Put both arms in the 180 degree position. (Just pull the extruder all the way out.)

2) Push the print bed to the bottom.

3) Push print.

BTW, I printed out Maggie's central hub with the same technology (printed plastic tube with a threaded end with 6702 bearings) that Wally is going to use and it worked beautifully.

Edited 1 time(s). Last edit at 08/04/2013 06:50PM by nicholas.seward.

In the meantime, here is my new arrangement of the xy-arms. I hated the break in symmetry of the previous arm mounts. I know that with this new design the arms are now asymmetric but I think the arrangement looks cool and purposeful. If you guys have any feedback to offer, I am going to start printing the large pulleys and forearms tomorrow.

Also, you can see the 180 degree stops for the arms. I am going to play with using no end stops just like I did with the original Simpson. (It worked great in case you were wondering.) The procedure for a print will be...

1) Put both arms in the 180 degree position. (Just pull the extruder all the way out.)

2) Push the print bed to the bottom.

3) Push print.

BTW, I printed out Maggie's central hub with the same technology (printed plastic tube with a threaded end with 6702 bearings) that Wally is going to use and it worked beautifully.

Edited 1 time(s). Last edit at 08/04/2013 06:50PM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 08:11PM |

Registered: 10 years ago Posts: 18 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 08:33PM |

Registered: 10 years ago Posts: 979 |

I tried that but this arrangement has 2 advantages. 1) I get 13.25mm more travel in the z direction with the same backboard height. 2) Only one part has to be printed sideways which is not preferred. (It is better to slice perpendicular to the axis of a bearing stack for strength purposes.)

The parts have to be different anyways.

Edited 2 time(s). Last edit at 08/04/2013 08:46PM by nicholas.seward.

The parts have to be different anyways.

Edited 2 time(s). Last edit at 08/04/2013 08:46PM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 09:21PM |

Registered: 10 years ago Posts: 100 |

nicholas.seward Wrote:

-------------------------------------------------------

> 2) Only

> one part has to be printed sideways which is not

> preferred. (It is better to slice perpendicular

> to the axis of a bearing stack for strength

> purposes.)

>

When I look at this part, I can't help but wonder about a bed insert that allows it to be printed in the preferred orientation. For instance, an aluminum block that is the height of the offset from the bed is placed on the bed after the part is printed up to the 45 deg ramp (no support) and paused for a bit. Then the printing resumes across the top of the block to finish the print.

You could also print a thin support wall at the point where the block is supposed to butt up to. That way the block could just be placed up against the support wall at the pause and there would be no question about alignment and proper matching of the heights.

The block could be there all along, but it would have to have a careful placement and a small gap to fill across so that the head did not bump it as it got close.

And the block could also be made of wood (end grain) to be more forgiving if the head bumped into it, but I was concerned if it was heavy enough to stay put -- double sided tape?

Could also print a short ring around the base that defines where the block will sit to make sure it is in the right place and does not move.

-------------------------------------------------------

> 2) Only

> one part has to be printed sideways which is not

> preferred. (It is better to slice perpendicular

> to the axis of a bearing stack for strength

> purposes.)

>

When I look at this part, I can't help but wonder about a bed insert that allows it to be printed in the preferred orientation. For instance, an aluminum block that is the height of the offset from the bed is placed on the bed after the part is printed up to the 45 deg ramp (no support) and paused for a bit. Then the printing resumes across the top of the block to finish the print.

You could also print a thin support wall at the point where the block is supposed to butt up to. That way the block could just be placed up against the support wall at the pause and there would be no question about alignment and proper matching of the heights.

The block could be there all along, but it would have to have a careful placement and a small gap to fill across so that the head did not bump it as it got close.

And the block could also be made of wood (end grain) to be more forgiving if the head bumped into it, but I was concerned if it was heavy enough to stay put -- double sided tape?

Could also print a short ring around the base that defines where the block will sit to make sure it is in the right place and does not move.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 09:24PM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 09:52PM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 10:20PM |

Registered: 10 years ago Posts: 100 |

nicholas.seward Wrote:

-------------------------------------------------------

> I agree in principle but in practice the end users

> should just hit print.

In that case, print out the support block for the critical circular interface area only, put some blue tape on top of it, then without removing the part, print the arm. With that 45 degree lower overhang ramp up, it will approach the support piece, only getting closer as it is getting taller. There will be a short gap to jump across (width of the head flat), but that should not be a big deal, even if it sags a tiny bit at that point.

Has this been done before?

-------------------------------------------------------

> I agree in principle but in practice the end users

> should just hit print.

In that case, print out the support block for the critical circular interface area only, put some blue tape on top of it, then without removing the part, print the arm. With that 45 degree lower overhang ramp up, it will approach the support piece, only getting closer as it is getting taller. There will be a short gap to jump across (width of the head flat), but that should not be a big deal, even if it sags a tiny bit at that point.

Has this been done before?

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 10:26PM |

Registered: 10 years ago Posts: 18 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 04, 2013 10:39PM |

Registered: 10 years ago Posts: 979 |

I love both of these ideas guys. I will have to try it on something.

However, I don't think I will be able to justify the complicated procedure when I can just turn it on its side. Even though this isn't the preferred orientation my current design standards make it stronger than it needs to be. (If you look at the shoulders of SimpleSimpson, you will see that there is not a way to get optimal slicing with a single piece. The Sextupteron could do some curvy slicing magic but planar slicing is just not up for the job. I layed it on its side and came out with a gorgeous print. Wally's z forearm will be similar.)

Edited 2 time(s). Last edit at 08/04/2013 10:41PM by nicholas.seward.

However, I don't think I will be able to justify the complicated procedure when I can just turn it on its side. Even though this isn't the preferred orientation my current design standards make it stronger than it needs to be. (If you look at the shoulders of SimpleSimpson, you will see that there is not a way to get optimal slicing with a single piece. The Sextupteron could do some curvy slicing magic but planar slicing is just not up for the job. I layed it on its side and came out with a gorgeous print. Wally's z forearm will be similar.)

Edited 2 time(s). Last edit at 08/04/2013 10:41PM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 05, 2013 10:02AM |

Registered: 11 years ago Posts: 58 |

One minor observation about the threaded tube that will be the center of the hub, it looks as though that size opening down the center will provide a lot of room for the filament to kink between the end of the Bowden tube and the top of the hotend. Perhaps the opening could be sized to allow a piece of 4 mm OD PTFE tube to be slid in, to make sure there's no sideways space for the filament? I've done something similar with our Printrbot laser cut Wade's to close up the rectangular space that is left when it is assembled, it's a fix that the forum members came up with a long time ago.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 05, 2013 10:25AM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 05, 2013 10:48AM |

Registered: 11 years ago Posts: 58 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 08, 2013 11:06AM |

Registered: 10 years ago Posts: 145 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 10, 2013 02:14AM |

Registered: 10 years ago Posts: 979 |

One thing that I have discovered is that Wally has a lot of wood compared to Simpson. I can fit both of Simpson's wooden pieces on Wally's back board. That is okay. Wood is cheap.

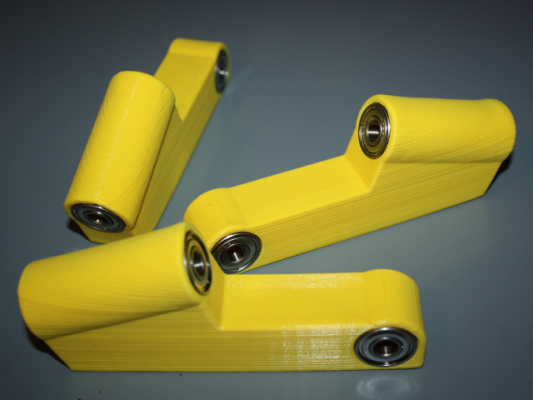

I have been fighting my CNC mill for several days. I was having some serious y-drift. In the past it has always been a bad electrical connection. I hunted and hunted but couldn't find any problems. I then decided to do my yearly maintenance and just give it a once over. I quickly discovered that the y lead screw coupler was loose. Make sense. Face palm. I am back on track. I milled all of Wally's parts. I have all the parts printed also. Here is a picture of most of them. I might have to reprint a part or two but it is all down to assembly and it is the weekend. :-)

If my wife asks, the junky counter is to help give you a sense of scale. Wally is bigger than I expected. I have been living and breathing the numbers but until you build something it is hard to know.

Edited 2 time(s). Last edit at 08/10/2013 02:17AM by nicholas.seward.

I have been fighting my CNC mill for several days. I was having some serious y-drift. In the past it has always been a bad electrical connection. I hunted and hunted but couldn't find any problems. I then decided to do my yearly maintenance and just give it a once over. I quickly discovered that the y lead screw coupler was loose. Make sense. Face palm. I am back on track. I milled all of Wally's parts. I have all the parts printed also. Here is a picture of most of them. I might have to reprint a part or two but it is all down to assembly and it is the weekend. :-)

If my wife asks, the junky counter is to help give you a sense of scale. Wally is bigger than I expected. I have been living and breathing the numbers but until you build something it is hard to know.

Edited 2 time(s). Last edit at 08/10/2013 02:17AM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 10, 2013 11:44AM |

Registered: 10 years ago Posts: 100 |

And I thought you were trying to point out how beautiful all the wood in Wally could look with some cabinet grade stain and poly finishing... ;-)

My quick and dirty cardboard model was not a wasted effort either to get a feel for the scale of Wally. Big in some respects, but sturdy and a handy size to move around.

nicholas.seward Wrote:

-------------------------------------------------------

> If my wife asks, the junky counter is to help give you a sense of scale.

> Wally is bigger than I expected. I have been living and breathing the numbers but until you build something it is hard to know.

My quick and dirty cardboard model was not a wasted effort either to get a feel for the scale of Wally. Big in some respects, but sturdy and a handy size to move around.

nicholas.seward Wrote:

-------------------------------------------------------

> If my wife asks, the junky counter is to help give you a sense of scale.

> Wally is bigger than I expected. I have been living and breathing the numbers but until you build something it is hard to know.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 15, 2013 03:26PM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 21, 2013 11:14AM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 22, 2013 09:33PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 22, 2013 09:46PM |

Registered: 10 years ago Posts: 979 |

I am done running around getting different parts going for the 22 beta machines. I am now assembling. If all goes well and I feel good about the design I will release the design within a week or two.

As you can see from the picture that I am testing my wifes good nature.

Edited 1 time(s). Last edit at 08/22/2013 09:47PM by nicholas.seward.

As you can see from the picture that I am testing my wifes good nature.

Edited 1 time(s). Last edit at 08/22/2013 09:47PM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 22, 2013 10:57PM |

Registered: 10 years ago Posts: 100 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 23, 2013 12:56PM |

Registered: 10 years ago Posts: 979 |

I put the arms on and am very happy. The arm level and the bed level only vary by 2mm from front to back. You have to apply large (non printing) forces to get things to flex. Software leveling will make this perfect.

I put the string on in the crossing fashion shown here. However, this has the tendency to pull in the arm as you rotate toward the backboard. The mechanical advantage was such that there was a big area where you could move the effector and the drive pulleys wouldn't budge. I uncrossed the string and the dead area went away.

BTW, I was able to string both sided in under 20 minutes. I think with practice I could do it in 5 minutes. The tensioner blocks also work great. If we find that the block bottoms out after too few uses (string creep) we can just loop the string around a few more times to make the tensioner more effective. One thing I was worried about for no reason was having the tension mess with the level of the arms. I over tightened and rechecked the level and didn't notice a difference with my microsensing optical transducer.

First moves should be early next week.

Interesting note: Wally can print parts for a 58% bigger Wally. Using my new lingo, Wally has a .58 macrocreation factor.

Edited 2 time(s). Last edit at 08/23/2013 01:01PM by nicholas.seward.

|

Re: Tri-Polar Bot Concept -- Meet Wally August 23, 2013 03:23PM |

Registered: 12 years ago Posts: 37 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 26, 2013 11:14AM |

Registered: 10 years ago Posts: 145 |

|

Re: Tri-Polar Bot Concept -- Meet Wally August 26, 2013 11:17AM |

Registered: 12 years ago Posts: 10 |

Sorry, only registered users may post in this forum.